Professional Documents

Culture Documents

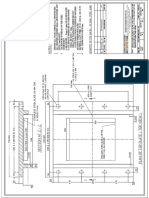

0 Line 29 Erection

Uploaded by

sudharshkumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0 Line 29 Erection

Uploaded by

sudharshkumarCopyright:

Available Formats

DVC, Electricity Dept., Spec. No.

EDCON/EHV/L-37 & 38

A.

SURVEY

Detailed Survey of the route has already been carried out. Check survey will be

carried out based on that. Detailed and Forest survey of a portion of the route may be

felt necessary during check survey, and that shall be conducted by the Contractor as

per route alignment approved by DVC.

A.01

DETAILED SURVEY :

The object of carrying out detailed survey is to prepare longitudinal and cross section

profiles on the approved alignment to prepare the route plan showing details of

deviation angles, important objects coming within the right of way.

Work of detailed survey is distinctly done in two stages :

1. Actual field observations taking level readings and calculating

distances, level differences, deflection angles, offset distances etc.

2. Plotting of profiles on graphed tracing papers.

TOWER SPOTTING :

The work of tower spotting is clearly divided into the following five

operations :

1. Sag tension calculations.

2. Preparation of Sag Template.

3. Application of Sag Template to decide optimum tower position on

Survey Chart.

4. Preparation of Structure Limitation Charts.

5. Deciding tower type and preparation of Tower Schedule.

SAG TEMPLATE

Sag Template drawing for AAAC (61/3.31mm) on DVC designed towers

shall be prepared by the Contractor and get approved from DVC. Inputs required for

preparation of Sag Template will be furnished by DVC to the Contractor. Based on

the above drawing the Contractor has to prepare Sag Template on rigid acrylic

transparent plastic sheet and provide two sets of the same to the owner for checking

purposes. With the help of Sag Template and tower spotting data, tower locations

shall be marked on the profiles.

A.02

CHECK SURVEY:

Check survey is carried out for the following:

1. To reconfirm the work carried out during detailed survey.

2. To locate and peg mark the tower position on ground controlling to

the route profiles.

1

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

3. To give direction pegs.

Check survey should be conducted to make rough check on detailed survey and to

locate and peg mark the tower position on ground conforming to the survey chart.

Position of Tower shall be kept on high places and good soil as far as practicable.

Any deviation of the actual tower position from the route profile drawing shall have

to be corrected by the contractor accordingly in the drawing.

A.03

FOREST SURVEY

1) Identification & survey of forest area & Jungle Jhari area. A

statement of Forest area and Jungle-Jhari area to be prepared. Demarcation of forest

boundary is to be done. Co-ordination & interaction with Forest Authority and

collection of Mouja map, necessary for survey work will be done by DVC.

Collection of Topo sheet is Contractors responsibility. The contractors

responsibility is to do the field survey work and align the route on Mouja map and

Topo sheet. All interaction and co-ordination with State Forest Department will be

done by DVC.

The tree-cutting shall be the responsibility of the owner except for

that required during survey. Contractor may please note that owner shall not pay any

compensation for any loss or damage to the properties or for tree cutting due to

contractors work. However, the contractor shall count, mark and put proper

numbers with suitable quality of paint at his own cost on all the trees that are to be

cut by the owner at the time of actual execution of the work.

2)To evaluate and tabulate the trees and bushes coming within 17.5

meters on either side of the centre line of alignment, the trees will be numbered and

marked with quality paint serially from angle point-1 onwards and the corresponding

number will be painted on the stem of the trees at height of 1 meter from ground

level.

3) The contractor shall be responsible for tree enumeration for the

purpose of initiating proposal for obtaining forest clearance from Ministry of

Environment and Forest. The contractor shall submit 2 copies of the complete

proposal to be moved for forest clearance to the satisfaction of the Engineer-incharge of the work.

A.04

PAYMENTS :

Separate payment shall be made for survey which the contractor should quote

separately for the same as indicated in the price schedule.

B.

GEO-TECHNICAL INVESTIGATION

2

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

B.01

GENERAL

The Transmission tower foundation shall be classified based on the soil conditions.

Optimization of foundation design and their safety mainly depend on correctness of

soil and their analysis. The scope of work includes detailed soil investigations at

various locations such as railway crossings, major road, crossing, power line

crossings, river crossings and wherever soil strata differs.

However, the soil investigation activities shall be completed before the

commencement of main erection activities. Soil investigation may not be needed for

all the locations of the line. The required locations will be at the discretion of DVC.

B.02

NORMAL LOCATIONS :

One bore hole of 150 mm dia shall be drilled at the centre point of the tower.

Standard penetration test (S.P.T) shall be carried out at 1.5 meter interval or change

of strata upto the required depth of 2.5 times blow the depth of foundation below

existing surface elevation or refusal whichever occurs earlier. (By refusal it shall

mean that a standard penetration below count N of 100 is recorded for 30 cm

penetration). Bore details and water table upto required depth below existing surface

elevation or refusal whichever occurs earlier shall be furnished in the report.

B.03

SPECIAL LOCATIONS :

At certain locations such as river banks, river beds or midstream of river and at other

places, special soil investigation shall be carried out by drilling two holes each of

150 mm diameter at each tower location on the diagonally opposite legs of the tower,

considering the base width of tower as 20 meter.

Standard penetration tests shall be carried out at every 1.5 meter interval or

change of strata till refusal is met subject to maximum of 40 meter below the existing

surface elevation.

Undisturbed samples of soils shall be collected at every 2.5 meter interval or

change of strata whichever occurs earlier.

In the hard rock the bore drilling shall be continued at least 5.0 meter to

ascertain its sufficient thickness.

B.04

SALIENT TEST REQUIREMENTS:

The following covers the technical requirements for a detailed Geo-Technical

Investigation & submission of a detail geotechnical report :

1.

Mobilization of all necessary equipment, men & materials to the

project site for carrying out geotechnical investigation and

demobilization of the same after completion.

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

2.

Sinking of 150 mm nominal diameter bore hole in all types of soil,

sand including laterite, at various locations up to a maximum depth of

20.0m 25.0m below ground level or upto rock level, whichever is

earlier, using suitable approved method of boring including chiseling,

cleaning, providing casing pipe as required :

a) Performing SPT at every meter interval, at change of strata and at

depths wherever undisturbed soil samples could not be collected,

b) Collection of undisturbed soil samples at every meter and at

change of strata,

c) Collection of disturbed soil samples and water samples,

d) Observation such as ground water table, rock level etc.

e) Transportation of collected samples to the laboratory,

f) Backfilling of bore holes with sand on completion.

Borehole to be properly stabilized with Bentonite.

Conducting laboratory test on soil samples including preparation of

soil samples to determine the following properties etc. &/or as per

specifications:

a) Bulk density & moisture content

b) Sieve analysis

c) Liquid limit and plastic limit

d) Triaxial shear test

e) Unconfined compressive strength.

B.05

PREPARATION OF TEST REPORTS:

The geotechnical investigation report shall include but not be limited

to the following:

i)

ii)

iii)

iv)

v)

vi)

vii)

Location & reduced levels of bore holes,

A true cross section of all bore holes showing the

classification & thickness of individual stratum, position of

G.W.T., rock stratum if met with etc.,

Water level & rock level contours,

Plot of SPT N values (both corrected & uncorrected) with

depth,

Results of all tests in tabular as well as graphical forms,

Values of cohesion, angle of internal friction, skin friction.

High flood level of the area.

The report should contain specific recommendation for the type of foundation. In

case the soil parameters obtained from the soil investigation report for a particular

4

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

tower location, differ from the ones considered during design, a fresh design has to

be developed for such locations.

B.06

RECOMMENDATIONS:

Recommendation shall include but not be limited to the following:

a) Type of foundation to be adopted for Transmission Towers duly

considering the sub-strata characteristics, G.W.T.

b) For shallow foundation the following shall be furnished :

Net safe bearing capacity for isolated square footing of size

4.0 m & 5.0 m at different founding depths of 3.0m, 4.0m &

5.0m below G.L. considering shear & differential settlement

criteria

c) If piling is envisaged the following shall be furnished with

comprehensive supporting calculations :

i)

Type of pile & reasons for recommendation.

ii)

Suitable founding strata for the pile.

iii)

Estimated length of 600/800 dia pile considering end

bearing and frictional resistances.

iv)

Safe lateral & tensile load carrying capacity of pile.

v)

Magnitude of negative skin friction considering Scour

Depth.

All work shall be carried out as per relevant I.S. code & standards etc.

C.

EARTHWORK IN EXCAVATION :

C.01

GENERAL

Each tower shall have four footings; the excavation of the pits for the four

footings shall be of same type unless otherwise approved by the Engineer. The four

pits shall be marked by the contractor at his cost as such the tower is open in the

direction of the line or the line bisecting the angle of deviation for angle location.

The levels up and down of each pit centre with respect to the centre of the tower

location shall be noted by the contractor & approved by the Engineer or his

authorised representatives before the excavation is started. The surfaces of the

excavated pits shall be made full dimensions required and as per drawings.

All the excavated materials shall be dumped away from the pits at a distance not

exceeding 50 meters preferably in diagonal directions keeping the space along the

centre line free for foundation work. Care shall be taken that no moving vehicles or

heavy equipments are drawn too near the foundation excavation.

5

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

C.02

CLASSIFICATION OF SOIL :

The classification of various types of soil will be as under:

Ordinary soil : The ordinary soil will mean all types of soil excluding all

kind of rocks and wet soil.

Hard soil

: Hard soil will mean soil mixed with moorum, kankor etc. but

not soft rock.

Slushy soil

: Slushy soil will mean the soil below water level.

Soft rock

: This will mean decomposed rock, hard gravel, kankor, limestone, laterite or any other soil which cannot be easily excavated with pick axe or

spade.

Hard rock : Hard rock will be that which requires chiseling or drilling

and blasting. The cost of drilling and blasting are to be included in the quoted rate.

The contractor shall supply requisite blasting material and be responsible for the

purpose of the storage and use of the material. Blasting shall be done so that pits are

as near to the designed dimension as practicable.

Fully/Partially submerged soil : Fully/Partially submerged soil means

locations where water is met within 1.5 meter / 0.75 meter from ground

respectively. It should be avoided as far as possible.

Filled up soil : It should be avoided.

Sandy soil : Soil mixed with Sand (or fully Sandy location).

The contractor will be required to submit at his own cost to the Engineer his

report about the water-logging, if any, sub soil water-table and type of soil

encountered at the locations along with his proposal for type of foundation.

He should also be satisfied that the allowable bearing pressure of the soil as

mentioned in the drawing will be available at the locations. The approval of

the Engineer should be obtained regarding type of foundation to be used.

C.03

CLASSIFICATION OF FOUNDATION:

Classification of soil shall be made according to I.S. 200 (Part-I) for

footing cast in open pits . Depending upon the ground water table and type of

soil / rock and presence of surface water the foundations can be classified as

follows :

a)

Normal Dry Soil Foundations

When water table is below foundation level and when soil is normal, dry,

cohesive and homogeneous upto the full depth having clay content of 1015%.

(b)

Wet Soil Foundations

When water table is above foundation level and up to 1.5 meter below ground

level. The foundations in the soils which have standing surface water for a

6

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

long period with water penetration not exceeding 1.5 meter below ground

level (e.g. paddy fields) are also classified as wet foundations.

(c)

Partially Submerged Foundations

When water table is at a depth between 1.5 meter and 0.75 meter below

ground level and when the soil is normal and cohesive.

(d)

Fully Submerged Foundations

When water table is within 0.75 meter below ground level and the soil is

normal and cohesive.

(e)

Black Cotton Soil Foundations

When the soil is cohesive having inorganic clay exceeding 15% and shrinks

when dry, swells when wet, (need not be always black in colour) resulting in

differential movement extending upto a depth of about 3.5 meter below

ground level.

(f)

Soft Rock/Fissured Rock Foundations

When decomposed or fissured rock, hard gravel or any other soil of similar

nature is met which can be executed without blasting. Under cut & Rock

Anchor type foundation can be used at these locations.

In case of fissured rock locations where water table is met at 1.5 meter or

more below ground level, submerged fissured rock foundation shall be

adopted. When the water table in such location is met within 1.5 meter from

ground level, fully submerged fissured rock type foundations shall be

adopted.

(g)

Hard Rock Foundations

Where chiseling, drilling and blasting is required for excavation hard rock

type foundation are to be used. Rock anchoring is to be provided to resist

uplift forces.

The above categorizations has been done for economizing the foundations, as uplift

resistance of foundation is a critical design factor which is greatly affected by the

location of water table and the soil surrounding the foundation.

In addition to the above, depending on the site conditions other types of

foundations may also be developed for :

1.

Intermediate conditions under the above classifications to

effect more economy or

2.

For locations where special foundations (well type or piles)

are necessitated.

While classifying foundations of Wet, Partially submerged, Fully submerged

foundations mentioned above, the worst conditions should be considered and not

necessarily the conditions prevailing at the time of inspection. For instance, there are

7

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

area where sub-soil water rises when canal water let-out in the fields raising sub-soil

water to a considerable degree. Similarly, the effect of monsoon or when the nearby

reservoirs are full should also be considered and not the conditions prevailing in

open season or summer when work is carried out normally.

C.04

DEWATERING :

Dewatering, if required, shall be done at the cost of the contractor either manually or

by mechanical pumps or power driven pumps to facilitate excavation and during

excavation. The pumps shall be suitable for handling mud water. The pits shall also

be kept water free during concreting and till 24 hours of concreting the foundation.

No backfilling should be done till pits are dewatered fully.

C.05

SHORING AND STRUTTING:

Shoring and strutting shall be used in pits excavated in sandy soil or in water bearing

strata if directed by the Engineer, where there is every likelihood of pit collapsing.

Shoring and strutting shall be made out of timber planks or steel frame and struts of

adequate strength to suit the requirement as directed by the Engineer-in-Charge.

Separate unit price per square meter shall be quoted for this item. Shoring and

strutting may be necessary during excavation or during concreting or during

excavation and concreting both. However, payment for shoring and strutting will be

made once and not for the second time even if shoring and strutting are required to

be provided during excavation and concreting both.

C.06

MEASUREMENT:

The payment for excavation of pits will be made on the basis of pre-work ground

level and post work ground level measurement of the tower pits. No payment will be

made for the excavation made in excess to the quantity of excavation shown in the

approved drawings. In case it is required to excavate more than what is mentioned in

such drawings, then approval of the Engineer should be obtained specifically for

such cases and in that case, payment will be made for the total excavated quantity

certified by the Engineer as per rate quoted by the contractor.

If the different types of soil are encountered within a pit while excavating, then

payment will be made as per volume measured for different types soil therein. No

payment for dewatering will be made for any type of soil. The rate of excavation for

different types of soil should include the cost of dewatering, if required and also the

cost of pit-marking.

Before starting the excavation of pits, the contractor or his representative should

inform the Engineer or his representatives. The contractor or his representative

should also inform the Engineer or his representative after the excavation is

8

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

completed but before backfilling to enable the Engineer to take measurement of the

quantity of earth excavated and type of soil encountered.

In case of the excavated pits being ready for backfilling after stub setting where

contractor has filed a statement protesting the measurement taken regarding the

quantity and nature of earthwork excavated for which payment is to be made, the

contractor shall delay back-filling work until the Engineer-in-Charge is able to verify

the necessary measurement or to secure such an additional data as may be necessary

for the proper consideration to the contractors protest, which shall be done by the

Engineer-in-Charge of the work within 10 days from the date of receipt of such

protest. Such delay shall be considered incidental to the work and no additional

compensation will be granted to the contractor thereof. Failure of the contractor to

permit such re-examination before back-filling shall be considered as waiver of all

claims.

C.07

PAYMENT :

Payment for excavation for tower foundation shall be made for unit price per cubic

meter. If, during the progress of excavation or after excavation is completed, it is

found necessary or desirable to change the type of footings or to change the

dimension of excavation for the footings from those shown in the drawings or

prescribed by the Engineer, payment for such change or allocation of cost thereof

shall be as follows :

D.

i)

Where the change in the type of footing or change in the dimension of

the excavation for a footing are the result of the faults on the part of

contractor e.g. defects in pit marking, improper excavation method or

means of supporting excavation or of taking inadequate means of

protection of the excavation from weathering or of the contractors

delaying between the excavation of footings and placing of concrete

etc., the cost of all additional excavation, reinforcement, cement

concreting and back-filling shall be borne by the contractor.

ii)

Where the type of footing or excavation is changed for no fault of the

contractor, but it is felt so necessary by DVC and done accordingly,

payment for excavation, back-filling etc. so performed shall be made

by DVC at the unit price for the items. No additional rate above the

unit price for the work shall be allowed to the contractor.

EARTHWORK IN BACKFILLING:

The backfilling of the excavation pits shall be carried out after the concrete work is

over, form work is opened, shoring and strutting, if any, are removed. The backfilling

shall be done by the contractor only after the receipt of approval from the Engineer or

his representative. Unless special instruction given in any specific case, no backfilling

work shall be carried out if the repair & finishing work is not complete. Finishing of

9

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

coping (the top of the foundation above ground) may be done after the

completion of backfilling. Backfilling shall be done with excavated soil if the

excavated soil is free from decomposed soft rock and gravels not more than 50 mm

and also free from organic and other foreign materials. In case the excavated soil is

not of such specifications backfilling should be done with normal soil from suitable

borrow pits.

The backfill should be compacted with special care. Good thorough compaction is to

be made for ensuring uplift resistance and development of passive earth resistance.

The backfill should be deposited in layers of thickness of not more than 200mm after

compaction. The back filling operation should be such that the materials when

compacted will be blended sufficiently to secure the best practicable degree of

compaction. The backfilling is to be carried out to an elevation up to concrete level

and with a size equal to maximum plan dimensions of excavated pits at ground level.

Volume of backfilling shall be considered equal to that of excavation to account for

the extra backfilling above ground level. The backfill material shall have optimum

practicable moisture content requiring for the purpose of compaction and curing as

determined by the Engineer and the moisture content shall be uniform throughout the

layers. The moisturing shall be made by sprinkling of water at the site of compaction.

The backfill shall be compacted by tamping or by such means or equipments as

approved by the Engineer. Care shall be taken that backfilling is started from inner

end of the pits, towards the outer end.

The stub template may be struck and removed only after getting clearance

from Engineer or his representatives.

The backfilling of foundation shall be carried out so that after one / two monsoon the

level of backfilled earth does not go below the surrounding ground level.

On completion of the backfilling as per above requirements and completion of curing

period, proper grading should be carried out to drain out the water.

Separate rate shall be quoted by the contractor for backfilling work (I) with soil

obtained from excavation of foundation and (II) with soil from borrow pits. In case

of backfilling being done with normal soil from borrow pits no separate payment for

excavation of such soil from borrow pits including its carriage to the place of

backfilling will be paid.

E.

SUB-BASE :

A lean concrete sub-base shall be provided if required and directed by the Engineerin-Charge. The work should be done as per instruction of the Engineer-in-Charge.

Payment for supplying and placing lean concrete sub-base will be made at unit price

per cubic meter.

10

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

F.

STUB-SETTING:

F.01

SETTING OF STUB WITH TEMPLATE :

The Stubs are set with the help of the Stub-setting Templates, which are supplied

loose, ready to be assembled at site. All four excavated pits are to be lean concreted

to correct level sighted through level and the stubs are to be placed on the lean

concrete pad. Correct alignment is carried out by 0.9 Kg. Plumb bob 4 in numbers

hung from centre of horizontal bracings.

Following is the procedure for Stub-setting at Site :

1.

2.

3.

4.

5.

6.

7.

8.

Assemble the Template as per the drawing along with the supply.

Set the Template as per the drawing at site.

Place the Stub-setting Jacks below the Template.

Align Template, along with the line and centre it over the centre peg of

the location.

Fix up the stub to the Template and with the help of a dumpy level, level

the Template corners to the required level.

Ensure that all the four stubs are at the same level.

Check the alignment and centering of the Template again.

By placing on 8 to `12 screw jacks according to the length of Template,

with a leveling instrument fine adjustment can be made by lifting /

lowering the screw jacks, and the stubs can be perfectly levelled. This

ensures accurate verticality of the tower. For ensuring all towers in one

line and cross-arms at right angle to it, 4 plumb bobs should be dropped

from the centre of the horizontal members of the Template to correspond

to the cross pegs and alignment pegs given during the line alignment

survey for the tower location.

The contractor shall be fully responsible for correct setting of stub in accordance with

the drawing supplied, at the exact locations and alignments and precisely at correct

level. The stubs are to be set with the help of stub setting templates supplied by DVC

& the contractor wherever necessary.

F.02

SETTING OF STUBS WITH SECTION METHOD :

There may be occasions when templates may not be available from DVC. In such

special and exceptional cases DVC may permit setting of the stubs by first section

method i.e. lowest section of the tower body complete with bracings may be used as

template.

F.03

PAYMENTS :

When stubs are set by using first section methods the contractor shall be entitled to no

additional payment over the unit price bid for setting of stub. Payment for erection of

11

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

first section with bracings, excluding weight of stubs, will be made at the unit rate

quoted for tower erection and will be included in the item Erection of tower.

However, if the contractor quote separate rate for setting of stubs by using first

section method, the same will be paid accordingly.

G.

CONCRETE :

G.01 GENERAL:

All reinforced concrete will be either with M-15, M-20 or M-25 concrete. Nominal

Mix proportion 1:2:4, 1:1.5:3 & 1:1:2 by volume shall be taken as equivalent to M-15,

M-20 and M-25 respectively. Characteristic compressive strength of 15 cm cube at 28

days for M-15, M-20 and M-25 mix is 15 N / Sq.mm , 20 N / Sq.mm and 25 N /

Sq.mm respectively.

All concrete work shall fully comply with the latest edition of Indian Standard

Specification IS : 456, "Code of Practice for Plain and Reinforced Concrete".

Cement, sand and stone chips (Coarse aggregate) shall be used for concreting with 20

mm and down stone chips for chimney and pyramid portion.

Approved mechanical vibration for all structural and reinforced concrete shall be

mandatory. Immersion type vibrators (65 mm and / or 75 mm dia and 500 mm to 600

mm long) with a minimum vibration of 8000 revolutions / minute shall be used. Use

of pneumatic and / or electrical vibrators are mandatory.

Sample of cement, stone chips and sand to be used for construction works by the

contractor must got approved by the Engineer before use. Cement, Stone chips and

sand are to be supplied by the contractor at his own cost.

Specification for the materials are given below .

G.02 MATERIALS :

a)

Cement :

Cement shall be ordinary cement conforming to IS : 269 / IS : 455. Cement shall be

kept in clean dry, moisture-proof covered stores. It shall be adequately protected

from condensation, rising damp and atmospheric moisture. Sufficient cement shall

be stored at all times to ensure continuity of work. Not more than ten bags shall be

stacked in any tier. The Engineer-in-charge if consider any cement defective, then

irrespective of its origin and / or manufacturers test certificates, such cement shall

be tested immediately at DVCs laboratory or any Laboratory approved by DVC,

and until the results of such tests are found satisfactory it shall not be used in any

work. The Contractor shall not be entitled to any claim of any nature on this account.

The cement supplied by contractor should be purchased directly from the approved

manufacturer and should be supported by matching challans of the manufacturer.

12

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

b)

Fine Aggregates :

Fine aggregates (Sand) shall be clean, sharp coarse, gritty to the touch and free from

elongated and flaky particles with a fineness modulus between 2.8 and 3.2 and shall

pass through sieve no. 16. It shall be clear and free from any mixture of clay, dust,

vegetable matter, mica, shale, loam, salts and organic matter, or other impurities,

which may be considered by the Engineer-in-Charge as harmful. Sand containing

clay shall be thoroughly washed by the contractor at his own expenses before use.

Unless otherwise specified fine sand may be used for sand filling and for mixing

with cement for mortar and plaster.

c)

Coarse Aggregates :

Coarse aggregates, whether crushed stone or washed and graded gravel shall

conform to sieve analysis presented in Table-II of IS : 383 and when tested shall

conform to IS : 2386 ( Pt.I to VIII )

Stone aggregates( 20 mm. & down ) shall consist of good, hard and broken stone of

the gauge specified and approximately cubicle in shape. It shall be free from dirt,

clay, heaves or any organic matter of admixture of soft or decayed stone. Different

sizes shall be stacked sufficiently apart or separated with approved wooden bulk

heads. The Engineer-in-Charge if consider any aggregate defective or of poor

quality, then irrespective of any previous approval or tests, samples of such materials

shall be immediately tested and until the result of such tests prove the materials to be

satisfactory, it shall not be used in any work. The contractor shall not be entitled to

any claim of any nature on this account.

d)

Water :

Water shall be clean, transparent, tasteless and free from organic or deleterious

matter in solution or suspension in quantities which may impair the strength or

durability of the concrete. Contractor shall provide his own arrangements and at his

own cost for distribution, store, filtration and / or treatment, as necessary of the

required quantity of water. The water should be reasonably clear and of turbidity

limit 2000 ppm.

e)

Reinforcement :

All reinforcement shall be of tested quality strictly in conformity with the relevant

Indian Standards. Steel reinforcement shall comply with the requirement of the latest

edition of IS-1786. All reinforcement shall be HYSD bars of Grade Fe-415. The

Engineer-in-charge shall check and ensure that appropriate test certificates of

materials are available to his satisfaction. If demanded by DVC the contractor shall

submit the manufacturers test certificate for steel. Otherwise, necessary tests shall

be made by the Contractor at his own cost to ensure that the quality and physical

13

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

properties of the materials used conform to the specification. No complaints or

claims shall be entertained on this account.

All reinforcement materials, before its final use, shall be free from loose mill scales,

loose rust, oily or bituminous coating or injurious adherents. Pitted and otherwise

defective rods shall not be used. The binding wire (18 SWG) shall be included in the

cost of reinforcement rod binding and shall be borne by the contractor.

All bars shall be rigidly held in position before concreting as per requirements of the

latest edition of IS:2502. No welding of rod shall be allowed. Laying of

Reinforcement bars shall be in accordance with relevant I. S. specifications unless

otherwise specified. Lap lengths shall not be less than the minimum values specified

in the relevant codes of practice. The laps shall be staggered. Dowel bars shall be

provided wherever required or as directed by the Engineer or as shown in the

approved drawings.

The Contractor shall check, ensure and procure in time, as necessary, the

reinforcement materials required for the continuous scheduled progress of the work

till completion.

All reinforcement steel shall be suitably stacked and stored by the Contractor to

protect it from damage by corrosion, and to prevent distortion of section in long

lengths.

The horizontal distance between parallel reinforcement bars in row shall not be less

than the greatest of the following :

a)

b)

c)

The larger diameter if the diameter be unequal.

Diameter, if the diameters are equal.

6 mm. more than the nominal maximum size of coarse

aggregate.

The vertical distance between two rows of reinforcement bars shall be not less than

12 mm unless they are cross reinforced or lapped. No reinforcement shall be bent

when in position in the work without approval whether or not this is partially

embedded in concrete. Reinforcement shall be accurately fixed and maintained in

position by approved means. Placing of reinforcement shall be completed well in

advance of concreting. In case reinforcement bars are in coil form, straightening of

the same shall be done by the contractor at his own cost.

G.03 MAINTENANCE OF LOG BOOK FOR CONCRETING WORK :

While all efforts shall have to be made by the contractor to achieve rapid

progress in construction in all sector and to avoid deterioration in the quality

14

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

of concrete work, it is necessary that for every tower a log book should be

maintained showing

a)

The date and time of commencement of pouring of concrete.

b)

The date and time of completion of pouring of concrete.

c)

The quantity of cement used in concreting foundation.

The log book shall have to be signed by both the representative of the

contractor and DVC.

G.04 CONSISTENCY :

The amount of water used in concrete shall be regulated as required to secure

concrete of proper consistency and to adjust for any variation in the moisture

content of grading of the sand and aggregates as they enter the mixture.

Addition of water to compensate stiffening of the concrete before placing will

not be permitted. Uniformity in concrete consistency from batch to batch will

be required. The slump of concrete after deposition but before it has been

consolidated shall not exceed 76.2 mm. DVC reserves the right to require a

lesser slump whenever concrete of such lesser slumps are required. DVC also

reserves the right to make the slump test in accordance with the latest

practice. The concrete mix has to be used within half an hour of the mixing.

The proportions of nominal mix concrete & amount of water may be

estimated in accordance with Table-4, Table-5 & Table-9 of IS : 456.

G.05 BATCHING :

The contractor shall provide equipment and shall maintain and operate the

equipment as required to accurately determine and control the amount of

each separate ingredient entering the concrete. The amount of cement, sand,

stone chips and water entering each batch of concrete shall be determined by

the volumetric measurement.

G.06 MIXING :

The concrete ingredients shall be mixed in a batch in right proportions in

mixing drum & shall be kept rotating for not less than two minutes after all

the ingredients except full amount of water are in the mixer. The Engineer

reserves the right to increase mixing time when charging and mixing

operation fails to produce a concrete batch whose consistency is not uniform.

The concrete as discharged from the mixture shall be uniform in composition

except where changes in composition or consistency are required. Excessive

over mixing requiring addition of water to preserve the required concrete

consistency will not be permitted. Any mixer when produce unsatisfactory

results shall be repaired promptly and effectively for controlling the mixing

time. Hand mixing as per standard practice will be allowed only when

concrete mixer fails during concreting. Hand mixing may also be allowed at

15

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

the discretion of DVCs representative in-charge of the work as also for the

location where mixer machine is not accessible.

When hand mixing is adopted it shall be carried out on a water tight platform

such as 1.8 mm galvanised iron plain sheets properly overlapped and placed

upon level ground. The coarse aggregates shall be spread out first evenly over

the sheets. The fine aggregate shall be evenly spread

out over the

coarse aggregate. The aggregates shall then thoroughly be mixed together and

leveled. The required amount of cement shall now be spread evenly over the

mixed aggregates and wet mixing shall start from one end with required

amount of water using shovels. The whole lot shall not be wetted, instead,

mixing shall proceed progressively. The whole operation shall not be taken

more than 15 minutes. If moist sand is used allowance for bulking shall be

made.

In case of such hand mixing being permitted, 10% extra cement on this

account will be added at Contractors expense.

For mixing in mechanical mixers, the same order of placing ingredient in the

loader/drum shall be adopted, that is coarse aggregates shall be put in first

followed by sand, cement & water.

G.07 FORMS (Form boxes or Muff box) :

Form boxes made of steel will be used to confine the concrete and shape it to

the required line. The inner side of the forms shall be cleaned and oiled

before concreting (quality of oil to be approved by Engineer or his

representatives). Immediately before the concrete is placed, precaution shall

be taken so that forms are in proper alignment and tight to prevent any loss of

mortar and forming of honey combing in the concrete and also its supports

are thoroughly secured and tight.

Steel Form Boxes which will be supplied to the contractor have to be returned

in good condition to DVC stores on completion of work, failing which cost of

form boxes (muff boxes) will be recovered by DVC from the contractor at the

rate decided by DVC, which in no case will be less than the rates paid to the

contractor for supply of this item. Steel form-boxes (muff-boxes) shall not be

galvanized, instead they will be painted with 2(two) coats of red-oxide primer

paint.

G.08 PLACING / DEPOSITING THE CONCRETE :

The contractor shall keep the Engineer or his representatives intimated at least 7

(seven) days in advance as to when placing of concrete will be performed. The

16

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

contractor should try to follow his programming in this regard. Incase of abnormal

situation or emergency condition, intimation shall be given to the Engineer or his

representative at least 24 hours before the starting of the work. Unless inspection is

waived out in any specific case, placing of concrete shall be performed only presence

of Engineer or his authorized representative. Contractor will arrange for transport for

the Engineer for inspection, if Engineer so desires.

The concrete must be used while fresh and shall be laid ( not thrown ) in layers not

exceeding 150 mm and consolidated well. The concrete shall be placed and

compacted before setting commences and should not be subsequently disturbed. The

placing should be such that no segregation takes place. Concrete shall be thoroughly

compacted during the placing operation and thoroughly worked around

reinforcements, embedded fixtures and into corners of form work by means of 16 mm

dia poking bars pointed at the ends so that no honey-combing is left in the concrete.

After concreting the chimney portion to the required height, the top surface should be

finished smooth, with slight slope towards the outer edge to drain off the rain water

falling on the coping. Concreting shall be done continuously so that their subsequent

layers are laid before the initial setting of the bottom layer begins. The time from

starting of mixing to ramming in final position shall not take more than 30 minutes.

If fresh concrete is to be laid on the old concrete which is less that 10 days old, the

surface of old concrete should be cleaned with wire brush and washed with a layer of

thick cement slurry before new concrete is laid. But if the concrete is 10 days or more

old, then the top of the set concrete should be chipped and cleaned thoroughly with

wire brush and fresh water, and layer of 12 mm thick cement mortar (1:2) shall be laid

evenly after giving a coat of cement slurry as specified above to ensure proper

bonding between old and new concrete, for which no extra payment over the unit

price for reinforced cement concrete work will be made.

G.09 CURING :

The concrete after setting for 24 hours shall be cured by keeping the concrete wet

continuously for a period of 14 days after laying. The pit may be back filled with

selected earth sprinkled with necessary amount of water and well consolidated in

layers not exceeding 200mm after a minimum period of 24 hours and thereafter both

the back filled earth and exposed chimney top shall be kept wet for the remainder of

the prescribed time of 14 days. The uncovered concrete chimney above the back filled

earth shall be kept wet by providing empty cement bags dipped in water fully

wrapped around the concrete chimney for curing and ensuring that the bags be kept

wet by frequent pouring of water on them.

No separate payment shall be made for curing. The rate for concrete should include

the curing charges.

17

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

G.10 REMOVING OF FORM WORK :

All form work shall be removed without such shock or vibration as would damage

the concrete or forms.

Under fair weather conditions (generally where average daily temperature is 25C or

above) and where ordinary cement is used, forms may be struck after 24 hours of the

placing of concrete. In dull weather (such as rainy periods) and very cold temperature,

the forms shall be struck after 48 hours of the placing of concrete. The consequences

arising during the removal of the shuttering shall be contractors entire responsibilities.

Before reuse all forms shall be thoroughly cleaned as specified earlier & may be used

after repair, if any, with the approval of the Engineer.

G.11 FINISHING OF CONCRETE :

If after the form work has been struck, the concrete surfaces are found to have defects,

all the damaged surface shall be repaired with mortar application composed of cement

and sand in the same proportion as the cement and sand in the concrete mix. Such

repairs shall be carried out within 24 hours after removal of forms and before the

foundation pits are backfilled. The form work is to be struck and repairing if required

is to be done in presence of the Engineer or his representative.

The cost of materials, labour and equipment, required in the repair of concrete shall be

borne by the contractor.

In case of salty / saltish soil, special type of bituminous paint shall be applied over the

finished concrete surface. The paint shall be supplied by DVC, but no payment for

painting will be made by DVC.

Exposed surface of the chimney portion of the foundation above the ground level

shall be brought to uniform surface by plastering. Finishing shall be neatly done with

cement punning. The top surface of the foundation shall be sloped towards the outer

edge to provide drainage from the steel stub angle. 12 mm thick cement mortar in 1:6

ratio shall be used.

G.12 PAYMENT :

Unit rate per cubic meter of reinforced cement concrete work including plastering

and neat cement punning of the exposed surface of chimney portion should be quoted.

In case of any special type of foundation and modification in the foundation design

resulting in excess quantity of concrete, contractor will be paid as per quoted rate.

No extra rate on this account will be entertained. However, if extra quantity of work is

involved, then it will be paid as per original rate quoted by the contractor in the

tender.

18

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

G.13 INSPECTION OF CONCRETING WORK :

The Engineer-in-charge reserves the right to uncover and examine any foundation and

if any foundation is found defective, the contractor shall be required to rectify or do

new foundation, if required; at his own cost and put all these back in order.

G.14 TOLERANCES:

The tolerances for various items connected to the foundation works of transmission

line are as under.

A) Stub-setting (Tower Footing)

All the stub angles for tower legs shall be set accurately to the grade and alignment

shown on the drawings. The difference in elevation between identical parts of any

two stub angles shall not exceed 1/1000 of the horizontal distance between the stubs,

allowance being made for difference, if any, in the lengths of legs and extensions.

The actual elevation of any stub angle shall not differ from the computed elevation by

more than 1/100 of foundation depth. Stub angles shall be located horizontally so that

each is within 6mm of its correct position, or by the amount of play as offered by the

clearance between bolts and holes of the stub-setting template. To ensure greater

accuracy, the hole clearance shall not be greater than 1.5mm on the punched side of

the Template members.

The following tolerances shall be applicable in case of position of foundations

erected with reference to the tower position spotted on Survey Charts :

Type

of Out

of From Centre Line From

Transverse

Tower

Alignment

of Route

Centre line

Suspension

0.5 degree

Tension

0.5 degree

(Set at bi-section of deviation angle)

25 mm

25 mm

+/-250 mm

+/-25 mm

B) Concrete and Form Dimension :

The maximum tolerance on the dimensions shall be +/-10 mm. All tolerances

shall not be on the negative side.

H.

MISCELLANEOUS :

H.01 ENCASING OF STUB :

19

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

Encasing upto top of stub by mass concrete after erection of tower may be required

to be done if desired by the Engineer. For that rate mentioned in the schedule for

mass concrete shall be applied.

H.02 EMBANKMENT :

The contractor shall construct embankment for towers at the locations where

embankment is to be made as directed by Engineer-in-Charge. The contractor should

quote different rates for stone pitching, random stone masonry and brick masonry

pitching.

J.

ERECTION OF TOWER :

J.01

GENERAL

The towers shall be erected on the foundations not less than 14 days after

concreting or till such time that the concrete has acquired sufficient strength. The

towers are erected as per the Structural / erection drawings furnished by DVC to

facilitate erection. For the convenience of assembling the tower parts during

erection operations, each member is marked in the factory to correspond with a

number shown in the erection drawing. Any damage to the steel and injuring of

galvanizing shall be avoided. No member shall be subjected to any undue overstress,

during erection.

Towers may be erected either by Built-up method or by Section method.

Built-up Method

This method consists of erecting the towers, member by member. The tower

members are kept on ground serially according to erection sequence to avoid search

or time loss. The erection progress from bottom upwards. The four main corner leg

members of the first section of the tower are first erected and guyed off. The

advantages of the built-up method are as follows:

a) Tower materials can be supplied to site in knocked down condition which

facilitates easier and cheaper transportation.

b) It does not require any heavy machinery such as cranes etc.

c) Tower erection activity can be done in any kind of terrain and mostly

throughout the year.

d) Availability of workmen at cheap rates.

20

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

Section Method

In the section method, major sections of the tower are assembled on the ground and

the same are erected as units. Either a mobile crane or a gin pole is used. The gin

pole used is approximately 10 m long and is held in place by means of guys by the

side of the tower to be erected. The two opposite sides of the tower section of the

tower are assembled on the ground. Each assembled side is then lifted clear of the

ground with the gin or derrick and is lowered into position on bolts to stubs or

anchor bolts. One side is held in place with props while the other side is being

erected. The two opposite sides are then laced together with cross members and

diagonals; and the assembled section is lined up, made square to the line. After

completing the first section, gin pole is set on the top of the first section. The gin

rests on a strut of the tower immediately below section. The gin rests on a strut of the

tower immediately below the leg joint. The gin pole then has to be properly guyed

into position.

The first face of the second section is raised. To raise the second face of this

section it is necessary to slide the foot of the gin on the strut of the opposite of the

tower. After the two opposite faces are raised, the lacing on the other two sides is

bolted up. The last lift raises the top of the towers. After the tower top is placed and

all side lacings have been bolted up all the guyes are thrown off except one which is

used to lower the gin pole. Sometimes whole on face of the tower is assembled on

the ground, hoisted and supported in position. The opposite face is similarly

assembled and hoisted and then the bracing angles connecting these two faces are

lifted.

J.02 TIGHTENING OF NUTS, PUNCHING OF THREADS AND TACK

WELDING OF NUTS :

All nuts shall be tightened properly using correct size spanners. Before tightening it

is ensured that filler washers and plates are placed in relevant gaps between

members, bolts of proper size and length are inserted and one spring washer is

inserted under each nut. In case of step bolts, spring washer shall be placed under

the outer nut. The tightening shall be carried on progressively from the top

downwards, care being taken that all bolts at every level are tightened

simultaneously. It may be better to employ four persons, each covering one leg and

the face to his right.

The threads of bolts shall be projected outside the nuts by one to two threads

and shall be punched at three positions on the top inner periphery of the nut and bolt

to ensure that the nuts are not loosened in course of time. If during tightening a nut

is found to be slipping or running over the bolt threads, the bolt together with the nut

shall be changed outright. The nuts upto Bottom Cross arm level shall be punched

and tack-welded.

21

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

J.03

PAINTING OF JOINTS :

For galvanized towers in coastal or highly polluted areas, the joints shall be painted

with zinc paints on all contact surfaces during the course of erection.

J.04

CHECKING THE VERTICALITY OF ERECTED TOWERS :

The finally erected tower shall be truly vertical after erection and no straining

is permitted to bring in is alignment. Tolerance limit for vertical shall be 1 in 360 of

the tower height.

J.05

PAYMENTS :

Payment for the erection of tower shall be made by DVC on the per Metric Ton

basis. The rate quoted by the tenders for erection of tower shall include all works

involved in the tower erection as per tower drawing, including transporting, storing

and carriage of all materials to site from contractors stores and checking and

punching and tack welding of bolts on the towers complete in all respect. For

erection of the extension pieces of special towers, whenever necessary, payment will

be made on Metric ton basis as per rate quoted for erection of towers and no

additional rate over the unit price bid for erection of tower will be allowed for the

above purpose. Measurement for payment of erecting the various types of steel

towers will be made on the basis of weights computed by DVC and calculated in

accordance with the bill of materials with variation sheets, if any. Final payments

shall become due only after complete erection of tower and proper punching and tack

welding.

K

GROUNDING OF TOWERS :

At all locations the tower shall have to be grounded to bring down the tower

footing resistance to 10 ohm and below. Measurement of the tower footing resistance

as per directive of the engineer has to be done by the contractor at his own cost. Such

measurement has to be done in dry weather in presence of the engineer or his

representative before the stringing of earth wire. The two stubs which are in

diagonally opposite direction are to be earthed. The earthing shall be done by G.I.

Pipe connected with stub through GI flats and as per drawing supplied by the

purchaser and as per instruction of the Engineer. One set of pipe earthing consists of

2 nos. GI pipe and GI flats. Where grounding of tower by GI pipe is not possible or

the desired level of tower footing resistance not obtained the counter-poise earthing

at the discretion of the site engineer should be done. The counterpoise earthing shall

be done as per drawing supplied by the purchaser and as per instruction of the

Engineer. In case counter poise earthing is required for 2 legs only that will be

considered as one set. Similarly grounding of tower at one leg for pipe type earthing

shall be treated as (Half) set.

22

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

The contractor should submit statement mentioning the date of measurement

of tower footing resistance and tower footing resistance value and details of

grounding adopted for each location.

K.01

PAYMENTS :

Payments for grounding including excavation or backfilling of tower shall be made

on per set basis. One set shall mean complete grounding of one tower at two legs for

pipe type earthing and counterpoise earthing.

If more than one set of grounding is required for any tower, then payment for the

additional set will be made at the rate quoted by the contractor. Pipe type earthing

and counterpoise earthing shall be done as per IS-3040-1966 and IS-5613 (PartII/Sec-2) 1976.

L.

INSULATOR HOISTING AND POWER AND EARTH CONDUCTOR

ERECTION INCLUDING RIXING OF TOWER ACCESSORIES :

Work involves :

1)

Hoisting of insulators and fixing on the towers and erection of

hardware sets.

2)

Jointing of conductors.

3)

Running out (also called paying out) and stringing (pulling up) of

conductor.

4)

Tensioning, sagging as per approved sag-tension (stringing) chart and

clipping in of the conductors (pulling up to proper tension, transferring

of conductor to insulators).

5)

Fixing of vibration dampers preformed armour rod and other tower

accessories. Viz. Number plate, Danger notice plate, Phase plate,

Circuit plate, Bird Guard, Anticlimbing devices and step bolts etc.

6)

Erection of jumpers at the section and angle towers and hoisting and

fixing of suspension insulator strings to restrict jumper swing.

23

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

The contractor shall be entirely responsible for any damage to tower,

conductor or its accessories during wiring of lines. He shall also be

responsible for proper distribution of the conductor drums to keep the number

and lengths of cut pieces of conductor to a minimum. Cut pieces as well as

empty drums of conductor and earthwire shall be taken away by the

contractor as per clause 8.11 of SCC. The following further precautions shall

be observed.

a)There shall be not be any joint in conductor in Railway crossing,

main road crossing, power line crossing and river crossing.

b)No joints shall be less than 30 M away from adjacent towers.

c)There shall not be fore than one joint in a span on each conductor.

d)Requisite and adequate precautionary measures are to be taken

while stringing & sagging power line, road, across Railway & other

important crossing.

Rate of stringing & sagging of power conductor & earth wire quoted

against specific item of erection schedule of works should cover crossing of

the power line, Railway line, small river, road etc. if any falling along the

transmission line. For big river crossing separate rate for string the span

between Anchor tower to Anchor tower as indicated may be quoted.

Requisite and adequate precautionary measures shall be taken

while stringing and sagging over power line, road, Railway and other

important crossing.

L.01

HOISTING OF INSULATORS & FIXING ON THE

TOWERS & ERECTION OF HARDWARE SETS :

The insulator string shall include shackles, yokes, clevises, dead end

fittings, strain and suspension clamps etc. associated with fittings, except

where otherwise specified. Single suspension insulator set of 14 disc shall be

used in tangent location, single strain insulator set of 15 disc shall be used in

angle location. For main road crossing, power line crossing etc. double

insulator set of 2 x 14 disc (suspension) at tangent location and 2 x 15 disc

(strain) at angle location shall be used. For Railway crossing 2 x 15 disc for

suspension and 2 x 16 disc for tension point shall be used and latest Railway

Regulation should be followed.

Insulator string shall be assembled on ground. These shall be cleaned

and examined before hoisting. All accessories shall be properly fitted

24

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

according to approved drawing. It shall be ensured that all current carrying

parts smooth and without dirt, grit, cuts, abrasions, projections etc. Insulators

with hair cracks or chips or those having glazing defects exceeding half

centimeter square will not be used. Security clips shall be in position for

insulators before hoisting. Care should be taken that W spring/security clips

are in current position & all splits pins are opened.

L.02

JOINTING OF CONDUCTOR :

Jointing of conductor shall be done by splicing sleeves of

compression type. All mid span joints or splices of conductor or earthwire

which are subjected to the tension shall be of tension type and joints or

splices of conductor used for jumper connection shall be of non-tension type.

Both of the splices shall be in accordance with the recommendation of

manufacturer. The contractor shall arrange the required compression jointing

machine and dies and other necessary tools. Each part of the joints shall be

cleaned by wire brush to make it free from rust or dirt etc. and proper nonoxide compound shall be placed before final compression is done with

compressors. Jointing shall be to the satisfaction of the Engineer.

The contractor shall be entirely responsible for the proper handling of

conductor, earthwire and accessories in the Site. Handling and transporting of

conductor and accessories shall be carried out in such a manner so to

minimise the possibility of damage from abrasion, through rough handling or

dirt and grit getting into reel and on the conductor causing injury to conductor

etc. Particular care shall be taken at all time to ensure that conductors do not

become kinked, twisted or abraded, bird caged in any manner.

If the conductor during operation got damaged, compression type

repair sleeves shall be used with the approval of the Engineer or his

representative to repair minor damage to the conductor provided that

a)

At the location on the damage on the conductor to be repaired

nor more than 1 or 2 or the aluminum strand are damaged over

a length of not more than 102 mm.

b)

Not more than 2 Aluminum strands in the outer layer are

broken and cross sectional area of any other of the damaged

Aluminum strands is not reduced by more than 25 percent. All

joints or splices or repair sleeves shall be made at least 30

meters away from the structure. No joints or splices shall be

made in span crossing over main roads, Railway, river. Nor

more than one joints or repair sleeve shall be allowed in one

span per conductor.

25

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

L.03

RUNNING OUT (PAYING OUT) & STRINGING

(PULLING UP) OF CONDUCTOR :

The reels on which the conductors are wound are to be raised from

ground so that they are free to rotate. The conductors are then to be pulled

out. Care must taken by the contractor to avoid any damage to the conductor

which are prone to become scratched. The conductor must be prevented from

pying too fast and becoming tangled. Suitable methods, proper scaffolding

are to be adopted by the contractor for crossing obstructions or roads or

existing power or Telephone line. Turn table may also be used depending on

suitability of work for running out of conductor.

As the conductors are reeled out they are to be hoisted up to the cross

arms level and pass through the travellers comprising of aerial rollers and

ground rollers. The travellers shall have a size and shape most suitable for the

type of stringing and size of conductor involved and as recommended by the

conductor manufacturer and DVC. The travellers contact surface with

conductor shall be coated with such materials e.g. neoprene rubber that

conductor is not damaged during pulling up operation. These rollers shall be

equipped with high quality ball or roller bearing for minimum friction. Proper

approval regarding the travellers shall have to be obtained from the

representative of the purchaser.

The aerial rollers shall be hung from cross arm of the tower by means

of requisite wire rope slinging such a way that the conductor on the traveller

will be at the same height as the suspension clamp to which it will be secured

after final adjustment of tension. Sacking is to be wrapped over the steel

work and under sling to avoid damage to the sling as well as to the protective

surface finish of the steel work.

The pulling up of conductor through traveller shall be carried out in

such a manner so that conductor is not damaged or contaminated with foreign

substance and that it may not be rubbed with rough ground surface.

During pulling up operation the tension in each conductor and

earthwire shall not exceed the design working tension of the conductor at the

actual prevailing temperature. After being pulled the conductor & earthwire

shall bot be allowed to hang in the straining blocks for more than 96 hrs. Care

should be taken in pulling up so that splices/joints and sleeves do not catch

on cross arms or in the sleeves of travellers. Any catch of this sort may

prevent the conductor from coming slip, as it should. Normally the joining of

conductor shall be so made so that the joints are not required to pass through

aerial roller.

26

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

L.04

TENSIONING, SAGGING

CONDUCTOR :

&

CLIPPING

IN

OF

THE

The conductor and earthwire shall be sagged in accordance with

erection sag tension chart supplied by the purchaser and as per instruction of

the Engineer before they are finally attached to the tower through the

earthwire clamps for earth wire and insulators strings and clamps for AAAC

conductor.

The sag shall be checked in the span which is nearly equal to the

equivalent span of the stringing section. The contractor shall be responsible

for any damage caused to towers or to the conductor through over stressing

during stringing dynamo-meter and sag boards shall be used to measure

tension and sag. The results are to be checked from the sag tension chart.

Dynamometer shall be periodically checked with standard Dynamometer.

The sag also to be checked when the conductor have been drawn up and

transferred from travellers to the insulator clamps. The conductor shall be

clamped within 36 hours or sagging in.

Sagging in operation shall not be carried out under wind, extremely

low temperature or other adverse weather condition, which prevent

satisfactory sagging. It should be carried out in the calm weather and when

rapid changes in temperature are not likely to occur.

All conductors shall be temporarily earthed in an effective manner at

every section point. Such temporary earth shall be removed after stringing of

the entire line is over and before testing and commissioning of the line.

L.05

FIXING OF VIBRATION DAMPER AND OTHER

ACCESSORIES :

Vibration dampers and/or armour rods for conductors shall also be

fitted according to the recommendation of the manufacturers and advised by

the purchaser. Anti climbing devices shall be fitted on towers at a height

approved by the Engineer. Danger plate & number plate shall have to be

fitted on all locations and phase marking to be provided. The step bolts shall

be provided on legs of tower and from height above ground level as specified

by the Engineer. Fasteners on all fittings, tower, insulators and conductor

accessories shall be secured in position, the security slips also properly

opened and sprung into position.

27

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

L.06

ERECTION OF JUMPERS AND SUSPENSION

INSULATORS TO RESTRICT JUMPER SWING :

The jumper at the section & angle tower shall be erected as advised

by the Engineer. These shall be formed to parabolic shape to ensure

minimum clearance requirements. Non-tension joints are to be made with the

dead end tension clamps to ensure continuity of the line as directed by the

Engineer or his authorised representative.

L.07

PAYMENTS :

Payments for the complete stringing work with 6 (six) Nos. AAAC

conductor shall be made on per KM basis separately. Complete stringing

works include all the work in items 1.10.00 to 1.10.06 and also the fitting of

accessories as directed by the purchaser. The contractor shall quote separate

rates for stringing of 6 Nos. AAAC conductor and 1 (one) No. earth wire on

per KM basis. The rate shall be inclusive of handling, storage and carriage of

all materials required for the purpose from contractors stores to work site.

L.12. FINAL CHECKING, TESTING & COMMISSIONING

After completion of the erection of line final checking shall be made by the

contractor at his own cost with the representative of the purchaser and shall

ensure that all the foundation work, tower erection and stringing has been

done strictly according to the specifications given herein and as per IS &

Electricity Act and rules. All works shall be thoroughly inspected keeping in

view the following main points.

1)

Finishing of coping with proper grading.

2)

Sufficient back filling with proper grading.

3)

Verticality of erected tower.

4)

Proper placing, tightening and punching of bolt.

5)

Normal position of the insulator string and clearance of conductor

from tower body.

6)

Proper sag and tension of the conductor with proper ground clearance

as per specification.

28

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

7)

No damage minor or major to the conductor earth wires, accessories

and insulator string remain unattended. After final checking the line

shall be tested for insulation in accordance with test prescribed by the

purchaser and as per I.S. All arrangements for such testing shall be

done by the contractor and necessary labor. Transport and equipment

shall be provided by him at his own cost. Any defects found out as a

result of such test, shall be rectified by the contractor forthwith

without any extra charges to DVC. In addition to the above, the

contractor shall be responsible for testing that the total and relative

sags of the conductor and earth wires are within the specified

tolerances. Such tests shall be carried out at selected points along the

route as required by the Engineer and the contractor shall provide all

necessary equipment and labour to enable the test to be carried out.

After satisfactory tests on the line and on approval by the Engineer in

writing. The line shall be energised at full operating voltages before

handling over.

COLLECTION OF MATERIALS :

Materials will be supplied by the contractor at their own stores at site.

Materials as detailed in Clause 5 A (Supply Part) of SCC will be issued to the

contractor by the purchaser for the execution of work either by paper

transaction at contractors site stores for the materials under their scope of

supply or from DVCs departmental stores at Maithon/ Dhanbad/ Giridih/

Koderma/ any other specified store. The cost involved in handling and

transporting of stores and storing the materials and carriage of all materials to

actual erection site shall be quoted as per Clause 8.05 of SCC. Land/sheds for

site storing of the materials by the successful tender shall be arranged at his

own cost. The site stores shall be got approved by the purchaser before

storing of the materials. The erection rate should also include the cost of

security arrangement of the materials and tools and plants issued by DVC.

The materials to be supplied and issued to the contractor in phased manner in

conformity with the progress of erection work. The supply schedule would be

fixed up by mutual agreement with the successful bidder after issuance of

LOA.

M.01

SECURITY AGAINST MATERIALS :

MATERIALS TO BE SUPPLIED BY THE CONTRACTOR :

The contractor shall supply all the materials such as cement, sand,

stone chips, gravels, non-oxide compound, M.S. rod, G.I. binding wire of 18

29

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

SWG etc which are not covered under supply schedule. The cost of these

materials including transportation to site shall be included in the erection rate.

The materials to be supplied by the contractor shall be approved by the site

Engineer before use.

M.02 RETURN OF MATERIALS :

All materials drawn by the contractor supplied by DVC in

excess of those actually used shall be returned by him at his own cost to the

purchasers stores at Maithon/ Dhanbad/ Giridih/ Koderma/ any other

specified store as per instruction of site Engineer.

Return of all the items as stated above shall be made within one

month from the date of completion of particular work for which the materials

were issued. For non-return of the same the purchaser shall realize the cost in

full from the contractor at rates indicated in the schedule apart from taking

any other action as per settled terms and conditions of contract.

N

APPROVAL FROM RESPECTIVE AUTHORITIES :

The contractor shall at his cost furnish well in advance before starting

erection of the line all necessary details and drawings as required for

obtaining approval from P&T Departmental/Rly. & other utility or civil

authorities etc. All these approval are to be liaisoned & to be arranged by the

contractor as per clause 8.06 (e), (f), & 8.07 of S.C.C..

O

MEASUREMENT OF WORK DONE :

Within 4 days from the date of completion of each item of work at

each location, measurement should be taken in the presence of the contractor

whose signature should be obtained in the M.Bs as a token of his acceptance

of the measurement. If the contractor fails to be present on the date of

measurement as specified by the Engineer or the authorized representative,

measurement taken by the purchaser shall be final and binding on the

contractor, unless specific written objections thereto are filed with the

Engineer within three days form the date of measurement.

P

TECHNICAL PARTICULARS :

Some essential particulars regarding the 220 kV D/C & 132 kV D/C

transmission line are given in Annexure A & Annexure B for guidance.

30

DVC, Electricity Dept., Spec. No. EDCON/EHV/L-37 & 38

COMPLETION OF DRAWINGS (AS EXCUTED) :

On satisfactory completion of the work the contractor will supply to

the Engineer free of cost As executed route profile of the line (one on good

quality reproducible & ten copies of prints) showing therein the actual

position and type of towers, double insulator points, forest, Rly, River,

Telecom & Power lines, road crossing together with measured span on a

scale of 25 meter to 1 cm horizontal and 2.5 meter to 1cm.vertical.

31

You might also like

- Data Recovery BookDocument136 pagesData Recovery BookPeter KaufmannNo ratings yet

- IITK-GSDMA Wind Codes Project ReportDocument106 pagesIITK-GSDMA Wind Codes Project ReportFung MakNo ratings yet