Professional Documents

Culture Documents

Latest Development in Fresh Water Generator

Uploaded by

mariner2006Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Latest Development in Fresh Water Generator

Uploaded by

mariner2006Copyright:

Available Formats

AQUA freshwater

generator

AQUA uses vacuum distillation to convert

seawater into high-quality freshwater for

domestic and process utilization on ships,

rigs, as well as in remote onshore locations.

Desalination of seawater is an economically

feasible and reliable solution.

The AQUA freshwater generator is a major advance based on proven Alfa Laval expertise.

AQUAs optimized process cuts seawater needs in half, which minimizes pipework and allows

the installation of smaller seawater pumps. This in turn reduces installation costs, fuel

consumption and CO2 emissions.

AQUA makes use of 3in1 plate technology, which enables desalination in a single plate pack

with one type of titanium plate. Since the plate pack also contains the process vacuum, AQUA

has no outer shell and is smaller than other freshwater generators. The plate pack slides open for

easy access to the interior without an additional service area.

The use of corrosion and erosion-resistant titanium, combined with an optimized process that

inhibits natural scaling, ensures that AQUA needs little maintenance. The system has been fully

tested both on and off shore, and is designed to last the lifetime of the ship.

Application

AQUA uses vacuum distillation to convert seawater into high-quality freshwater for domestic

and process utilization. By providing a constant supply of low-salinity water and continuously

controlling the water quality, it eliminates the need for bunker water.

AQUA is designed for automatic operation in periodically unmanned engine rooms and other

automated operations. Jacket water, steam injection or a Hot Water Loop can all be used as

heating media.

Features and benefits

Half the seawater flow

Compared to other freshwater generators only half the seawater is needed, which means

smaller seawater pumps can be used. Optimized distribution prevents dry spots and

inhibits the natural scaling process.

Lower costs and emissions

The reduction in seawater pumping needs has a corresponding effect on the consumption

of electrical energy. Less fuel has to be burned, which reduces both operating costs and

CO2 emissions.

3-in-1 plate technology

AQUA incorporates the evaporation, separation and condensation processes into a single

type of titanium plate. Desalination is handled within a single plate pack that also

contains the process vacuum. No outer shell is necessary.

Simple, compact installation

With no outer shell and no additional service area, AQUA has a minimal weight and

footprint. Assembly can be handled on site and installation is simplified by the ability to

use smaller seawater pumps and pipes.

Since AQUA is not sensitive to roll and pitch motions of ships, it can also be installed in

any direction on board a ship.

Easy operation and maintenance

AQUA offers start-and-forget operation, which saves time for the crew. Maintenance

intervals are long and the plate pack slides open for easy access to the interior.

Long product lifetime

High-grade materials that resist corrosion and erosion, including titanium for the plates

and other wetted parts, ensure that AQUA will last as long as a ship.

Low-salinity water

The fresh water supplied has a lower content of salt and other dissolved solids than that

supplied by other freshwater generators. It can be used directly by the steam boilers.

Continuous quality control

AQUAs salinometer-equipped control system continuously monitors the quality of the

outgoing fresh water.

Capacity range

The AQUA series covers a capacity range from 3.1 to 60 m3/24 h, depending on the heating

medium and cooling water temperatures. An AQUA freshwater generator can be dimensioned to

suit any jacket water temperature from 55-95C at any cooling water temperature.

Basic equipment

The AQUA freshwater generator consists of a single plate pack containing a flexible number of

titanium process plates. These plates are suspended within a frame, which comprises a carrying

bar, frame plate and pressure plate. Evaporation, separation and condensation all occur within the

same plate pack.

Among the plate pack features are gaskets with rubber flaps that indicate correct plate assembly,

as well as distance pipes that ensure proper plate alignment and correct tightening.

Connected to the plate pack is a combined system for feed water, condenser cooling water and

ejector water. The freshwater system consists of a freshwater pump and a freshwater control

sensor that ensures a stable outgoing flow.

Additional equipment

Combined cooling and ejector water pump with electric motor

Control panel with motor starters and salinometer

Anti-scale chemical dosing unit for feed water

Optional equipment

Steam heating system with direct steam injection

Equipment for steam boosting and hot water loop system

Extended control panel with motor starters and salinometer

Freshwater pH adjustment equipment

Freshwater disinfection equipment

Connections according to DIN, JIS and ANSI standards

Cleaning-in-Place (CIP) unit

For viewing the image of the equipment visit:

http://www.alfalaval.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- MC145031 Encoder Manchester PDFDocument10 pagesMC145031 Encoder Manchester PDFson_gotenNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Structural Testing Facilities at University of AlbertaDocument10 pagesStructural Testing Facilities at University of AlbertaCarlos AcnNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- GR 5 Unit Plan 18-19 Art Warli ArtDocument4 pagesGR 5 Unit Plan 18-19 Art Warli ArtSanjay RautNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Procedural Text Unit Plan OverviewDocument3 pagesProcedural Text Unit Plan Overviewapi-361274406No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Basics of Hacking and Pen TestingDocument30 pagesThe Basics of Hacking and Pen TestingAnonNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Relay Testing Management SoftwareDocument10 pagesRelay Testing Management Softwarechichid2008No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Custom Fabricators, Incorporated Case StudyDocument3 pagesCustom Fabricators, Incorporated Case StudyUmair MajeedNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Print Application FormDocument4 pagesPrint Application Formarjun guptaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- RBI and Maintenance For RCC Structure SeminarDocument4 pagesRBI and Maintenance For RCC Structure SeminarcoxshulerNo ratings yet

- Agricultural Typology Concept and MethodDocument13 pagesAgricultural Typology Concept and MethodAre GalvánNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 8 DaysDocument337 pages8 Daysprakab100% (1)

- 0418 w08 QP 1Document17 pages0418 w08 QP 1pmvarshaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Honey Commission InternationalDocument62 pagesHoney Commission Internationallevsoy672173No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Navier-Stokes EquationsDocument395 pagesNavier-Stokes EquationsBouhadjar Meguenni100% (7)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Develop Your Kuji In Ability in Body and MindDocument7 pagesDevelop Your Kuji In Ability in Body and MindLenjivac100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Proportions PosterDocument1 pageProportions Posterapi-214764900No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Bluehill BrochureDocument24 pagesBluehill BrochureGeorge SingerNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- 4idealism Realism and Pragmatigsm in EducationDocument41 pages4idealism Realism and Pragmatigsm in EducationGaiLe Ann100% (1)

- Activity Design ScoutingDocument10 pagesActivity Design ScoutingHoneyjo Nette100% (9)

- ASTM C 136 Sieve Analysis of Fine and Coarse Aggregates (D)Document5 pagesASTM C 136 Sieve Analysis of Fine and Coarse Aggregates (D)Yasir DharejoNo ratings yet

- McCann MIA CredentialsDocument20 pagesMcCann MIA CredentialsgbertainaNo ratings yet

- Engineering Mathematics I - Class Test December 2015Document6 pagesEngineering Mathematics I - Class Test December 2015Kunal RamnatsingNo ratings yet

- Fiber Optic Communication PDFDocument2 pagesFiber Optic Communication PDFluisperikoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2016 John Timm Final Narrative WeeblyDocument8 pages2016 John Timm Final Narrative Weeblyapi-312582463No ratings yet

- Chapter 3 - Basic Logical Concepts - For Students PDFDocument65 pagesChapter 3 - Basic Logical Concepts - For Students PDFTiên Nguyễn100% (1)

- Es E100091 Pi PDFDocument1 pageEs E100091 Pi PDFCarlos Humbeto Portillo MendezNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentxandercageNo ratings yet

- Plato Aristotle Virtue Theory HappinessDocument17 pagesPlato Aristotle Virtue Theory HappinessMohd SyakirNo ratings yet

- Carnot CycleDocument3 pagesCarnot CyclealexontingNo ratings yet

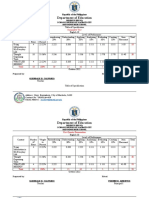

- Table of Specification ENGLISHDocument2 pagesTable of Specification ENGLISHDonn Abel Aguilar IsturisNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)