Professional Documents

Culture Documents

LNG - An Alternative To Diesel?: What Is Liquefied Natural Gas (LNG)

Uploaded by

Pankaj KambleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LNG - An Alternative To Diesel?: What Is Liquefied Natural Gas (LNG)

Uploaded by

Pankaj KambleCopyright:

Available Formats

Our energy working for you.

TM

Power topic #GLPT-5932-EN | Technical information from Cummins Power Generation

LNG - an Alternative to Diesel?

White Paper

By Keith Packham, ESB Applications Manager, Cummins Power Generation

Demand for LNG is growing globally

as its use in utility networks increases.

The infrastructure of liquefaction, large

scale sea transportation, storage

and vaporisation is also growing to

meet demand. This, together with

the clean burning image of gas, has

stimulated interest in small scale LNG

use and this should lead to a growth

in investment for distribution systems

that can start to compete with the well

established diesel distribution system.

LNG storage tanks

What is Liquefied Natural

Gas (LNG)

Natural gas is predominately made up of

Methane, but generally also contains a mixture

of longer chain Hydrocarbon compounds such

as Ethane, Propane, Butanes, Pentanes, etc. at

progressively smaller amounts. The percentage

of the longer chain compounds varies with the

specific source of the natural gas, but a typical

pipeline natural gas would be as below.

Compound Name

Formula

Volume (%)

Methane

CH4

>85

Ethane

C2H6

3-8

Propane

C3H8

1-2

Butane

C4H10

<1

Pentane

C5H12

<1

Carbon dioxide

CO2

1-2

Nitrogen

N2

1-5

Helium

He

<0.5

If this mix of compounds is reduced in

temperature, at normal atmospheric

pressure, then at approximately -165 degrees

centigrade (deg.C) the Methane will condense

out and turn to liquid, as will any other

compound that has a boiling temperature

above -165deg.C. For example, Ethane

has a boiling temperature of approximately

-89deg.C, but the boiling temperature of

Nitrogen is approximately -196deg.C.

This resultant liquid is referred to as Liquefied Natural Gas

(LNG). The volume of 1kg of natural gas is approximately

600 times the volume of 1 kg of LNG, and the latent heat

of vaporisation is approximately 512kj.

LNG Storage

Modern large LNG storage tanks are typically of the

bunded or twin walled full containment type, where

a high-nickel steel inner tank, sits inside a concrete

tank with extremely efficient insulation between them.

Large tanks are low aspect ratio (height to width) and

cylindrical in design with a domed steel or concrete

roof. The storage pressure in these tanks is very low,

less than 10 kPa.

Smaller tanks may be horizontal or vertical steel with a

vacuum jacket insulation design, and can hold higher

pressures up to approximately 1700kPa.

For LNG to remain a liquid it must be kept cold, and

this property is independent of pressure. Therefore, as

even efficient insulation will not prevent heat transfer to

the tank there will inevitably be some heat leakage into

the LNG, which will result in vaporisation of some of the

LNG. Because the change of state from liquid to gas

requires heat energy, the boil-off process draws this

energy from the liquid and keeps the LNG cold, which

in turn limits the boil off quantity. The boil-off gas can

either be used, or reliquefied and returned to the tank.

Why Use LNG

The reasons for using LNG change with the scale

of use. For example, if there is a natural gas source

which is a long distance from the point of use, it may

be cost beneficial to create LNG and transport it with

ships rather than build a pipe line.

For small scale use, other factors such as changing

emissions regulations or finding an alternative to oil

or coal take over. Therefore, if a site is considering

producing small scale on site power or heat, then the

use of LNG to replace traditional diesel fuel may be

considered.

Some benefits of using LNG:

Exhaust emissions regulations may be easier to

meet with LNG derived gaseous fuel.

Lean burn gas engines have much lower NOx

and particulate emissions than diesel engines,

and should a catalyst be necessary it will be

significantly smaller on a gas engine.

Oil based fuels may create a high risk environmental

hazard.

The storage and transfer of liquid fuel does create

a risk of spillage. The consequences of a spill will

be different, in that LNG will evaporate and create

a flammability hazard, whereas a diesel spill will

create an environmental /pollution hazard.

Delivery tanker transferring LNG to storage facility

power.cummins.com

2014 Cummins Power Generation

02 Power Topic #GLPT-5932-EN

Once the consumption rate exceeds the boil-off rate

then heat must be supplied to the LNG to produce the

gas volume required.

The cost per kWh of LNG derived gas may be less

than that of oil based fuel.

Factors to consider:

Is there a capable delivery infrastructure that can

provide the LNG?

The energy content of a cubic metre of LNG

is less than that of a cubic metre of diesel, so

the required delivery volume is greater. This will

result in more delivery cycles for the same power

output, and increase the LNG price per kWh.

The current LNG infrastructure is for large scale

liquefaction, transportation by ship and on shore

storage and vaporisation of the LNG for use in

gas utility networks.

In addition, the price of gas has generally been

artificially linked to the price of oil, and this may

make LNG less attractive to replace diesel.

Is there a cheap source of heat that can be used to

vaporise the LNG?

The ideal would be to use some of the waste

heat from the engine, for example the low grade

intercooler heat.

If the gas consumption does not exceed the boil off

rate then a liquefaction plant will be necessary to

avoid release of gas.

Environmental regulations may restrict or prohibit

the release of Methane into the environment

as it is a significant Greenhouse gas. Therefore

the operational characteristics of the site must

be carefully assessed to ensure LNG boil off is

consumed at all times.

It may be possible to use ambient heat for

vaporisation, but that will depend upon the

consumption rate.

Changes in LNG Composition

When LNG is taken from a storage tank, vaporised

and consumed, and the tank refilled, the make-up

of the gas after vaporisation can change due to

the different boiling temperatures of the constituent

compounds. This is a problem for reciprocating

engines, so the vaporisation process must ensure that

all of the constituents are vaporised at the same time.

Change in LNG composition within a container as the LNG ages due to the Methane

boiling off and being replaced with LNG of the original compositional mixture

1

0.8

0.7

0.6

0.5

This graph illustrates the concept of how the

compostion of the LNG changes over time as the

Methane preferentially boils off from external

pumps and the boil-off is replaced by fresh LNG

from the tank (which is assumed not to have

aged). The Ethane, Propane and Butane are

0.3

assumed to not be present in the boil-off gas.

Although this assumption is essentially true at high

Methane concentrations, it becomes less accurate

as the Methane concentration drops, and

correspondingly the temperature of the mixture

0.2

rises, thereby allowing the higher hydrocarbons to

become signicant contributors to the boil-off gas.

0.4

0.1

0

Time

Methane mole fraction

Ethane mole fraction

Propane mole fraction

Butane mole fraction

power.cummins.com

2014 Cummins Power Generation

03 Power Topic #GLPT-5932-EN

Mole fraction of components

0.9

About the author

Keith Packham started out as a marine

engineer working in the UK Merchant Navy.

He is now ESB Applications Manager for

Cummins Power Generation, and provides

expert technical advice and support to the

global Energy Solutions Business team

on the design, installation and operation

of energy efficient plants. He has been

involved with the design, installation, maintenance,

and operational aspects of combined heat and power

(CHP) plants, boiler plants for steam or hot water,

power generation and distribution, refrigeration, water

and effluent treatment plants and their optimum

performance. He holds a Bachelors degree in Energy

Engineering from Southbank University in England.

Conclusion

Demand for LNG is growing globally as its use in

utility networks increases. The infrastructure of

liquefaction, large scale sea transportation, storage

and vaporisation is also growing to meet demand.

This, together with the clean burning image of gas,

has stimulated interest in small scale LNG use and this

should lead to a growth in investment for distribution

systems that can start to compete with the well

established diesel distribution system.

power.cummins.com

2014 Cummins Power Generation Inc.

All rights reserved. Cummins Power Generation

and Cummins are registered trademarks of

Cummins Inc. Our energy working for you.

is a trademark of Cummins Power Generation.

GLPT-5932-EN

04 Power Topic #GLPT-5932-EN

For more information, visit power.cummins.com

or email energysolutions@cummins.com

You might also like

- Underground Gas Storage Facilities: Design and ImplementationFrom EverandUnderground Gas Storage Facilities: Design and ImplementationNo ratings yet

- Next Generation OnShore LNG Plant DesignsDocument18 pagesNext Generation OnShore LNG Plant Designsdigeca50% (2)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Methanol Plant Process Description LurgiDocument6 pagesMethanol Plant Process Description LurgiGaukharAlzhanova0% (1)

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- CNG LCNG HCNGDocument29 pagesCNG LCNG HCNGShrey SimediyaNo ratings yet

- Syngas: Synthetic Gas Synthesis Gas Wood Gas Pyrolysis Gas Producer GasDocument4 pagesSyngas: Synthetic Gas Synthesis Gas Wood Gas Pyrolysis Gas Producer GasConstantin StanNo ratings yet

- Nathalie MillotDocument10 pagesNathalie MillotAnastasia YuandyNo ratings yet

- Clarke Energy - SyngasDocument3 pagesClarke Energy - SyngasAnthony Carr100% (1)

- Fluor LNGRegasificationUtilizationDocument20 pagesFluor LNGRegasificationUtilizationMahesh DivakarNo ratings yet

- Technical Paper On Power Plant Energy Savings (Bee Issue # Ee28)Document15 pagesTechnical Paper On Power Plant Energy Savings (Bee Issue # Ee28)sureshNo ratings yet

- Cryocar ReportDocument10 pagesCryocar ReportTharun Kaushik VP100% (1)

- LNG Process Selection Considerations For Future DevelopmentsDocument9 pagesLNG Process Selection Considerations For Future Developmentsromdhan88No ratings yet

- Deploying Gas Power With CCS: The Role of Operational Flexibility, Merit Order and The Future Energy SystemDocument25 pagesDeploying Gas Power With CCS: The Role of Operational Flexibility, Merit Order and The Future Energy SystemZeSnexNo ratings yet

- Energy MixDocument10 pagesEnergy MixPara DiseNo ratings yet

- JSW Steels LimitedDocument18 pagesJSW Steels Limitedrinkal_143No ratings yet

- Report On CNGDocument17 pagesReport On CNGAjay JhaNo ratings yet

- Comparison of Present Day Peakshaving Liquefaction TechnologiesDocument18 pagesComparison of Present Day Peakshaving Liquefaction Technologiesfericoolabiss100% (1)

- Boil-Off Gas Handling Onboard LNG Fuelled ShipsDocument6 pagesBoil-Off Gas Handling Onboard LNG Fuelled ShipsPutu Indra Mahatrisna100% (1)

- Evaluating Hydrogen Rich Fuel Gas FiringDocument4 pagesEvaluating Hydrogen Rich Fuel Gas FiringVenkatesh Kumar RamanujamNo ratings yet

- Liquefaction Technology Selection For Baseload LNG PlantsDocument6 pagesLiquefaction Technology Selection For Baseload LNG Plantsbaiju79No ratings yet

- Innovations To Reduce Cost and Schedule For Small-Scale LNG: J. Voda, F. Chen and A. GarciaDocument5 pagesInnovations To Reduce Cost and Schedule For Small-Scale LNG: J. Voda, F. Chen and A. GarciadevakimdNo ratings yet

- AmmoniaDocument8 pagesAmmoniakrishna_pipingNo ratings yet

- UK's Gasconsult ZR-LNG Liquefaction TechnologyDocument5 pagesUK's Gasconsult ZR-LNG Liquefaction TechnologyamirlngNo ratings yet

- Flare Gas Capture For LNG ProductionDocument9 pagesFlare Gas Capture For LNG ProductionKommu RohithNo ratings yet

- Adapting Boilers To Utilize Landfill GasDocument4 pagesAdapting Boilers To Utilize Landfill GasAnonymous MVHQ97KEoPNo ratings yet

- Selected Problems of Boil-Off Gas Utilization On LNG CarriersDocument8 pagesSelected Problems of Boil-Off Gas Utilization On LNG CarriersJuan Diego Guerrero MateoNo ratings yet

- LNG - Gas Combustion UnitsDocument13 pagesLNG - Gas Combustion UnitsmorgothsNo ratings yet

- PDFDocument15 pagesPDFJohansen HasugianNo ratings yet

- Liquefied Natural GasDocument7 pagesLiquefied Natural GasAkash BhudyeNo ratings yet

- 3.2.1.4.1-1 Trapped Vortex CombustionDocument9 pages3.2.1.4.1-1 Trapped Vortex Combustiontesfaye awelNo ratings yet

- Hydrogen Production by Steam Reforming of HC by TopsoeDocument2 pagesHydrogen Production by Steam Reforming of HC by TopsoeMainak Sarkar100% (1)

- Benefits of Integrating NGL Extraction and LNG RecoveryDocument8 pagesBenefits of Integrating NGL Extraction and LNG RecoveryEdgar HuancaNo ratings yet

- Combined Power PlantDocument10 pagesCombined Power PlantManoj SunchauriNo ratings yet

- Futtsu Power PlantDocument49 pagesFuttsu Power PlantJericho CruzNo ratings yet

- 30 Naphtha Firing in Gas Turbines PDFDocument10 pages30 Naphtha Firing in Gas Turbines PDFcynaidu100% (2)

- Reciprocating Generator Sets A Viable Choice in Sustainable Energy LEXE0046-01Document9 pagesReciprocating Generator Sets A Viable Choice in Sustainable Energy LEXE0046-01sdiamanNo ratings yet

- Topsoe Methanol Coal Gasification Paper - AshxDocument3 pagesTopsoe Methanol Coal Gasification Paper - AshxAde RahmadiNo ratings yet

- LNG Reliquefaction Systems2Document14 pagesLNG Reliquefaction Systems2123habib123fikriNo ratings yet

- About LNGDocument22 pagesAbout LNGAnjar Banjar100% (1)

- CDU Enhance Energy EfficiencyDocument5 pagesCDU Enhance Energy Efficiencyrvkumar61100% (2)

- Integrated Gasification Combined Cycle (Igcc) : CharacteristicsDocument4 pagesIntegrated Gasification Combined Cycle (Igcc) : CharacteristicsDanielNo ratings yet

- Course On LNG Business-Session3Document28 pagesCourse On LNG Business-Session3Rahul AtodariaNo ratings yet

- Man CHP: Decarbonizing With Combined Heat and Power For Industrial ApplicationsDocument14 pagesMan CHP: Decarbonizing With Combined Heat and Power For Industrial Applicationsmanpreet singhNo ratings yet

- Position-Paper: Information About The Use of LNG As Engine FuelDocument3 pagesPosition-Paper: Information About The Use of LNG As Engine FuelАндрейNo ratings yet

- LNG As Fuel - Bunkering, Storage and Processing: Jürgen HarperscheidtDocument2 pagesLNG As Fuel - Bunkering, Storage and Processing: Jürgen HarperscheidtB6D4N0No ratings yet

- Agitation ReviewDocument9 pagesAgitation ReviewPurushottam Karthik JanaswamyNo ratings yet

- Aeroderivative Gas Turbine FinalDocument16 pagesAeroderivative Gas Turbine Finaldylan_dearing@hotmail.comNo ratings yet

- Let Me Explain Issues Related To LNG in Question and Answer FormDocument23 pagesLet Me Explain Issues Related To LNG in Question and Answer Formashdimri100% (6)

- Assignment On Natural GasDocument7 pagesAssignment On Natural GasDonald Oseghale OkohNo ratings yet

- Manage TEG Liquid and Corrosion in Sales Gas Pipelines PDFDocument7 pagesManage TEG Liquid and Corrosion in Sales Gas Pipelines PDFfhtgerthrgergNo ratings yet

- Collodi Ref.9Document4 pagesCollodi Ref.9Josiph BukairNo ratings yet

- LNG 3 3 e 11 150dpi NB19 15617Document24 pagesLNG 3 3 e 11 150dpi NB19 15617Pawan ChaturvediNo ratings yet

- Course On LNG Business-Session12Document31 pagesCourse On LNG Business-Session12Rahul Atodaria100% (2)

- Gaseous FuelsDocument2 pagesGaseous FuelsSree MurthyNo ratings yet

- Alternative Fuel Systems - CNG 101: Natural Gas As A Motor FuelDocument2 pagesAlternative Fuel Systems - CNG 101: Natural Gas As A Motor FuelBelma Hajdarevic-PecarNo ratings yet

- Cryocar Report EditedDocument18 pagesCryocar Report EditedAjish S Ashok100% (1)

- RedBus Ticket TK4584488458 BNG To Mum 7th MarchDocument2 pagesRedBus Ticket TK4584488458 BNG To Mum 7th MarchPankaj KambleNo ratings yet

- RAABTA - Ik Vaari Aa Chords and Lyrics - ChordZoneDocument2 pagesRAABTA - Ik Vaari Aa Chords and Lyrics - ChordZonePankaj KambleNo ratings yet

- Saarang TicketsDocument3 pagesSaarang TicketsPankaj KambleNo ratings yet

- Brochure Engine 51-60GDocument7 pagesBrochure Engine 51-60GAnonymous 0irJN2UINo ratings yet

- TSI Rotostat Profile Latest1Document39 pagesTSI Rotostat Profile Latest1Pankaj KambleNo ratings yet

- SFGLD480Document2 pagesSFGLD480Pankaj KambleNo ratings yet

- 5160DF PowerDocument7 pages5160DF PowerPankaj Kamble100% (1)

- SFGLD360Document2 pagesSFGLD360Pankaj KambleNo ratings yet

- SFGLD240Document2 pagesSFGLD240Pankaj KambleNo ratings yet

- SFGLD560Document2 pagesSFGLD560Pankaj KambleNo ratings yet

- Biomass Syngas Generator 68Document1 pageBiomass Syngas Generator 68Pankaj KambleNo ratings yet

- Datasheet of MWM-DeUTZ Gas Generator EM-1250NDocument1 pageDatasheet of MWM-DeUTZ Gas Generator EM-1250NPankaj KambleNo ratings yet

- EP 4page BrochureREV2013Document2 pagesEP 4page BrochureREV2013Pankaj KambleNo ratings yet

- Lexe8179 02Document2 pagesLexe8179 02Pankaj KambleNo ratings yet

- MWM DEUTZ Natural Gas Generator 63Document1 pageMWM DEUTZ Natural Gas Generator 63Pankaj KambleNo ratings yet

- LEXE0839 00 - 1 UDocument2 pagesLEXE0839 00 - 1 UPankaj KambleNo ratings yet

- g3520c Im Natural Gas For 1966Document6 pagesg3520c Im Natural Gas For 1966Pankaj KambleNo ratings yet

- Payment Advice Outward Telegraphic Transfer: DateDocument2 pagesPayment Advice Outward Telegraphic Transfer: DateRomanov DalsheNo ratings yet

- Zypper Cheat Sheet 2Document1 pageZypper Cheat Sheet 2norbulinuksNo ratings yet

- New DatabaseDocument18 pagesNew DatabaseShafiq RosmanNo ratings yet

- Revista Stiinte Politice Issue 42Document264 pagesRevista Stiinte Politice Issue 42Costel111No ratings yet

- Automotive Engg. & TechnologyDocument15 pagesAutomotive Engg. & TechnologysayuuishotNo ratings yet

- Atoll 3.3.2 Technical Reference Guide RadioDocument912 pagesAtoll 3.3.2 Technical Reference Guide Radioratelekoms100% (4)

- Lesson 1 DataDocument4 pagesLesson 1 Dataapi-435318918No ratings yet

- Contamination ControlDocument5 pagesContamination ControlPadmanabhan DhanasekaranNo ratings yet

- Promt MidjourneyDocument2 pagesPromt MidjourneyMarcelo PaixaoNo ratings yet

- BS en 00480-6-2005 PDFDocument8 pagesBS en 00480-6-2005 PDFShan Sandaruwan AbeywardeneNo ratings yet

- Ahsmrw30dam SD101Document48 pagesAhsmrw30dam SD101ibrahimNo ratings yet

- SFP Module PDFDocument2 pagesSFP Module PDFMario PatarroyoNo ratings yet

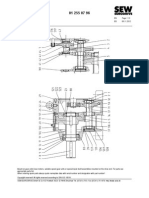

- Parts List 01 255 07 96: Helical Gear Unit R107Document3 pagesParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Operaional Manual: YZBF-120LDDocument16 pagesOperaional Manual: YZBF-120LDMohamed AnwarNo ratings yet

- OC Thin Shell Panels SCREENDocument19 pagesOC Thin Shell Panels SCREENKushaal VirdiNo ratings yet

- Project TemplatesDocument64 pagesProject TemplatesMahad AbdiNo ratings yet

- kp-57-65wv600 SONYDocument33 pageskp-57-65wv600 SONYdjcamdtvNo ratings yet

- Getting Started With DockerDocument8 pagesGetting Started With DockerdenisaNo ratings yet

- Chapter 19 Malicious LogicDocument16 pagesChapter 19 Malicious LogicAnita Sofia KeyserNo ratings yet

- Abstract Superstructure Conc - Frame WestgateDocument2 pagesAbstract Superstructure Conc - Frame WestgateTashamiswa MajachaniNo ratings yet

- LAB3Document5 pagesLAB3Kaishavi UmrethwalaNo ratings yet

- EE 303 Tutorial 1Document19 pagesEE 303 Tutorial 1Syama SameekshaNo ratings yet

- Senses of Success and The Rise of The Blockbuster by Charles AclandDocument9 pagesSenses of Success and The Rise of The Blockbuster by Charles AclandMittsouNo ratings yet

- Database Testing: Prepared by Sujaritha MDocument21 pagesDatabase Testing: Prepared by Sujaritha Mavumaa22No ratings yet

- Coal JourneyDocument2 pagesCoal JourneyasnandyNo ratings yet

- 7.sieve Analysis AhmedDocument9 pages7.sieve Analysis AhmedJin AhmedNo ratings yet

- HPB Install Manual ABB - Distribution BUS BarsDocument11 pagesHPB Install Manual ABB - Distribution BUS BarsArunallNo ratings yet

- Frequency Control On An Island Power System With Evolving Plant MixDocument221 pagesFrequency Control On An Island Power System With Evolving Plant MixKing KingNo ratings yet

- Project Goals/ ObjectivesDocument51 pagesProject Goals/ ObjectivesJoyce Abegail De PedroNo ratings yet

- Internship Report (EWSD)Document23 pagesInternship Report (EWSD)Spartacus GladNo ratings yet