Professional Documents

Culture Documents

H Quality and Certification Requirements-SP

Uploaded by

El_memitoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H Quality and Certification Requirements-SP

Uploaded by

El_memitoCopyright:

Available Formats

Minera Yanacocha, S.R.L.

Conga Project

A3SP

Form 000.450.F2013

Date 14Oct2011

Page 1 of 3

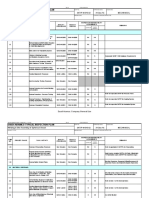

QUALITY AND CERTIFICATION REQUIREMENTS

FABRICATED STRUCTURAL STEEL / LADDERS & PLATFORM

FABRICACION DE TECHO REMOVIBLE METALICO PARA

CASETA DE VALVULAS EN CHAILHUAGON SEDIMENT POND

Equipment Description:

Tag No.'s:

RFQ / P.O. Number:

Originator:

A3SP-2-1011-01-P/FAB

File Number:

=

Inspect

R =

Review

Verify

W =

ACTION TYPE:

= Hold Point

X =

Supplier Action Required

O = Observation Point

INSPECTION ACTIVITY

FLUOR

I

I. INSPECTION & TEST PLAN /

PROCEDURE REVIEW

Suppliers Quality Plan

Suppliers Inspection & Test Plan

f

f

Weld Procedures

Weld Consumable Control

Procedure

Weld Repair Procedures

NDE Procedures

Pre Heat Procedures

Fireproofing Sealant Procedure

Paint Procedures

Galvanizing Procedures

Refractory/Fireproofing

Procedures

II. DOCUMENT REVIEW

Order & Sub-Order(s)

Material Test Reports

Origin of Material / AML

Supplier Inspector Qualifications

Welder Qualification Records

NDE Personnel Qualifications

NDE Reports (HT, VT, MT, PT,

RT, UT)

Galvanizing Reports

Paint Reports

Material / Weld / NDE Maps

Manufactures Data Book(s) as

per SDDR

Date:

03-Jul-2013

of

DEFINITIONS:

b = First Article Only Random Thereafter

c1 = Random Inspection

(Engineered Equipment)

c2 = Random Inspection

(Non Engineered Equipment)

f = 100% Examination

Witness

Assignment Date:

Assignment Page:

REQUIREMENT TYPE:

I

A. Puentes / C. Gallardo

Rev.:

Review: Physical examination of documents

Verify: Verify all procedures as required by the PO have been reviewed by

Fluor and authorized for use, and physically verify the implementation of

those procedures as applicable, on a random basis.

Hold Pt.: Activity is not to proceed until Inspected by Fluor SQS

Observation: Fluor SQS to be notified - however, the supplier may

proceed if Fluor SQS is not available

Random Inspection (Engineered Equipment) = In-process planned and

unsystematic patterns of all necessary actions to provide adequate

confidences to the Fluor SQS representative that the product quality fulfils

the PO Quality Requirements

Random Inspection (Non Engineered Equipment) = In-process planned and

unsystematic representative sampling activities necessary to provide

adequate confidences to the Fluor SQS representative that the product

quality fulfills the PO Quality requirements.

COMMENTS

H

Welding Procedure Specification (WPS), Procedure Qualification Record (PQR), Welder

Performance Qualification (WPQ), according to AWS D1.1.

f

f

f

See item IV

f

f

Certifications of Materials: bolts, connection plates, columns, beams, etc.

f

f

f

All welds shall be 100% visually examined prior to, and after welding in accordance AWS D1.1

See item IV

See item IV

f

f

f

Refractory/Fireproofing Test

Results

Copyright 2011, Fluor Corporation. All Rights Reserved.

Supplier Quality Surveillance

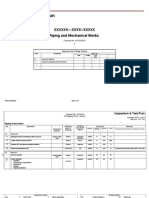

Minera Yanacocha, S.R.L.

Conga Project

A3SP

Form 000.450.F2013

Date 14Oct2011

Page 2 of 3

QUALITY AND CERTIFICATION REQUIREMENTS

FABRICATED STRUCTURAL STEEL / LADDERS & PLATFORM

INSPECTION ACTIVITY

FLUOR

I

III. IN PROCESS VERIFICATION

(Visual / Dimensional)

Fit Up

Material Thickness & Condition

Measuring & Test Equipment

Welding Consumables

Welding (Size / Appearance)

Material Stamping / Traceability

Pre-Heat / Pre-Heat Maintenance

Special Cleaning

Dimensional Check

Weld Internal / External

Major Weld Repairs

Trial Assembly

Base plates/Bearing plate

Safety Gates

Grating / Floor Plate

Toe Kick Plate

COMMENTS

H

f

f

X

X

All welds shall be 100% visually examined prior to, and after welding in accordance AWS D1.1

Acceptance Criteria AWS D1.1

f

X

X

IV. NON DESTRUCTIVE /

SPECIAL TESTING

HT (Hardness)

Charpy Impacts

VT (Visual Inspection)

MT (Magnetic Particle)

PT (Liquid Penetrant)

RT (Radiography)

UT (Ultrasonic)

V. PAINT, MARKING, &

SHIPPING PREPARATION

Surface Preparation / Anchor

Profile

Coating Appearance & DFT (Dry

Film Thickness)

Galvanizing

Fireproofing

Blockout Areas

Piece Marking / Tagging

Bar Code Labels

Preparation for Shipment

Ship Loose Items

c2

10% in Welds

f

f

f

f

VI. SUPPLEMENTAL

VERIFICATION (as reqd per

P.O. / Specifications)

Bolt, Nuts and Washers

Final Dimensional

f

f

Copyright 2011, Fluor Corporation. All Rights Reserved.

Supplier Quality Surveillance

Minera Yanacocha, S.R.L.

Conga Project

A3SP

Form 000.450.F2013

Date 14Oct2011

Page 3 of 3

QUALITY AND CERTIFICATION REQUIREMENTS

FABRICATED STRUCTURAL STEEL / LADDERS & PLATFORM

The Quality and Certification Requirement document provide guidelines to enable the supplier to understand the minimum

level of inspection involvement intended for the purchased equipment. The Quality and Certification Requirements are not

intended to outline all requirements for inspection and quality control as required by the purchase order, material requisition,

referenced codes, specifications and standards listed in the order requirements. Witnessed inspections, documentation

reviews, procedural compliance checks and supplemental inspections by the buyer will be conducted to ensure the

equipment's compliance with the purchase order, applicable codes, specifications and standards has been attained.

The Quality and Certification Requirement document does not imply that Fluors SQS representative will perform 100%

inspection on each listed activity or that the material or equipment will be accepted based on that assumption.

The Fluor SQS representative will issue an NCR to the seller when a product or service, presented to the Fluor SQS

representative for Fluor acceptance, fails to comply with PO (Purchase Order) quality requirements. The intent of the NCR is to

document the nonconforming condition for proper and timely disposition and to document the corresponding failure in the

supplier's quality system.

HOLD POINTS ASSOCIATED WITH REVIEW ACTIVITES WILL BE PERFORMED AT OR BEFORE FINAL RELEASE FOR SHIPMENT AND IS

NOT TO BE INTERPERTED AS AN ACTIVITY THAT HALTS MANUFACTURING.

HOLD POINTS ARE NOT INTENDED TO IMPEDE MANUFACTUERS PRODUCTION SCHEDULE PROVIDED HOLD POINT/OBSERVATION

NOTIFICATION IS PROVIDED TO FLUOR IN ADVANCE OF ACTIVITY.

SUPPLIER ACTION REQUIRED - applies to Hold and Observation columns only. Supplier is to note all 'X' marks and transfer those points

to their Inspection and Test Plans. The Fluor SQS representative will review the other action types (noted as b, c or f) with the supplier

during the Supplier Quality Alignment Meeting. These other action types are to be addressed in the Supplier's Inspection and Test Plans or

supporting Quality System.

Copyright 2011, Fluor Corporation. All Rights Reserved.

Supplier Quality Surveillance

You might also like

- 8-10370 - Flawless and Q Training - Construction MaterialsDocument50 pages8-10370 - Flawless and Q Training - Construction MaterialsNadeem JavedNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordproxywarNo ratings yet

- Welding Variables for Qualification of Base Metals and Filler MetalsDocument3 pagesWelding Variables for Qualification of Base Metals and Filler MetalsAdilMunirNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Iqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFDocument12 pagesIqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFNassim SabriNo ratings yet

- Specification and Requisition For Ball Valve: GTF-3-XXXX-XXX-XX-X-0Document13 pagesSpecification and Requisition For Ball Valve: GTF-3-XXXX-XXX-XX-X-0shyamNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Appendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Document14 pagesAppendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Jobaer ShaonNo ratings yet

- STIR (Surface Treatment Inspection) Qaqc-003Document1 pageSTIR (Surface Treatment Inspection) Qaqc-003AliDadKhanNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- Material Receiving Inspection Report: Project TitleDocument2 pagesMaterial Receiving Inspection Report: Project TitleGomathyselviNo ratings yet

- Monthly Progress Report FDRD Aug 11Document11 pagesMonthly Progress Report FDRD Aug 11Dimitri LasoNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- 4.7 Curs 2 VT - Alexandrina MihaiDocument51 pages4.7 Curs 2 VT - Alexandrina MihaiAlexandra Bolog100% (1)

- OCTGDocument1 pageOCTGMurugananthamParamasivam100% (1)

- NABL 103 Doc Chemical Testing LaboratoryDocument30 pagesNABL 103 Doc Chemical Testing LaboratoryKaushik SenguptaNo ratings yet

- Surface Preparation ReportDocument18 pagesSurface Preparation ReportSyaiful Rasyidi TamsirNo ratings yet

- Bluewater MIR Roc Master CPP IR 003 (Jun.20 PDFDocument8 pagesBluewater MIR Roc Master CPP IR 003 (Jun.20 PDFANIL PLAMOOTTIL100% (1)

- Wps 06Document2 pagesWps 06eldobie3No ratings yet

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Mukesh Shahaji More mechanical engineer resumeDocument6 pagesMukesh Shahaji More mechanical engineer resumePramod Gr100% (1)

- ACP-EU Energy Facility LVIA Shashamene Final AuditDocument3 pagesACP-EU Energy Facility LVIA Shashamene Final AuditTesfuNo ratings yet

- CSWIP-3.2.2 & API 570 - BiswajitDocument5 pagesCSWIP-3.2.2 & API 570 - BiswajitmanojNo ratings yet

- Daily Report-31 (Su Jinlong)Document3 pagesDaily Report-31 (Su Jinlong)sujinlongNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- 05 12 00 Structural Steel FramingDocument15 pages05 12 00 Structural Steel FramingAbdul RafiqueNo ratings yet

- Worksheet For Calibration CTMDocument1 pageWorksheet For Calibration CTMAnuj ShahNo ratings yet

- ការគណនាគ្រឹះជម្រៅ PDFDocument34 pagesការគណនាគ្រឹះជម្រៅ PDFMen Keo RathaNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument5 pagesTuv India Private Limited: Inspection Visit ReportAkhtar aliNo ratings yet

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- Inspection of Testing LaboratoryDocument4 pagesInspection of Testing Laboratorycristina23No ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Welding VI ProcedureDocument5 pagesWelding VI Proceduretri_bobNo ratings yet

- Metal Magnetic MemoryDocument41 pagesMetal Magnetic MemoryBogdan MunteanuNo ratings yet

- AWS Structural Welding Fabrication Quality Manual SampleDocument16 pagesAWS Structural Welding Fabrication Quality Manual SampleNithish KuttanNo ratings yet

- E-Mail Transmission: TO: Transmittal Ref. No.Document7 pagesE-Mail Transmission: TO: Transmittal Ref. No.Rahul MoottolikandyNo ratings yet

- Procurement Capacity Development PlanDocument3 pagesProcurement Capacity Development PlanErnane RitaNo ratings yet

- Inspection and Test PlanDocument5 pagesInspection and Test Planmuhammad afrizalNo ratings yet

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- TWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFDocument60 pagesTWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFRicardoSchayerSabinoNo ratings yet

- SECTION 09960 High-Performance Coatings Rev 0Document48 pagesSECTION 09960 High-Performance Coatings Rev 0rachedNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWNo ratings yet

- Variable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aDocument7 pagesVariable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aSaut Maruli Tua SamosirNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- Visual Inspection of Weld Joints Welding and NDTDocument7 pagesVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- Pipeline Welding InspectionDocument4 pagesPipeline Welding InspectionRizky TrianandaNo ratings yet

- TGN-M-02 Voltage Reducing DevicesDocument11 pagesTGN-M-02 Voltage Reducing Devicessalekojic5332No ratings yet

- ACG 22 Requirements For Lifting Equipment Inspection BodiesDocument14 pagesACG 22 Requirements For Lifting Equipment Inspection BodiesramodNo ratings yet

- Welding Log DW-CWDocument12 pagesWelding Log DW-CWhasan shahriarNo ratings yet

- Inspection and Test Plan: PT. People MecDocument3 pagesInspection and Test Plan: PT. People MecHaryanto RNo ratings yet

- QCF111 Cement Concrete Paving ReportDocument2 pagesQCF111 Cement Concrete Paving ReportminhnnNo ratings yet

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- Engineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas AlgeriaDocument3 pagesEngineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas Algeriaait.koufiNo ratings yet

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Installation Static Equipment ITPDocument3 pagesInstallation Static Equipment ITPAwais Tariq90% (10)

- Visible Dye Penetrant P101S AerosolDocument5 pagesVisible Dye Penetrant P101S AerosolEl_memitoNo ratings yet

- Ogp1 Pintura PDFDocument19 pagesOgp1 Pintura PDFEl_memito100% (1)

- Welding Procedures and Inspection Methodology For In-Service WeldingDocument14 pagesWelding Procedures and Inspection Methodology For In-Service WeldingEl_memitoNo ratings yet

- PMC14 As 0 404 4 0035Document1 pagePMC14 As 0 404 4 0035El_memitoNo ratings yet

- 02.34 25635-220-3PS-MHCB-00001 Technical PDFDocument32 pages02.34 25635-220-3PS-MHCB-00001 Technical PDFEl_memitoNo ratings yet

- 240K C2 QCR 15 007 A PDFDocument3 pages240K C2 QCR 15 007 A PDFEl_memitoNo ratings yet

- Fabrication of Structural and Miscellaneous Steel, Peruvian Package Scope of WorkDocument66 pagesFabrication of Structural and Miscellaneous Steel, Peruvian Package Scope of WorkEl_memitoNo ratings yet

- Specifications For SSDocument16 pagesSpecifications For SSpipedown456No ratings yet

- Fabrication of Structural and Miscellaneous Steel Supplier Drawing & Data Commitment (SDDC) FormDocument7 pagesFabrication of Structural and Miscellaneous Steel Supplier Drawing & Data Commitment (SDDC) FormEl_memitoNo ratings yet

- Paint Equipment Standards: Sociedad Minera Cerro Verde S.A.ADocument26 pagesPaint Equipment Standards: Sociedad Minera Cerro Verde S.A.AEl_memitoNo ratings yet

- General Site Conditions Design Criteria: Sociedad Minera Cerro VerdeDocument9 pagesGeneral Site Conditions Design Criteria: Sociedad Minera Cerro VerdeEl_memitoNo ratings yet

- Pma XT SP0012 PDFDocument25 pagesPma XT SP0012 PDFEl_memitoNo ratings yet

- 240K C2 CS 15 022 C PDFDocument23 pages240K C2 CS 15 022 C PDFEl_memitoNo ratings yet

- 240K C2 CS 15 012 C PDFDocument21 pages240K C2 CS 15 012 C PDFEl_memitoNo ratings yet

- 240K C2 CS 15 021 C PDFDocument25 pages240K C2 CS 15 021 C PDFEl_memitoNo ratings yet

- Metal Decking Construction Specification: Sociedad Minera Cerro Verde S.A.ADocument10 pagesMetal Decking Construction Specification: Sociedad Minera Cerro Verde S.A.AEl_memitoNo ratings yet

- PMC06 XT SP0012 PDFDocument6 pagesPMC06 XT SP0012 PDFEl_memitoNo ratings yet

- Workmanship Standards SummaryDocument17 pagesWorkmanship Standards SummaryEl_memito100% (1)

- Pma XT SP0012 PDFDocument25 pagesPma XT SP0012 PDFEl_memitoNo ratings yet

- ASTM 4228 - Calificacion Aplicadores de Recubrimientos PDFDocument3 pagesASTM 4228 - Calificacion Aplicadores de Recubrimientos PDFEl_memito100% (1)

- Inmaculada Technical Specifications Gen001-RevB PDFDocument6 pagesInmaculada Technical Specifications Gen001-RevB PDFEl_memitoNo ratings yet

- Pma XT SP0009 PDFDocument15 pagesPma XT SP0009 PDFEl_memitoNo ratings yet

- General Site Conditions Design Criteria: Sociedad Minera Cerro VerdeDocument9 pagesGeneral Site Conditions Design Criteria: Sociedad Minera Cerro VerdeEl_memitoNo ratings yet

- Metal Decking Construction Specification: Sociedad Minera Cerro Verde S.A.ADocument10 pagesMetal Decking Construction Specification: Sociedad Minera Cerro Verde S.A.AEl_memitoNo ratings yet

- 240K C2 CS 15 022 C PDFDocument23 pages240K C2 CS 15 022 C PDFEl_memitoNo ratings yet

- 240K C2 CS 15 021 C PDFDocument25 pages240K C2 CS 15 021 C PDFEl_memitoNo ratings yet

- 240K C2 CS 15 012 C PDFDocument21 pages240K C2 CS 15 012 C PDFEl_memitoNo ratings yet

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Document58 pagesFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000No ratings yet

- Osha 1926.452Document14 pagesOsha 1926.452Binoy GopinathanNo ratings yet

- Caterpillar 914GDocument28 pagesCaterpillar 914GForomaquinas100% (3)

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Operating Instructions, FormulaDocument35 pagesOperating Instructions, FormulaandymulyonoNo ratings yet

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Document6 pagesHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseNo ratings yet

- Lg938l - Operation & Maintenance ManualDocument114 pagesLg938l - Operation & Maintenance ManualMuhammad Nadim MakhlufNo ratings yet

- InverterDocument8 pagesInverterrajinipre-1No ratings yet

- Generation of Electrical Energy - B. R. GuptaDocument171 pagesGeneration of Electrical Energy - B. R. GuptaIbrahim Ahmed43% (23)

- Boundary Layer Thickness and Heat Transfer CalculationsDocument9 pagesBoundary Layer Thickness and Heat Transfer Calculationsannie100% (1)

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocument7 pagesPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4No ratings yet

- 6GK52160BA002AA3 Datasheet en PDFDocument6 pages6GK52160BA002AA3 Datasheet en PDFgrace lordiNo ratings yet

- Beumer - Pipeconveyor TechnologyDocument51 pagesBeumer - Pipeconveyor TechnologyAli AlatasNo ratings yet

- PVT Correlations McCain - ValkoDocument17 pagesPVT Correlations McCain - ValkoAlejandra Maleja RivasNo ratings yet

- Kepb003404 PDFDocument472 pagesKepb003404 PDFELIAS100% (1)

- Woodson Property Group's Conditional Use Permit ApplicationDocument108 pagesWoodson Property Group's Conditional Use Permit ApplicationShannon GeisenNo ratings yet

- CA2E AdminGuide ENUDocument170 pagesCA2E AdminGuide ENUomarNo ratings yet

- Anchors and Fall Arrest System A Guide To Good Practice: PublicationDocument22 pagesAnchors and Fall Arrest System A Guide To Good Practice: PublicationEdward C100% (1)

- Siremobil Compact PDFDocument108 pagesSiremobil Compact PDFhector anguiano100% (2)

- Struts by Kamalakar DanduDocument237 pagesStruts by Kamalakar DanduKamalakar DanduNo ratings yet

- PT6C-67C MM Chap 4-5Document39 pagesPT6C-67C MM Chap 4-5anony810388% (8)

- AZAR Block CostcomparisonDocument8 pagesAZAR Block CostcomparisontckittuNo ratings yet

- Inspection and Adjustment of Pump Ls ControlDocument10 pagesInspection and Adjustment of Pump Ls ControlHai Van100% (1)

- Foxpro For O LevelDocument3 pagesFoxpro For O LevelShiv PathakNo ratings yet

- TMC 421 PDFDocument82 pagesTMC 421 PDFJamie MooreNo ratings yet

- DMD Documentation Error - Freetronics ForumDocument3 pagesDMD Documentation Error - Freetronics ForumapofviewNo ratings yet

- TDS2000 Rig Systems DiagramsDocument13 pagesTDS2000 Rig Systems DiagramsBaskar KannaiahNo ratings yet

- Power Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesDocument29 pagesPower Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesPhD EENo ratings yet

- Reinforced ConcreteDocument13 pagesReinforced ConcreteRenukadevi Rpt17% (18)

- Motorola's TQM Journey to Six Sigma QualityDocument19 pagesMotorola's TQM Journey to Six Sigma QualityKatya Avdieienko100% (1)

- Strength and Insulating Properties of Building Blocks Made From Waste MaterialsDocument7 pagesStrength and Insulating Properties of Building Blocks Made From Waste Materialsmjrobust05No ratings yet