Professional Documents

Culture Documents

FHWA Design For Soil-Nail Walls - SLD Method

Uploaded by

pkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FHWA Design For Soil-Nail Walls - SLD Method

Uploaded by

pkCopyright:

Available Formats

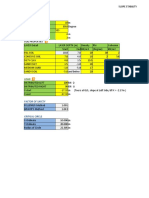

252472886.xls.

ms_office

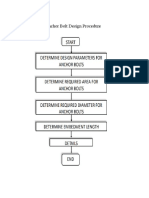

FHWA Design and Analysis of Soil-Nail Walls

Abdulrahman Alhabshi

Texas Tech University

This spreadsheet was developed based on the FHWA Method presented in Publication No. FHWA A-SA-96-069R

Please use this spreadsheet along with Charts provided in the above report

Prepared by:

hybridwall

Title

Example from FHWA-RD-89-193

Date

January 3,2006

Units

EN

Soil Parameters

Soil Type

Ultimate Bond Stress (pullout), Qu

Select Qu

g

fu

Medium dense sand and silty sand/sand silt

7.0 - 11.0

psi

21.7

psi

=

4090

120

pcf

0

36

Cu

180

psf

Back Slope, b

Broken Slope

0

No

lbs/ft

10

for DGC = 5

in

10

Wall Parameters

H

Face Batter, h

SV

40

0

5

SH

ft

15

5

8

No

Soil Nail Inclination, a

Drill Hole Diameter, DGC

Bar #

Surcharge Load

ft

0

ft

in

D [in]

1

A [in2]

0.79

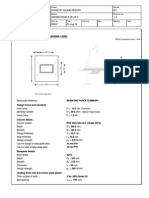

Step 1: Set Up Critical Design Cross-Section

1- Simplified design-charts for preliminary design

Load Combination (AASHTO)

Ff

FC

Group I

1.35

1.35

fD = tan-1(tanfu/Ff)

28.3

CD = CU/(FC gH)

0.028

2- Determine the required nominla nail strength, TNN

TD (check Figs. 4.27-4.34) pg176-183

TNN = TD [gHSVSH) / aNN

0.24

52364

lbs

60

ksi

0.87

8

in2

tanfD

CD

0.54

0.03

D [in]

1

A [in2]

0.79

3- Select Bar #

Grade (FY)

Area required (AB) = TNN/FY

Bar #

1/5

252472886.xls.ms_office

4- Compute the dimensionless nail pullout resistance, QD

QD = aQQU / (gSVSH)

0.682

5 - Determine nail length, L

TD / QD

L/H (check Figs. 4.27-4.34) pg176-183

L

tanfD

0.54

0.35

0.75

30.0

CD

0.03

Step 2: Compute the Allowable Nail Head Loads

Wall Type

Shortcrete Facing Thickness, hc

fc '

Reinforcement

Vertical Bearing bars

Bar No.

Spacing

Horizontal Waler bars

Bar No.

Spacing

Bearing Plate Dimension [W x L]

Bearing Plate Thickness [t]

Stud Diameter

Temporary

4

4

6x6 - W2.9xW2.9

Yes

3

in

ksi

Yes

3

8

1

7/8 x 5 3/16

22

A [in2/ft]

0.058

Wt. [lbs/ft2]

2.05

A [in2]

0.22

2x

3

300

2x

3

300

where; W = L

in

in

D [in]

0.375

A [in2]

0.22

1- Determine the nail head strength

A - Facing Flexure

A-1 Compute negative and positive nominal unit moment, m v,neg and mv,pos

mv,neg

0.98

in-kip/in

Asneg

0.510

in2

mv,neg

0.57

in-kip/in

Aspos

0.290

in2

CF

2.0

A-2 Determine the critical nominal nail head strength, T FN

(Table 4.2 pg 104)

TFN

25

kips

B - Facing Punching Shear

D'c

B-1 The nominal shear stress, VN

12

in

VN

38.1

CF (Table 4.2 pg 104)

2.5

Dc

16

B-2 The critical nominal nail head strength, TFN

kips

TFN

kips

44

Ac [in2] AGC [in2]

2.01E+02 1.96E+01

in

C - Headed-Stud Tension

The nominal nail head strength associated with headed-stud, TFN

TFN

91

Shortcrete Facing

Failure Mode

Facing Flexure

Facing Punching

Nominal Strength

TFN

25

44

Allowable Load

TF

17

29

kips

kips

ASTM A 325 Bolt

2/5

252472886.xls.ms_office

Step 3: Minimum Allowable Nail Head Service Load Check

KaC

0.260

tF

15.6

<

17

OK - The estimated nail head service load does not exceed the allowable nail head load

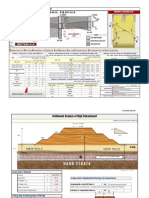

Step 4: Define the Allowable Nail Load Support Diagam

1- Allowable Pullout Resistance, Q

2- Allowable Nail Tendon Load, TN

2.0

26.1

kips/ft

kips

3- Allowable Nail Head Load, TF

16.6

kips

Allowable Nail Load Support Diagram

27kips

3kips/ft

3kips/ft

17kips

Step 5: Select trial spacings and lengths

Use varying nail lengths

QD/(L/H)

R

No. of soil nails (n)

Nail No

1

2

3

4

5

6

7

8

No

0.91

0.31

2.2

1.72

Trial Length

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

ft

1

2

X

37.8

32.8

27.8

22.8

17.8

12.8

7.8

2.8

Rx

1.00

1.00

1.00

1.00

0.92

0.75

0.58

0.41

ft

L Dist.

30.0

30.0

30.0

30.0

30.0

30.0

30.0

30.0

45

40

35

30

25

H

20

15

10

5

0

-5 0

10

20

30

-10

3/5

40

252472886.xls.ms_office

Step 6: Tension ditribution along nails

T2

T3

T1

Q(X3)

Q(X1)

T0

X3

X2

X1

x

L = X1+X2+X3

Nail #

1

2

3

4

5

6

7

8

X (ft)

14.8

16.4

18

18.8

20.8

22

24

26.4

T (kips)

26.1

26.1

26.1

26.1

26.1

26.1

26.1

24.0

Step 7: Check the upper cantilever

d = (2/3) f'

KaC

Sheat Check

Shear force v1 (due to soil above 1st nail)

Nominal one-way unit shear strength, VNS

Allowable one-way unite shear, V = aFVNS

24.0

0.235

62.31

1000.0

670.0

lbs/ft

lbs/ft

lbs/ft

50.022

657.77

lbs-ft/ft

lbs-ft/ft

v1 < V, the desing for shear is adequate

Flexure Check

ms = 1/3 (H/cos(h)) v1

Allowable one-way unit moment, M=aFmv,NEG

ms < M, the desing for flexure is adequate

4/5

T1 (kips)

26

26

26

26

26

26

26

26

T2 (kips)

26

26

26

26

26

26

26

26

T3 (kips)

17

17

17

17

17

17

17

17

X1 =

b=

h=

H=

SV =

a=

X2 =

g=

f=

c=

You might also like

- Thompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsDocument49 pagesThompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsMike Cedersköld100% (5)

- Design of Stone ColumnDocument2 pagesDesign of Stone Columnabmisra183% (6)

- Sheet Pile Wall Design ExampleDocument7 pagesSheet Pile Wall Design ExampleAfreen Shaik100% (9)

- MSE Wall DesignDocument119 pagesMSE Wall Designshafiullah0% (1)

- Pump Foundation DesignDocument18 pagesPump Foundation DesignSourav92% (12)

- Input Parameters: 3 H V U S y v1 T 1Document4 pagesInput Parameters: 3 H V U S y v1 T 1Rakesh7770No ratings yet

- Soil Nailing Design PDFDocument32 pagesSoil Nailing Design PDFteh100% (3)

- Pile Capacity & SettlementDocument7 pagesPile Capacity & SettlementbonnicoNo ratings yet

- STP 777 1982Document426 pagesSTP 777 1982pkNo ratings yet

- Cantilever Sheet Pile WallDocument9 pagesCantilever Sheet Pile Wallmicomak100% (5)

- Anchored Sheet Pile WallDocument8 pagesAnchored Sheet Pile WallGerald MagingaNo ratings yet

- Stone Column DesignDocument3 pagesStone Column Designnidhin100% (1)

- Cantilever Sheet Pile DesignDocument14 pagesCantilever Sheet Pile DesignMaltesh H100% (3)

- Slope Stability + SOIL NAIL V2.1Document24 pagesSlope Stability + SOIL NAIL V2.1shimant100% (4)

- Retaining Wall With AnchorsDocument11 pagesRetaining Wall With Anchorsmailmaverick8167100% (3)

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Document8 pagesContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreNo ratings yet

- Soil Nail Wall Design ReportDocument37 pagesSoil Nail Wall Design Reportkanishka100% (1)

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- Design of Stone Columns HooghlyDocument4 pagesDesign of Stone Columns Hooghlyhemantkle2u100% (2)

- Settlement Calculation: For Square Footing 1) Consolidation Settlement (Se)Document8 pagesSettlement Calculation: For Square Footing 1) Consolidation Settlement (Se)raghuveer11No ratings yet

- Sheet Pile DesignDocument5 pagesSheet Pile DesignnileshbhusariNo ratings yet

- Sheet Pile 1Document13 pagesSheet Pile 1belacewNo ratings yet

- Shore Pile DesignDocument38 pagesShore Pile DesignEngDbt100% (2)

- Micropile Structural Capacity CalculationDocument7 pagesMicropile Structural Capacity CalculationEncik BadrulNo ratings yet

- Retaining WallDocument1 pageRetaining WalljemtanNo ratings yet

- Design of Base PlateDocument166 pagesDesign of Base PlateAnonymous ciKyr0t86% (7)

- Laterally Loaded PileDocument151 pagesLaterally Loaded Pilevpamatya100% (1)

- Reinforced Soil Retaining Wall: A Feasible Eurocode 7 Design Approach Derived From Bs 8006Document78 pagesReinforced Soil Retaining Wall: A Feasible Eurocode 7 Design Approach Derived From Bs 8006ajlaNo ratings yet

- Secant Pile RC Retaining WallDocument6 pagesSecant Pile RC Retaining WallUmesh Chamara100% (2)

- Full Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFDocument42 pagesFull Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFtimothy.mees27497% (39)

- Broms Method-Xls-Lateral Pile Capacity in Cohesive SoilDocument1 pageBroms Method-Xls-Lateral Pile Capacity in Cohesive SoilMUHAMMAD ALI100% (1)

- Shoring Design - Contiguous Pile, Soldier Piles System, Secant Piles SystemDocument53 pagesShoring Design - Contiguous Pile, Soldier Piles System, Secant Piles Systemျမတ္ သူ ေအာင္No ratings yet

- Slope Stability Anderson & MD NoorDocument6 pagesSlope Stability Anderson & MD NoorWan0% (1)

- Mechanically Stabilized Earth (MSE) Walls Design GuidanceDocument100 pagesMechanically Stabilized Earth (MSE) Walls Design GuidanceAndreas GiannakogiorgosNo ratings yet

- Pile Conditions: Input Quantities Value Units CommentDocument18 pagesPile Conditions: Input Quantities Value Units CommentFidel Rodriguez HerrerosNo ratings yet

- Sec 400 (Most Version)Document37 pagesSec 400 (Most Version)abhijit_xpNo ratings yet

- Programming MillDocument81 pagesProgramming MillEddy ZalieNo ratings yet

- Rock Slope StabilityDocument7 pagesRock Slope Stabilitysarvannn100% (1)

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Asaoka Method PDFDocument67 pagesAsaoka Method PDFAdriel Elezar100% (1)

- YhhjjDocument52 pagesYhhjjSam CunananNo ratings yet

- 29.sec.2900 (Pipe Culverts)Document4 pages29.sec.2900 (Pipe Culverts)Rakesh ParaliyaNo ratings yet

- Soil Nailing PDFDocument123 pagesSoil Nailing PDFAnonymous fE2l3Dzl83% (6)

- OENG1068 Consolidation Settlement Calculation SpreadsheetDocument70 pagesOENG1068 Consolidation Settlement Calculation SpreadsheetBishwajit Chowdhury100% (1)

- PILE Analysis - Design 1.4Document99 pagesPILE Analysis - Design 1.4HanafiahHamzahNo ratings yet

- Anchor Calculations 1.0Document4 pagesAnchor Calculations 1.0AhmedKarim67% (3)

- Four Bolt Unstiffened End PlateDocument7 pagesFour Bolt Unstiffened End PlateRnD2013No ratings yet

- Vsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeDocument5 pagesVsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeSri RamprasathNo ratings yet

- FM Testbank-Ch18Document9 pagesFM Testbank-Ch18David LarryNo ratings yet

- Design Methods Forthe Reinforcement of Highway Slopes by Reinforced Soil and Soil Nailing TechniquesDocument108 pagesDesign Methods Forthe Reinforcement of Highway Slopes by Reinforced Soil and Soil Nailing TechniquesNita BogdanNo ratings yet

- Transformational LeadershipDocument75 pagesTransformational LeadershipvincentpalaniNo ratings yet

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- Seismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2Document36 pagesSeismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2m7j7a7No ratings yet

- Chapter S1 (Celestial Timekeeping and Navigation)Document28 pagesChapter S1 (Celestial Timekeeping and Navigation)Марко Д. Станковић0% (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Retaining Wall With PilesDocument7 pagesRetaining Wall With PilesKaosar Alam Rocky100% (3)

- Settlement Analysis Jrob Re Wall Abutment 02 30.10.2018Document5 pagesSettlement Analysis Jrob Re Wall Abutment 02 30.10.2018Chowdhury Priodeep100% (1)

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Braced CutsDocument47 pagesBraced CutsArun Goyal83% (6)

- Preliminary Examination The Contemporary WorldDocument2 pagesPreliminary Examination The Contemporary WorldJane M100% (1)

- Pile Capacity On RockDocument2 pagesPile Capacity On RockSathyanarayanan Dhandapani100% (1)

- Prefabricated Vertical DrainsDocument26 pagesPrefabricated Vertical DrainsMayank Prakash100% (1)

- Learning Module - Joints, Taps and SplicesDocument9 pagesLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- Pile Group AnalysisDocument3 pagesPile Group AnalysisnonameNo ratings yet

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringFrom EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringNo ratings yet

- HK Soil Nail DesignDocument20 pagesHK Soil Nail DesignDaltonWong100% (1)

- Precast Segmental Pile DesignDocument1 pagePrecast Segmental Pile DesigncivixxNo ratings yet

- 10-Retaining Wall and PilesDocument25 pages10-Retaining Wall and PilesAhmed KhalifaNo ratings yet

- Spread/individual/isolated Footings: Course 5Document21 pagesSpread/individual/isolated Footings: Course 5Claudiu MarianNo ratings yet

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 pagesTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaNo ratings yet

- SEPA15015 MFSFF CV 21 CAL 102 - Calculation Report For Tank Foundation - MFS T 241A B - REV ADocument23 pagesSEPA15015 MFSFF CV 21 CAL 102 - Calculation Report For Tank Foundation - MFS T 241A B - REV APruthviraj JuniNo ratings yet

- Method Statement For Soft Soil Treatment (PVD)Document50 pagesMethod Statement For Soft Soil Treatment (PVD)pkNo ratings yet

- India: Wind and Cyclone Hazard MapDocument1 pageIndia: Wind and Cyclone Hazard MapnavinzhereNo ratings yet

- 202 Soil Profile From CPTDocument21 pages202 Soil Profile From CPTSapria AdiNo ratings yet

- Bearing CapacityDocument2 pagesBearing CapacitypkNo ratings yet

- Event Schedule Planner 2015Document3 pagesEvent Schedule Planner 2015Amar MuseljicNo ratings yet

- Is 7916Document8 pagesIs 7916pkNo ratings yet

- 39 Excel 2003 MacrosDocument63 pages39 Excel 2003 Macrosstjon1954No ratings yet

- B 02Document6 pagesB 02pkNo ratings yet

- SEC 2800repair of StructuresDocument20 pagesSEC 2800repair of StructurespkNo ratings yet

- Vba To VB Net XLL Add in With Excel DnaDocument51 pagesVba To VB Net XLL Add in With Excel Dnapk100% (2)

- SEC 3200 Box and Slab CulvertsDocument2 pagesSEC 3200 Box and Slab CulvertspkNo ratings yet

- SEC200 (MOST Version)Document7 pagesSEC200 (MOST Version)pkNo ratings yet

- SEC 3000 Maintenance of RoadDocument8 pagesSEC 3000 Maintenance of RoadpkNo ratings yet

- SEC 900 Quality Control For RoadDocument24 pagesSEC 900 Quality Control For RoadpkNo ratings yet

- SEC 1000 Materials For StructuresDocument15 pagesSEC 1000 Materials For StructurespkNo ratings yet

- Appendices (MOST)Document48 pagesAppendices (MOST)Anuran GayaliNo ratings yet

- Concrete Pavement SpecificationsDocument35 pagesConcrete Pavement Specificationssrinu001No ratings yet

- SEC 800 Traffic Signs, MarkingsDocument28 pagesSEC 800 Traffic Signs, MarkingspkNo ratings yet

- SEC200 (MOST Version)Document7 pagesSEC200 (MOST Version)pkNo ratings yet

- Irc-Contents - Cover PageDocument3 pagesIrc-Contents - Cover PagepkNo ratings yet

- CBR CorrelationsDocument2 pagesCBR CorrelationsSuneel PalukuriNo ratings yet

- The Charles E. Via Jr. Department of Civil and Environmental EngineeringDocument3 pagesThe Charles E. Via Jr. Department of Civil and Environmental EngineeringpkNo ratings yet

- Section 300 - Volume 2 ModificationsDocument20 pagesSection 300 - Volume 2 ModificationspkNo ratings yet

- Sec 300Document49 pagesSec 300abhijit_xpNo ratings yet

- Poulos (Liquefaction Evluation Procedure)Document11 pagesPoulos (Liquefaction Evluation Procedure)pkNo ratings yet

- Marachi (Properties of Rockfill Material)Document11 pagesMarachi (Properties of Rockfill Material)Scott DownsNo ratings yet

- Review and Basic Principles of PreservationDocument43 pagesReview and Basic Principles of PreservationKarl Marlou Bantaculo100% (1)

- Alienation Thesis StatementDocument8 pagesAlienation Thesis Statementafbteepof100% (2)

- Lesson 23 Career PathwaysDocument34 pagesLesson 23 Career PathwaysAlfredo ModestoNo ratings yet

- NZ2016SH (32k) - e - NSC5026D 3.3V +100ppmDocument2 pagesNZ2016SH (32k) - e - NSC5026D 3.3V +100ppmDumarronNo ratings yet

- Spring 12 ECON-E370 IU Exam 1 ReviewDocument27 pagesSpring 12 ECON-E370 IU Exam 1 ReviewTutoringZoneNo ratings yet

- List of Bird Sanctuaries in India (State-Wise)Document6 pagesList of Bird Sanctuaries in India (State-Wise)VISHRUTH.S. GOWDANo ratings yet

- Course Outline Cbmec StratmgtDocument2 pagesCourse Outline Cbmec StratmgtskyieNo ratings yet

- USTH Algorithm RecursionDocument73 pagesUSTH Algorithm Recursionnhng2421No ratings yet

- Limestone Standards PDFDocument2 pagesLimestone Standards PDFJacqueline BerueteNo ratings yet

- Visual Inspection ReportDocument45 pagesVisual Inspection ReportKhoirul AnamNo ratings yet

- Paper 4 Material Management Question BankDocument3 pagesPaper 4 Material Management Question BankDr. Rakshit Solanki100% (2)

- Sinamics g120p Cabinet Catalog d35 en 2018Document246 pagesSinamics g120p Cabinet Catalog d35 en 2018Edgar Lecona MNo ratings yet

- Name of The Business-Rainbow Blooms LLC. Executive SummaryDocument17 pagesName of The Business-Rainbow Blooms LLC. Executive SummaryAhamed AliNo ratings yet

- One and Half SindromeDocument4 pagesOne and Half SindromeYulia DamayantiNo ratings yet

- RADMASTE CAPS Grade 11 Chemistry Learner GuideDocument66 pagesRADMASTE CAPS Grade 11 Chemistry Learner Guideamajobe34No ratings yet

- Southern California International Gateway Final Environmental Impact ReportDocument40 pagesSouthern California International Gateway Final Environmental Impact ReportLong Beach PostNo ratings yet

- U2 KeyDocument2 pagesU2 KeyHằng ĐặngNo ratings yet

- Introduction of ProtozoaDocument31 pagesIntroduction of ProtozoaEINSTEIN2D100% (2)

- Coefficient of Restitution - Center of MassDocument3 pagesCoefficient of Restitution - Center of MassMannyCesNo ratings yet

- Financial Management of Public Sector Unit (PSU) - NotesDocument23 pagesFinancial Management of Public Sector Unit (PSU) - Notesbiz19100% (1)

- Volcano Lesson PlanDocument5 pagesVolcano Lesson Planapi-294963286No ratings yet