Professional Documents

Culture Documents

Cyclohexanol To Cyclohexene

Uploaded by

Sukumar Pani100%(1)100% found this document useful (1 vote)

750 views3 pagestells how to convert cyclohexanol to hexene

Original Title

Cyclohexanol to Cyclohexene

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttells how to convert cyclohexanol to hexene

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

750 views3 pagesCyclohexanol To Cyclohexene

Uploaded by

Sukumar Panitells how to convert cyclohexanol to hexene

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

Synthesis and Reactions of Alkenes:

Cyclohexene from Cyclohexanol

from K. L. Williamson, Macroscale and Microscale Organic

Experiments, 2nd Ed. 1994, Houghton Mifflin, Boston d. p268;

revised 10/10/98, adapted from the microscale synthesis posted

by:

http://courses.chem.psu.edu/chem35/HTML/Experiments/Exp72.pdf

Prelab Exercise: Prepare a detailed flow sheet for the

preparation of cyclohexene, indicating at each step which layer

contains the desired product.

Introduction

Dehydration of cyclohexanol to cyclohexene can be accomplished by

pyrolysis of the cyclic secondary alcohol with an acid catalyst

at a moderate temperature or by distillation over alumina or

silica gel.

The procedure selected for this experiment involves catalysis by

sulfuric acid. When a mixture of cyclohexanol and sulfuric acid

is heated in a flask equipped with a fractionating column, the

formation of water is soon evident. On further heating, the water

and the cyclohexene formed distill together by the principle of

steam distillation, and any high-boiling cyclohexanol that may

volatilize is returned to the flask. However, after dehydration

is complete and the bulk of the product has distilled, the column

remains saturated with water-cyclohexene that merely refluxes and

does not distill. Hence, for recovery of otherwise lost reaction

product, a chaser solvent is added, and distillation is

continued. A suitable chaser solvent is the water-immiscible,

aromatic solvent toluene, boiling point 110C; as it steamdistills, it carries over the more volatile cyclohexene. When the

total water-insoluble layer is separated, dried, and redistilled

through the dried column, the chaser again drives the cyclohexene

from the column; the difference in boiling points is such that a

sharp separation is possible. The column holdup (retention of

distillate) in the metal sponge-packed column is so great that if

a chaser solvent is not used in the procedure, the yield will be

much lower.

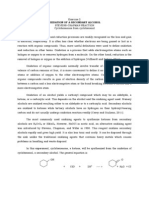

The mechanism of this reaction involves initial rapid protonation

of the hydroxyl group by the sulfuric acid. This is followed by

loss of water to give the unstable secondary carbocation, which

quickly loses a proton to water or the conjugate acid to give the

alkene.

Procedure: Preparation of Cyclohexene

Add 1.5 mL of water into a 25 mL round bottomed flask. To this,

add 2.0 mL of concentrated sulfuric acid, followed by 10.0 g of

cyclohexanol (note, this is 10.0 g not 10.0 mL), and a boiling

chip. Put a cork on the top of the flask, and shake gently to mix

the layers. Put your hand around the flask to feel the evolution

of heat. Set up the arrangement for fractional distillation as

performed previously. Note that the bulb of the thermometer must

be completely below the side arm of the distilling head. Wrap the

fractionating column and distilling head with glass wool. Be sure

to thoroughly insulate the apparatus to help speed up the

distillation process. (See the experiment on fractional

distillation in for details of this technique.)

Distill the mixture gently on the heating mantle, collecting

the distillate in a graduated cylinder. Distill until the liquid

remaining in the distillation flask has a volume of about 2.0 mL

and very little material is distilling; Record the boiling

temperature range. The reaction mixture will turn black and a

small amount of black solid will start to form due to side

reactions caused by the conc. H2SO4, but this is normal. Let the

assembly cool a little after removing it from the sand, remove

the thermometer briefly, and add 4 mL of toluene (the chaser

solvent) into the flask. Note the amount of the organic (upper)

layer in the boiling flask and distill again until the volume of

this layer has been reduced by about half. Transfer the contents

of the vial into a 50 mL Erlenmeyer flask, and rinse the round

bottom flask with a little toluene. Use toluene for rinsing in

subsequent operations. Wash the toluene/product distillate with

an equal volume of saturated sodium chloride solution, remove the

aqueous layer, and then add sufficient anhydrous sodium sulfate

to the reaction tube so that it does not clump together. Shake

the solution with the drying agent, and let it dry for at least 5

min. While this is taking place, clean the distilling apparatus

first with water, then ethanol, and finally a little acetone. It

is absolutely essential that the apparatus be completely dry;

otherwise, the product will be contaminated with whatever solvent

is left in the apparatus. Transfer the dry cyclohexene solution

to the distilling flask, add a boiling chip and distill the

product. At the moment the temperature starts to rise above the

plateau at which the product distills (83C), stop the

distillation to avoid contamination of the cyclohexene with

toluene. A typical yield of this volatile alkene is about 3.5 g.

Report your yield in grams and your percentage yield.

Analyses: Analyze your sample with IR and determine how

differences in b.p. are related to % yield.

Post Lab Questions

1. Assign the peaks of the 'H NMR spectrum of cyclohexene below

to specific groups of protons on the molecule.

2. What product(s) can be obtained by the dehydration of

(a) 2-heptanol

(b) 2-methyl-1-hexanol?

3. Write a detailed mechanism for the dehydration of cyclohexanol

to cyclohexene.

You might also like

- Preparing Cyclohexene from CyclohexanolDocument7 pagesPreparing Cyclohexene from CyclohexanolDumile Nombasa100% (5)

- Synthesis of An Alkyl HalideDocument4 pagesSynthesis of An Alkyl HalideJoseph CatiisNo ratings yet

- Ester Synthesis LabDocument6 pagesEster Synthesis LabMuhammad Abdur RokhimNo ratings yet

- FR 1 (E6)Document5 pagesFR 1 (E6)JR CastorNo ratings yet

- Experiment 9 - : Alkene Synthesis From Alcohol Preparation of Cyclohexene From CyclohexanolDocument6 pagesExperiment 9 - : Alkene Synthesis From Alcohol Preparation of Cyclohexene From CyclohexanolSoo Hui Yan0% (2)

- Cyclohexene Synthesis via Cyclohexanol DehydrationDocument3 pagesCyclohexene Synthesis via Cyclohexanol DehydrationImani London Smith67% (3)

- CE - Experiment 2 Extraction With Acid and AlkalineDocument8 pagesCE - Experiment 2 Extraction With Acid and AlkalineWeiChingNo ratings yet

- Exp 3-Reduction of Cyclohexanone With Sodium BorohydrideDocument11 pagesExp 3-Reduction of Cyclohexanone With Sodium Borohydrideakuserai100% (3)

- Lab 10 - Diels AlderDocument4 pagesLab 10 - Diels AlderAlison NguyenNo ratings yet

- Oxidation of Cyclohexanol To CyclohexanoneDocument5 pagesOxidation of Cyclohexanol To CyclohexanoneChandrani Chakraborti100% (1)

- Exp 6 Williamson Ether SynthesisDocument5 pagesExp 6 Williamson Ether SynthesisSherry0% (1)

- Ester of Carboxylic AcidsDocument6 pagesEster of Carboxylic Acidsmaryam_m_chemNo ratings yet

- Sythesization and Purification of Acetanilide by Acetylation and Re CrystallizationDocument4 pagesSythesization and Purification of Acetanilide by Acetylation and Re CrystallizationToni Sy EncinaresNo ratings yet

- CHEM 334L - Conductance of Solutions - Estimating K For A Weak AcidDocument4 pagesCHEM 334L - Conductance of Solutions - Estimating K For A Weak Acidfdobonat613100% (1)

- Lab Report 11Document3 pagesLab Report 11PaulNo ratings yet

- Experiment 1 OrgChem Lab 2Document5 pagesExperiment 1 OrgChem Lab 2John Harvey Santos100% (2)

- Lab C-Methyl OrangeDocument4 pagesLab C-Methyl Orangetopikamew100% (1)

- Preparation and Purification of An Alkyl Halide FRDocument6 pagesPreparation and Purification of An Alkyl Halide FRCamille GrefaldiaNo ratings yet

- Experiment 8 The Preparation of AcetanlideDocument12 pagesExperiment 8 The Preparation of AcetanlideRadhwanNo ratings yet

- Qualitative Organic Analysis - Sem 3Document37 pagesQualitative Organic Analysis - Sem 3Reshma SomanNo ratings yet

- Objectives: FIGURE A: Example of Coordination CompoundsDocument7 pagesObjectives: FIGURE A: Example of Coordination CompoundsNurul izzatiNo ratings yet

- Isolation of Casein From Skimmed Milk and Seperation and Identification of Amino Acids by Paper ChromatographyDocument8 pagesIsolation of Casein From Skimmed Milk and Seperation and Identification of Amino Acids by Paper ChromatographyKc CalderonNo ratings yet

- Recrystallization of AcetanilideDocument2 pagesRecrystallization of Acetaniliderm_gabriel07No ratings yet

- Chemistry Lab ReportDocument4 pagesChemistry Lab Reportahlam23a0% (2)

- Solubility of Organic CompoundsDocument4 pagesSolubility of Organic CompoundsJeremy Noceda100% (1)

- Recrystallize Aspirin & Purify Salicylic AcidDocument32 pagesRecrystallize Aspirin & Purify Salicylic AcidYosita RahmawatiNo ratings yet

- Transition Metal ReactionsDocument11 pagesTransition Metal ReactionsFarahSyazwani100% (1)

- Lab 2 - Preparation of AcetaminophenDocument4 pagesLab 2 - Preparation of Acetaminophenapi-281862068100% (3)

- Synthesis of Acetanilide and Its Purification Through RecrystallizationDocument4 pagesSynthesis of Acetanilide and Its Purification Through RecrystallizationTeresa Saylo100% (1)

- Aspirin Synthesis LabDocument7 pagesAspirin Synthesis LabTrương Thị Bích LiễuNo ratings yet

- Experiment 9 Formal Laboratory ReportDocument5 pagesExperiment 9 Formal Laboratory ReportNathaniel Argelio Dimaano100% (1)

- EXPERIMENT 5 Common Ion EffectDocument4 pagesEXPERIMENT 5 Common Ion EffectNat DabuétNo ratings yet

- Practical 4 - Classification and Identification of Aldehydes and KetonesDocument4 pagesPractical 4 - Classification and Identification of Aldehydes and KetonesAsyraff AhmadNo ratings yet

- Partially Miscible LiquidsDocument8 pagesPartially Miscible LiquidsRenz Roger Esteves Buendicho100% (1)

- Exer2 PrelabDocument3 pagesExer2 Prelabkarinadegoma100% (1)

- Iodoform ReactionDocument5 pagesIodoform Reactionmarwazohdi100% (1)

- Experiment 32Document14 pagesExperiment 32Morgan Elizabeth Lepley100% (6)

- Obtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessDocument5 pagesObtaining Pure Acetanilide From Crude Acetanilide by Recrystallization ProcessCharlot NavarroNo ratings yet

- NaBH4 Reduction of Cyclohexanone to Cyclohexanol (87Document8 pagesNaBH4 Reduction of Cyclohexanone to Cyclohexanol (87hahadindongNo ratings yet

- Experiment One Preparation of Benzophenone Oxime: 1. ProcedureDocument5 pagesExperiment One Preparation of Benzophenone Oxime: 1. Procedurek ucheNo ratings yet

- Nucleophlic Acyl Substitution - The Synthesis of Ethyl ButanoateDocument5 pagesNucleophlic Acyl Substitution - The Synthesis of Ethyl ButanoateRuther Cabral67% (3)

- Lab Report (Final Editied)Document8 pagesLab Report (Final Editied)Alexia Channer100% (4)

- Determination of Calcium Carbonate in EggshellsDocument4 pagesDetermination of Calcium Carbonate in EggshellsJaz100No ratings yet

- Analysis of Lipids in Chicken Egg Yolk by Chromatography and TestsDocument8 pagesAnalysis of Lipids in Chicken Egg Yolk by Chromatography and TestsChristine DelmendoNo ratings yet

- Acid-Base Titration LabDocument5 pagesAcid-Base Titration Labshoaib2769504No ratings yet

- Formal Report For Synthesis of An Alkyl HalideDocument5 pagesFormal Report For Synthesis of An Alkyl HalideLovelyn Marie Morada Nievales80% (5)

- Dehydration of An AlcoholDocument13 pagesDehydration of An AlcoholButterlesstoastNo ratings yet

- Preparationofpotassiumtrisoxalateferrateiitrihydrate 140328134711 Phpapp02Document15 pagesPreparationofpotassiumtrisoxalateferrateiitrihydrate 140328134711 Phpapp02Guru P MNo ratings yet

- Synthesis of Tert-Butyl Chloride from AlcoholDocument7 pagesSynthesis of Tert-Butyl Chloride from AlcoholFerdinand Tamayo Cayabyab Jr.No ratings yet

- Winkler Titration FRDocument4 pagesWinkler Titration FRanaperturescienceNo ratings yet

- CHEM 22161 Lab 1 :synthesis of Medicinal Agent: Synthesis of AspirinDocument8 pagesCHEM 22161 Lab 1 :synthesis of Medicinal Agent: Synthesis of AspirinKasun WekasingheNo ratings yet

- Di Benz Al AcetoneDocument3 pagesDi Benz Al AcetoneKristine Mae De GuzmanNo ratings yet

- ELECTROPHILIC AROMATIC SUBSTITUTIONDocument5 pagesELECTROPHILIC AROMATIC SUBSTITUTIONXyrell Claude Monta100% (2)

- Chem 31 AtqE1Document3 pagesChem 31 AtqE1Anonymous GO6JVW9WudNo ratings yet

- Partition Coefficient DeterminationDocument4 pagesPartition Coefficient DeterminationMostafa HamawandyNo ratings yet

- Synthesis of Isoamyl AcetateDocument3 pagesSynthesis of Isoamyl AcetateClaire TiongsonNo ratings yet

- Figure 5.1 Preparation of CyclohexeneDocument5 pagesFigure 5.1 Preparation of CyclohexeneMark Cliffton BadlonNo ratings yet

- Expt 05 - CyclohexeneDocument5 pagesExpt 05 - CyclohexeneMark Cliffton BadlonNo ratings yet

- Experiment 12 Preparation of Adipic Acid From CyclohexeneDocument6 pagesExperiment 12 Preparation of Adipic Acid From Cyclohexenesaransh1994No ratings yet

- ObjectivesDocument6 pagesObjectivesTtalgis CartNo ratings yet

- Photo Catalysis CDocument19 pagesPhoto Catalysis CSukumar PaniNo ratings yet

- Sukumar 3Document13 pagesSukumar 3Sukumar PaniNo ratings yet

- Ground and Excited State Intramolecular Proton Transfer in Salicylic Acid: An Ab Initio Electronic Structure InvestigationDocument6 pagesGround and Excited State Intramolecular Proton Transfer in Salicylic Acid: An Ab Initio Electronic Structure InvestigationSukumar PaniNo ratings yet

- Photocatalysis ADocument13 pagesPhotocatalysis ASukumar PaniNo ratings yet

- Cyclo Dextrin 2Document10 pagesCyclo Dextrin 2Sukumar PaniNo ratings yet

- CSIR NET NotificationDocument8 pagesCSIR NET NotificationTHIYAGUNo ratings yet

- Infra Red 1Document18 pagesInfra Red 1Sukumar PaniNo ratings yet

- Magnetic PropertiesDocument29 pagesMagnetic PropertieshrsreenathNo ratings yet

- Lec1 PDFDocument3 pagesLec1 PDFSukumar PaniNo ratings yet

- Foundations of Chemical Kinetics Kramers Theory: Marc R. Roussel Department of Chemistry and BiochemistryDocument17 pagesFoundations of Chemical Kinetics Kramers Theory: Marc R. Roussel Department of Chemistry and BiochemistrySukumar PaniNo ratings yet

- Ulloa FullerenesDocument5 pagesUlloa FullerenesSukumar PaniNo ratings yet

- Fresher DayDocument9 pagesFresher DaySukumar PaniNo ratings yet

- An THR A QuinonesDocument23 pagesAn THR A QuinonesSukumar PaniNo ratings yet

- Apple Seeds4Document6 pagesApple Seeds4Sukumar PaniNo ratings yet

- OLED Seminar Report SummaryDocument36 pagesOLED Seminar Report SummarySukumar PaniNo ratings yet

- Effective Communication ApproachesDocument10 pagesEffective Communication ApproachesSukumar Pani60% (5)

- MOT-Diatomic Ch. Tab - PlotssDocument5 pagesMOT-Diatomic Ch. Tab - PlotssSukumar PaniNo ratings yet

- Infra Red Absorption SpectrosDocument18 pagesInfra Red Absorption SpectrosSukumar PaniNo ratings yet

- StabilitycomplexDocument9 pagesStabilitycomplexAmitranjan KarNo ratings yet

- Popular Uuchemistryprize2016Document7 pagesPopular Uuchemistryprize2016AarcamNo ratings yet

- Bent Rule and EnergeticsDocument13 pagesBent Rule and EnergeticsSukumar Pani50% (2)

- EducationDocument189 pagesEducationAmitranjan KarNo ratings yet

- Food & Nutrition SecurityDocument1 pageFood & Nutrition SecuritySukumar PaniNo ratings yet

- 2D Nanomaterials Revolutionizing Device DesignDocument6 pages2D Nanomaterials Revolutionizing Device DesignSukumar PaniNo ratings yet

- TTDocument1 pageTTSukumar PaniNo ratings yet

- Food Security in OdishaDocument8 pagesFood Security in OdishaSukumar PaniNo ratings yet

- Directional Overcurrent RelayDocument4 pagesDirectional Overcurrent RelaySukumar PaniNo ratings yet

- Cable Condition Monitoring To Improve ReliatilityDocument14 pagesCable Condition Monitoring To Improve ReliatilitySukumar PaniNo ratings yet

- Poisson PresentationDocument22 pagesPoisson PresentationmoochoosNo ratings yet

- Ek Series Spec Sheet en Us 5403644Document2 pagesEk Series Spec Sheet en Us 5403644muhamad solehNo ratings yet

- Zinc Flake Technology-Technical PDFDocument1 pageZinc Flake Technology-Technical PDFKalyan DhakaneNo ratings yet

- 3 Edwin NT JongDocument15 pages3 Edwin NT JongfelixNo ratings yet

- Chemical Reaction Engineering and Reactor Technolo... - (Chapter 5. Catalytic Two-Phase Reactors) PDFDocument74 pagesChemical Reaction Engineering and Reactor Technolo... - (Chapter 5. Catalytic Two-Phase Reactors) PDFazNo ratings yet

- Assignment No. 2 in MDSPDocument14 pagesAssignment No. 2 in MDSPRex RebuyasNo ratings yet

- Thinners Classification and DetailsDocument3 pagesThinners Classification and DetailsZia Ur RehmanNo ratings yet

- Abrasive Grinding PresentationDocument28 pagesAbrasive Grinding PresentationSanjay MehrishiNo ratings yet

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5Document1 pageTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5IonutCiobanuNo ratings yet

- Production Process Flow DiagramDocument4 pagesProduction Process Flow DiagramSuntech Engineering CorporationNo ratings yet

- Advent Product CatalogDocument64 pagesAdvent Product CatalogmiculinicNo ratings yet

- Damp Protection Method StatementDocument5 pagesDamp Protection Method Statementalfaaleem_1830No ratings yet

- Kalmetall W Kalpraxis GBDocument12 pagesKalmetall W Kalpraxis GBkaniappan sakthivelNo ratings yet

- What Is 3D Printing - The Definitive Guide - 3D HubsDocument45 pagesWhat Is 3D Printing - The Definitive Guide - 3D HubsDavid PmNo ratings yet

- Sidestream Membrane Bioreactor - Genex UtilityDocument7 pagesSidestream Membrane Bioreactor - Genex UtilityYashwanth Raj MNo ratings yet

- Customer Complaints About Wet Storage Stain - American Galvanizers AssociationDocument3 pagesCustomer Complaints About Wet Storage Stain - American Galvanizers AssociationNsidibe Michael EtimNo ratings yet

- Theory of Arc Welding pt1Document115 pagesTheory of Arc Welding pt1Koushik SarkarNo ratings yet

- Normes ToyotarcDocument13 pagesNormes Toyotarcerwin_teichmannNo ratings yet

- Undercarriage 1Document11 pagesUndercarriage 1klairobNo ratings yet

- Metallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoDocument1 pageMetallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoEmigdio MartinezNo ratings yet

- Af 163-2Document10 pagesAf 163-2lacsmm982No ratings yet

- Practical Guide To Blow MouldingDocument216 pagesPractical Guide To Blow Mouldingamitav.datta80% (5)

- Polymer Processing TechniquesDocument17 pagesPolymer Processing TechniquesAnonNo ratings yet

- AM Process - Generic - New TemplateDocument9 pagesAM Process - Generic - New TemplateSURESHKUMAR KANNAPPANNo ratings yet

- The Forms of Corrosion-Part2Document71 pagesThe Forms of Corrosion-Part2quiron2010100% (1)

- AUGUST 2021 Surplus Record Machinery & Equipment DirectoryDocument719 pagesAUGUST 2021 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Micro Tuff ProtectionDocument3 pagesMicro Tuff ProtectionScott NiedfeldtNo ratings yet

- Tds Weathershield Powerflexx PKDocument3 pagesTds Weathershield Powerflexx PKShahid RashidNo ratings yet

- BHS Solid-Liquid Filtration and Final Drying OptimizationDocument28 pagesBHS Solid-Liquid Filtration and Final Drying OptimizationBarry PerlmutterNo ratings yet

- Machine Design Final Coaching Shuffled PDFDocument385 pagesMachine Design Final Coaching Shuffled PDFJaypes ManzanoNo ratings yet

- Steel Forgings, Stainless, For Compressor and Turbine AirfoilsDocument4 pagesSteel Forgings, Stainless, For Compressor and Turbine AirfoilsDarwin DarmawanNo ratings yet