Professional Documents

Culture Documents

App D Painting Specifications

Uploaded by

Jignesh PandyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

App D Painting Specifications

Uploaded by

Jignesh PandyaCopyright:

Available Formats

Coos County Oregon

Bid Documents for the Natural Gas Pipeline Project

Appendix D:

Painting Specifications

1.0.

SCOPE

This specification covers the minimum requirements for the selection of paint

systems, the purchase of material, surface preparation, and the application of

coatings for pressure vessels, heat exchangers, mechanical equipment, and

structural steel which are fabricated and/or erected either in a vendors shop or in

the field.

1.1. Section 9.0 of this Appendix contains a Paint Schedule which

summarizes coating requirements.

1.2.

Section 9.1 of this Appendix gives the color scheme.

1.3.

Galvanizing is outside the scope of this specification.

1.4. Paint for buildings, concrete, or masonry is outside the scope of this

specification.

1.5. This specification does not apply to items that are purchased with a

manufacturers standard coating unless provisions have been made

otherwise in the purchase order.

2.0.

GENERAL REQUIREMENTS

2.1. All coating of steel surfaces shall be performed in accordance with

Structural Steel Painting Council (SSPC) Paint Application Specification

SSPC-A1 for Shop, Field, and Maintenance Painting, and the coating

manufacturers recommendations.

2.2. Maximum temperatures which are higher than normal operating

temperatures (e.g. such as steam out or catalyst regeneration conditions)

shall be considered in specifying the coating system to be used.

3.0

MATERIALS

3.1. No material substitutions will be allowed without written approval from

County (Project Advisors).

3.2. Paint and coating materials shall be delivered in unbroken, original

packages leaving the manufacturers name and material designation. All

materials shall be applied in accordance with the individual manufacturers

recommendation.

Revised 1/10/03

Coos County Bid Documents App D Painting Specifications.doc

Page D-1

Coos County Oregon

Bid Documents for the Natural Gas Pipeline Project

3.3. The prime coat materials shall be as specified in Section 9.0 of this

Appendix and shall be applied by brush or spray.

3.4. The finish coat shall be as specified in Section 9.0 of this Appendix. In

the event that thinners or retarders are necessary, the wet film thickness must

be increased proportionally to produce the correct dry film thickness. Any

tinting material used shall be compatible with the paint system and shall not

be detrimental to its service life.

3.5. The paints and coating materials as shown in Section 9.0 of this

Appendix have been selected to set a standard of quality. Primers and finish

coats should be by the same manufacturer or of proven compatible materials

for adjacent coats.

4.0.

SURFACES TO BE PAINTED

4.1. The surfaces to be coated will generally exist in one of the following

conditions:

4.1.1 Bare surfaces which require cleaning, surface preparation and

coating.

4.1.2 Shop prepared and coated surfaces which have been damaged

and require spot surface preparation and coating.

4.2.

Items to be painted include, but are not limited to, the following:

4.2.1 All un-insulated carbon steel and low alloy piping, pressure vessels,

heat exchangers, storage tanks, drums, towers, etc.

4.2.2. All insulated carbon steel and low alloy piping, pressure vessels,

heat exchangers, storage tanks, drums, towers, etc., with operating

temperatures of 50OF to 250OF (prime coat only).

4.2.3. Heaters, boilers, ducts and stacks.

4.2.4 All structural steel, except that which is galvanized.

4.2.5 Pumps, compressors and other machinery and equipment,

including factory painted items, that are not properly finished.

4.2.6 Fire proofed carbon steel surfaces (only prime coat is required).

4.3 Certain equipment (pumps, compressors, motors, instruments, electrical

items, etc.) that are supplied with manufacturers standard finish paint will not

Revised 1/10/03

Coos County Bid Documents App D Painting Specifications.doc

Page D-2

Coos County Oregon

Bid Documents for the Natural Gas Pipeline Project

require field painting except for repair of damaged surfaces and to provide the

desired finish color.

5.0.

SURFACE PREPARATIONS

5.1. The following surface finishes referenced in this specification are

defined in SSPC Paint Application Specification SSPC PA1:

5.1.1.

5.1.2.

5.1.3.

5.1.4.

5.1.5.

5.1.6.

SSPC-SP1

SSPC-SP2

SSPC-SP3

SSPC-SP5

SSPC-SP6

SSPC-SP10

Solvent Cleaning

Hand Tool Cleaning

Power Tool Cleaning

White Metal Blast Cleaning

Commercial Blast Cleaning

Near White Blast Cleaning

5.2. Surfaces which have been cleaned and prepared for coating shall

receive the first or prime coat the same day and, in all cases, before the

cleaned surface shows oxidation or is subjected to contamination. Areas

developing rust before being primed shall be recleaned.

5.3. All surfaces to be coated shall be free of all foreign matter such as mill

scale, rust, dirt, grease, oil and other deleterious substances.

5.4. Bare steel surfaces shall be solvent-washed as required to assure an

oil and grease free surface in accordance with the Structural Steel Painting

Council Specification, SSPC-SP1. Final wiping shall be done with clean rags

and solvent so as to leave no oil residue.

5.5. Steel surfaces of unprimed steel shall be cleaned to bare metal by an

approved surface blasting process which will produce a finish conforming to

SSPC-SP5, SSPC-SP6, or SSPC-SP10, as required for the primer material

specified

5.6. Still surfaces that cannot be cleaned by blasting as specifically

specified shall be cleaned to bare metal by wire brushing or other mechanical

means conforming to SSPC-SP3 or SSPC-SP2.

5.7. Primed surfaces shall be cleaned of dirt, grease, oil and foreign

material. When primed surfaces have been subjected to welding, all slag

deposits, welding fume deposits and oxides formed by welding shall be

removed for a distance of six inches from the weld area by sandblasting, win

brushing of other mechanical means conforming to SSPC-SP2 or SSPC-SP3.

This procedure also applies to the repair of surfaces which have been shop

primed and damaged during shipment or construction.

Revised 1/10/03

Coos County Bid Documents App D Painting Specifications.doc

Page D-3

Coos County Oregon

Bid Documents for the Natural Gas Pipeline Project

5.8. Items of manufactured equipment such as pumps, compressors,

motors instruments, electrical items that have been painted or primed with

manufacturers standard paint shall not be blast cleaned.

5.9. Steel surfaces which have been coated with inorganic zinc which have

areas showing either poor adhesion or areas damaged during shipment or

construction shall be cleaned as per Paragraph 5.6. After cleaning these

areas shall be coated with an inorganic zinc coating with a 2.5 mils minimum

dry film thickness.

6.0.

COATING APPLICATION

6.1.

All work shall be performed with good clean brushes, approved rollers

or approved spraying equipment, which will produce a finished surface free

from drops, ridges, waves, laps, and brush marks. Suitable air filters and

traps shall be installed on blasting and spraying to equipment to remove

moisture and oil from the compressed air.

6.2. Whenever possible, surfaces which are inaccessible after erection

shall be treated, primed and painted prior to erection.

6.3. Paint shall be applied only when the air temperature is above 40OF,

less than 100OF, and the relative humidity is less than 85%. Priming shall be

discontinued whenever the temperature is expect to drop to 32OF before the

primer has dried. Paint shall not be applied to a surface that is at a

temperature which will cause blistering porosity, or otherwise will be

detrimental to the life of the paint. Moisture cure paints and primers may be

applied per manufacturers instructions.

6.4. Paint or coating materials shall not be applied in damp or foggy

weather, when it is raining or snowing or under any conditions that will result

in condensation on the surface to be painted.

6.5. Finish coats shall not be applied to surfaces on which the prime is

scratched until such damaged area has been cleaned and primed.

6.6. Each coat of paint shall be in a proper state of cure or dryness before

the application of the succeeding cost.

6.7. Whenever bare metal is exposed during cleaning of previously painted

steel, a prime coast shall be applied to the exposed area before proceeding

with the finish coat.

6.8. The paint manufacturers recommendations for mixing, thinning

handling, and applying their products are incorporated into and made a part of

this specification.

Revised 1/10/03

Coos County Bid Documents App D Painting Specifications.doc

Page D-4

Coos County Oregon

Bid Documents for the Natural Gas Pipeline Project

6.9. The minimum dry film thickness in mils for each primer and paint coat

shall be as specified in Section 9.0 of this Appendix. Dry film thickness will be

measured with a calibrated thickness gauge. For steel surfaces, the

minimum dry film thickness for the paint system, comprising the primer finish

coats, shall be 5.0 mils, unless otherwise specified. All measurements taken

shall be according to SSPC-PA 2TBT.

6.10. To secure a satisfactory thickness of primer, rivet heads, bolt heads,

nuts, all edges, corners and crevices shall be striped with priming paint by

brush or a single pass spray before the surfaces receive the prime coat of

paint. Such striping shall extend one inch from all edges.

7.0.

REPAIR WORK

7.1. Pinholes, skips, and areas with less than specified dry film thickness

shall be touched up or recoated.

7.2. Unacceptable runs, sags, dry over-spray, orange peel, and embedded

dust shall be removed by sanding or blasting. The surface shall be blown

with compressed air and vacuumed or wiped clean prior to being touched up

or recoated.

7.3. Coatings that are damaged, blistered, cracked, peeling, or delaminated

shall be removed to the bare substrate and the surface prepared per

specification. Areas less than thirty (30) square inches may be prepared by

power tools. Dust and loose particles shall be removed by compressed air

and vacuumed or wiped clean prior to being recoated.

7.4. The paint subcontractor in the field shall be responsible for touch-up

and repair of all shop primed items. All surfaces shall be properly cleaned

and primed before the finished coat is applied.

8.0.

INSPECTION AND TESTING

8.1. The dry film thickness shall be verified by measuring with a magnetic

gauge in accordance with SSPC-PA2.

8.2.

Each cost shall be examined for the following:

8.2.1. Missed or skipped areas

8.2.2. Roughness or loss of gloss caused by embedded dust, dry overspray, orange peel, or other similar conditions

8.2.3. Film defects such as pinholes, peeling, blistering, or de-lamination

Revised 1/10/03

Coos County Bid Documents App D Painting Specifications.doc

Page D-5

Coos County Oregon

Bid Documents for the Natural Gas Pipeline Project

8.2.4. Runs, sags and over 150 percent of maximum or under 90 percent

of the minimum specified dry film thickness.

8.2.5. Softness or tackiness

8.3. Each coat shall be examined before recoating to verify that the surface

is clean, dry and free of contaminants.

8.4. The color of the finish coat shall be verified as correct by comparison

with an accepted color sample.

8.5.

9.0

The finished coating shall be the specified total dry film thickness and

shall be uniform in appearance and free of shadows.

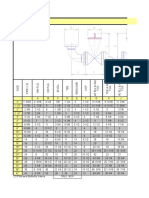

Paint System

For bare surfaces, including pipe, valves, fittings, structural steel:

Prime:

Intermediate

Coat:

Single component, moisture cure zinc rich urethane

Wasser MC-Zinc

Surface prep: Commercial blast, SSPC SP-6

2.5-3.5 mils DFT

Single component, moisture cure urethane

All colors except white:

Wasser MC-Ferrox B

3.0-5.0 mils DFT

White:

Top Coat:

9.1

Wasser MC-CR

3.0-5.0 mils DFT

Single component, moisture cure aliphatic urethane

Wasser MC-Luster

2.0-3.0 mils DFT

Paint System

All surfaces:

Wasser Terra Green color.

Revised 1/10/03

Coos County Bid Documents App D Painting Specifications.doc

Page D-6

You might also like

- Coating Application & Inspection Procedure-Rev 0Document27 pagesCoating Application & Inspection Procedure-Rev 0tinphat100% (1)

- Specification For Painting-Piping & EquipmentDocument21 pagesSpecification For Painting-Piping & EquipmentAlvin Smith100% (2)

- Cisper Paint ProcedureDocument6 pagesCisper Paint ProcedureMike PrescottNo ratings yet

- Method Statement For APCS-113A (1) 22-6-2011Document7 pagesMethod Statement For APCS-113A (1) 22-6-2011sharif339No ratings yet

- Procedure For Surface PreparationDocument10 pagesProcedure For Surface PreparationEric MagnayeNo ratings yet

- Internal PaintingDocument9 pagesInternal Paintingtzimtiger50% (2)

- Painting Scheme StructureDocument10 pagesPainting Scheme StructureVeerapandianNo ratings yet

- Ampp Nace Code Estructural CoatingDocument12 pagesAmpp Nace Code Estructural CoatingJavier Enrique Diaz ChacinNo ratings yet

- Painting Process Equipment and PipingDocument17 pagesPainting Process Equipment and PipingJoseph Darwin ZionNo ratings yet

- Iso 9223-Corrosiovity of Alloys PDFDocument5 pagesIso 9223-Corrosiovity of Alloys PDFabhibmaneNo ratings yet

- Ves 5140 R13Document23 pagesVes 5140 R13Dwiadi CahyabudiNo ratings yet

- 022 Painting Spec (A)Document8 pages022 Painting Spec (A)sravan_kits929No ratings yet

- Industrial Coating ApplicationDocument22 pagesIndustrial Coating ApplicationaamirsaddiqNo ratings yet

- 3 Coat SpecsDocument4 pages3 Coat SpecsSarathiraja SekarNo ratings yet

- Painting ProcedureDocument8 pagesPainting ProcedureSunday Paul50% (2)

- Con-011 Instruction For Painting Work Rev.0Document11 pagesCon-011 Instruction For Painting Work Rev.0monchai_626No ratings yet

- InternalPainting PDFDocument9 pagesInternalPainting PDFPhilip LonerganNo ratings yet

- REAL Painting SpecificationDocument46 pagesREAL Painting SpecificationVivek Rathod100% (2)

- Painting SpecDocument10 pagesPainting SpecTroy HooperNo ratings yet

- GAIL Tender For Specification For Painting of PipelinesDocument13 pagesGAIL Tender For Specification For Painting of PipelinesKumararaja Konikki100% (1)

- Method Statement For APCS-113A - MS-FBE-002 - 9 JULY 2011Document9 pagesMethod Statement For APCS-113A - MS-FBE-002 - 9 JULY 2011sharif339No ratings yet

- Blasting and Painting Procedure - 1Document6 pagesBlasting and Painting Procedure - 1Azrul Rais64% (11)

- SP-93-1 Paint and Coatings PDFDocument12 pagesSP-93-1 Paint and Coatings PDFMahmoud Al HomranNo ratings yet

- BCS 060 PaintingDocument6 pagesBCS 060 Paintingjames_chan2178No ratings yet

- Petrox, S.A. Refineria de Petroleo: 668-83A1 Page: A of C Rev.: 0 Date: 06-5-2002Document28 pagesPetrox, S.A. Refineria de Petroleo: 668-83A1 Page: A of C Rev.: 0 Date: 06-5-2002Victor Hugo Bustos Beltran0% (1)

- Procedure of PaintingDocument10 pagesProcedure of PaintingMahmoud AymanNo ratings yet

- MaklvDocument12 pagesMaklvKelz KelzNo ratings yet

- GTL-81-02 Rev 01 Coating and Wrapping of Buried PipingDocument17 pagesGTL-81-02 Rev 01 Coating and Wrapping of Buried Pipingjasminnee100% (2)

- Work Method ProceduresDocument37 pagesWork Method ProceduresAnonymous K0fqIO100% (2)

- BlastpaintDocument12 pagesBlastpaintdeje1726No ratings yet

- 6.PEB Painting Procedure (P0371) Rev.01Document22 pages6.PEB Painting Procedure (P0371) Rev.01MOHAMEDNo ratings yet

- Procedure For Surface Preparation-Painting - For Storage TankDocument8 pagesProcedure For Surface Preparation-Painting - For Storage Tankcristinelb50% (2)

- Painting Specfication ASSENT Doc No: PR-2019-05-007: 076551C-0000R-MR 1 8 0 0 1 0 1Document23 pagesPainting Specfication ASSENT Doc No: PR-2019-05-007: 076551C-0000R-MR 1 8 0 0 1 0 1j fNo ratings yet

- Blasting and Painting Procedure 1Document6 pagesBlasting and Painting Procedure 1vishwas salunkheNo ratings yet

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- Sched v7Document16 pagesSched v7Wael HannonNo ratings yet

- Blasting Coating ProcedureDocument61 pagesBlasting Coating ProcedureZohair Aftab100% (1)

- Method Statement For Surface Preparation Prtective CoatingDocument10 pagesMethod Statement For Surface Preparation Prtective CoatingJaved MANo ratings yet

- External Coatings LCLDocument10 pagesExternal Coatings LCLyusuf.yuzuakNo ratings yet

- 1.0 Description: Specifications For Coating Structural SteelDocument11 pages1.0 Description: Specifications For Coating Structural SteelCrni LabudNo ratings yet

- RA1158-RHDHV-EG-ZZ-SC-S-9001-A1-C06 - Dock Gates Specification-Pg27-28Document2 pagesRA1158-RHDHV-EG-ZZ-SC-S-9001-A1-C06 - Dock Gates Specification-Pg27-28AnasNo ratings yet

- WD946-EZ300-00009 Procedure For Painting Rev 0Document21 pagesWD946-EZ300-00009 Procedure For Painting Rev 0Manuel BurdilesNo ratings yet

- Paint Inspection ServicesDocument27 pagesPaint Inspection ServicesJAVID TAJHIZ MAHAN100% (1)

- CGD PaintingDocument11 pagesCGD PaintingDevang PatelNo ratings yet

- 09 Samss 069Document10 pages09 Samss 069Selvakpm06No ratings yet

- Method Statement For APCS-113A For Alloy Steel - Otc - Fbe-002Document7 pagesMethod Statement For APCS-113A For Alloy Steel - Otc - Fbe-002sharif339100% (2)

- Surface Preparation and Painting Procedure Rev.01 PDFDocument23 pagesSurface Preparation and Painting Procedure Rev.01 PDFSaid Alauddeen Faisz100% (1)

- 2 75 Eng FRDocument21 pages2 75 Eng FRShirley HurtubiseNo ratings yet

- Paint Inspection Services - Specifications RXDocument28 pagesPaint Inspection Services - Specifications RXTony NellickenNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- Painting SpecificationDocument19 pagesPainting Specificationamirthraj74No ratings yet

- Painting ProcedureDocument10 pagesPainting ProcedureLiyakathalikhan Shahjahan50% (2)

- Painting Specification PDFDocument17 pagesPainting Specification PDFGaurav TripathiNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- A105 - 02 PDFDocument5 pagesA105 - 02 PDFJignesh PandyaNo ratings yet

- L&T Valves - PpsDocument1 pageL&T Valves - PpsJignesh PandyaNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Sampleezdi2083% (23)

- L&T Valves - PpsDocument1 pageL&T Valves - PpsJignesh PandyaNo ratings yet

- Piping Valve Flange DimensionsDocument252 pagesPiping Valve Flange DimensionschadNo ratings yet

- Duplex SSDocument7 pagesDuplex SSJignesh PandyaNo ratings yet

- RDocument161 pagesRJignesh PandyaNo ratings yet

- Butterfly ValvesDocument17 pagesButterfly ValvesJignesh PandyaNo ratings yet

- Inspection of Double Tube Sheet Exch - Presentation1Document37 pagesInspection of Double Tube Sheet Exch - Presentation1Asad Bin Ala QatariNo ratings yet

- M-630 Material Data Sheets For PipingDocument85 pagesM-630 Material Data Sheets For Pipingsun2meltNo ratings yet

- Licensed by Information Handling ServicesDocument14 pagesLicensed by Information Handling ServicesJignesh PandyaNo ratings yet

- TGN-PE-02 Temper Bead WeldingDocument9 pagesTGN-PE-02 Temper Bead WeldingNatrajiNo ratings yet

- M-CR-621 1st 1994 Common Requirements - GRP Piping MaterialsDocument8 pagesM-CR-621 1st 1994 Common Requirements - GRP Piping Materialsks2000n1No ratings yet

- Trunnion Mounted Ball ValveDocument20 pagesTrunnion Mounted Ball ValveJignesh PandyaNo ratings yet

- API2000 Tank Venting CalcsDocument5 pagesAPI2000 Tank Venting CalcsfajaraminwahyullahNo ratings yet

- M-CR-621 1st 1994 Common Requirements - GRP Piping MaterialsDocument8 pagesM-CR-621 1st 1994 Common Requirements - GRP Piping Materialsks2000n1No ratings yet

- List of Pharma Companies With Email IDDocument2 pagesList of Pharma Companies With Email IDPandya Jatin66% (88)

- Heat Exchanger - PPT (Recovered)Document53 pagesHeat Exchanger - PPT (Recovered)Jignesh PandyaNo ratings yet

- Norsok M001 MaterialsDocument31 pagesNorsok M001 MaterialsbreeeeezzzzzeNo ratings yet

- Inspection of Double Tube Sheet Exch - Presentation1Document37 pagesInspection of Double Tube Sheet Exch - Presentation1Asad Bin Ala QatariNo ratings yet

- HE MaterialDocument3 pagesHE MaterialJignesh PandyaNo ratings yet

- Piping Valve Flange DimensionsDocument252 pagesPiping Valve Flange DimensionschadNo ratings yet

- Std. Material CompositionDocument2 pagesStd. Material CompositionJignesh PandyaNo ratings yet

- Heat ExchangerDocument51 pagesHeat ExchangerJignesh PandyaNo ratings yet

- 2 - Niro Standard 1.61Document6 pages2 - Niro Standard 1.61Jignesh PandyaNo ratings yet

- App D Painting SpecificationsDocument6 pagesApp D Painting SpecificationsJignesh PandyaNo ratings yet

- Heat ExchangerDocument51 pagesHeat ExchangerJignesh PandyaNo ratings yet

- GBSP 22Document7 pagesGBSP 22Jignesh PandyaNo ratings yet

- Thu Jun 07 07:52:00 2001Document40 pagesThu Jun 07 07:52:00 2001Jignesh PandyaNo ratings yet

- App D Painting SpecificationsDocument6 pagesApp D Painting SpecificationsJignesh PandyaNo ratings yet

- Dawn of The Duke PDFDocument24 pagesDawn of The Duke PDFMichael MerlinNo ratings yet

- The Story of The Stinson WreckDocument15 pagesThe Story of The Stinson WrecksquatterNo ratings yet

- Reading ComprehensionDocument4 pagesReading Comprehensionhani100% (1)

- Test 4 - Unit 4 (III)Document1 pageTest 4 - Unit 4 (III)dechillbroNo ratings yet

- 11 Qty Tech Updated PDFDocument7 pages11 Qty Tech Updated PDFWilsonNo ratings yet

- Crude Oil Gathering SystemDocument31 pagesCrude Oil Gathering SystemMohanad HussienNo ratings yet

- I, 1010 - Water - Water - Everywhere-1-6Document6 pagesI, 1010 - Water - Water - Everywhere-1-6Hamza MesrarNo ratings yet

- DeLand Frost GuardDocument7 pagesDeLand Frost GuardAlexandru IsacNo ratings yet

- SoB29 Fields of The DeadDocument29 pagesSoB29 Fields of The DeadBruce WilliamsNo ratings yet

- Towler2010 PDFDocument10 pagesTowler2010 PDFNibaldo BernardoNo ratings yet

- Chapter IDocument22 pagesChapter IRom Jason GacusanaNo ratings yet

- Science 7 Q4 W3Document9 pagesScience 7 Q4 W3Khryzha Mikalyn GaligaNo ratings yet

- English Grammar ExerciseDocument2 pagesEnglish Grammar ExerciseCristian Rodrigo Flores MaldonadoNo ratings yet

- Section 02 - Heat TransferDocument39 pagesSection 02 - Heat TransferaminNo ratings yet

- Memmert - UM SM ULM SLM - Manual PDFDocument20 pagesMemmert - UM SM ULM SLM - Manual PDFJuan Carlos Terrones NuñezNo ratings yet

- Motorcycle DiariesDocument9 pagesMotorcycle DiariesGelo De Guzman100% (1)

- PDFDocument140 pagesPDFRamsha TjwNo ratings yet

- The Little MatchDocument2 pagesThe Little MatchReza Dwi FajarNo ratings yet

- Onuru Air Part A ManualDocument473 pagesOnuru Air Part A ManualflorentNo ratings yet

- TR 102 Adamson 1981 Southern African Storm Rainfall NodataDocument109 pagesTR 102 Adamson 1981 Southern African Storm Rainfall NodataAlan HughesNo ratings yet

- Effective Temp ChartDocument12 pagesEffective Temp ChartRonald GeorgeNo ratings yet

- Reading Comprehension ITP 1Document38 pagesReading Comprehension ITP 1Reini KurniawatiNo ratings yet

- Prepositions WorksheetDocument17 pagesPrepositions WorksheetSteve MahashabdeNo ratings yet

- 4.13.10,11 Selection of Refractories PDFDocument5 pages4.13.10,11 Selection of Refractories PDFAbdul SabirNo ratings yet

- Manual Aire AcondicionadoDocument22 pagesManual Aire AcondicionadoMartin CastroNo ratings yet

- Infographic: AvalanchesDocument1 pageInfographic: AvalanchesedsunonlineNo ratings yet

- Manufacturing and Production ProcessDocument13 pagesManufacturing and Production ProcessVarun MudirajNo ratings yet

- Types of BiomeDocument8 pagesTypes of Biomelizzie_mcgNo ratings yet

- Toefl 2Document12 pagesToefl 2YzifarNo ratings yet