Professional Documents

Culture Documents

Application of Two Methods To Evaluate Matrix Acidizing Using Real-Time Skin Effect in Saudi Arabia - SPE 73703, 2002

Uploaded by

alizareiforoushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Two Methods To Evaluate Matrix Acidizing Using Real-Time Skin Effect in Saudi Arabia - SPE 73703, 2002

Uploaded by

alizareiforoushCopyright:

Available Formats

SPE 73703

Application of Two Methods to Evaluate Matrix Acidizing Using Real-Time Skin Effect

in Saudi Arabia

A.M. Al-Dhafeeri, SPE, T.W. Engler, SPE, New Mexico Tech., H.A. Nasr-El-Din, SPE, Saudi Aramco

Copyright 2002, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the SPE International Symposium and Exhibition

on Formation Damage Control held in Lafayette, Louisiana, 2021 February 2002.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300

words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

The effectiveness of acid treatment is commonly evaluated by

a reduction in skin factor determined through pre-and/or postwell test analysis. However, mathematical models have been

developed to monitor the change in skin while injecting acid

and therefore obtaining real time skin values. This work

demonstrates the application of monitoring real change in skin

effect during the acid treatment with several field examples in

carbonate formation.

Two real-time monitoring methods1,2 were used to capture

the effect of treating fluids on the formation. The field

applications using the two methods were conducted on two

water injectors in Saudi Arabia to evaluate stimulation

performance with in-situ Gelled Acid systems. From the

calculated bottomhole pressure and injection rate, skin effect

was determined as a function of time. In this manner, the

effectiveness of acid injection into the formation

was estimated.

The Paccalonis method, which is a direct result of the

steady state assumption, was conducted to monitor the skin

factor during the acid job. The second method, by Prouvost

and Economides was also used to illustrate the effect of the

treating fluid on formation damage, but is based on transient

flow equations. Both methods can readily be included in acid

treatment monitoring; however, the latter method is preferred

due to the better agreement in the field cases.

This study provides a field application comparing the two

methods and demonstrates the ability to capture the effect of

diversion when the gelled acid increased viscosity in the

formation by a subsequent increase in skin, and also the

cleanup (decrease skin) that occurred when the regular acid

reacts with the formation. This study also helps field

engineers to ensure that no damage remains and no excessive

acid is injected. The benefits of applying these two methods

result not only in an operation cost reduction but also in a

higher return on the stimulation investments.

Introduction

The purpose of matrix treatment is to remove the damage

around the wellbore, therefore, the acid treatment should flow

through the porous rock matrix. To insure this goal, the

injection pressure must be adjusted to avoid formation

fracturing. In matrix acidizing treatments, it is extremely

important that the variations in skin effect are calculated

during the progression of an acid treatment on-site. The

application of a real-time technique to determine the skin

effect during matrix treatment would help in evaluating

stimulation performance and optimizing the treatment, as well

as any upcoming treatment in the same area. The methods

adopted in this study for accomplishing this real time

monitoring utilize the continuous measured bottomhole

pressure and acid injection rate during the course of the acid

treatment. Previous methods calculate the skin effect by using

pressure buildup or falloff techniques. By applying the real

time monitoring technique to evaluate an acid treatment on

site, the effectiveness of the acid treatment can be assessed to

ensure that the acid is removing the damage from the

formation and no excess acid is being injected.

This paper proposes the use of real-time matrix acidizing

data in conjunction with real-time calculations. Benefits from

this work are the ability to monitor treatment performance and

make design modifications for future acid treatments in the

same formation. By providing the engineer with commonly

acquired information about the status of the treatment on-site,

the engineer has the ability to follow up and make an

appropriate decision regarding well treatment.

The objective of measuring the efficiency of an acid job is

to prove that the technical and economic components have

been completed. For many years, the only means to evaluate

the efficiency of an acidizing job on a production well was by

measuring the increase in the production rate or the

productivity index (PI). Acid stimulation is considered one of

A.M AL-DHAFEERI, T.W. ENGLER, H.A NASR-EL-DIN

the ultimate techniques for increasing productivity and

recovery from the entire exposed pay zone.

In this paper, application of two methods was used to

evaluate the acid treatment on-site using real-time skin effect

evolution technique. Both steady state and transient solutions

were applied on two-field cases from Saudi Arabia. Values of

the reservoir parameters, bottomhole treating pressure, and

injection rates are required for either method to produce

reasonably accurate skin effect values.

Fundamentals of Skin Effect Calculation

The skin effect has various meanings and uses. This value can

be calculated during the acid treatment, providing a

quantitative measure of the effectiveness of the overall job,

and whether to stop the treatment with zero skin factor or a

negative value of skin. The observation of skin trend can be

also be used to modify the program of acid treatment from the

original design based on the response of the well. For

example, if the skin value has become stable, there is no need

to add more acid because no benefit would be gained by

injecting the entire designed volume.

Skin effect measurement may be recorded during the

course of an acid treatment in order to assess the effect of the

fluid stages individually. This information could be used as a

reference for changing the stimulation fluid or the volumes

applied on following treatments. In addition, it could also be

used to evaluate the effectivness of diverting stages required to

distribute the treating fluid more uniformly across the

damage intervals.

Real-Time Skin Monitoring Techniques

Several techniques for real-time evaluation of matrix acidizing

have been presented over the years.1-3 Real-time monitoring of

the acidizing process has been shown to be an effective means

of optimizing matrix acidizing treatments, especially to help

the engineer in the field to determine when a sufficient volume

of acid has been injected. The real-time measuring concept is

based on the instantaneous injection rate and the

corresponding bottomhole pressure during acid pumping, from

which the evolving skin is determined during the course

of treatment.

Paccaloni1 presented a monitoring technique based on

steady-state Darcy flow during the course of an acid treatment.

Paccaloni assumed an acid bank radius, rb, of 4 ft to simplify

the calculations. Unfortunately, the majority of the pressure

drop occurs within this radius; therefore, this assumption leads

to an overestimation of the skin effect. In this work,

Paccalonis method was used to test the method's accuracy.

Paccaloni calculated steady-state skin factor according to:1

S (t ) =

r

0.00708khp

+ ln b

re

.q i

(1)

Prouvost and Economides2 presented an improved method

to determine the changing skin factor during matrix acidizing.

SPE 73703

They simulated the transient pressure response that would

occur with the injection rate schedule used during the

treatment. The difference between the actual bottomhole

pressure during the treatment and simulated pressure is

attributed to skin factor. This technique can be applied as a

real-time monitoring method to calculate the skin factor

during the course of an acid treatment on site.

The method considers the pressure transient analysis

under infinite acting boundary and initial conditions:4

4kt

p(r , t ) = pi

ln

2

4kh

c r

t w

qi

(2)

Including skin effect and modifying to acid injection, the

equation becomes:4

p sim = pi +

162.6qi B

k

log t + log

3.2275 + 0.87 S o

2

kh

c r

t w

(3)

After changing the injection rate, the transient response would

follow a superposition relationship; the injection pressure for

one rate change would be:

p

162.6q B

k

i

log(t + t ) + log

3.2275 + 0.87 S +

o

2

kh

c r

t w

162.6 q q B

k

i2

i i

log t + log

3.2275 + 0.87 S o

2

kh

ct rw

= p +

sim

i

(4)

The difference between the simulated pressure and the

measured value is interpreted as due to the difference between

the actual skin value and the initial value used for

the simulation:2

S (t ) = S +

o

kh

p

(t ) p

(t , S ) (5)

meas

sim

o

5

2.34 x10 q i B

Field Cases Study

The real-time monitoring methods were applied for two power

water injectors in Saudi Arabia to evaluate stimulation

performance. The ultimate goal of the study is to optimize

subsequent treatments in the same field. Values of the

reservoir parameters, bottomhole treating pressure, and

injection rate are required for either calculation method to

produce reasonably accurate estimations of the skin effect.

Well Description

A large carbonate reservoir in Saudi Arabia has been

undergoing water injection to maintain the pressure and to

increase the sweep efficiency. Two power water injection

wells were selected as examples to verify this work. The two

SPE 73703

APPLICATION OF TWO METHODS TO EVALUATE MATRIX ACIDIZING USING REAL-TIME SKIN EFFECT IN SAUDI ARABIA

wells are vertical with 6 openhole completions over an

interval of nearly 200 ft. Wellbore volumes are 300 to 400

barrels. The reservoir contains 20 to 75 wt% dolomite, with a

permeability range of 50 to 100 md and a porosity varying

from 10 to 15%. The temperature of the formation is 100 to

120oF. Table 1 gives the chemical analysis of the treated

seawater, which is used for the injection.5

Treatment Description

The treatment objective was to remove the damage near the

wellbore in the openhole section. Acid distribution has a

strong impact on the performance of the stimulation treatment;

therefore the formation was treated with alternating stages of

regular acid (15 wt%) HCl and in-situ gelled acid. Increasing

the acid viscosity in-situ resulted in a high efficiency of acid

diversion into the formation. In contrast, injecting a regular

acid (15% HCl) in the treatment without using in-situ gelled

acid results in poor acid distribution and less depth of

penetrating wormholes into the formation. Table 2 presents

the analysis of field mixing water, which was used as a

preflush and overflush in order to displace the matrix acid into

the formation.

Well A

Well A is a water-injection well located in Saudi Arabia. This

well was completed with 202 feet of open hole into a

limestone zone. Well A was damaged since the beginning of

injection and the acid treatment was proposed to restore the

injectivity. A pre-stimulation well test confirmed the damage

condition with a skin value of +4.5. This well was treated with

a total of 249 bbls of 15wt% regular acid (HCl) and 213 bbls

of in-situ gelled acid at an injection rate of 25 bpm. Table 3

shows the treatment program for well A.

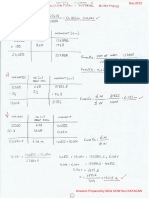

Figure 1 shows the skin values during the acid treatment

as calculated by both modified Paccalonis Technique and

Prouvoust & Economides Technique. The value of the initial

skin effect, So, as calculated by the modified Prouvost &

Economides Technique was 4, while the value obtained

through modified Paccalonis Technique was 6.3. It appears

that the steady-state pressure calculation method of the

modified Paccalonis Technique results in an over prediction

of the true skin effect during the entire course of injection.

This is because the steady-state pressure drop has a value

higher than the pressure drop in the infinite-acting transient

pressure. In this case, it is clear that the measurement by

transient pressure assumption was close to the actual

calculation by well testing. The progression of the curve of

skin effect by modified Paccalonis method shows that the

damage started to decline slowly, but by midtreatment (Stages

2, 4, and 6), it exhibited an upward trend indicating the acid

was damaging the formation. Damage associated with gelled

acid was caused by the change in injected fluid viscosity as it

entered the formation. This increase in fluid viscosity caused

a precipitate to form when the pH value increased as the acid

reacted with the formation, resulting in cross-linking of the

polymers. Moreover, the polymer present in the in-situ gelled

acid can form an external filter cake that causes a skin effect

increase.

This damage can be observed in the skin

calculations from the steady-state equations6.

The modified Prouvost & Economides Technique was

also able to predict the change of skin effect during the acid

treatment. For example, in stages 2,4, and 6, an increase in the

skin effect due to the cross-linking reaction was observed.

This increased skin effect was then removed by injecting the

15 wt% HCl into the formation, as seen by the decrease in skin

effect in stages 3, 5, and 7.

Figure 2 shows the calculated bottomhole pressure and

injection rate recorded by the service company during the

treatment. It indicates that an increase in bottomhole pressure

during the entire acid treatment occurred when in-situ gelled

acid was injected into the formation. For the majority of the

treatment, the calculated bottomhole pressure was maintained

between 3800 psi and 4700 psi by either increasing or

decreasing the injection rate. It is interesting to note that as

the flow rate remains constant, the bottomhole

pressure increases.

Figure 3 shows the difference in calculated skin effects

between the two modified methods during the treatment.

From the figure, it can be observed that the difference in

calculated skin effects ranges mostly between 1.5 and 2.5.

This difference in calculated skin effect arises from the fact

that Paccalonis method assumes a steady-state pressure

behavior while the original Prouvosts method assumes a

transient pressure behavior.

Well B

Well B is a water-injection well located in Saudi Arabia. Well

B was open hole completed with a 236 ft limestone injection

zone. This well was treated with a total of 314 bbls of 15 wt%

HCl and 214 bbls of in-situ gelled acid. The original acid

treatment program for this well can be found in table 4. The

initial skin effect before conducting the acid treatment was

+10. This value was obtained through well test analysis

before the acid treatment. This high value of skin effect

indicated that well B had severe formation damage.

Figure 4 illustrates the progression of the skin effect

during the course of the acid treatment. The initial value of

skin started with a value of 15.24 by modified Paccalonis

Technique and 10.1 by modified Prouvost & Economides

Technique. The actual value of skin, which was measured by

well testing analysis before the acid treatment, was 10.

Therefore, it is in agreement with the modified Prouvost &

Economides Technique. The results from this technique

matched the well testing results because the transient pressure

response is accounted for in the modified Prouvost &

Economides Techique. The periods of increasing skin effect

were due to the formation of gelled acid (stages 2, 4, 6) in the

formation. The increased viscosity of the gelled acid due to

the cross-linking reaction resulted in the treating fluid being

more uniformly distributed across the damaged intervals.

Diversions in this treatment were effective, as indicated by the

apparent skin effect increasing after each injection of the

diverting agent. This increased skin effect was then removed

by introducing the 15 wt% HCl into the formation, as seen by

A.M AL-DHAFEERI, T.W. ENGLER, H.A NASR-EL-DIN

the rapid decrease in skin effect in stages 3, 5, and 7 in figure

4. The reduction of skin effect is a result of the HCl

dissolving the cross links in the gel. In stage 7, the removal of

damage was immediate and dramatic. The skin effect value

dropped to 1.2. The rate of the damage removal during this

stage indicated that the formation damage in this well was

localized in the very near wellbore region, within several

inches into the formation.

It is observed from the response curve in Figure 4 that the

damage mechanism was clearly dissolved by the HCl in stage

7. It reached a minimum skin value of 1.2. However, the skin

effect value increased in stage 8 when the UER water was

introduced. The main reason for the increase of skin effect in

stage 8 was due to the incompatibility of UER water with the

formation water.

This incompatibility resulted in the

deposition of scale in the formation. Although the acid

volume used in stage 7 was sufficient to remove the near

wellbore damage, the use of the UER water resulted in redamaging of the formation. It is likely that the damage could

have been avoided by using an overflush that matched the

formation water composition. This example demonstrates the

ability of the two methods to provide real-time skin effect

calculations and also to show the effect of the treating fluid on

the formation.

Figure 5 shows the flow rate and the bottomhole pressure

during real-time monitoring of the acid treatment. The service

company provided this record. The flow rate profile did not

change significantly during the acid treatment. Figure 5

shows that the flow rate profile remained between 15 and 25

bbls/min. The result from the injection rate was more reliable.

A direct relationship exists between the bottomhole pressure

and injection flow rate.

Figure 6 shows the difference in calculated skin effects

between the two modified methods during the real-time

monitoring of the treatment. It can be observed that the

difference in calculated skin effects remains at an average

value of nearly 3. As previously stated, this difference in

calculated skin effect arises from the fact that Paccalonis

method assumes a steady-state pressure behavior while

Prouvosts method assumes a transient pressure behavior.

Conclusions

The results obtained from the study can be summarized as

follows:

1. An application of real-time monitoring of skin effect has

been developed to help operations in the field.

2. Two methods permit a continuous measurement of skin

effect, however, the steady-state calculation consistently

yields an overprediction of the skin effect during the acid

treatment.

3. By monitoring skin throughout the acid treatment, it is

possible to identify particular fluids (or stages), which are

incompatible with the reservoir as evidenced by increasing

skin trend.

4. The effectiveness of diversion techniques during a

multistage treatment can be evaluated and modified for

future applications.

SPE 73703

Acknowledgments

The authors would like to thank Dr. Geir Hareland for his

guidance and useful discussions. Thanks are also due to the

professional and technical staff of the Department of

Petroleum Engineering at New Mexico Tech. The authors

appreciate the great efforts and contribution made by Saudi

Aramco (R&D Center).

References

1. Paccaloni, G.: New Method Proves Value of Stimulation

Planning, OGJ. (Nov. 26, 1979) 61-65.

2. Prouvost, L.P., and Economides, M.J.; Application of

Real-Time Matrix Acidizing Evaluation Method, Paper

SPE 17155 (November 1989) 401-7.

3. Mcleod, H.P. and Coulter, A.W.: The Stimulation

Treatment Pressure Record-An Overlooked Formation

Evaluation Tool, JPT (August 1969) 952-960.

4. Earlougher, R.C.: Advances in Well Test Analysis, SPE

Monograph Volume 5, Dallas, TX (1977) Chap. 2.

5. Taylor, K.C. and Nasr-El-Din, H.A.: Flowback Analyiss

of Acid Stimulation of Seawater Injection Wells: Case

Histories paper SPE 58736 presented at the 2000 on

Formation Damage held in Lafayatte, Lousiana, 23-24

February.

6. Lynn, J.D. and Nasr-El-Din, H.A.: A Core Based

Comparison of the Reaction Characteristics of Emulsified

and In-Situ Gelled acid in Low Permeability, High

Temperature, Gas Bearing Carbonates paper SPE 65386

presented at the 2001 Oilfield Chemistry, held in Houston,

Texas, 13-16 February.

Nomenclature

B

= Formaton volume factor, rbbl/stb

BHP = Bottomhole pressure, psi

ct

= Total compressibility, psi-1

h = Reservoir thickness, ft

=

Intial reservoir pressure, psi

pi

pmeas =

Measured bottomhole injection pressure, psi

psim =

Simulated pressure response, psi

qi

=

Injection rate,bpm

rb

=

Acid bank radius, ft

re

=

Effective wellbore radius, ft

S

=

Skin factor , dimensionless

So : =

Initial skin factor, dimensionless

t = Time, hour

p = Difference pressure between intial reservoir

pressure and well flowing pressure, psi

t = Time difference, hour

= Acid viscosity, cp

= Porosity, fraction

= Euler constant

SPE 73703

APPLICATION OF TWO METHODS TO EVALUATE MATRIX ACIDIZING USING REAL-TIME SKIN EFFECT IN SAUDI ARABIA

Table 1: Typical Chemical Analysis of Treated

Seawater Used for Injection 5

Table 2: Analysis of Field Mixing Water for Two

wells5

Variable

Sodium, mg/L

Calcium, mg/L

Magnesium, mg/L

Sulfate, mg/L

Chloride, mg/L

Carbonate, mg/L

Bicarbonate, mg/L

Total dissolved solids, mg/L

pH

Density, g/cm3 at 60 oF

Iron, mg/L

Variable

Bicarbonate, mg/L

Calcium, mg/L

Carbonate, mg/L

Hydroxide, mg/L

Magnesium, mg/L

Sodium, mg/L

Chloride, mg/L

Sulfate, mg/L

Total dissolved solids, mg/L

Density @60 oF, g/cm3

pH

Total dissolved iron, mg/L

Conductivity @ 25oC,

micromhos

Value

16,870

700

2,040

4,150

30,040

0

160

53,960

7.5

1.0418

<0.01

Table 4: Treatment Program for Well B.

Table 3: Treatment Program for Well A.

Stage

No.

1

2

3

4

5

6

7

8

9

Fluid Type

Pre-flush

Field Mixing

Water

In-Situ

Gelled Acid

15 wt% HCl

Acid

In-Situ

Gelled Acid

15 wt% HCl

Acid

In-Situ

Gelled Acid

15 wt% HCl

Acid

Overflush

Field Mixing

Water

Displacement

Total

15 wt% HCl

Total In-Situ

Gelled Acid

= 249

bbls

Acid =

213

bbls

Pre-flush

Stage

No.

1

12.4

Diverter

71

14.9

71

14.9

Acid

Treatment

Diverter

83

17.4

83

17.4

Acid

Treatment

Diverter

95

20

Acid

Treatment

Overflush

Displacement

(Sea water)

Volume

(bbls)

230

Volume

(Gal/ft)

59

100

190

52.3

gal/ft

44.7

gal/ft

Remarks

Value

210

137

0

0

48

210

371

270

1257

1.0011

8

1

2040

Fluid Type

Pre-flush

Field Mixing

Water

In-Situ

Gelled Acid

15 wt% HCl

Acid

In-Situ

Gelled Acid

15 wt% HCl

Acid

In-Situ

Gelled Acid

15 wt% HCl

Acid

Overflush

Field Mixing

Water

Displacement

Volume

(bbls)

300

Volume

(Gal/ft)

Remarks

60

12.4

Diverter

71

14.9

71

14.9

Acid

Treatment

Diverter

83

17.4

83

20

Pre-flush

95

Acid

Treatment

Diverter

Acid

Treatment

Overflush

100

389

Displacement

(Sea water)

Total

15 wt%

HCl

=

314 bbls

56.4

gal/ft

Total In-Situ

Gelled Acid

Acid =

214 bbls

38.4

gal/ft

A.M AL-DHAFEERI, T.W. ENGLER, H.A NASR-EL-DIN

Fig. 1: Real-Time Monitoring of Matrix Acidizing in Well A.

Fig. 3: The Difference in Skin values Between Paccaloni

and Prouvost & Economides Methods for Well A.

Paccaloni method

Prouvost method

9

1 2 3

5 6 7

9

S(Paccaloni)-S(Prouvost)

Skin effect

3

2

1

HCl

Gelled HCl

Acid

0

0

10

20

Gelled Acid

Gelle Acid

Field Mixing water

Field

Mixing

HCl

Sea

water

Water

30

40

50

60

Flow rate, bbl/min

Bottomhole pressure

4900

45

40

4700

35

15

Gelled HCl

Gelled

HCl

HCl

4500

Field Mixing Water

20

Gelled

Field Mixing Water

Flow rate, bbl/min

30

seawater

4300

4100

3900

10

3700

5

0

3500

0

10

15

20

25

Time, min

30

35

40

45

50

Bottomhole pressure, psi

1.5

0.5

0

10

20

30

Time, min

Fig. 2: Flow Rate and Bottomhole Pressure for Well A.

2.5

Time, min

25

SPE 73703

40

50

SPE 73703

APPLICATION OF TWO METHODS TO EVALUATE MATRIX ACIDIZING USING REAL-TIME SKIN EFFECT IN SAUDI ARABIA

Fig. 4: Real-Time Monitoring of Matrix Acidizing in Well B.

Fig. 6: The Difference in Skin values Between Paccaloni

and Prouvost & Economides Methods for Well B.

Paccaloni's Metod

1 2

Skin Difference between Two Methods

HCl

Gelled Acid

HCl

10

15

20

S(Paccaloni) - S (Prouvost)

Gelled Acid

Field Mixing

HCl

Field Mixing Water

Gelled Acid

Skin effect

Prouvost's Method

24

22

20

18

16

14

12

10

8

6

4

2

0

Sea

water

25

30

35

Time, min

5

4

3

2

1

Fig. 5: Flow Rate and Bottomhole Pressure for the Well B

0

0

Flow rate

Bottomhole pressure

12

5000

4500

20

HCl

Gelled

HCl

seawater

HCl

Field Mixing Water

10

Gelled

4000

Field Mixing Water

Gelled

Flow rate, bbl/min

25

15

3500

3000

2500

0

10

15

20

Time, min

10

15

20

Time, min

25

30

35

Bottomhole pressure, psi

30

25

30

35

You might also like

- Pansystem Analysis of Drawdown and Build-Up TestDocument11 pagesPansystem Analysis of Drawdown and Build-Up TestSayaf SalmanNo ratings yet

- 6.1 Applications of Darcy's Law: Figure 6.1 Model For Radial Flow of Fluids To The WellboreDocument33 pages6.1 Applications of Darcy's Law: Figure 6.1 Model For Radial Flow of Fluids To The Wellborekhan.pakiNo ratings yet

- Level HE6: RAS AL Khaimah CampusDocument6 pagesLevel HE6: RAS AL Khaimah CampusUmer RaufNo ratings yet

- Lab ManuelDocument79 pagesLab ManuelMarty SmurdaNo ratings yet

- PythonDocument4 pagesPythonabcd12345432167% (3)

- 780 2147 1 SMDocument17 pages780 2147 1 SMhari6622100% (1)

- Application of Buckingham π theoremDocument7 pagesApplication of Buckingham π theoremAritra Arsenous KunduNo ratings yet

- Step Functions and Laplace Transforms of Piecewise Continuous FunctionsDocument20 pagesStep Functions and Laplace Transforms of Piecewise Continuous FunctionsLemuel C. FernandezNo ratings yet

- Tracer Flow TestingDocument2 pagesTracer Flow TestingaytihdaNo ratings yet

- Vi. Fluid Friction in Steady One Dimensional FlowDocument38 pagesVi. Fluid Friction in Steady One Dimensional FlowAlna LiviaNo ratings yet

- Venturi MeterDocument15 pagesVenturi MeterFatimah BadruddinNo ratings yet

- EXP 7 Pipe FrictionDocument10 pagesEXP 7 Pipe Frictionsiva ramNo ratings yet

- Deconvolution of Wellbore Pressure and Flow Rate: Fikrl J. Kuchuk, Richard G. Carter, LWS AyestaranDocument7 pagesDeconvolution of Wellbore Pressure and Flow Rate: Fikrl J. Kuchuk, Richard G. Carter, LWS AyestaranSergio FloresNo ratings yet

- Lab Report 2 RheologyDocument17 pagesLab Report 2 Rheologyluis nunezNo ratings yet

- D - Two-Phase Flow Lab ManualDocument23 pagesD - Two-Phase Flow Lab ManualdanielNo ratings yet

- Chapter 1 - Process DiagramsDocument36 pagesChapter 1 - Process Diagramsmrajim93No ratings yet

- Ojo Poe SLBDocument16 pagesOjo Poe SLBSebastian MorenoNo ratings yet

- Consolidation LabDocument5 pagesConsolidation LabfostbarrNo ratings yet

- EDD Calibration TrimDocument23 pagesEDD Calibration TrimAnonymous cXjAZTNo ratings yet

- Empirical IPRDocument4 pagesEmpirical IPRRichard GutierrezNo ratings yet

- Fuzzy Logic: AssignmentDocument8 pagesFuzzy Logic: AssignmentChirag GautamNo ratings yet

- CHE515 Experiment 4Document2 pagesCHE515 Experiment 4Muhammad NursalamNo ratings yet

- A Multiple Regression Approach To Optimal Drilling and Abnormal Pressure DetectionDocument14 pagesA Multiple Regression Approach To Optimal Drilling and Abnormal Pressure DetectionTui DuangkamonNo ratings yet

- Example For NumericalDocument9 pagesExample For Numericaltekalign yerangoNo ratings yet

- Determination Discharge and Mean VelocityDocument11 pagesDetermination Discharge and Mean VelocityMd. Naimul Islam SanyNo ratings yet

- Lab Report Fluid FrictionDocument7 pagesLab Report Fluid FrictionMohd Haikal ShukorNo ratings yet

- 3Document10 pages3JaeDukAndrewSeoNo ratings yet

- Assignment # 1: Date: August 21, 2015, Before 11:59 PMDocument3 pagesAssignment # 1: Date: August 21, 2015, Before 11:59 PMQil Aznan0% (1)

- Center of PressureDocument3 pagesCenter of PressureTemoteo L Pupa IIINo ratings yet

- Fluid Dynamics Past Exam SolutionDocument4 pagesFluid Dynamics Past Exam SolutionPaulo PolloNo ratings yet

- 4 Liquid PermeabilityDocument5 pages4 Liquid Permeabilityhari662250% (2)

- Lesson 3 Homework Solutions - Density ViscosityDocument11 pagesLesson 3 Homework Solutions - Density ViscosityMark Moran0% (1)

- 05 Degree of Freedom AnalysisDocument6 pages05 Degree of Freedom AnalysisLucas Wang100% (1)

- CEWB21 Exp 4 Full ReportDocument9 pagesCEWB21 Exp 4 Full ReportNur FarehaNo ratings yet

- Kel-1 GAs Lift1Document12 pagesKel-1 GAs Lift1Indra ArdiansyahNo ratings yet

- CAD PracticeDocument65 pagesCAD PracticeAgnihothra Sarma Oruganti100% (1)

- Part 15 Slug DST MDT IpttDocument15 pagesPart 15 Slug DST MDT IpttChai CwsNo ratings yet

- Liquid Diffusion Coefficient Apparatus BP09Document4 pagesLiquid Diffusion Coefficient Apparatus BP09Ahmed AliNo ratings yet

- Lecture10 PTEG-431 SinglePhase 19.09.2018Document48 pagesLecture10 PTEG-431 SinglePhase 19.09.2018Akhil GodavarthiNo ratings yet

- TH35 Ejercicio ADocument3 pagesTH35 Ejercicio ALuis CuzcoNo ratings yet

- Dead Weight GaugecalibrationDocument3 pagesDead Weight Gaugecalibrationusman_uet08No ratings yet

- Exp 1-Hele ShawDocument1 pageExp 1-Hele Shawadityain2003No ratings yet

- Handout 2 PTT Measurements PCB3013Document12 pagesHandout 2 PTT Measurements PCB3013Chai CwsNo ratings yet

- Flow Through Small Orifice PDFDocument10 pagesFlow Through Small Orifice PDFYasser AlshantiNo ratings yet

- 7405Document8 pages7405Ebby OnyekweNo ratings yet

- Residual Properties by Equations of StateDocument2 pagesResidual Properties by Equations of Statehameed1966No ratings yet

- Orifice MeterDocument9 pagesOrifice MeterEran LopezNo ratings yet

- Apects of Porosity Units and Zonation in Carbonate ReservoirDocument39 pagesApects of Porosity Units and Zonation in Carbonate ReservoirHuner YarsanNo ratings yet

- Gas Flow Rate Calculation From Wellhead PressuresDocument1 pageGas Flow Rate Calculation From Wellhead Pressureschandramohan murugan100% (1)

- Spot Speed StudyDocument7 pagesSpot Speed StudyJohnson KenNo ratings yet

- Exam 1999Document30 pagesExam 1999jawadkh76No ratings yet

- Corrected Momnetum and Energy Equations Disprove Betz's LimitDocument25 pagesCorrected Momnetum and Energy Equations Disprove Betz's LimitLarry MansbergerNo ratings yet

- Lab Report - Particle Size Distribution (PSD) - Dry SievingDocument6 pagesLab Report - Particle Size Distribution (PSD) - Dry SievingSheikh BajunaidNo ratings yet

- Damotta 1997Document4 pagesDamotta 1997Ilham SaputraNo ratings yet

- Coagulation Control Using The Streaming Current Detector: Problems and A Possible SolutionDocument4 pagesCoagulation Control Using The Streaming Current Detector: Problems and A Possible SolutionMohammad Ali ZamanNo ratings yet

- Ramondenc 2013Document11 pagesRamondenc 2013ali87simNo ratings yet

- SPE-WVS-215: A Methodology For Lab-Stimulation Tests To Improve Well ProductionDocument20 pagesSPE-WVS-215: A Methodology For Lab-Stimulation Tests To Improve Well ProductionRaifel MoralesNo ratings yet

- 068 ProNetDocument117 pages068 ProNethuynhhaichauchauNo ratings yet

- Environmental Monitoring Risk AssessmentDocument22 pagesEnvironmental Monitoring Risk AssessmentMarcelo CarvalhoNo ratings yet

- GP 10 10 11 June 2008 Well Control PRT 1Document23 pagesGP 10 10 11 June 2008 Well Control PRT 1alizareiforoushNo ratings yet

- Drilling Rig Audits and Rig Acceptance: Group PracticeDocument14 pagesDrilling Rig Audits and Rig Acceptance: Group PracticealizareiforoushNo ratings yet

- GP 10 10 11 June 2008 Well Control PRT 2Document22 pagesGP 10 10 11 June 2008 Well Control PRT 2alizareiforoushNo ratings yet

- GP 10-16 9 July 2008Document17 pagesGP 10-16 9 July 2008alizareiforoushNo ratings yet

- GP 10-20 26 August 2008Document41 pagesGP 10-20 26 August 2008alizareiforoushNo ratings yet

- Moving and Securing of Mobile Offshore Drilling Units: Group PracticeDocument17 pagesMoving and Securing of Mobile Offshore Drilling Units: Group PracticealizareiforoushNo ratings yet

- GP 10-20 26 August 2008 222Document41 pagesGP 10-20 26 August 2008 222alizareiforoushNo ratings yet

- SLB Enhanced Dominator Motor - Product BulletinDocument15 pagesSLB Enhanced Dominator Motor - Product BulletinalizareiforoushNo ratings yet

- GP 10-15 9 July 2008Document19 pagesGP 10-15 9 July 2008alizareiforoushNo ratings yet

- An Expert System For Casing String Design SPE 20328 1990Document8 pagesAn Expert System For Casing String Design SPE 20328 1990alizareiforoushNo ratings yet

- Well Integrity Management System - Leak Rate CriteriaDocument1 pageWell Integrity Management System - Leak Rate CriteriaalizareiforoushNo ratings yet

- Secondary Well Control - Well Control EquipmentDocument43 pagesSecondary Well Control - Well Control EquipmentalizareiforoushNo ratings yet

- Casing Design PreliminaryDocument29 pagesCasing Design Preliminaryalizareiforoush100% (2)

- Coiled Tubing Running SpeedsDocument1 pageCoiled Tubing Running SpeedsalizareiforoushNo ratings yet

- IPS-46 - Flare DesignDocument57 pagesIPS-46 - Flare DesignalizareiforoushNo ratings yet

- Pickling Tubing StringsDocument3 pagesPickling Tubing StringsalizareiforoushNo ratings yet

- Recommend Frequency of Well Integrity MonitoringDocument1 pageRecommend Frequency of Well Integrity MonitoringalizareiforoushNo ratings yet

- TWPCEDocument1 pageTWPCEalizareiforoushNo ratings yet

- Well Integrity Within NorskDocument23 pagesWell Integrity Within Norskalizareiforoush100% (1)

- MER - Maximum Efficient RateDocument13 pagesMER - Maximum Efficient Ratealizareiforoush100% (1)

- Industry Practices To Address SCP (Sustained Casing Pressure)Document10 pagesIndustry Practices To Address SCP (Sustained Casing Pressure)alizareiforoushNo ratings yet

- Lab Report 1Document11 pagesLab Report 1Haziq HakimiNo ratings yet

- Chem 206 Lab ManualDocument69 pagesChem 206 Lab ManualDouglas DlutzNo ratings yet

- 02 Chapter 3 - Weight Volume Relationships PDFDocument42 pages02 Chapter 3 - Weight Volume Relationships PDFAbd El Rhman Mohamed50% (2)

- Murrel Farming Using Biofloc TechniqueDocument16 pagesMurrel Farming Using Biofloc TechniqueSanThosh ChInnuNo ratings yet

- Training Manual For Beginners in Process SimulationDocument42 pagesTraining Manual For Beginners in Process SimulationGianfabrizioNo ratings yet

- Astm D 4745Document6 pagesAstm D 4745Bipin SasikumarNo ratings yet

- Fire Scenarios & Buildings - AnderbergDocument11 pagesFire Scenarios & Buildings - AnderbergMouhaNo ratings yet

- Marine Engineering 1921Document908 pagesMarine Engineering 1921Samuel Sneddon-Nelmes0% (1)

- Rioflex UgxDocument2 pagesRioflex UgxCyprien YENo ratings yet

- Me22 M1a1Document2 pagesMe22 M1a1Jihoo JungNo ratings yet

- BS en Iso 03233-3-2015Document26 pagesBS en Iso 03233-3-2015Radhakrishna VachaNo ratings yet

- Quality Control Standards For Base CourseDocument5 pagesQuality Control Standards For Base Courseprobook450_ehsanNo ratings yet

- IMO MSC Circ.670Document11 pagesIMO MSC Circ.670Mihailescu IulianNo ratings yet

- Dokumen - Tips Ship Stability Tutorials Mca Oow Unlimited Written Exam Nuri KayacanDocument185 pagesDokumen - Tips Ship Stability Tutorials Mca Oow Unlimited Written Exam Nuri KayacanMike MSBNo ratings yet

- Effects of Polymer Melt Compressibility On Mold Filling in Micro Injection MoldingDocument10 pagesEffects of Polymer Melt Compressibility On Mold Filling in Micro Injection MoldingOakmeNo ratings yet

- D 2663 - 14Document12 pagesD 2663 - 14Salma FarooqNo ratings yet

- TestingDocument41 pagesTestingJorge Gerardo Riascos QuiñonesNo ratings yet

- 3M Novec 7600 InfoDocument6 pages3M Novec 7600 InfoadrrineNo ratings yet

- Alfa Laval mmpx404Document189 pagesAlfa Laval mmpx404Vlad100% (1)

- Particle Shape, Surface AreaDocument6 pagesParticle Shape, Surface AreaZeta Tuntun GamingNo ratings yet

- Cross Sectional Area of WeldsDocument4 pagesCross Sectional Area of WeldsJuan RodriguezNo ratings yet

- Ceramic Tile Waste As A Waste ManagementDocument9 pagesCeramic Tile Waste As A Waste Managementmz zhenNo ratings yet

- Washability AnalysisDocument11 pagesWashability AnalysisnarendrasinghsjsNo ratings yet

- Benchmarking of Polyurethane Technologies For AutoDocument9 pagesBenchmarking of Polyurethane Technologies For AutoLugiana FazarudinNo ratings yet

- 2 - Weight Volume RelationshipDocument29 pages2 - Weight Volume RelationshipMohd Asis LatipNo ratings yet

- Taller en Ingles de FisicaDocument2 pagesTaller en Ingles de FisicaYesid Manrrique AntorvezaNo ratings yet

- Case Study LPG Measurement Standard SelectionDocument13 pagesCase Study LPG Measurement Standard SelectionMiroslav Kadrchanov Machu100% (1)

- FPP Performance ReviewerDocument3 pagesFPP Performance ReviewerRyanNo ratings yet

- End of Term RevisionDocument127 pagesEnd of Term RevisionEsa FarhanNo ratings yet

- Metric Basic Units and Prefixes: Example Exercise 2.1Document42 pagesMetric Basic Units and Prefixes: Example Exercise 2.1Idris Ibrahimov100% (1)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- The Perfumed Pages of History: A Textbook on Fragrance CreationFrom EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationRating: 4 out of 5 stars4/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesFrom EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesRating: 5 out of 5 stars5/5 (1)

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignFrom EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignRating: 4 out of 5 stars4/5 (16)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookNo ratings yet

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet