Professional Documents

Culture Documents

Engine Principles and Fundamentals (Final)

Uploaded by

velumani2003Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Principles and Fundamentals (Final)

Uploaded by

velumani2003Copyright:

Available Formats

Engine Principles and Fundamentals

1. Engine principles and fundamentals

1.1 Introduction

Basic engine nomenclature.

Classification of automobile engines.

Use of engines

1.2 Merits and Demerits of vertical and horizontal engines.

1.3 Four stroke SI and CI engine

Two stroke cycle engine.

Comparison of two stroke and four stroke cycle engine

Reasons for using single cylinder two stroke and four stroke cycle engine.

1.1. Introduction:

Basic Engine nomenclature:

Figure shows the cross section of a single cylinder spark ignition internal combustion engine

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 1 of 14

Engine Principles and Fundamentals

1. The cylinder is supported in position by cylinder block and the top end is covered by

cylinder head.

2. In cylinder a piston travels in reciprocating motion. The space between upper part of

cylinder and top of piston is called combustion chamber. Piston has circumferential

grooves for piston rings, which prevents leakage of charge from combustion chamber.

3. In the cylinder head are 2 valves, Inlet valve for talking charge inside cylinder & Exhaust

valve for discharging the products of combustion.

4. A spark plug at top of cylinder initiates the combustion. The energy of expanding gas is

transmitted by the piston through gudgeon pin to connecting rod.

5. The connecting rod and the crank arm of crankshaft translate the reciprocating motion

of piston in to rotational motion of crankshaft.

6. Crankshaft is supported in bearing attached to the crankcase.

7. Camshaft is driven by crankshaft through timing gear. Lobed cam on camshaft actuates

the pushrod and rocker arms for opening the valves against the force of valve spring.

8. Crankcase is the main body of the engine to which the cylinder block is attached.

Terminologies used in internal combustion Engine:

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 2 of 14

Engine Principles and Fundamentals

1. Cylinder bore (D): The nominal inner diameter of the engine cylinder.

2. Piston area (A): The area of a circle whose diameter is equal to the cylinder bore.

3. Stroke (L): The distance travelled by the piston in moving from T.D.C to B.D.C.

4. Dead centre: The position of the working piston and the moving parts which are

mechanically connected to it at the moment when direction of the

pistons motion is reversed.

a) Bottom Dead centre (BDC): This refers to the position of the crankshaft when

piston is in its lowest position i.e. when piston is nearest to the crankshaft.

b) Top Dead centre (TDC): This refers to the position of the crankshaft when the

piston is in its topmost position i.e. when the piston is farthest from the crankshaft.

5. Displacement volume or Piston swept volume (Vs): The nominal volume

generated by the piston when travelled from 1 dead centre to the other. It is calculated

as product of piston area and stroke.

Swept Volume (Vs) = A x L

(W-12)

6. Clearance Volume (Vc): The volume of the space on the combustion side of the

piston at TDC.

Clearance Volume (Vc) = V - Vs

7. Cylinder Volume(V): The sum of piston swept volume and clearance volume.

Cylinder volume (V) = Vs + Vc.

8. Compression ratio (r): The ratio of cylinder volume divided by the clearance volume.

Compression ratio (r) = V/ Vc

Above given are some important terminologies used in internal combustion engine.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 3 of 14

Engine Principles and Fundamentals

Classification of Automobile engines:

(W11/S12/W12)

The automobile engines are classified on following basis:

Use of Engine (Application):

(S12)

I.C. engines are used in following application.

1.

2.

3.

4.

Road vehicles: 2 wheelers, Passenger cars, Light & heavy commercial vehicles.

Small aircrafts, Helicopters & Railway locomotives.

Marine applications, Ships.

Industrial electric power generation.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 4 of 14

Engine Principles and Fundamentals

Merit n Demerit of vertical and horizontal engine (W-12)

1.2.

Horizontal and vertical engine are identified by the line of stroke. If the line of an engine

piston is vertical, its vertical engine. The line of stroke is horizontal it horizontal engine.

Merits of vertical engine:

Demerits of Vertical engine:

Merits of Horizontal engine:

Demerits of horizontal engine:

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

(W 11/S12)

(S12)

Page 5 of 14

Engine Principles and Fundamentals

1.3.

Four stroke SI and CI engine:

A. Four Stroke Spark ignition engine (SI):

Working:

In this working cycle is completed in 4 strokes of piston or 2 complete revolutions of

crankshaft. In this engine, valves are used and complete compression of the charge takes

place.

1. Suction stroke :

In the stroke inlet valve is opened and exhaust valve is closed. When piston goes

down from TDC to BDC, the Vacuum is created inside the cylinder and charge

(proportionate mixture of air and fuel) is drawn inside the cylinder. This will continue till

piston reaches BDC (i.e.: crank rotates through 180).

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 6 of 14

Engine Principles and Fundamentals

2. Compression stroke:

The Inlet and exhaust valve are closed. The charge is compressed as piston

moves from BDC to TDC. The crank completes 1 complete revolution (i.e.: 360).

3.

Power stroke or Working stroke:

The Inlet and exhaust valves are closed. The charge is ignited by means of

Spark plug and results in high temperature, high pressure gases push the piston from

TDC to BDC. This stroke is known as Power stroke.

The crank completes one and half rotation (i.e.: 540).

4. Exhaust stroke:

The Inlet valve is closed and exhaust valve is opened. The piston begins to move

from BDC to TDC, exhaust valve is open through which the piston forces the burnt gases

into the atmosphere. So working cycle is completed in 2 full rotation of crankshaft (i.e:

720).

Above given is working principle of four stroke SI (PETROL) engine.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 7 of 14

Engine Principles and Fundamentals

B. Four Stroke Compression engine (CI):

The working of four stroke CI engine is similar to 4 stroke S.I engine but it

operates at much higher compression ratio. The compression ratio of SI engine is 6

10 while that of CI engine is 16 20.

In CI engine during suction stroke, only air is sucked instead the cylinder instead

of air-fuel mixture as in SI engine. Due to high compression ratio the temperature

generated in compression stroke is sufficient to self ignite the fuel which is injected into

the combustion chamber at the end of compression stroke.

In CI engine, a fuel pump and injector are provided to inject fuel into

combustion chamber. Carburetor and sparkplug is not necessary in CI engine.

Working:

The working of 4 stroke CI engine is as given below:

1. Suction stroke:

During this stroke inlet valve is open and exhaust valve is closed. Only air is

sucked into cylinder during this stroke.

The piston moves from TDC to BDC and crank shaft rotates through 180.

2. Compression Stroke:

The air inducted in the cylinder is compressed to the clearance volume. Both the

valves are closed during this stroke.

The piston moves from BDC to TDC and crank shaft rotates through 360.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 8 of 14

Engine Principles and Fundamentals

3. Power stroke or Working stroke:

At the end of the compression stroke the fuel (diesel) is injected into the hot

compressed air. The rate of injection is such a that pressure remains constant instead of

change in piston position. Thus this stroke is called constant pressure stroke.

After injection of the fuel is complete the hot gases expand. The piston moves

from TDC to BDC position and crank shaft rotates through 540.

4. Exhaust Stroke:

The inlet valve remains closed and the exhaust valve opens. The piston

move from BDC to TDC position which pushes the burnt gases outside the combustion

chamber. Crankshaft rotates by two complete revolutions through 720.

Above given is working principle of four stroke CI (DIESEL) engine.

Differentiate between SI and CI engine:

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

(S12/W11/W12)

Page 9 of 14

Engine Principles and Fundamentals

Two Stroke Cycle Engine:

A. Two stroke Spark Ignition (Petrol) engine:

(S12/W12)

Working Principle of 2 stroke (SI) engine

In 2 stroke SI engine working cycle is completed in 2 strokes of the piston or in 1

revolution of the crankshaft. It is a crankcase compression in which charge

(proportionate mixture of air and fuel) before being supplied to engine cylinder is

compressed by the pump action of underside of piston.

It is used in small engines. In these engines ports are used instead of valves in

the cylinder wall. Below given are 3 ports;

1. Transfer Port: The charge from crankcase is supplied to cylinder by means of transfer

port.

2. Inlet Port: Charge is taken to crank case through inlet port.

3. Exhaust Port: It is used to discharge the burnt gases.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 10 of 14

Engine Principles and Fundamentals

Working:

The working principal of 2 stroke (CI) engine is as given below:

FIG A:

The piston is at TDC and charge is being fired due to combustion of fuel, heat

energy is produced. At the same time, the edge of piston uncovers the inlet port.

Fresh charge enters in the crankcase.

FIG B:

Due to the combustion piston goes down & the inlet port is covered then charge

is compressed in crankcase. After completion of 4/5th of the power stroke the exhaust

port is uncovered and some of the burnt gases escape to the atmosphere.

Later the piston uncovers the transfer port and allows fresh charge to enter into

the combustion chamber through transfer port. Due to the deflector on the piston

crown, fresh charge will move up to the top of the cylinder and forces out the

remaining burnt gases through exhaust port.

During scavenging process a apart of the fresh charge leaves the cylinder along

with burnt gases.

FIG C:

After the piston reaches BDC it moves up and closes the transfer port first and

then the exhaust port closes. The compression begins until piston reaches TDC,

when piston is at TDC, the inlet port is again uncovered and the fresh charge is

taken inside the crank case due to the partial vacuum created in crank case and at

the same time charge is compressed in the combustion chamber due to ascending

piston.

Now piston is at TDC and the charge at high temperature and high pressure is

burnt due to spark generated by spark plug and the cycle goes on repeating itself.

(S12)

Scavenging: Scavenging is process of forcing the burnt gases by deflecting the fresh charge

across the cylinder.

At the end of the expansion stroke, combustion chamber of the 2 stroke engine

is left full of product of combustion. This is because there is no separate exhaust stroke

to clear burnt gases. The process of clearing the cylinder after expansion stroke is called

scavenging.

B. Two stroke Compression ignition (Diesel) engine:

(W11)

In 2 stroke cycle compression ignition engine only air is compressed inside the

cylinder and the fuel (diesel) is injected by an injector fitted in the head of the cylinder.

There is no spark plug in this engine. The remaining operation of the 2 stroke cycle,

compression ignition engine is exactly the same as those of spark ignition engine.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 11 of 14

Engine Principles and Fundamentals

Differentiate between 4 stroke and 2 stroke engine.

Reason for using single cylinder 2 stroke & 4 stroke cycle

engine

(W11)

a) 2 stroke engine find their application in scooters, small generating sets, pumping sets

because of their simplicity and low cost.

b) 2 stroke diesel engines are generally high powered engines because every revolution of

the crankshaft we get 1 power stroke thus they are used in ships.

c) 4 stroke single cylinder engines find application in bikes, scooters, Mobile electricity

generating sets because of high fuel efficiency as compared to 2 stroke engine,

compactness, smooth working ability & less pollution as compared to 2 stroke engine.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 12 of 14

Engine Principles and Fundamentals

Engine classified on the basis of the types of cycle:

A) Otto Cycle or Constant Volume cycle:

(S12)

The engine operating on this cycle are known as Otto cycle engine. The petrol engine operates

on this cycle.

1 2 Adiabatic Compression.

2 3 Heat addition at constant volume.

3 4 Adiabatic Expansion.

4 5 Heat rejected at constant volume.

At Point 1: The air in the cylinder is initially corresponding to p1, v1, T1 (pressure, volume &

absolute temperature). The piston compresses the air adiabatically during compression stroke.

Point 2: The condition of air is p2, v2, T2. The air now compresses to clearance volume of

cylinder. A hot body is then brought into contact with cylinder end such a that heat is supplied

at constant volume. This increases pressure and temperature of air, corresponding to p3, v3,

T3.

Point 3: The hot body is removed and the air is expanding adiabatically during the expansion

stroke, up to point 4 corresponding to p4, v4, T4.

Point 4: A cold body is then brought in contact with the cylinder end such a that the pressure

drops at constant volume, corresponding condition p1, v1, T1.

Thus the air finally returns to its original condition and the cycle is completed.

B) Diesel Cycle or Constant Pressure Cycle:

Diesel cycle was introduced by Dr. Rudolf Diesel. The engine operating on this cycle is

known as Diesel engine.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 13 of 14

Engine Principles and Fundamentals

1 2 Adiabatic Compression.

2 3 Heat addition at constant pressure.

3 4 Adiabatic Expansion.

4 5 Heat rejection at constant Volume.

The diesel cycle differs from the Otto cycle in one respect. In Diesel cycle, the heat is

added at constant pressure instead of at constant volume.

From point 1 to 2: The air is compressed in the cylinder during the compression stroke.

From point 2 to 3: Heat is added at constant pressure.

From point 3 to 4: The air expands adiabatically.

From point 4 to 1: finally the heat is rejected at constant volume.

The air returns to its original condition and the cycle is completed.

Mr. A.A. Bhosale, Department of Automobile, New Polytechnic, Kolhapur.

Page 14 of 14

You might also like

- Cummins Engine Company, Inc M-90196 4BT3.9-MDocument2 pagesCummins Engine Company, Inc M-90196 4BT3.9-Mคุณชายธวัชชัย เจริญสุข100% (1)

- JS200Document28 pagesJS200VandersonOrtolaniNo ratings yet

- FM400 - 8x4 Tipper - 18.7cum PDFDocument12 pagesFM400 - 8x4 Tipper - 18.7cum PDFavinawsh100% (1)

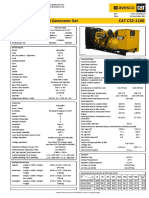

- Cat C32-1100 en PDFDocument1 pageCat C32-1100 en PDFOsanebi Chukwudi LuckyNo ratings yet

- Ks En268id Zx48u 5a IndonesiaDocument2 pagesKs En268id Zx48u 5a IndonesiaAkhmad SebehNo ratings yet

- D375a 6 - Cen00372 02Document14 pagesD375a 6 - Cen00372 02Daniel FerreiraNo ratings yet

- Basic Information of This Scania P380Document2 pagesBasic Information of This Scania P380rudy_423522658No ratings yet

- Xenia 1000cc ABSDocument1 pageXenia 1000cc ABSSANTRI BLAMBANGANNo ratings yet

- Engine FundamentalsDocument36 pagesEngine FundamentalsRahul RaiNo ratings yet

- SDLG Lg936l BrochureDocument3 pagesSDLG Lg936l Brochureade pratamaNo ratings yet

- 1 Defence University, College of EngineeringDocument41 pages1 Defence University, College of EngineeringGetachew TikueNo ratings yet

- Cummins Service SY120 & SY210 & SY215Document1 pageCummins Service SY120 & SY210 & SY215satyam gangeleNo ratings yet

- Variants: Cx130 - Case Crawler Excavator (North America) (04/00 - 12/08) 02 - Engine 02-18 - Cylinder BlockDocument4 pagesVariants: Cx130 - Case Crawler Excavator (North America) (04/00 - 12/08) 02 - Engine 02-18 - Cylinder BlockErick Christopher Galeano 6-3No ratings yet

- 3202C 3232C 320GC Hydraulic Excavator - Family Brochure 02.18Document8 pages3202C 3232C 320GC Hydraulic Excavator - Family Brochure 02.18Allan Jude C. Abapo Jr.No ratings yet

- List Sparepart Service UnitDocument9 pagesList Sparepart Service UnitFredyMesyaNo ratings yet

- Part Maintenance D375-5 Dan D375-6RDocument4 pagesPart Maintenance D375-5 Dan D375-6RAdi MNo ratings yet

- Loader (Equipment)Document6 pagesLoader (Equipment)Arul Selvan RajaduraiNo ratings yet

- John Deere 125 HP PDFDocument2 pagesJohn Deere 125 HP PDFJulio TovarNo ratings yet

- Service Manual Nissan PDFDocument39 pagesService Manual Nissan PDFayi darwisNo ratings yet

- Air Compressor Data SheetDocument2 pagesAir Compressor Data Sheetرنا حركاتيNo ratings yet

- HR/MR Engine: Technology OverviewDocument2 pagesHR/MR Engine: Technology Overviewarseniy762No ratings yet

- Hydraulic SystemsDocument23 pagesHydraulic Systemsaapale75% (4)

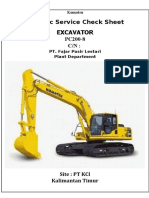

- PSCS - PC200-8Document6 pagesPSCS - PC200-8mahmudiNo ratings yet

- 12h Identification Des Pieces Service BrakeDocument3 pages12h Identification Des Pieces Service BrakeaniriNo ratings yet

- 850J (Tier III) PMDocument4 pages850J (Tier III) PMwachira chantabandit100% (1)

- HM400 2 - Cen00078 06Document12 pagesHM400 2 - Cen00078 06ibnu malkanNo ratings yet

- Rawler Ozer: With Steering Clutch/Brake SystemDocument10 pagesRawler Ozer: With Steering Clutch/Brake SystemDinh Phu LeNo ratings yet

- Backhoe Loader B877Document4 pagesBackhoe Loader B877MS Buk3100% (1)

- D85ESS-2A: Horsepower Net: 149 KW Operating Weight 20670 KGDocument8 pagesD85ESS-2A: Horsepower Net: 149 KW Operating Weight 20670 KGHeronimus RigoNo ratings yet

- Electronic FundamentalDocument12 pagesElectronic FundamentalZjian WaiNo ratings yet

- 05 Toyota - 5FG 5 8Document8 pages05 Toyota - 5FG 5 8Edwin NgNo ratings yet

- Raftar Formula Racing IIT Madras Powertrain Systems Recruitment 2017 InstructionsDocument2 pagesRaftar Formula Racing IIT Madras Powertrain Systems Recruitment 2017 InstructionsanirudhNo ratings yet

- Doosan S140LCV Hydraulic ExcavatorDocument3 pagesDoosan S140LCV Hydraulic ExcavatorDidik HartadiNo ratings yet

- Brochure R 9350 English 2013-04 - 11723-0 PDFDocument22 pagesBrochure R 9350 English 2013-04 - 11723-0 PDFJulhefry Maroan Situngkir100% (1)

- Tier 4 Final Lamps: QSF3.8 QSB4.5 QSB6.7 Qsl9 QSG12 QSX15Document2 pagesTier 4 Final Lamps: QSF3.8 QSB4.5 QSB6.7 Qsl9 QSG12 QSX15Ali SadeghiNo ratings yet

- Brake Parts Manual PageDocument1 pageBrake Parts Manual PageveereshNo ratings yet

- THF6 - .Joystick Control PDFDocument12 pagesTHF6 - .Joystick Control PDFmusafirNo ratings yet

- EL-HKN 31021601e 01-9Document114 pagesEL-HKN 31021601e 01-9KiranKumarReddy100% (1)

- Hydraulic Excavator: Engine WeightsDocument28 pagesHydraulic Excavator: Engine WeightsAkhmad SebehNo ratings yet

- CodingDocument16 pagesCodingDiane VillarmaNo ratings yet

- MARUMA UndercarriageDocument4 pagesMARUMA UndercarriageaafloreshNo ratings yet

- EX1200-7 Specs Digital-Only 18-11 PDFDocument20 pagesEX1200-7 Specs Digital-Only 18-11 PDFvitaliyNo ratings yet

- Wheel Loader 937H: Technical SpecificationDocument3 pagesWheel Loader 937H: Technical SpecificationMuhamad AdamNo ratings yet

- Deutz 1013 Agricultural Specs PDFDocument6 pagesDeutz 1013 Agricultural Specs PDFALWINo ratings yet

- The Basic Principles of HydraulicsDocument8 pagesThe Basic Principles of Hydraulicsyakarim100% (3)

- LIEBHERR R984C Conch China GB - PDF (2) 8697-0 PDFDocument4 pagesLIEBHERR R984C Conch China GB - PDF (2) 8697-0 PDFAnthony Andrés Rojas Guerrero100% (1)

- Spec C32 746kW@1800rpmDocument15 pagesSpec C32 746kW@1800rpmPhuc DcNo ratings yet

- 385C Cat Vs PC8007 KomatsuDocument78 pages385C Cat Vs PC8007 KomatsuKolo BenduNo ratings yet

- YTG30TLV LeafletDocument1 pageYTG30TLV LeafletandriNo ratings yet

- 6BT5.9-DM Non-Certified Ratings SSDocument2 pages6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- Basic Engine: Replace Fuel ElementDocument6 pagesBasic Engine: Replace Fuel Elementraymond ngoNo ratings yet

- Idler Ass D 375-6Document2 pagesIdler Ass D 375-6subandi pippoNo ratings yet

- XCMG Wheel Loader LW300KNDocument4 pagesXCMG Wheel Loader LW300KNMeliw WuNo ratings yet

- Unit 3Document16 pagesUnit 3Shivanand BurliNo ratings yet

- Applied Thermal EngineeringDocument83 pagesApplied Thermal Engineeringommech2020No ratings yet

- I.C. Engines: (I) According To The Type of Fuel UsedDocument15 pagesI.C. Engines: (I) According To The Type of Fuel UsedSreejith VaneryNo ratings yet

- Lecture Notes ON Internal Combustion Engine: Course Code: Me 4101Document10 pagesLecture Notes ON Internal Combustion Engine: Course Code: Me 4101MahiNo ratings yet

- Applied ThermodynamicsDocument83 pagesApplied ThermodynamicsKaranNo ratings yet

- I C - Engines-NotesDocument15 pagesI C - Engines-Notessuhas_SCEMNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Sci Lab IntroDocument125 pagesSci Lab IntroRizqy-y WaluyoNo ratings yet

- Lab Manual - Manufacturing TechnologyDocument79 pagesLab Manual - Manufacturing Technologyvelumani2003No ratings yet

- Water Rocket Manual: Everything You Ever Wanted To Know About Water Rockets and LaunchersDocument7 pagesWater Rocket Manual: Everything You Ever Wanted To Know About Water Rockets and Launchersvelumani2003No ratings yet

- 6 - CNC Part ProgrammingDocument8 pages6 - CNC Part Programmingvelumani2003No ratings yet

- Engineering Graphics Question January 2011 Bibin'sDocument3 pagesEngineering Graphics Question January 2011 Bibin'sBIBIN CHIDAMBARANATHANNo ratings yet

- Velalar College of Engineering and Technology, Erode-12Document2 pagesVelalar College of Engineering and Technology, Erode-12velumani2003No ratings yet

- Producing Transportation Fuels From AlgaeDocument1 pageProducing Transportation Fuels From Algaevelumani2003No ratings yet

- Engineering Graphics Question January 2013 Bibin'sDocument2 pagesEngineering Graphics Question January 2013 Bibin'sBIBIN CHIDAMBARANATHANNo ratings yet

- Engineering Graphics Question January 2013 Bibin'sDocument2 pagesEngineering Graphics Question January 2013 Bibin'sBIBIN CHIDAMBARANATHANNo ratings yet

- 05polymer 2 6f1Document8 pages05polymer 2 6f1Ruhul Amin MukutNo ratings yet

- 1 s2.0 S221192641400023X MainDocument10 pages1 s2.0 S221192641400023X Mainvelumani2003No ratings yet

- 6th Mech SyllabiDocument23 pages6th Mech Syllabivelumani2003No ratings yet

- AutoCAD - Modify ToolbarDocument18 pagesAutoCAD - Modify ToolbarMarcusNo ratings yet

- HD 70 CDocument101 pagesHD 70 CPhamVanGiangNo ratings yet

- Neraca energiATK-2Document29 pagesNeraca energiATK-2MauliyaLailaNo ratings yet

- Research MethodsDocument10 pagesResearch MethodsAhimbisibwe BenyaNo ratings yet

- Modul Ke-4 Perhitungan Sieve AnalisisDocument36 pagesModul Ke-4 Perhitungan Sieve AnalisisFredi CherboundNo ratings yet

- Microwave Mini ProjectDocument21 pagesMicrowave Mini Projectfaizan4033No ratings yet

- Tutorial 1 PDFDocument9 pagesTutorial 1 PDFMuaz Mohd ZahidinNo ratings yet

- DWSIM Training-V02-30dec17Document58 pagesDWSIM Training-V02-30dec17Zanariah HashimNo ratings yet

- Soal B.inggris Paket 3Document9 pagesSoal B.inggris Paket 3sitiNo ratings yet

- DI CaseletesDocument9 pagesDI Caseletessprem4353No ratings yet

- JCrenshaw ImplementingCRCsDocument17 pagesJCrenshaw ImplementingCRCsspyeagleNo ratings yet

- Risk Assessment of Ship Platform ColissionDocument6 pagesRisk Assessment of Ship Platform Colission123habib123fikriNo ratings yet

- Neeraj Pal 2Document1 pageNeeraj Pal 2NeerajPalNo ratings yet

- Pick and Place Robotic Arm Controlled by Computer - TJ211.42.M52 2007 - Mohamed Naufal B. OmarDocument26 pagesPick and Place Robotic Arm Controlled by Computer - TJ211.42.M52 2007 - Mohamed Naufal B. OmarSAMNo ratings yet

- What Is Trim?: Changed by Moving Masses Already On Board Forward or AFTDocument2 pagesWhat Is Trim?: Changed by Moving Masses Already On Board Forward or AFTamirsyawal87No ratings yet

- Projectile Motion at An AngleDocument25 pagesProjectile Motion at An AngleKenneth Kent Stinson FloresNo ratings yet

- TRM Reb670Document490 pagesTRM Reb670jayapalNo ratings yet

- Communication ManagementDocument20 pagesCommunication Managementmandalapu_devi5240No ratings yet

- Pitcher TemplateDocument1 pagePitcher Templatem.usmanNo ratings yet

- Hybrid Nanophotonics: Review of Actual ProblemsDocument68 pagesHybrid Nanophotonics: Review of Actual ProblemsTarun SinghalNo ratings yet

- DF1740N PLCC Modem Catalog: DescriptionDocument3 pagesDF1740N PLCC Modem Catalog: DescriptionmanishNo ratings yet

- Ultra Structure of ChromosomeDocument9 pagesUltra Structure of ChromosomeJigarS.MehtaNo ratings yet

- 12 MarksDocument23 pages12 Markslakshmigsr6610No ratings yet

- UM - HX204 - EN User ManualDocument32 pagesUM - HX204 - EN User Manuals7631040No ratings yet

- Design of The Power Control Module of TDDocument9 pagesDesign of The Power Control Module of TDGurbir SinghNo ratings yet

- Eaton Fuller - Autoshift 16 Service Manual (T20891)Document81 pagesEaton Fuller - Autoshift 16 Service Manual (T20891)Miller Andres ArocaNo ratings yet

- TECNICA 140.1 - 142 TECNICA 1400-1600: Inver TerDocument20 pagesTECNICA 140.1 - 142 TECNICA 1400-1600: Inver TerabdessNo ratings yet

- Al-Farabi The Theory of Emanation and THDocument14 pagesAl-Farabi The Theory of Emanation and THManuel Ricardo Fernandes SoaresNo ratings yet

- Turbo-Pump Supply System For Liquid-Propellant Rocket EngineDocument8 pagesTurbo-Pump Supply System For Liquid-Propellant Rocket EngineĐinh Quốc TríNo ratings yet

- 100 Irregular Plural Nouns ListDocument3 pages100 Irregular Plural Nouns Listjinesham007No ratings yet