Professional Documents

Culture Documents

Soil Reinforcement With Secugrid Geogrids

Uploaded by

oanaariadnaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soil Reinforcement With Secugrid Geogrids

Uploaded by

oanaariadnaCopyright:

Available Formats

Soil reinforcement with

Secugrid geogrids

Case studies

The ideal geosynthetic reinforcement

Installation of

the frost protection layer onto

Secugrid.

Secugrid is a laid geogrid made of extruded monolithic flat

bars with welded junctions for soil reinforcement in earth,

landfill and road construction as well as in hydraulic engineering applications. Secugrid is the ideal geosynthetic reinforcement for

- base courses in conventional road engineering

- temporary construction roads

- base courses or subgrades in railway engineering

- park, industrial and storage areas

- container terminals

- areas prone to subsidence

- dam foundations on soft subsoils

- 30 cm frost protection layer

- steep earth slopes and retaining structures

- geogrid reinforcement

- soil layers on membrane covered slopes

Secugrid reinforcement was placed onto the profiled sub-

- trench covers and beds.

soil and covered with 15 cm of the frost protection layer. The

Secugrid excels by

Secugrid was then folded back at the edges for 50 cm (con-

high strength and low elongation due to extruded ele-

forming with the specification) and covered with the remai-

ments

robustness due to monolithic flat bars

ning 15 cm of the frost protection material.

During removal of the former road structure, the tires of the

interlocking due to junction stiffness

excavator caused heavy rutting (to a depth of 10 cm) in the

a broad product range offering the versatility of biaxial and

weak sub-soil present on site. These deformations were very

uniaxial geogrids (Q and R products)

low due the good dry weather conditions. Secugrid geogrids

highly competitive prices

60/60 Q6 were cut to the necessary enveloping length and

The following three case studies represent the numerous fields

installed directly on the profiled subsoil. Then the 15 cm thick

of application:

frost protection layer was installed. On this uncompacted

layer there were only imprints and compactions up to max. 2

Significantly

lower rutting on

the uncompacted frost

protection layer

due to the use

of Secugrid.

Improvement of Bearing Capacity

cm in the area of lorry traffic, driving on the 15 cm thick frost

The existing road from Tessin to Wesselstorf (near Rostock in

protection layer. The Secugrid geogrid lying over the edges

North East Germany) had to be rebuilt due to subsidence.

was turned back on both sides 50 cm onto the frost protec-

Since the subsoil consisted of peat and sand, the required

tion layer and covered with additional 15 cm of the same

bearing capacity was not achieved in load plate bearing tests.

material. After installation of the frost protection layer an EV2

Therefore, an EV2 value of the formation of approx. 5 MN/m

value of 80 to 90 MN/m could be achieved by installing

was assumed as a basis for the dimensioning. The owner de-

Secugrid 60/60 Q6. After filling and compaction of the base

cided upon a road structure with a total thickness of 60 cm

course of crushed stone, the required EV2 values of 120 MN/m

reinforced with geogrids (from top to bottom):

were significantly exceeded.

- 10 cm asphalt overlay

- 20 cm base course with crushed stone

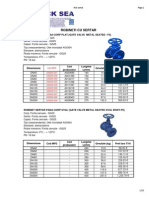

Protection against base failure

The Road Construction Agency Aurich in North West Germany

is currently extending the existing city highway by adding two

lanes to the Federal Motorway A 31. Following completion of

the first section in 1999, work begun on the next phase of

works, however, the route of this section of motorway leads

over soft soil layers which have a low bearing capacity up to

7 m below the road. It is especially interesting that this new

route leads over ground which has been previously compacted

(former city highway) as well as uncompacted ground. The

Federal Agency for Road Engineering (bast) was involved in

assessing the subsoil conditions and earth construction measures for the West bypass motorway Emden (A1). The bast

thoroughly tested and examined the feasibility of three possibilities of extension to overcome the soft soil conditions:

1. construction of a bridge

Slope reinforcement

2. construction of a heavily reinforced road using geogrids

When a 10 m high noise barrier at the motorway A 12 from

3. a full soil exchange under protection with sheet piling.

Utrecht to The Hague was being designed, stability calculations showed that the requested slope inclinations were too

steep. The stability of the system could not be ensured without additional reinforcement measures. The consulting company Enviro recommended the combination of the following

measures in order to protect the whole system:

- reduction of the cover layer from 2.00 to 1.50 m

- flattening of the slope inclination on the road side from

1(V) : 1.5(W) to 1 : 2

Installation of

the pre-load

dam onto

Secugrid.

- installation of a reinforcement geogrid with a strength of

120 kN/m in the longitudinal direction.

In order to minimise the dangers to the houses which are

directly adjacent to the route, a bridge was first taken into

consideration. After the investigations of the bast which also

included the assessment of the costs, the owner decided upon

a reinforced road construction which showed cost savings of

approximately 5 mio. DM compared to a bridge. Due to the

stability calculations, a geosynthetic with a short-term tensile strength of 400 kN/m was required to prevent base failure.

The Road Construction Agency Aurich and the bast supported

Installation of

Secugrid with a

spreader bar.

the use of Secugrid 400/60 R6 geogrids with a strength of

400 kN/m in longitudinal and 60 kN/m in transverse direction

for in-situ tests. In order to determine the consolidation and

The slope inclination on the side of the houses did not

deformation behaviour, the bast is currently conducting geo-

need to be reduced because later it was to be filled up with

technical measurements.

soil up to 1:5. Due to its manufacturing width of 4.75 m, the

selected geogrid Secugrid 120/40 R6 could be installed

quickly and easily on the previously installed sealing system

consisting of a Bentofix geosynthetic clay liner, Carbofol

geomembrane and Secutex protection nonwoven. In order to

take the forces directed down the slope, the geogrid was

embedded into the filll crest. By using polyester/PET resins

for the production of Secugrid, a low creep factor could be

taken in consideration for the calculation. As a result a shortterm tensile strength for Secugrid of 120 kN/m was accepted. Furthermore, an optimum interlocking with the soil was

Installation of

the elongation

measuring

device.

achieved by the robust monolithic flat bars and the strong

junctions. The first construction section (600 m length) has

In order to gain suitable soil stability, the highway route

over the soft ground requires both compaction and consolidation treatment. This is to be done by placing an overburden

soil layer of approximately 4 m in height on the Secugrid

400/60 R 6 until the required settlement is achieved (vertical

drains are additionally installed to accelerate this process).

The overburden soil will then be lowered to a height of approximately 2.5 m and the road will be constructed on top of this

base. Since mid September 1999 the overburden soil layer has

been placed to a height of 2.00 m. Final results of the elongation, consolidation and deformation behaviour will be possible only after a longer period of loading. The deformation

measuring devices already show the expected activation.

already been finalised, the second section (900 m length) is

planned for spring 2000.

View over the

noise barrier

with the geogrid

Secugrid

120/40 R6 in

the foreground.

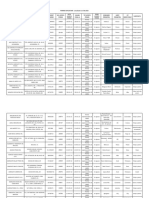

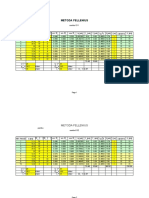

Secugrid Product Range

Secugrid Q-Familiy (biaxial):

Type

Tensile strength

(kN/m)

Resin

Dimensions

Secugrid 30/30 Q1

Secugrid 40/40 Q1

Secugrid 60/60 Q1

30/30

40/40

60/60

Polypropylene/PP

Polypropylene/PP

Polypropylene/PP

4,75 m x100 m

4,75 m x100 m

4,75 m x100 m

Secugrid 80/80 Q1

80/80

Polypropylene/PP

4,75 m x100 m

Combigrid 30/30 Q1 / 151 GRK 3:

Combigrid 60/60 Q1 / 251 GRK 4:

4,75 m x50 m

4,75 m x50 m

Combigrid: Composite of a Secugrid geogrid 30/30 Q1 or 60/60 Q1 connected

with a Secutex separation and filtration nonwoven from the Geotextil-RobustheitsKlasse 3 oder 4.

Secugrid R-Family (uniaxial):

Type

Secugrid

Secugrid

Secugrid

Secugrid

120/

200/

400/

600/

40

40

40

60

R6

R6

R6

R6

Tensile Strength Resin

(kN/m)

Dimensions

120/ 40

200/ 40

400/ 40

600/ 60

4,75

4,75

4,75

4,75

Polyester/PET

Polyester/PET

Polyester/PET

Polyester/PET

m

m

m

m

x100 m

x100 m

x50 m

x50 m

2002 by Naue Fasertechnik GmbH & Co. KG, Lbbecke, Germany All Rights reserved. No. 45 Status 02/02.

The information contained herein is the best to our knowledge, true and accurate. There is no implied or expressed warranty.

Naue Fasertechnik GmbH & Co. KG

Wartturmstrae 1 32312 Lbbecke

Telefon 0 57 41 / 40 08 - 0

Telefax 0 57 41 / 40 08 - 40

e-mail: info@naue.com

Internet: www.naue.com

You might also like

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- SR en 1317-1 Part 1 Road Restraint Systems Terminology and GDocument36 pagesSR en 1317-1 Part 1 Road Restraint Systems Terminology and GDan PodarNo ratings yet

- SR en 1594 - Sisteme Alimentare Gaz Presiuni Mai Mari de 16 BarDocument0 pagesSR en 1594 - Sisteme Alimentare Gaz Presiuni Mai Mari de 16 BarGeorge GhitaNo ratings yet

- Autoperforantes TITAN PDFDocument12 pagesAutoperforantes TITAN PDFAlan Cipra DextreNo ratings yet

- Sibelius - Armonie Ghid Foarte BunDocument2 pagesSibelius - Armonie Ghid Foarte BunbobomirutaNo ratings yet

- Permise Exploatare 14 03 2023Document66 pagesPermise Exploatare 14 03 2023Raul MiclăușNo ratings yet

- Dimensiuni Fitinguri PPDocument6 pagesDimensiuni Fitinguri PPmyrella06No ratings yet

- Romanian Standard STAS 1913/12-88: 1.1 ScopeDocument22 pagesRomanian Standard STAS 1913/12-88: 1.1 Scopealboi_petruNo ratings yet

- Pod x3 User Manual Rev B English PDFDocument122 pagesPod x3 User Manual Rev B English PDFxvs1100No ratings yet

- Afuieri Pod Rau OLT KM 44+500Document17 pagesAfuieri Pod Rau OLT KM 44+500Donna WorkmanNo ratings yet

- Plan Control Calitate PCCVIDocument24 pagesPlan Control Calitate PCCVIlimpsize0074161No ratings yet

- Profile Laminate Otel-Beton Prop Mecanice Compozitie ChimicaDocument12 pagesProfile Laminate Otel-Beton Prop Mecanice Compozitie ChimicaVantu-Voiculescu CristiNo ratings yet

- Stas 6400-84-EngDocument12 pagesStas 6400-84-EnglucicotoiNo ratings yet

- Caiet de Sarcini Partea 1Document110 pagesCaiet de Sarcini Partea 1Florin Man100% (1)

- Conjugarea Verbelor in Limba Engleza La Toate Timpurile - Trecut, Prezent, Viitor - Online PDFDocument3 pagesConjugarea Verbelor in Limba Engleza La Toate Timpurile - Trecut, Prezent, Viitor - Online PDFDianna Mizin100% (1)

- Janobike English Instruction ManualDocument10 pagesJanobike English Instruction ManualKakumkum BlancoNo ratings yet

- About The Network ArchDocument36 pagesAbout The Network ArchSergio Adolfo ParedesNo ratings yet

- Catalogue EKOVAL VALVEDocument4 pagesCatalogue EKOVAL VALVERoxy AksesoriesNo ratings yet

- Chivalry II Sicilian Vespers 3.3 - Faction ListDocument5 pagesChivalry II Sicilian Vespers 3.3 - Faction ListAnonymous 6nJiT3XNo ratings yet

- Indicatoare Norme Deviz S Instalatii Sanitare Editie 1981Document308 pagesIndicatoare Norme Deviz S Instalatii Sanitare Editie 1981LegumeOrganiceNo ratings yet

- Extras ArmareDocument7 pagesExtras ArmareDaniel LazărNo ratings yet

- Technical Manual: VRF Standard Ambient SystemDocument268 pagesTechnical Manual: VRF Standard Ambient SystemJose CuevasNo ratings yet

- ARD Brochure-BricsCAD - RO Site PDFDocument2 pagesARD Brochure-BricsCAD - RO Site PDFcristina.serbanNo ratings yet

- EXEMPLU FelleniusDocument3 pagesEXEMPLU Felleniusrelu59No ratings yet

- Faza / Phase: PTH: Armare Pilot Pile ReinforcementDocument1 pageFaza / Phase: PTH: Armare Pilot Pile ReinforcementBogdan Constantin-BabiiNo ratings yet

- # Catalog Sistem Usi Culisante Sticla Classic 80-LDocument10 pages# Catalog Sistem Usi Culisante Sticla Classic 80-LLeon ConstantinNo ratings yet

- 4 Profile Tip Traian-27Document1 page4 Profile Tip Traian-27Burlacu Marian AlinNo ratings yet

- Technical Memoir: I. General DataDocument6 pagesTechnical Memoir: I. General DataSuciu Bogdan AlexandruNo ratings yet

- Glosar Termeni Drumuri Ro-EnDocument6 pagesGlosar Termeni Drumuri Ro-Enelsie_oneNo ratings yet

- Hora Lui Ion CaraiDocument1 pageHora Lui Ion CaraicucersNo ratings yet

- Profil IPE - H Metal - Www.h-MetalDocument1 pageProfil IPE - H Metal - Www.h-MetalGrigoreOzonNo ratings yet

- Dicţionar de Petrol Englez - RomânDocument236 pagesDicţionar de Petrol Englez - RomânGeorge BlumNo ratings yet

- Armaturi Industriale FontaDocument15 pagesArmaturi Industriale FontaCarmen DanaNo ratings yet

- CD31 2002 PDFDocument26 pagesCD31 2002 PDFbogdan constantinescu100% (1)

- Arcelor - Catalog Cu Palplanse Metalice - 1 PDFDocument80 pagesArcelor - Catalog Cu Palplanse Metalice - 1 PDFVG_victo100% (1)

- ANTIEFRACTIEDocument11 pagesANTIEFRACTIEAdrian FilipNo ratings yet

- Alfa - 159 - Service ScheduleDocument3 pagesAlfa - 159 - Service ScheduleDanut - Florian TiparuNo ratings yet

- Plan Armare Radier Culee - 297x1200Document1 pagePlan Armare Radier Culee - 297x1200Mihai GheorghiuNo ratings yet

- 12-02-15 Z250 Users GuideDocument63 pages12-02-15 Z250 Users GuideTin Win HtutNo ratings yet

- Fisa Tehnica de Securitate ADEZIV EDR-finalDocument1 pageFisa Tehnica de Securitate ADEZIV EDR-finalSilviuNo ratings yet

- Limba - Harta A Organelor Interne!Document5 pagesLimba - Harta A Organelor Interne!xtixNo ratings yet

- m3 - NAUE Steel PDocument4 pagesm3 - NAUE Steel PoanaariadnaNo ratings yet

- Copia Di CH-Albania - TR - Rraeshen-Kalimash Highway Paramesh Structure 2009Document3 pagesCopia Di CH-Albania - TR - Rraeshen-Kalimash Highway Paramesh Structure 2009Snopi DeGrauNo ratings yet

- m3 - Naue WrapDocument4 pagesm3 - Naue WrapoanaariadnaNo ratings yet

- m3 - NAUE GabionDocument4 pagesm3 - NAUE GabionoanaariadnaNo ratings yet

- Geogrid Reinforced Soil Slope With Tenax RivelDocument16 pagesGeogrid Reinforced Soil Slope With Tenax RivelKhumairaNisaNo ratings yet

- Rs Wall Design For Asansol (Allied Infra) 07.03.2024Document161 pagesRs Wall Design For Asansol (Allied Infra) 07.03.2024Soumodip SahaNo ratings yet

- GEOGRIDS Final ReportDocument58 pagesGEOGRIDS Final ReportJovan BucolNo ratings yet

- Dreno Tex PDFDocument10 pagesDreno Tex PDFvranceanu.ovidiu-1No ratings yet

- Bentofix Case StudiesDocument6 pagesBentofix Case StudiesDhananjay ShahNo ratings yet

- Geo Grids and Geo CompositesDocument25 pagesGeo Grids and Geo CompositesnehaprajapatiNo ratings yet

- Mixed RSS For The Rreshen-Kalimash HighwayDocument3 pagesMixed RSS For The Rreshen-Kalimash HighwaybrowncasNo ratings yet

- Method Statement For Installation of Soil Nails SK Kauluan, Ranau .Document9 pagesMethod Statement For Installation of Soil Nails SK Kauluan, Ranau .Asdia Aseffah FathiyaNo ratings yet

- Geosynthetics India 2008 - J Thomas P TripthaiDocument5 pagesGeosynthetics India 2008 - J Thomas P TripthaiJimmy ThomasNo ratings yet

- GME 2009 - Jimmy Thomas - PaperDocument5 pagesGME 2009 - Jimmy Thomas - PaperJimmy ThomasNo ratings yet

- Mapegrid G 220Document2 pagesMapegrid G 220draganugNo ratings yet

- SecutexDocument4 pagesSecutexam23iNo ratings yet

- Profi FOOD - CTP Bucharest ParkDocument26 pagesProfi FOOD - CTP Bucharest ParkGaftoi TicaNo ratings yet

- Bentofix GCLDocument4 pagesBentofix GCLmeridian360No ratings yet

- Geosynthetics in Roadways and PavementsDocument18 pagesGeosynthetics in Roadways and PavementsVijay KumarNo ratings yet

- Secugrid - Geogrid IntroductionDocument8 pagesSecugrid - Geogrid IntroductionoanaariadnaNo ratings yet

- m3 - NAUE GabionDocument4 pagesm3 - NAUE GabionoanaariadnaNo ratings yet

- m3 - Naue WrapDocument4 pagesm3 - Naue WrapoanaariadnaNo ratings yet

- m3 - Naue NailDocument4 pagesm3 - Naue NailoanaariadnaNo ratings yet

- m3 - NAUE Steel PDocument4 pagesm3 - NAUE Steel PoanaariadnaNo ratings yet

- Cost Saving With Combigrid and SecugridDocument2 pagesCost Saving With Combigrid and SecugridoanaariadnaNo ratings yet

- Secutex - Geotextile IntroductionDocument4 pagesSecutex - Geotextile IntroductionoanaariadnaNo ratings yet

- UV-resistance of GeotextilesDocument1 pageUV-resistance of GeotextilesoanaariadnaNo ratings yet

- Geotechnics With Geosynthetics NewDocument24 pagesGeotechnics With Geosynthetics NewoanaariadnaNo ratings yet

- Artificial Intelligence in ProsthodonticsDocument31 pagesArtificial Intelligence in Prosthodonticsanantha narayanan100% (1)

- LUN Provisioning FormDocument4 pagesLUN Provisioning FormluckysrvstvNo ratings yet

- Fire Hose System Reports: Prepared byDocument13 pagesFire Hose System Reports: Prepared byaya maapNo ratings yet

- Karet Susu Hino 500Document3 pagesKaret Susu Hino 500JokoNo ratings yet

- Superhuman: Human Enhancement and AdvancementDocument3 pagesSuperhuman: Human Enhancement and AdvancementShyamol BoseNo ratings yet

- Acct Statement - XX4534 - 10042024Document39 pagesAcct Statement - XX4534 - 100420247898081578shivamNo ratings yet

- SUSPENSION SYSTEMS - LectureDocument84 pagesSUSPENSION SYSTEMS - LectureEbrahem Ahmed HafezNo ratings yet

- KHOBBY SimHelper ManualDocument3 pagesKHOBBY SimHelper Manualtedi mardetaNo ratings yet

- Analysis of Ring Topology For NoC ArchitectureDocument8 pagesAnalysis of Ring Topology For NoC Architecture赵子杰No ratings yet

- Engine MountDocument1 pageEngine MountHarist ArdyNo ratings yet

- Tis Aut TMRDocument2 pagesTis Aut TMRLas PalmasNo ratings yet

- Eco-Friendly Diapers: Current Market Outlook: PrescouterDocument18 pagesEco-Friendly Diapers: Current Market Outlook: PrescouterramaNo ratings yet

- Age and Gender Detection Using Deep LearningDocument14 pagesAge and Gender Detection Using Deep LearningShilpa KamagariNo ratings yet

- Lab 6 Mux and DecoderDocument6 pagesLab 6 Mux and DecoderIfthakharul Alam ShuvoNo ratings yet

- Review of Related LiteratureDocument3 pagesReview of Related LiteratureJennifer L. LapizNo ratings yet

- B 1900 Peso y BalanceDocument3 pagesB 1900 Peso y BalanceAlbert BenitezNo ratings yet

- 3638 - Simba M7 CDocument4 pages3638 - Simba M7 Cheleloy1234No ratings yet

- Astm A516 1990Document5 pagesAstm A516 1990Indra Gugun GunawanNo ratings yet

- Shiprocket Manifest: S.no Order No Awb No BarcodeDocument2 pagesShiprocket Manifest: S.no Order No Awb No BarcodeSneha BhosaleNo ratings yet

- Guideline EMR DesignDocument3 pagesGuideline EMR Designumie khoirunNo ratings yet

- Part 1 - Design: Water Supply Code of Australia Agency RequirementsDocument12 pagesPart 1 - Design: Water Supply Code of Australia Agency RequirementsTailieukythuat DataNo ratings yet

- 2 Maps TypesDocument22 pages2 Maps TypesSiphumeze TitiNo ratings yet

- Company Profile HRKDocument8 pagesCompany Profile HRKEmir SuryohadiprojoNo ratings yet

- Project Management Skills Unit-5Document26 pagesProject Management Skills Unit-5ಹರಿ ಶಂ100% (1)

- 01 DPC 2802 - DatasheetDocument2 pages01 DPC 2802 - DatasheetJusril HidayatNo ratings yet

- (Winter 2021) : CS231A: Computer Vision, From 3D Reconstruction To Recognition Homework #0 Due: Sunday, January 17Document2 pages(Winter 2021) : CS231A: Computer Vision, From 3D Reconstruction To Recognition Homework #0 Due: Sunday, January 17Nono Nono100% (1)

- Information ProcessingDocument10 pagesInformation ProcessingSusan BarriotNo ratings yet

- 2021 - QP - PCA - End Term ExamDocument1 page2021 - QP - PCA - End Term ExamMuhammed Ashiq SNo ratings yet

- 3 ERP Software RFP Exhibit GDocument575 pages3 ERP Software RFP Exhibit GJacob YeboaNo ratings yet

- BMW-Bus Systems PDFDocument76 pagesBMW-Bus Systems PDFNasiri6594% (17)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- The Perfumed Pages of History: A Textbook on Fragrance CreationFrom EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationRating: 4 out of 5 stars4/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesFrom EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet