Professional Documents

Culture Documents

Cone Crusher

Uploaded by

mahaveenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cone Crusher

Uploaded by

mahaveenCopyright:

Available Formats

Ch

ina

Cone Crusher

Cone Crusher

1 Application Of Cone Crusher:

Specifications Of Cone Crusher:

she

2 2.

rO

fS

han

gh

ai Z

eni

th

Of

This series of cone crushers is widely used to crush hard and mid-hard ores and rocks

in metallurgy, construction, road building, chemistry, such as iron ores, copper ore,

limestone, quartz, granite, etc.

Co

ne

Cru

Max feeding

size(mm)

Recommend max

feeding size (mm)

Discharge

opening(mm)

Capacity (t/h)

Power (Kw)

Speed of

motor(r/min)

Voltage (V)

PYD1200

PYZ1200

PYB1200

170

115

60

145

100

50

20-50

8-25

3-15

110-168

110

42-135

110

18-135

110

730

730

730

220/380

220/380

220/380

3.

300

300

150

150

25

24.82

300

150

25.7

Structure and working principle Of Cone Crusher:

Of

Swing Num of mail

shaft

Total pressure of

spring

Weight (motor

included)

Ch

ina

Cone Crusher

Cru

she

rO

fS

han

gh

ai Z

eni

th

The crusher consist of main frame, transmission device, hollow eccentric shaft,

crushing cone, adjustment device, adjustment cover, springs and hydraulic station for

adjusting the discharge opening.

During the operation, the motor drive the eccentric cover to rotate through the

horizontal axle and bevel gears. The center axle of crushing cone swings with the

force of the eccentric shaft cover so that the crushing surface is close to the mortar

from time to time. In this way, the materials will be crushed through continuous

pressing. Diagram 1 is the cutaway view of the machine.

4. Installation and debugging

1). This instruction book only includes some special installation instructions of the

machine. The rest can refer to the instructions of general machine.

2). The lifting device

In crusher installation room, there should be a lifting device which can be used when

installation and maintenance. The lifting device can be chosen from the following

table according its lifting ability.

Weight (Kg)

Name

Need time

PYD1200

PYZ1200

PYB1200

Main frame

5000

5000

5000

Installation

Transmission

Installation and

540

540

540

device

maintenance

Hollow

Installation and

883

883

883

eccentric shaft

maintenance

Bowl-shaped

Installation and

1004

1004

1004

bearing

maintenance

Installation and

Crushing cone

3125

3125

3380

maintenance

3400

3400

3751

Installation and

maintenance

Adjustment

cover

3751

3751

3950

Installation and

maintenance

ne

Adjustment

device

Co

3). Installation instructions

A. check the number of the spare parts before installation. Check and make sure there

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

are no damage to the spare parts during transportation and clean the protect painting

and the dust or dirty materials on the spare parts.

B. when installation, spare some dry oil on the fixed surface of the spare parts, and

spare some watery oil on the movable surface.

4). Base

A. the crusher should be installed on concrete base. The depth of the concrete is

determined by the local conditions.

B. to prevent the rocks piling, there should be enough space under the base...

C. to protect the base, a protection board should be put on the base. Clients prepare

these themselves.

D. we provide foundation diagram only for reference.

E. the place of lubrication system and electric controlling system can be changed

according to different environment, but the sequence cannot be changed.

5). Installation of the frame

A. strictly vertical and horizontal must be ensured when installing the frame. Use the

gradienter and suspender to check the central line of the bottom base. (diagram 2)

B. after adjusting the bottom base with the adjustment wedge, fasten the ground bolt

and begin the second grounting.

C. when the second grounting is fixed, withdraw the wedge from the bottom of the

crusher and fill the gap with concrete. Then, check under the condition of frame

installation A.

D. keep the bottom base vertical and horizontal. Make sure the machine operate

properly, otherwise, the copper cover will be imbalantly touched, the eccentric

cover will be fractioned and the sealing device will be out of work.

6). Installation of transmission axle

A. when installing the axle, an adjusting mat will be put between the bottom base and

the flan of the transmission part.

B. after installing the device, use a template to check all the size concerned with the

transmission gears.

C. the moving range of the transmission gear should be kept between 0.4-0.6mm.

(that is, the gap of the two ends of B).

D. when dismantling the transmission axle, use the bolt on the flang to prop it up. The

square bolt should not be fastened without dismantling the transmission device.

7). Installation of hollow eccentric shaft

A. before installation put the mat on the bottom cover. Then, use a sling to put the

cover under the frame. After that, put the upper round plate and lower round plate

on the bottom cover in sequence and make sure the heave place on the lower plate

and the concave place in the bottom cover are locked. (Diagram 5)

B. when installing the hollow eccentric shaft, a round-end bolt can be used to put the

eccentric shaft into the central hole in the frame. Be sure the gears are not stricken

when installing.

C. after installation, the out surface of the big and small gear must be at same level

and check the gap between the gears. For the model 1200, the warp is about

2.1-2.58mm.

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

8). Installation of bowl-shaped bearing

A. preparation

a. get rid of the sundries in the oil groove and oil hole.

b. make sure there is no damage to the dust-proof mat and oil seal mat.

c. make sure the processed surface is in good condition. If any damage, it should be

repaired immediately.

B. the bowl-shaped bearing support should be close to the bottom base and check the

interface of the horizontal with gap ganged. (Diagram 8)

C. after installing the bowl-shaped bearing put a cover on the bowl-shaped tile. Take it

off when installing the crushing cone.

D. when installing the bowl-shaped bearing, make sure the water-in pipe, water-out

pipe, oil seal ring and dust proof ring are in good condition.

9). Installation of crushing cone

A. before installation set up a firm and tall wooden support to help install the crushing

cone.

B. clean the protective oil layer on the shaft and spherical surface and clear up the oil

hole and oil groove with wind.

C. spare a layer of dry butter on the cone shaft and a layer of watery oil on the

spherical surface.

D. when installing the crushing cone, put it lightly in to the hollow eccentric shaft to

prevent the circle ring being damaged.

10). Dust-proof device

A. the dust proof device of this crusher adopts dry oil to seal. See diagram 9.

B. the sealing structure of this crusher is similar to Symons in America. This structure

is reliable and with low cost since a set of water-supplying is saved.

C. when installation, fill the cavity with dry oil. Refill it when checking.

Notes:

If clients ask water to be the dust proof device, they should prepare water supplying

system as

shown in Diagram 10-1.

A. set up a mouth-type pipe near to the water box

B. a water adjusting valve should be installed in water-in pipe.

C. When the crusher stops, the water in the dust proof device should be discharged

totally.

11). Installation of lubrication system

A. the installation of lubrication system can refer to the installation instruction book

of the factory, or refer to local conditions. But if the allocation is decided by clients,

they should prepare the spare parts themselves.

B. the installation of lubrication system should make it convenient to oil the machine.

C. installation of lubrication system is finished before crushing cone. Because the test

of lubrication system should be carried first so that it is convenient to maintain if there

are problems in lubrication system.

12). No-load trial operation

After the above steps, trial operation should be taken to check whether the installation

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

is qualified.

A. before starting the crusher, check the connection parts.

B. Before starting, rotate the transmission part with hand, and make sure the hollow

eccentric shaft rotate at least 2-3 circles. If it is flexible, start the crusher.

C. Start the oil pump before starting the crusher until all the lubrication points are

oiled. After seeing the oil return the oil tank, start the crusher.

D. The no-load trial operation should be at least 2 hours.

E. The no-load trial operation should reach the following requirement.

a. self rotation of crushing cone should be at most 15 rounds per minute.

b. The cone gear should have no periodical noise.

c. The lubrication system should meet the following requirement:

the pressure of the oil should be within 0.8-1.5kgf/cm2.

The temperature of the returned oil should be below 50

d. after trial operation, there should be no burning and damage in every friction

part.

e. If the rotation speed of the crushing cone is too quick, stop the crusher

immediately and maintain it on time. Check the oil quantity and retrial again.

f. If there is periodical noise to the cone gear, check whether the gear is installed

correctly and check the gap between the gears.

13). Installation of adjustment device, adjustment cover and springs (diagram 11)

A. clean the supporting cover and the adjusting ring. Spare mixer of dry and watery

oil on the toothed whorl. Install locking oil tank on the supporting cover. Connect

locking oil tank with the hydraulic station.

B. install the supporting cover to the main frame.

C. put the adjustment ring into the supporting cover.

D. screw the latch on the supporting cover. Strike four tags into four corresponding

keyhole.

E. install funnel stand and funnel.

F. install dust proof cover. Make sure the four keys of the adjusting ring are in the

groove of dust proof cover.

G. adjust the height of spring according to the diagram.

H. install the energy accumulator of the pusher tank. First install the pusher tank

according to diagram 13. Interface M and N of the pusher tank is connected with M

and N on the hydraulic station. Hold the energy accumulator on the feeding support

with a folder. The energy accumulator is connected with the locking oil tank through

and cross joint.

14). Installation of feeding device

A. incorrect installation will lead to following troubles.

a. capacity is lowered.

b. the size of final product is uneven, big size cover a large percentage.

c. the abradability of the wear parts is not even or they wear too quickly.

B. the height between feed opening and distributor is very important to the crusher. If

it is too high, the raw materials cannot easily enter the crushing chamber. Therefore,

the height should be based on the instructions.

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

C. arcuate steel plate is used to protect the feeding box from damaging and protect the

materials from being stuck in the feeding box. When installation, keep the arc steel

plate in good shape and pay attention to the space between the arc steel plate and the

edge of the feed opening to protect materials from being stuck. (see diagram 14)

15). Installation of hydraulic station and debugging

A. the hydraulic station of the crusher is installed on a proper position on the base to

make operation convenient. The connecting spare parts between the hydraulic station

and main unit can be installed according to the local conditions.

B. the interface M, N, P of hydraulic station is connected with interface P of locking

tank.

C. after installing the hydraulic station takes the pressure test. The temperamental

pressure is 140kgf/cm2.

D. take locking test.

a. fill 75-80 kgf/cm2 nitrogen gas to the energy accumulator before press air into the

locking tank.

b. only after the pushing tank discharges air can locking tank is filled with air.

c. during the test, the left air in the locking tank and its pipes can be let out through

at bottom of the pipes or the energy accumulator.

E. debugging test: After locking tank discharges air, use pushing tank to take the test

of adjusting the discharge opening.

F. make sure the spare parts of the hydraulic station are in good condition. (see

diagram 16)

16). Load test

A. if the no-load test is ok, the load test can be taken.

B. the load test should last 48 hours.

C. at the beginning of the test, put small quantity of rocks into the crusher, then,

gradually, add the quantity.

D. the load test should reach the following requirement:

a. there is no acute vibration and no big noise

b. both the feeding and discharging are in good condition. The capacity is similar to

stipulated capacity.

c. the hydraulic station operates well

d. the lubrication system should meet the following requirement:

the pressure of the oil should be within 0.8-1.5kgf/cm2.

temperature of returned oil should be lower than 60

e. there is no damage to the wear parts.

f. the electric system is in good condition

5. Maintenance

17). Notes

A. the materials must be in the middle of the distributor, see diagram 14. it is not

allowed to put the materials into the crushing chamber directly, because it will make

the crusher overloaded and the liner plate will be abraded unevenly.

Correct feeding conditions:

a. the materials are distributed equally to the crushing chamber.

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

b. The quantity of materials should not higher than the mortar.

B. the max feeding size should not equal to the feed opening, (the max feeding

size85% of the feed opening) otherwise, it will lead to:

a. the capacity is low

b. some spare parts will be damaged.

C. crusher is not allowed to start in overload condition in case of accident.

D. when stop the crusher, stop the feeder first. After the materials are all discharged

out, stop the crusher.

E. the locking system and hydraulic station should be checked often to avoid

problems.

18). Capacity of the crusher

Capacity is subject to feeding method, material size, size of final product, material

nature, temperature, etc. the range is wide. The capacity is under certain conditions.

19). Change of mortar

There are u-shaped bolts on the adjusting ring. Fill zinc alloy into the space. When

installing or changing the mortar, after 6-8 hours operation, check the fastening

conditions and screw the U-shaped bolts again.

20). Change of the crusher inner wall

The cone crusher inner wall is fixed to the cone crusher body through a cone end.

There is zinc alloy between them. When installing or changing the inner wall, after

6-8 hours operation, check the fastening conditions. If there is loose, fasten it.

21). Mesh of gears

The friction of round plate changes the gap between gears. To make the gears

properly meshed, clients are required to put a mat on the bottom cover. The thickness

of the mat should equal to the friction of the round plate.

22). Bowl-shaped bearing and sealing device

When installing the bowl-shaped bearing, make sure the oil seal is not damaged by

the steel cable.

When assembly, scrape the spherical surface to ensure the space between crushing

cone and the spherical surface is kept within 0.35-0.5mm.

The bowl-shaped tile is fixed to the bowl-shaped bearing support through lock pins to

prevent the tile rotate in circle.

The bowl-shaped bearing support and the frame are fixed together by lock. If there is

space between the support and the frame, deal with it immediately.

23). The cylinder liner and the frame is the third transient assembly. To avoid the liner

rotating, the upper part of liner is filled with zinc alloy. When changing new liner,

make sure it is according to the practical size because the after long times operation

and assembly, some changes may happen to the crusher. If the space is too large, the

liner will be broken.

24). Conic liner

The cone cover and the eccentric shaft should wring each other. Fill in some zinc

alloy to stop the cover rotating. The space should be full of zinc alloy. The cover may

change its shape due to the hot zinc alloy, so check the size of d1, d2 and B of a new

cover. If it is incorrect, correct it. When making spare parts, make sure it is fit for the

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

practical size of the inner diameter of eccentric shell.

25). Springs

A. The function of springs is: when some uncrushed materials enter the crusher, they

will prevent crusher from damaging. Therefore, the pressure of the springs and the

crusher is corresponding to each other. If the crusher is in good condition, the spring

is stable; only when uncrushed materials enter the machine will the springs be

pressed.

B. if the upper part of crusher vibrates, clients are required to check the machine

carefully and solve the problem. If pressing the springs incorrectly, some parts may be

damaged, because pressing the spring will increase the pressure of the crusher.

The reason why the upper parts of crusher vibrate is:

a. feeding unevenly or overfeeding

b. there are many small lump materials in the raw materials or the humidity is too

high

c. the discharge opening is too small.

26). The outer rotation parts of the crusher should be protected with cover which is

prepared by clients.

6. Lubrication system

27). Since the friction surface receives much pressure, lubrication is very important to

the crusher. The crusher is centrally lubricated with watery oil.

Oil route

There are two routes for the oil to enter the machine; one is through the oil hole at the

bottom of the crusher, then to the hollow eccentric shaft surface, bowl-shaped bearing

and the big and small gears through 3 separate ways. The other is through the hole in

the transmission shaft support, then to the transmission bearing. The return route is a

spill hole at the bottom of the small bevel gear and another spill hole in the dust-proof

cover.

28) lubricating oil

In winter, steam turbine oil should be adopted; in normal circumstances, diesel oil

should be adopted; in summer, No. 11 gas oil is suitable. To ensure normal operation

of the crusher, if there is no heating system in the workshop, an ohimc heater should

be set in the oil tank to increase the temperature. In summer, the oil temperature is

high, so the oil should first go through a heat exchanger.

29). The hydrostatic pressure of heat exchanger is 23kgf/cm2, and the water

temperature must be lower than 28. The water should be clean.

30). The oil pressure of the machine should be up to 0.81.5kgf/cm2.

31) if the pressure is lower than 0.81.5kgf/cm2, the electric system will send out

signal. At this moment, stop the feeder and check the reason.

32). Due to long term operation, the temperature of lubricating oil may be very high,

but it should not higher than 60, otherwise, stop the crusher and check the reason.

33). In winter, if the machine stays out of work for long time, clients should adopt

some measures to stop the oil from frozen. The best way to do this is operate it in

no-load condition periodically. If necessary, use the ohmic heater.

34). Newly-installed crusher should be changed lubricating oil every 1-1.5 months in

Cone Crusher

Co

ne

Cru

she

rO

fS

han

gh

ai Z

eni

th

Of

Ch

ina

the first 3-4 months. After that, change the oil every 3-4 months and add to the

lubricating oil periodically.

35). Make sure the filter is clean. If the oil quantity is reduced during operation, it is

possible that the cylinder is blocked. Stop the crusher and check it.

36). Check, clean and maintenance of the machine should at least once a year.

37). When cleaning the catheter of the lubrication system, choose the place where

may be residua deposition, for example, the turning point. According to the conditions,

check the whole catheter or part of it.

38). After using the new oil, the filter should be cleaned after 1-5 days and nights.

Also, the filter should be repaired every time checking the machine.

39). The oil pump should be checked at least once a year.

40). When the lubrication system is broken, the oil level in the oil tank should reach

the highest level. When the lubrication system is at work, the oil level should not

lower than the lowest level.

You might also like

- Operation of Coal-Based Sponge Iron Rotary Kiln To Reduce Accretion Formation and Optimize Quality and Power GenerationDocument8 pagesOperation of Coal-Based Sponge Iron Rotary Kiln To Reduce Accretion Formation and Optimize Quality and Power GenerationJJNo ratings yet

- Apron Feeder: Made in IndonesiaDocument4 pagesApron Feeder: Made in IndonesiaBayu EkosaputroNo ratings yet

- Nickel / Cobalt Laterite Processes: by Boy Adhitya Presented By: Frans AttongDocument30 pagesNickel / Cobalt Laterite Processes: by Boy Adhitya Presented By: Frans AttongSlamet SetyowibowoNo ratings yet

- Introduction of Shaorui: Shaorui Heavy Industries Co., LTDDocument27 pagesIntroduction of Shaorui: Shaorui Heavy Industries Co., LTDduyNo ratings yet

- A 144Document1 pageA 144AnuranjanNo ratings yet

- IB-3006 Global Track Jaw Crusher (GT-125) 6-12Document168 pagesIB-3006 Global Track Jaw Crusher (GT-125) 6-12Manuel VenturaNo ratings yet

- CrawlerMobileCrusher SDocument7 pagesCrawlerMobileCrusher Sjoyalcrusher100% (1)

- Continous Miner and Road HeaderDocument22 pagesContinous Miner and Road HeaderAhsan AliNo ratings yet

- Thermol-D DescriptionDocument4 pagesThermol-D Descriptionajeeit8No ratings yet

- Manual de Instalacion de Cono (Chancadora)Document62 pagesManual de Instalacion de Cono (Chancadora)Dennis Vicente Ayala100% (1)

- Taihong Catalogue-2018Document16 pagesTaihong Catalogue-2018SoLe Gahona100% (1)

- Presented by M .Javaid (BCHE - FA11.041) Jawed Rafique (BCHE - FA11.027)Document13 pagesPresented by M .Javaid (BCHE - FA11.041) Jawed Rafique (BCHE - FA11.027)Adeel AshiqNo ratings yet

- Final Report - STONE CRUSHERDocument71 pagesFinal Report - STONE CRUSHERneusonNo ratings yet

- Report Internship NLCDocument39 pagesReport Internship NLCjaganNo ratings yet

- Greasing Standar ProcedurDocument7 pagesGreasing Standar ProcedurAnnes HutagalungNo ratings yet

- araña3CR285DME Eng MANUAL-DE-OPERACIONDocument20 pagesaraña3CR285DME Eng MANUAL-DE-OPERACIONtincho_0026No ratings yet

- REMU XO CrossoverBucketDocument6 pagesREMU XO CrossoverBucketScott GuimondNo ratings yet

- Design, Fabrication and Testing of a Screw ConveyorDocument24 pagesDesign, Fabrication and Testing of a Screw ConveyorKing Maker100% (1)

- NAWA Spiral ClassifierDocument2 pagesNAWA Spiral ClassifierChandra ShekarNo ratings yet

- 4TE RockBreaker LeafletDocument4 pages4TE RockBreaker LeafletJet OrtegaNo ratings yet

- Hydraulic Cone Crusher PDFDocument16 pagesHydraulic Cone Crusher PDFJanethDeNunuraNo ratings yet

- Improving The Sink Roll Life in GalvalumeDocument6 pagesImproving The Sink Roll Life in GalvalumePraful PatilNo ratings yet

- Cone CrusherDocument3 pagesCone Crusherchand_yelNo ratings yet

- REV 1 Screen MediaDocument10 pagesREV 1 Screen MediaDyego GarciaNo ratings yet

- Crushing Plants, Crushers and Crushing TechnologiesDocument27 pagesCrushing Plants, Crushers and Crushing TechnologiesFavorSea Industrial Channel LimitedNo ratings yet

- ZYS High Efficient Cone CrusherDocument18 pagesZYS High Efficient Cone CrusherjoyalcrusherNo ratings yet

- Component Condition Report DM007Document9 pagesComponent Condition Report DM007ahmat ramadaniNo ratings yet

- Blast FurnaceDocument3 pagesBlast FurnaceNarendra Singh ShekhawatNo ratings yet

- Jaw Crusher Daily Inspection FormDocument6 pagesJaw Crusher Daily Inspection FormjlfyNo ratings yet

- Komatsu WA600-6R Wheel Loader Specs and FeaturesDocument12 pagesKomatsu WA600-6R Wheel Loader Specs and Featuresjaved samaaNo ratings yet

- 320C Vs Deere200EnglishDocument52 pages320C Vs Deere200EnglishFernando Omar ArenaNo ratings yet

- Proportional Hydraulic Drive DesignDocument22 pagesProportional Hydraulic Drive DesignThafer MajeedNo ratings yet

- Sample Brochure - Crusher PDFDocument3 pagesSample Brochure - Crusher PDFBiswajit DuttaNo ratings yet

- Comet - Glands 2023 List PriceDocument2 pagesComet - Glands 2023 List PriceNIRALI PRAJAPATINo ratings yet

- Simplex Infrastructures Limited: Grasim Cement Plant Project, KotputliDocument82 pagesSimplex Infrastructures Limited: Grasim Cement Plant Project, KotputliSulabh TiwariNo ratings yet

- Danroll Drum MotorDocument112 pagesDanroll Drum MotorEnrique MurgiaNo ratings yet

- Timken Split Block SAF HU CatalogDocument126 pagesTimken Split Block SAF HU Catalogmans2014100% (1)

- DMI Super 6-20Document2 pagesDMI Super 6-20Darko KljajićNo ratings yet

- Archimedys Technical Data - Metric - GB 11264 PDFDocument43 pagesArchimedys Technical Data - Metric - GB 11264 PDFAnonymous Cxriyx9HIXNo ratings yet

- Single Toggle Jaw Crusher OTSUKATEC-2Document7 pagesSingle Toggle Jaw Crusher OTSUKATEC-2moddysNo ratings yet

- Vibrating MillDocument6 pagesVibrating MillJorge Alexander Rocha Alvarez100% (1)

- KOMAC Crusher MANUALDocument41 pagesKOMAC Crusher MANUALhenry vegaNo ratings yet

- Drill Handbook GuideDocument26 pagesDrill Handbook Guidebilly_bNo ratings yet

- Cut82hr Manual Parts (Cr9b-) 130712siDocument43 pagesCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735No ratings yet

- NHI Brief IntroductionDocument56 pagesNHI Brief IntroductionThanhluan NguyenNo ratings yet

- Differences Between Apron Feeder and Vibrating FeederDocument1 pageDifferences Between Apron Feeder and Vibrating FeederAnkon Mukherjee100% (1)

- 08 Industrial Minerals (Pages 743-806)Document66 pages08 Industrial Minerals (Pages 743-806)Ali YukselNo ratings yet

- Part 1 C38 Operations Manual REV001 EnglishDocument102 pagesPart 1 C38 Operations Manual REV001 EnglishSergNo ratings yet

- Stockpile Coal Handling - Sec 23Document10 pagesStockpile Coal Handling - Sec 23Muksin SalehNo ratings yet

- Equipment status and maintenance scheduleDocument11 pagesEquipment status and maintenance scheduleAbdi AnsharyNo ratings yet

- Backlash adjustmentDocument2 pagesBacklash adjustmentHendra MonoNo ratings yet

- Electrical Motors DetailsDocument195 pagesElectrical Motors Details243avinashNo ratings yet

- Jaw CrusherDocument4 pagesJaw CrusherRebekah HaleNo ratings yet

- Sandvik Mobiles: Double Screen Principles & Key Sales PointsDocument38 pagesSandvik Mobiles: Double Screen Principles & Key Sales PointsDyego Garcia100% (1)

- Acura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairDocument11 pagesAcura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairCarlos Gunter Tamayo MoralesNo ratings yet

- Up150 38BDocument40 pagesUp150 38BRamKS80100% (3)

- Boiler Ash Handling Operation & Maintenance PDFDocument64 pagesBoiler Ash Handling Operation & Maintenance PDFdreamboy87No ratings yet

- Sgs3468ahd PDFDocument62 pagesSgs3468ahd PDFDilan BvlyNo ratings yet

- 9 Maintance and Repair of Shipboard Machinery and EquipmentDocument9 pages9 Maintance and Repair of Shipboard Machinery and EquipmentridhoNo ratings yet

- Crankshaft - InstallDocument7 pagesCrankshaft - InstallLeonardo PerezNo ratings yet

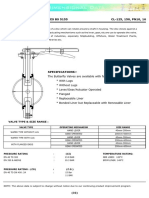

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Stainless Steel Pipe SCHDocument5 pagesStainless Steel Pipe SCHmahaveenNo ratings yet

- Gear Coupling Selection Guide & SpecificationsDocument3 pagesGear Coupling Selection Guide & SpecificationsmahaveenNo ratings yet

- Technical SpecsDocument8 pagesTechnical Specscostea0028No ratings yet

- Valve Brochure Data PDFDocument6 pagesValve Brochure Data PDFmahaveenNo ratings yet

- Control Valves: Controls - Protects - PerformsDocument12 pagesControl Valves: Controls - Protects - PerformsmahaveenNo ratings yet

- Gear Coupling Selection Guide & SpecificationsDocument3 pagesGear Coupling Selection Guide & SpecificationsmahaveenNo ratings yet

- L&T Ball Valves: 3-Piece DesignDocument8 pagesL&T Ball Valves: 3-Piece DesignmahaveenNo ratings yet

- Csggcdom Cast ValvesDocument32 pagesCsggcdom Cast ValvesmahaveenNo ratings yet

- Camlock PDFDocument10 pagesCamlock PDFmahaveenNo ratings yet

- Gear Coupling Selection Guide & SpecificationsDocument3 pagesGear Coupling Selection Guide & SpecificationsmahaveenNo ratings yet

- AC/DC TIG Welding Machine SpecificationDocument5 pagesAC/DC TIG Welding Machine SpecificationmahaveenNo ratings yet

- A Basic Guide of Arc Welding Electrodes: by Bruce BauerleinDocument4 pagesA Basic Guide of Arc Welding Electrodes: by Bruce BauerleinRajeev KhantwalNo ratings yet

- 1 Answer: Full Gear Coupling - A Full Gear Coupling Has A Toothed Hub Which Is Fixed in BothDocument1 page1 Answer: Full Gear Coupling - A Full Gear Coupling Has A Toothed Hub Which Is Fixed in BothmahaveenNo ratings yet

- Nucor Steel Seattle Caster Upgrade Focuses on Core ComponentsDocument8 pagesNucor Steel Seattle Caster Upgrade Focuses on Core ComponentsmahaveenNo ratings yet

- Weld Filler Metal SelectionDocument7 pagesWeld Filler Metal SelectionsusanwebNo ratings yet

- Welding Electrodes Classification and Selection for Thermal Power PlantsDocument2 pagesWelding Electrodes Classification and Selection for Thermal Power Plantskiki270977No ratings yet

- Combined Drawing Systems: For Coil To Bar and Bar To Bar ProductionDocument15 pagesCombined Drawing Systems: For Coil To Bar and Bar To Bar ProductionmahaveenNo ratings yet

- Effects of Welding Parameters on TIG Welding of Aluminum PlateDocument48 pagesEffects of Welding Parameters on TIG Welding of Aluminum PlatekarthickNo ratings yet

- Gurudev Surana Industries LTD - Integrated Steel Complex Raichur. Indent For ProcurementDocument2 pagesGurudev Surana Industries LTD - Integrated Steel Complex Raichur. Indent For ProcurementmahaveenNo ratings yet

- D&H Sécheron Electrodes Private Limited: Approximate Comparison WithDocument5 pagesD&H Sécheron Electrodes Private Limited: Approximate Comparison WithmahaveenNo ratings yet

- Is 822 1970Document43 pagesIs 822 1970Santosh KumarNo ratings yet

- Nucor Steel Seattle Caster Upgrade Focuses on Core ComponentsDocument8 pagesNucor Steel Seattle Caster Upgrade Focuses on Core ComponentsmahaveenNo ratings yet

- Shaft Alignment: Nizwa College of TechnologyDocument15 pagesShaft Alignment: Nizwa College of TechnologyAnonymous ffje1rpaNo ratings yet

- Page 1Document1 pagePage 1mahaveenNo ratings yet

- Conversion FactorDocument3 pagesConversion FactorpetluanduyNo ratings yet

- Page 1Document1 pagePage 1mahaveenNo ratings yet

- Shaft Alignment: Nizwa College of TechnologyDocument15 pagesShaft Alignment: Nizwa College of TechnologyAnonymous ffje1rpaNo ratings yet

- Accumalator PDFDocument30 pagesAccumalator PDFmahaveenNo ratings yet