Professional Documents

Culture Documents

Cement Plant Safety Guide Asia

Uploaded by

Ziaul OnimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Plant Safety Guide Asia

Uploaded by

Ziaul OnimCopyright:

Available Formats

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Audit Elements

H&S Pictorial Guide

Chapter 1/5: Group Standards

East and South-West Asia Regions

Version 1: Dated 25th Jan 2010

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Table of Content

1. Group Standards

4. Site Standards

Working at Height (WAH)

Energy

PPE

Isolation

(includes

conveyor

LOTOTO advisories)

2. Group Advisories

;

Mobile Equipment

Stockpile & Surge Pile

Confined Space

3. Systems & Processes

;

Risk Assessment

Inspections

Training

Emergency Preparedness & Response

&

Housekeeping

Safety in Design

Illumination

Lifting equipment & Hoists

Compressed Gases and Hoses

Laboratory

Harbour

Coal Shop

5. Management

;

Leadership & Administration

Communication Signs

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Group Standard Work At Heights

; Scaffolding

; Platforms

; Stairways

; Falling Objects

; Portable Ladders

; Fall Protection Equipments Harness etc.

; Gaps, Holes on platforms

; WAH Permits

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights Scaffolds

Illustration of a standard scaffold

height

Access to landing

platform is restricted

Ladder not extended 1

meter from platform

Bracings not up to

standard

base

Base to height ratio of

4:1 not followed

Fatality - A contractor in Fumin project in YunNan (China) got killed in a 14-meters fall when climbing

down the scaffolding.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights Scaffolds

FHRA displayed at the various work locations.

Scaffolds being used

without inspection

(no inspection tag)

Scaffolding tag Green scaff tag denoted

that Scaffold is Fit To Use

Fatality - A contractor in Fumin project in YunNan (China) got killed in a 14-meters fall when climbing

down the scaffolding.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights - Scaffolds

Scaffolding inspection training program conducted

Gap at platform

Broken wood

planks

Fatality:

Substandard

platform

gave

away

&

the

person fell all

the way to the

ground & died.

Trained & certified team of scaffolders

Fatality: In Saudi Arabia, while working inside the main chimney on a hanging platform, 2 contractors

died when the platform tipped over, provoking a fall from 95 meters.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights - Scaffolds

Using planks with

various shapes and

sizes

braces properly

spaced and rigid

Gaps between

planks

Improper cross

bracing

Planks not tied to

ledgers and

transoms

Tubes protrusion

not less than 4

inches from clamp

Rough edges of

scaffolding pipes

Fatality: A Sub Contract Concrete Pumping Supervisor died after being struck on the head by a falling

wooden scaffold pole

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights - Scaffolds

Access ladder extended up to 1

meter from the access platform

No top rail, toe board and access ladder

2

Self-closing door at access

platform of a scaffold

A-frame scaffolding used for a height

more than 1.5 meter

Fatality: In Malawi, an artisan welder was hit by a falling pipe while he was leading dismantling works

at the decommissioned Changalume plant.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Missing toe board

Missing toe board

Working-At-Heights - Platforms

Rails in place

Inside silo, a temporary platform

found without railings.

Toe board on working

platform

A rope used for Edge

protection

Fatality: In Algeria, the victim (Guerine) was at the very top of the installation, the structural fixings of the access stairway

gave way. Guerine fell from a height of 30 meters and died instantly.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights - Platforms

Toe board with large opening

Big gap between toe

board and floor

Standard railings and

access stairs

Standard toe board on

working platform

An example of how an object (iron

bar), can slip through an opening

& fall

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights - Stairways

Accumulated materials on

stairways

Heavy materials stored

on working platform

Standard railings and

access stairs

Missing handrail

Access stairs free from

trip hazards

Fatality : In Algeria, a contractor felt from 30 meters when the structural fixing of the access ladder he

was climbing on (for an unknown reason) gave away.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights Falling object

;

Use of safety net during construction activity,

to reduce the risk exposure of any falling

object.

No established Drop

Zone. Workers can

access below the

suspended load

No safety signage to

alert people of men

working at height

Drop zone clearly identified

below the area, where WAH

activity is taking place.

Inspection

tags

men working below

3 fatalities happened in 2009, as a result of objects falling from height - Morocco, Malawi, Malaysia.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights Falling object

;

Wire rope with Bulldog clamping grips as per

standard.

Only 1 bulldog

grip installed

3 fatalities happened in 2009, as a result of objects falling from height - Morocco, Malawi, Malaysia.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Steel ladder not properly

stored

Portable ladder used as

permanent access way

Working-At-Heights Portable Ladders

;

Portable ladders are inspected before use

Damaged or defective ladders are removed from

service Tagging system in place.

Ladders are used properly: one person on a

ladder at a time, 3 feet extension above the

roof.

Angle of the ladder at least 4:1 (length of the

ladder against base distance from the wall).

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights Portable Ladders

Portable ladder left lying

on operation site.

Metallic ladder being used

in electrical substation

Portable ladder properly stored and secured

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Using portable ladder

considering other hazards

without

Working-At-Heights Portable Ladders

mobile elevated working platform

Use of appropriate working platform

Height ~ 5

meters

Uneven footing

mobile scaffolds

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights Fixed Ladders

Cage installed on

monkey ladder

Monkey ladder

without cage

Lockable barrier

to regulate

access

7 feet

from the

ground

Monkey ladder

without cage

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights General Requirements

;

Bag handler using fall protection equipment

(retractable lanyard anchored unto lifeline)

during WAH.

Cement bag

loader without

fall protection

Cement bag

loader with fall

protection

Height ~

2.5 meters

worker using retractable

lanyard

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Climbing up the bulk tanker without

proper access and fall protection

Truck loading facility

without proper access

Working-At-Heights General Requirements

Bulk loading facility with access way and fall protection

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights General Requirements

;

Harness not secured properly

Proper donning of fall protection equipment

Employees are properly trained in

including rescue & suspension trauma.

WAH,

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Worn out lanyard protection

against metal edges

Working-At-Heights General Requirements

;

Fall arrest and fall restrain equipment are in

good condition

Inspection tags showing the date of

inspection and the date of next inspection.

Inspection

tags

Repaired safety harness

(using rivets on sewed

portion) highly

prohibited!

;

:

Use of rope grab fall arrestor

Fatalities: In Egypt, a contractor employee died while using substandard fall arrest equipment. In Nigeria, a Lafarge employee died after

falling from the top of a kiln shell. He was using a defective safety harness. In India, a mechanical erection contractor employee fell from

the platform inside the cyclone under construction 14 meters to his death. He was not using the harness.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights General Requirements

;

Can this lifeline support

all of them? If one falls,

others will follow

Lifeline inspected,

clamped

tagged

and

properly

Bulldog

clamps

Lifeline

maximum

capacity

Lifeline

should

be designed to

support at least

5000 lbs, per

person

attached.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working-At-Heights General Requirements

Large openings around the working platform,

which increases the exposure of fall risk.

Floor openings observed on

temporary installations

Typical cover of ducts

Typical covering of ducts (with allowable gap for metal expansion)

Uncovered portion of ducts

Fatalities : In India, a contractor fell to his death through a hole while trying to lift a metal sheet to

cover another hole on the roof of the cement mill.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Group Standard Energy Isolation

; Unexpected energization, start-up, or release of hazardous

energy when performing tasks on machines, equipment and

process (MEP).

; LOTOTO Lock Out Tag Out Try Out

; Energy Isolation Matrix

; Conveyor Safety Guarding & Pull Cords

; Spillages around Conveyors

; Inspection & Clean out doors

; Pressurized Tanks & Vessels

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation General Requirements

;

Permit

shows 2

persons

working

Energy Isolation

complied

and

LOTOTO

sequence

Only one

padlock at

the LOTOTO

box

Multi-hasp

with

personal

padlocks

Worker still

with padlock

on his waist

while working

on machine

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation General Requirements

;

Display

of

isolation

matrix

and

maintained individual lockout box.

Energy

Isolation

available at site

well

Dusty LOTOTO

boxes

LOTOTO boxes

without label

and

LOTOTO

Broken glass of

LOTOTO box

EI Matrix

devices

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Lockout/Tagout/Tryout

;

Energy isolation devices installed

sources of hazardous energy

Ball valve without

energy isolation device

An electrical panel which can be

open even while energized

Ball valve with energy isolating

devices

on

all

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Lockout/Tagout/Tryout

Energy isolation devices installed & used prior

to doing any task on MEP.

Workers habitually work on running conveyors,

such as to take out jammed bags in packing plant

Compromising LOTOTO

completing task.

procedure

with

the

urgency

of

VCS (visible cutoff switch)

Is locked

Fatality happened here

Fatality: Hasim Yozgat was asked to clean alone the area near the conveyor belt that is bringing recycling waste to the drier. He was used to do

this operation. His right arm was caught between the running conveyor belt and the counter belt that bring the material up. He died after being

crushed by the conveyor belt. In Sichuan (China), an experienced contractor died while cleaning a conveyor belt in the quarry.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

No proper identification of authorized individual

doing the LOTOTO procedure.

Padlocks without owners

identification

Isolation box without label

Energy Isolation Lockout/Tagout/Tryout

Personnel padlock with employee identification,

and information tag

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Non-lockable

inspection door

Energy Isolation Lockout/Tagout/Tryout

Visible safety sign

of the hazard

Inspection door secured with metal

wedge and welding electrode

Inspection door

with lock

Inspection door secured

with poking bar, worn out

tool and leftover metallic

materials

Safety Pictorial Guide: East & South West Asia Region Cement Audits

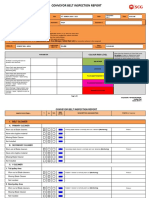

Energy Isolation Conveyor Safety

Defective pull switch

Cut off emergency pull cord

Operational pull

switch

Pull rope with built

up materials

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Conveyor Safety

;

Pull cord is installed 100mm 200mm

above the level of the conveyor belt

Sagging pull rope along the

belt conveyor

Properly tensioned pull rope

Pull rope installed at 100 200 mm

above the conveyor belt

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Conveyor Safety

Belt conveyor with audible and /

or visible start up warning system

Conveyors without audible or visual start up warning

system

Fatality: In South Africa, a general worker died after being caught in the tail pulley of the conveyer belt

extracting rock from the primary stockpile of the granular plant of the quarry.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Conveyor Safety

Conveyors with gaps along the access way

and nip points not guarded

Belt conveyor with proper

guarding at nip points

Fatality: In South Africa, a general worker died after being caught in the tail pulley of the conveyer belt

extracting rock from the primary stockpile of the granular plant of the quarry.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Conveyor Safety

Gravity Tensional Unit (GTU)

not properly isolated

Barrier not locked

No restriction for entry

Fully enclosed Gravity Tensioning Unit

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Machine guard not reinstalled after repair

Machine guard not reinstalled after repair

Energy Isolation Conveyor Safety

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Guards deliberately opened for

lubrication job

Energy Isolation Conveyor Safety

Lubricating hose located

outside of the machine guard

Lubricating stations located

outside of the machine guard

Rotating parts without machine guards

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Conveyor Safety

Proper machine guarding

Nip point can be

accessed from here

Nip point can be

accessed from here

Machine guard at tail end of conveyor

No guards at the discharge

points of belt conveyor

Adjusting bolts outside of machine guard of conveyor

Fatality: A contractor in Sichuan died after he was caught by a conveyor while cleaning the

unguarded portion of the return rollers.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Conveyor Safety

;

Safety communication campaign is conducted

to raise awareness regarding conveyor safety.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Inspection and Clean out Doors

;

Transfer point inspection

hole with defective cover

Transfer point with

unsecured door

Guarded transfer point

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Inspection and Clean out Doors

Poke holes provided with

proper platform

Clean out door with hinge design

and quick opening mechanism

Makeshift platform

(wood planks)

Inspection hole

being worked on

Poke holes above the working

platform

Platform provided above the

cyclone roof

SER: In Germany a serious burn injury happened due to the discharge of hot meal on a cyclone

platform.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Inspection and Clean out Doors

Inspection door

with no locking

provision

Poke holes provided

with hinge type cover

Inspection door

with lock

Inspection door

with no locking

provision

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Corroded

pressure vessel

Energy Isolation Pressurized tanks & vessels

Pressure vessels wit inspection

tag indicating test date and

condition

Pressure vessels without

inspection tag indicating test

date and condition

Fatality: In Brazil, a death of a mechanic occurred, following the accidental explosion of a pressurized

valve.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Pressurized tanks & vessels

Air cannon

complete with

pressure gauge and

relief valve

Air cannon without

pressure gauge and

relief valve

Air cannon without

pressure gauge

Fatality happened in Cantagalo plant on 14 April 2008 when the air cannon valve was

loosened and the restraining cable failed.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Pressurized tanks & vessels

Maximum stress at

mounting flange

Minimum stress on

the valve flange

RECOMMENDATIONS FOR INSTALLATION, OPERATION

AND MAINTENANCE OF AIR CANNONS

Initiate or verify the LOTOTO procedure for air cannons

Read entire Manufacturers installation manual before

beginning any work and check for compliance

Initiate inspection and maintenance program as per

Manufacturers recommendation (monthly and yearly)

Inspect all discharge valves and remove cracked valves

out of service immediately

Initiate replacement of all old-design discharge valves

with re-enforced valves, and use the latter in any new

installation.

Limit the stress on the valve by mounting the tanks in

the most vertical position with short extensions

On hot application air cannons, install Air Cannon

Thermo Safety Shields

Inspect all restraining cables and replace if worn or

incorrectly installed. Check cable sizing with air cannon

manufacturer.

Minimize compressed CO2 blasts in the direct vicinity of

air cannons

If compressed CO2 blasts are used near air cannons,

slide gates must be installed to isolate the air cannons

from CO2 blast

Establish a safety zone and route around operating air

cannons

Train ALL employees on the hazards of air cannons

and these types of failures

Revise site-specific training to ensure this training is

provided to visitors and contractors

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Pressurized hoses tied

with G.I. wire

Energy Isolation Pressurized tanks & vessels

Hose clips are used

according to application

Locking device to prevent snaking of

High pressure hose

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Energy Isolation Pressurized tanks & vessels

Pressurized hoses tied

with G.I. wire

Locking device to prevent snaking of

High pressure hose, installed here

Pressurized hoses tied with G.I. wire can snap

and cause whipping action or snaking of

hose that can hit anybody nearby

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Punctured pressurized

hose

Energy Isolation Pressurized tanks & vessels

High pressure hose without

punctures and with standard

hose clip

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Personal Protective Equipment

; Selection, issuance, use, maintenance and replacement of

Personal Protective Equipment (PPE).

; General PPE Requirements.

; Site Specific & Task Specific PPE.

; Quality of PPE.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

PPE General Requirements

No fire resistant protection

Standard dust masks /

respirators are used at site

Cloth, instead of dust mask to

cover the nose

Different types of masks

Safety Pictorial Guide: East & South West Asia Region Cement Audits

PPE General Requirements

Bump cap used in site

Standard safety helmets (EN 397

compliant or equivalent) used at site

Standard hand protection used at site

Gloves with holes

Different types of masks

Safety Pictorial Guide: East & South West Asia Region Cement Audits

PPE General Requirements

Complete PPE for preheater

works

Worker not wearing heat resistant PPE

during de-clogging of preheater cyclone

No face shield

No long sleeve

coat

Asbestos suit being

used during cyclone

declogging

Person not fully protected during hot

meal sampling activity

SER: In Mexico, Luis took the sample according to the procedure; he was wearing his Basic PPE which was not the appropriate

for the activity he was about to perform. When he took off the cover lock from the sampling port, the lid opened, throwing

out the hot meal under pressure. Realizing that the hot meal spillage started to burn electrical wires, Luis tried to close the

port, which provokes that the hot meal reached his gloves and caused superficial burns on his hands.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Helmet made of

soft material

PPE General Requirements

Standard safety helmet (EN

397 compliant)

Painted helmet

Additional features like reflective strips

Safety Pictorial Guide: East & South West Asia Region Cement Audits

PPE General Requirements

Standard safety shoes (EN

345-1 compliant)

Safety shoes laced with nylon rope

Worn out safety shoes

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poorly maintained earplug

PPE General Requirements

Standard ear protection

Chin strap on safety helmet

Chin strap not properly mounted

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working without the right PPE

PPE General Requirements

Very specific PPE requirements for

hazards on site

Safety Pictorial Guide: East & South West Asia Region Cement Audits

PPE General Requirements

Very specific PPE requirements for

hazards on site

Workers taking off their PPE at PPE Zone

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Insufficient PPE for electrical works

Having only one pair of HV

gloves in the substation

PPE General Requirements

Properly insulated stool for electrical works

Wooden fabricated stool

for HV panel works

Sufficient electrical tools at

the substation

Purely manual racking

mechanism for HV panels

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Audit Elements

H&S Pictorial Guide

Chapter 2/5: Group Advisories

East and South-West Asia Regions

Version 1: Dated 25th Jan 2010

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Table of Content

1. Group Standards

4. Site Standards

Working at Height (WAH)

Energy

PPE

Isolation

(includes

conveyor

LOTOTO advisories)

2. Group Advisories

;

Mobile Equipment

Stockpile & Surge Pile

Confined Space

3. Systems & Processes

;

Risk Assessment

Inspections

Training

Emergency Preparedness & Response

&

Housekeeping

Safety in Design

Illumination

Lifting equipment & Hoists

Compressed Gases and Hoses

Laboratory

Harbour

Coal Shop

5. Management

;

Leadership & Administration

Communication Signs

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Group Advisory Mobile Equipment

; Assessing the Risks.

; Circulation Plan Edge protection, Speed Limit, Parking

; Safe Zone Pedestrian walkway, visibility, Gradient, Sand Traps

; Reversing of vehicles Alarm, Light, Camera, Illumination

; Motor Boys

; Overloading

; Seat Belts & Cell Phone Extra pasengers

; Energy working under power lines

; Drugs & Alcohol

; Mobile Equipment Condition - Inspections

; Qualification & Training of Driver

; Behavior of Drivers

; Journey Management Assessing the risks

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Insufficient berm wall or edge protection

Using boulders as edge protection

Edge protection < 1.5 meters

Mobile Equipment Safety Circulation Plan

Proper berm wall at quarry access road.

Edge protection > 1.5 meters

high

Edge protection with strips

Slightly graded haul road with sufficient width

and high berm with interval luminous marking

Fatality: A quarry contractor died after his dump truck transporting limestone fell off a ramp and crashed 9

meters to a lower bench, due to insufficient edge protection.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Circulation Plan

Safety sign and speed limit along the quarry road

N o safety / warning sig ns

along the quarry road

Tractor with operator w/o seat

belt and ferrying passengers.

Fatalities: In Cameroon, a driver employed by our transport contractor, his motor-boy and two

unknown passengers were killed in a road accident while delivering clinker to the plant.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Trucks left by drivers with engine still ON.

No system of parking (reverse parking? Forward parking?

Mobile Equipment Safety Circulation Plan

Reverse parking system in place

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Circulation Plan

Safety sign at parking area

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

Revolving light for

smaller vehicles

Smaller vehicles follow the

same route as larger vehicle

without sufficient visibility

Vehicles Smaller vehicles may be at risk of being crushed. Like pedestrians they should be kept away from areas where large

vehicles operate. If this cannot be achieved: i) smaller vehicles should operate with headlights on at all times; ii) fitted with flashing

lights (i.e. strobe lights) and flags (i.e. buggy whips) or otherwise made readily visible to the operators of large vehicles.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

Revolving light and flag

for smaller vehicles

Smaller vehicles follow the same route as larger

vehicle without sufficient visibility

Detachable magnetic

revolving light

Fatalities: In Sichuan (China), a contractor got run over by an excavator while he was conducting

maintenance works on a temporary access road.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

Undersized

wheel stopper

Stone used as wheel block

Typical design of an effective wheel stopper,

painted with light color

Worn out tires

Good tire

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

Personnel walking outside of the pedestrian lane

Personnel walking along the

designated pedestrian lane

No designated pedestrian lane on plant site

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

Pedestrian lane not respected

at process line

Very narrow

pedestrian lane

Well established pedestrian lane

Designated pedestrian lane inside the process line

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

Unstable structure

Pe

de

st

ria

ro

ut

Truck ro

ute

Established circulation Plan at plant site

No clear separation of pedestrian & trucks

Established circulation Plan at quarry site

Fatality: In Wapco (Nigeria), a driver working with one of our contracted transporters died after having

been run over by his own truck driven by his assistant at the plant entrance

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Safe Zone

;

High gradient road with no facility for

emergency stops in case of brake failure

Sand traps provided on high gradient quarry

roads, to facilitate any emergency stoppage

of vehicle.

Sand trap provided on high gradient quarry road, to

facilitate emergency stop in case of brake or

equipment failure

SER : 3 persons suffered fractured legs & bruises when a loaded

truck with failed brakes, crashed into a fence, as there

was no provision made for a sand pit on a high gradient

road.

Sand Pit

Fatalities: In Algeria, two drivers employed by Lafarge died in a road accident after losing control of the

truck on a downward slope ending with a turn.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

High gradient road with no facility for emergency stops

in case of brake failure

Mobile Equipment Safety Safe Zone

Sand trap provided on high gradient quarry road, to facilitate

emergency stop in case of brake or equipment failure

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Towing process not regulated in the site

Mobile Equipment Safety - Reversing

Camera installed behind all tippers operating in the quarry

for safe reversing

Camera

Behind the

truck

Contractor driver Shi Rui was crushed under the wheels

of his truck while attempting a rolling start using a

second truck/ Fumin Project in Yunnan.

TV Screen on

dash board

Motor boys commonly entering at sites

Fatalities: In Egypt, a motor boy employed by a transport contractor was killed after being run over

by his own truck. In India, a motor boy was crushed under the truck, during the reversing process.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Payloader operating without reversing alarm and

revolving light

Poorly maintained equipment operating at our site

Mobile Equipment Safety Equipment Condition

Payloader with reversing alarm, revolving light and

reflective paints

Mobile equipment not allowed to operate in the site unless

inspected for fitness

Fatalities: In 2009, a Lafarge employee was run over by a reversing wheel loader which did not have a

reversing alarm installed.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Drivers not resting properly sleepy while driving.

Excessive overloading of vehicles.

Mobile Equipment Safety - Driving

Defensive Driving Training for drivers, include a

specific module for trailer truck safety focusing on

reactions to accident situations (with simulations).

A tipper trolley carrying

coal, was toppled inside

coal yard while

unloading the coal. The

unloading cylinder was

found bend and it was

found the tripper was

overloaded & the driver

had not rested properly.

N o t hi ng happened to

any body. But it had the

p o t e n ti a l f o r s e ri o us

Injury. The entire truck

carrying coal got

t o p pl e d o n one side.

Diver was feeling

sleepy while driving

The tipper had get out

from material gate at

morning 2.30 AM. Driver

l o s t hi s c o n t r o l o v er

steering as he feel

sleepy at round 4:00

AM resulting tipper to

move to extreme end of

the road & toppled on

t h e

w a y .

Driver sustained bruise

and strain on his head.

Driver & motor boy both

were not wear safety

b

e

l

t

.

Overloading prohibited & adhered to for all mobile

equipments.

Fatalities: In Spain, a driver employed by a contractor died in a collision on his way from Sagunto to

deliver clinker to the Cementos Esfera grinding plant.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Drivers & operators do not keep a safe separation of 3 7 metres

(depending on voltage) when operating mobile equipment within close

proximity to power lines (shown in miniature).

~ 3 meters (for

50KV line)

Mobile Equipment Safety - Driving

Established a Journey Management Plan for critical and

frequented roads by trucks plying route from plants to

depot.

Journey Management Plan

Warehouse / Depot

Trucks routine path

XYZ Plant

Tipper under High Tension cable

SER: A tipper was engaged for

shifting of soil in railway corridor.

The Driver placed the Tripper below

the 33 KV HT line for unloading the

soil. Tippers top portion came in the

range of 33 KV HT line and caught

the fire during unloading. Anyhow

driver managed to escape from the

burning tipper & he is safe. The

driver is not traceable. It was found

that the Driver had not under gone

the safety induction.

Adapted example

Fatalities: In Spain, a driver employed by a contractor died in a collision on his way from Sagunto to

deliver clinker to the Cementos Esfera grinding plant.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Drugs and Alcohol

Site do not have clear guidelines on

alcohol and drug testing for operators

and drivers

No instrument to monitor level of

alcohol operators and drivers entering

the site

Drivers

training,

motivation

&

engagement issues (over speeding,

non use of stoppers, PPEs non

compliances observed).

Alcohol Tester for mobile equipment operators

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Seatbelts

Truck driver wearing a functioning seatbelt.

Delivery truck without seatbelt

installed for driver and passenger

Driver wearing a non-functioning seatbelt

Fatalities: In Pakistan, a driver died in a tragic road accident while trying to stop his truck whose brakes

were not working.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Seatbelts

Driver with extra passenger in the

cabin

Forklift operator wearing seatbelt

Seatbelt tied with G.I. wire

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Seatbelts / Reverse alarm

Forklift with reversing alarm and revolving light. Operator is

wearing seatbelt.

No reversing alarm

and revolving light

Working without seatbelt

Operators must remain inside the cab within

operating areas.

SER: This case is demonstrating the need of wearing seat belt in forklift...even for short / limited operations. Approximately 20 buckets (20kg) of wetmix product

fell on top of a forklift truck while being driven by an operator at the Frampton site. The buckets were on a pallet on the top shelf of storage racking. The operator

was removing a pallet from the shelf below and as he was reversing the top of the vertical back rest on the fork lift truck lifted the cross bar of the storage shelf.

The shear bolt activated allowing the wooden shelf to drop causing the top two layers of buckets to topple downwards onto the roof of the FLT. The drivers

immediate reaction was to get out of the FLT, but as he was wearing his seatbelt he remained in the cab. The driver was unhurt due to the protective cage.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Reversing

Stopper arrangement to prevent fall during reversing

Missing edge protection. Trucks reversing during operations

Tyres for buffering any impact during reversal of vehicle

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mobile Equipment Safety Vehicle Inspection

Daily inspection of mobile equipment and records are maintained for

reference.

Ignition key left in the switch

No reversing alarm

Worn out tire

Broken rear light

Inspection tag for

every vehicle

Fatalities: In Pakistan, a driver died in a tragic road accident while trying to stop his truck whose brakes

were not working.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Group Advisory - Working Safely

Around Stockpiles and Surge piles

; Angle of Repose.

; Pedestrian Access - Barricading.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Unstable stockpile

Angle of

repose

>40 deg

Working Safely Around Surgepile and Stockpiles

Typical angle of repose for this type of stockpile

<40 deg

Stable stockpile, with concrete barrier and isolated from

pedestrians

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe angle of repose not observed

Working Safely Around Surgepile and Stockpiles

Safe angle of repose

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working Safely Around Surgepile and Stockpiles

Stable stockpile, with covers (tarpaulin) and isolated from

pedestrians

Alternative fuel not properly barricaded

No Retainer for loose stockpile resulting in spreading of

materials which could cause skidding of heavy vehicles

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Working Safely Around Surge pile and Stockpiles

Worker standing too close

to the moving equipment

SER: The Event - A Caterpillar D9T dozer rolled of a turn down the slope of a stockpile. The operator was pushing limestone as required on the top of a

secondary surge pile. In the process of backing up, the dozer went too close to the piles outer edge and could not recover, it lost traction and slid down the edge of

the pile. The operator was wearing his seatbelt and the dozer was equipped with a Roll Over Protection Structure (ROPS). The operator was not injured. He stayed

inside the enclosed cab until help arrived. The dozer sustained limited damage. The repair cost was approximately $35,000 resulting in 3 weeks of downtime.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Group Advisory - Confined Space Entry

; Confined Space Entry Permit.

; Visible Signage on Entry Door.

; Secure & Lock Entry Doors.

; Emergency Rescue System in Place.

; Well Laid out Procedures.

; Activity performed only by Trained Persons.

; Clear Identification Outside on who is Inside the Confined Space.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Confined Space Entry

Confined spaces are clearly identified and controls are in

place prior to entry

Use of unprotected lighting fixture

inside a confined space

Some areas (such as this ball mill) is not considered a

confined space, thus no control measures for CSE is

implemented

Fatality: In China, the victim entered into a hopper and the head has been caught by the breaker

device, apparently causing immediate death.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Confined Space Entry

Clear identification and tagging done at the entrance of a

confined space

Confined space with no

access door to regulate entry

CSE tag placed at the entrance

of a confined space

Fatality: Two workers entered the bin through manhole to clean the blockage. Coal sticking on the walls

detached and engulfed both the worker. One of the worker managed to get out and rushed to bring

rescue, victim was dragged out from the chute but died while transporting to hospital.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Confined Space Entry

;

All confined space activities are performed by

trained persons, after duly taking the permit

for working in a confined space.

Entrant should be above the top of material

buildup!

Doing confined space entry without any permit

procedure

Person inside a CSE without a designated Entrant /

Watchman !

Fatality: To check the stock of additive in the silo, the victim went alone at the silo top, removed the

grill & while introducing the measuring tape, fell in side the silo & died.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Confined Space Entry

;

Confined space entry procedure being

followed prior to entry

Gas Measurement

Self Contain Breathing Apparatus

Fatality: Two contractors went into a coal silo to try and clean a blockage. The coal sticking on the

side collapsed on them. One of them died engulfed.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Audit Elements

H&S Pictorial Guide

Chapter 3/5: Systems & Processes

East and South-West Asia Regions

Version 1: Dated 25th Jan 2010

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Table of Content

1. Group Standards

4. Site Standards

Working at Height (WAH)

Energy

PPE

Isolation

(includes

conveyor

LOTOTO advisories)

2. Group Advisories

;

Mobile Equipment

Stockpile & Surge Pile

Confined Space

3. Systems & Processes

;

Risk Assessment

Inspections

Training

Emergency Preparedness & Response

&

Housekeeping

Safety in Design

Illumination

Lifting equipment & Hoists

Compressed Gases and Hoses

Laboratory

Harbour

Coal Shop

5. Management

;

Leadership & Administration

Communication Signs

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Risk Assessment

; Risks adequately identified, controlled and managed for All Tasks.

; Risk Assessment done on Site (not in office).

; Participation of all involved in task.

; Refresher Training on Risk Assessment & Hazard Identification.

; Monitoring and alert system.

; Review & Audit of Risk Assessment process.

; Tool Box Meeting.

; Management of Risks through Hierarchy of Controls.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Entering into the manhole ???

Drop Zone ??? Watcher???

Safety Latch??? Trailing Rope

Risk Assessment

Risk Assessments are done based on sequence of

activities.

Hazards are identified based on job steps.

Risk level are evaluated based on probability of

occurrence and severity

Specific control measures are evaluated based on

hierarchy of control, i.e. elimination, substitution /

isolation, engineering and administrative controls. PPE is

the last control identified.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Risk Assessment

Control measures are clear and specific to the

hazard and consequence identified in the

assessment.

Lafarge standard, advisories and control

measures are the basis of control measures.

Generic control measures

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Risk Assessment

Poor system of Hazard Identification and

Control

Work at heights

Standing too

close to unstable

load

No PPE

Safety Pictorial Guide: East & South West Asia Region Cement Audits

No barricade in the work area

Welding machine close to

pressurized cylinder

No barrier for radiation and flux

Risk Assessment

All persons involved in the job participate in

the risk assessment process

Risk Assessment covers all hazards and posted

on site with Work Permit.

Refresher training and workshop on Risk

Assessment technique including on the job

audit/observation of correct way of filling up of

forms done, periodically.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

No visible evidence to show that toolbox

meetings are being held regularly.

Risk assessment being done only for

select major jobs, not for all tasks

(regardless of routine, non-routine, major

and minor).

Risk Assessment

10 risk assessments are selected per month & is reviewed

by a taskforce team (comprising representatives from

maintenance, production, safety, etc.) to brainstorm and

enhance the quality of those risk assessments.

Toolbox meeting held regularly

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspections

; Inspections- visual walkabout focused on:

; Housekeeping

; Equipment condition

(e.g. Tools, Cylinders, Pipes, Hoists etc.)

; Working environment

(e.g. lighting, ventilation, cleanliness).

; Should cover Contractor Equipments as well.

; Guided checklist or informal.

; Can be planned or unplanned.

; Should take place on a regular basis.

; Reported findings should be acted with timeline of completion.

; Visible records of Inspections.

; Participation of Line Management & Supervisors is Key.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspections Tools

Gas regulator in

good condition

Broken glass of oxyacetylene regulator

Substandard clip used for

pressurized hose

Crimped type fitting used

for pressurized hose

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspections Tools

Broken handle of

a sledge hammer

Safe and standard tools

Broken tools still used on

site

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspections Tools

Contractor tools and equipment pass through safety

inspection, prior to use.

Broken lanyard

Lever block without

safety latch

Verified by safety

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspections Tools & Tackles

Unreliable grounding tool for welding machine

Standard grounding clamp

for welding works

Fatality: electrocution

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspection Safety Observation

;

:

:

:

Supervisors not fully participating in H&S

inspection

Senior management not consistently doing

H&S observations.

Inspections are focused on operations

issues. Safety & improvement of site

standards gets a lower priority.

No periodic safety specific patrol, to

capture

issues

like

house

keeping,

spillages, missing railings & guarding, loose

electrical wiring, unsafe behaviors.

No

proper

tracking/Monitoring

of

observation result per Department /

section of the plant.

Inspections are noted and reviewed by

the team for proper action

MONTH

KPI

Nov '07

Dec '07

Jan '08

Feb '08

Mar '08

Apr '08

No. of Audits Made

63

33

61

37

107

89

No. of audit findings

179

30

73

225

198

138

0.7811

0.7814

0.3347

0.4157

0.3536

0.4662

17

11

14

29

28

21

UA per man-hour

No. of auditors with 2

or more audits

conducted

Nb of actions

Nb of actions applicab

Nb of actions completed

Nb of actions not started

Nb of actions on going

( < 50% completed )

Nb of actions on going

(> 50% to < 100 %

completed )

Safety

36

36

35

0

Maint

43

43

31

5

Production Admin-Gen Finance Opti-Envi

46

7

4

7

46

7

4

7

40

6

4

7

2

0

0

0

Total

143

143

86%

5%

5%

4%

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspection Work Area Inspection

Inspections are noted and reviewed by the team for

proper action

Inspection Log without entry

Inspection not consistently done

Inspection record

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Inspection Work Area Inspection

Inspections are noted and reviewed by the team for

proper action

Inspection record

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poor system of area inspection

Oil leaks trip hazard

Deteriorating equipment condition not acted upon

Broken pull switch handle not reported for correction

Inspection Preventive Maintenance and Testing

Inspections are noted and reviewed by the team

for proper action

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Training

; Training Matrix Who needs training on what!

; Tracking system for training undergone by people.

; Use of Good & Effective training tools & material.

; Specific Focus on Contractor safety Training.

Training Training Schedule

Safety Pictorial Guide: East & South West Asia Region Cement Audits

No structured training matrix for all level

of staffs (including what is mandatory,

compulsory and optional for a specific

role).

No systematic tracking system of training

undergone for specific mobile equipments.

Systematic tracking system of training

undergone for specific mobile equipments.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Training Training Schedule

;

No system of training for contractors and

visitors

Site- specific training for new facilities not

being done

:

fire alarm

understood

system

in

not

fully

Training on use of Mobile Elevated

Working Platform (MEWP) not done

Systematic tracking system of training

undergone for specific mobile equipments.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Training

;

One size Fits all training program No

specific training / coaching based on

individuals

profile

(do

competence

mapping & then design which training for

whom!!).

Need to plan the refresher trainings &

higher frequency for some of the plant

population (contractor workers, pay

loader operators, lab team, guards,

dispatchers, packers/loaders etc.).

No effective

supervisors.

training

program

Use of training tools for easy awareness and

understanding

for

Use of magnetic

pieces of PPE ,

used as a training

tools

for

easy

awareness

and

understanding.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Training

Use of training

understanding

tools

for

easy

awareness

and

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Contractor Safety Management standard is not

well communicated to regular employees.

Roles of management and contractors are not

clearly identified.

No formal training of contractors regarding

CSM and the Lafarge HS standard and

advisories.

CSM Roles and Responsibilities

Contractor Safety Training is conducted before

contractor personnel are allowed to work in

any Lafarge site.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Plant feedback is not duly considered before

finalization of contract.

Contractors were found doing unsafe

operations, but no clear penalty clause exists

for contracts.

CSM Roles and Responsibilities

Contract Management procedure is in place.

BU HS Coordinator is a signing authority of PO

for CAPEX items.

Penal action, against safety non compliance, is

defined in the Purchase Order.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness

; Established Emergency Response Plan.

; Fire Suppression system Extinguishers, Hydrants.

; Quality & Condition of equipments Inspections.

; Periodic Review, Mock Drills, Testing.

; Electrical Safe Work Practices.

; Restricted Entry in Risky Areas.

; Emergency Exit Doors.

; First Aid, Ambulance, Medical Support.

; Labeling & Signage.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

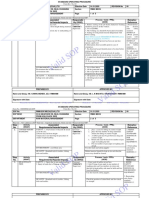

Emergency Preparedness Emergency Response Plan

Inadequate site emergency response plan, that include:

:

not updated telephone numbers, contact persons

and emergency response team membership

not addressing all types of emergencies that

have a high probability of occurring

limited Assembly Areas

Unclear notification procedure (areas of the emergency

and containment of emergency or re-entry plan)

Not updated emergency telephone numbers

Emergency Preparedness and Response

clearly posted on prominent locations

communicated

procedure

and well

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness Fire Extinguishers

Missing fire extinguisher

Fire extinguisher mounted on

site and periodically inspected

Poorly maintained fire extinguisher lever filled with dust

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness Water Storage and Hose Systems

Well maintained fire fighting facility

Poorly maintained fire hydrant system

Periodic inspection being done for all fire fighting

equipment

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness Water Storage and Hose Systems

Hydrant hose not properly rolled

trapped water can cause deterioration

Properly rolled hydrant hose in cabinet

Hydrant valve without cover

Deteriorated hydrant hose

Hydrant valve with cover

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness Water Storage and Hose Systems

Periodic testing of fire fighting equipment

Non-operational fire fighting equipment

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness Readiness

Mock Drills are done to ensure readiness of Fire Brigade and

First Aid Team

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Emergency Preparedness Water Storage and Hose Systems

Hydrant water used for other purposes

drant

Main hy

pipe

Dedicated equipment for fire fighting purposes

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Electrical Safe Work Practice

Panic bar

Substation door with luminous EXIT sign but

no emergency panic bar

Substation door with luminous EXIT sign and emergency panic bar

Panic bar

Substation door without luminous EXIT sign and emergency panic bar

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Substation used as storage/ parking area

Substation used as dwelling area

Safe Work Systems Electrical Safe Work Practice

Electrical substation restricted for entry

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Electrical Safe Work Practice

Un insulated floors of motor control center

Insulation mats are provided at front and rear of MCCs

Tools are kept beside

HV panels

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safe Work Systems Electrical Safe Work Practice

No warning sign or lock installed. Free access

to high tension cables.

Restricted access to risky areas.

Properly locked / secured entrance door of

electrical room

Unlocked access door of electrical room

Fatalities: In Cameroon, an operator in a subcontracting civil engineering company, died from

electrocution.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Electrical panels without label

Safe Work Systems Electrical Safe Work Practice

;

Properly labeled electrical panel

SER: A serious explosion occurred & section stoppage happened, when an electrician mistakenly drew out an energized

vacuum circuit breaker. This could have been avoided if all VCB (visible circuit boards) in the substation had proper labels on

them.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Electrical panels without label

Safe Work Systems Electrical Safe Work Practice

;

Properly labeled electrical panel

SER: A serious explosion occurred & section stoppage happened, when an electrician mistakenly drew out an energized

vacuum circuit breaker. This could have been avoided if all VCB (visible circuit boards) in the substation had proper labels on

them.

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Health, Safety and Environmental Controls

First Aid kits available on all areas

Ambulance with designated drivers

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Health, Safety and Environmental Controls

Hazardous areas are labeled and

safety instructions are clearly posted

Noise level determined and measures

are posted to control the hazard

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Audit Elements

H&S Pictorial Guide

Chapter 4/5: Site Standards

East and South-West Asia Regions

Version 1: Dated 25th Jan 2010

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Table of Content

1. Group Standards

4. Site Standards

Working at Height (WAH)

Energy

PPE

Isolation

(includes

conveyor

LOTOTO advisories)

2. Group Advisories

;

Mobile Equipment

Stockpile & Surge Pile

Confined Space

3. Systems & Processes

;

Risk Assessment

Inspections

Training

Emergency Preparedness & Response

&

Housekeeping

Safety in Design

Illumination

Lifting equipment & Hoists

Compressed Gases and Hoses

Laboratory

Harbour

Coal Shop

5. Management

;

Leadership & Administration

Communication Signs

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Housekeeping

; Key Priority.

; Managing Scrap & Unusable Items.

; Storage Facilities.

; 5S Housekeeping Process.

; Clean walkways Trip Hazards.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Storage Facilities

Poor system of managing scrap & usable items.

No segregation of larger, heavier items and

light materials

Storage area for usable and scrap items

should be fenced and entry shall be

regulated

There should be two entry/exit points in a

storage area.

The area should be located such that the

use of cranes are possible without creating

any hazard to personnel.

Storage area shall be designated far from

any overhead electrical lines, HV lines and

overhead installations.

5 S for Good Housekeeping

Storage area can be accessed by unauthorized

personnel

1.

Seiri: Sorting / Segregating

2.

Seiton:

3.

Seiso:

4.

Seiketsu: Standardization

5.

Shitsuke: Self Discipline

Self arrangement

Spic & Span

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Storage Facilities

Poor system of managing scrap & unused items.

Usable items mixed with scraps

Items are segregated according to size and weight

Usable items are kept in racks

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Storage Facilities

;

Pipes stored in a enclosed section

Bins placed to dump the items

Scraps are dumped in various locations

Post-shutdown materials are left at site

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Walkways / Housekeeping

Clean walkway without obstruction

Cables are laid out along the walkway

Clear stairway free from trip hazards

Hoses and welding cables laid out along the stairway

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Walkways / Housekeeping Safety

Material spillages

along access way

Access way free from material

build ups and accumulation

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Walkways / Housekeeping

Uncovered drainage along access ways

Fully covered drainage along the

access way

Slippery Conditions Open drain

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Safety in Design

; Safety in Design

(e.g. Face Shields, Guards, Barriers).

; Restricted Access.

; Storage Facilities.

; Blasting Shelter

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Grinding wheel with no guards to protect against

direct contact with rotating parts

Blurred wheel guard

Site Standards Grinding Wheels

Pedestal grinder complete with wheel guards.

no wheel guards

Face shield not attached to the helmet

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Mill with no barrier around and no proper access

platform for entering into into manhole

Site Standards Access ways

Ball

mill complete

platform

with

barriers

and

access

No fall protection above the mill

No platform above the mill

Unsecured landing area

Unsecured fence around the ball mill

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Specific Shops Explosives and Charging

There is an existing procedure to limit the

quantity if explosives available in the area.

Storage for explosives are gazetted as

restricted area whereby proper separation is

done

There is an established procedure for securing

the quarry before any blasting operation is

initiated.

Vegetation within the vicinity of explosive magazine

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Storage Facilities

Containers located near a property line

No secondary containment in case of leaks or spills

Fuel storage with secondary containment and isolated from

other structures

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

No secondary containment in case of leaks or spills

Site Standards Storage Facilities

Fuel storage with secondary containment and isolated from

other structures

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Specific Shops Explosives and Charging

Blasting shelter provided on site

during blasting activities

Person B

Person A

Persons C,D

People within close vicinity from the

blasting site without protection

Fatality: In Nigeria, Ewekoro quarry (Wapco), an employee was killed while attempting to perform a

blast in the quarry.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Illumination, Rest Rooms, Shelter

; Proper Lighting & Illumination at site.

; Testing & monitoring Illumination Levels.

; Mobile Lighting.

; Proper & Sanitized Resting Facilities for Workers.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poor illumination in the process line

Storage area with nonexplosion proof lighting above

flammable liquids

Site Standards - Illumination

;

Good illumination in the process line

Inadequate lighting system in

the process line

Proper lighting system provided in the process line

Inadequate lighting system in the process line

Illumination level tested in the process line

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards - Illumination

Proper lighting system provided in the process line

Inadequate lighting system in

the process line

Missing lighting fixture

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poorly maintained lighting fixtures

Cobwebs covering the florescent tube

Site Standards Illumination

Proper lighting system provided in the process line

Blurred floodlight glass

lighting fixtures provided in

every level of pre-heater tower

Hardened cement dust on floodlight

Hanging cover of florescent fixture

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Substandard resting facilities

Site Standards Restrooms, Lunchrooms and Lockers

Good resting facility for workers

Makeshift restroom with defective chairs in untidy area

Makeshift restroom beside charged electrical panels

Sanitary toilet and wash room

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Restrooms, Lunchrooms and Lockers

No proper resting shelter at site.

Proper resting shelter at site.

Workmen sleeping at site and the cable drum

kept very near to them in unstable condition.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Lifting Equipment & Hoist

; Safety Latch & Limiting Switch.

; Parking of Hoist & Pendant Switch.

; Storage & Inspection of Hoists & Lifting Devices.

; Quality & Inspection of Lifting Ropes Inspection Tags.

; Proper Mounting of Lifting Devices.

; Free Movement of Hoisting Equipment.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Lifting Devices

Chain block with

defective safety

latch

Chain block

with good

safety latch

Chain block without

safety latch

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Lifting Devices

Hoist pendant switch is locked whereby the key is

kept by a certified hoist operator or Area Owner.

Hoist pendant switch

unsecured and lying on

the platform

Fatalities: A contractor in Malaysia died after the hook block of an overhead crane fell and hit him.

The hook was suspended above a working area.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Site Standards Lifting Devices

Hoist hooks are provided with parking

bay at the ground floor

Hoist hook suspended

above a working area

Fatalities: A contractor in Malaysia died after the hook block of an overhead crane fell and hit him.

The hook was suspended above a working area.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Hoists and lifting devices not properly stored

Site Standards Lifting Devices

;

Hoists and lifting devices properly stored &

inspected. Visible inspection tags in place.

Unused hoist not properly stored

Usable lifting cables mixed with defective ones, not

properly stored

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Hoists and lifting devices not properly stored

Site Standards Lifting Devices

Hoists and lifting devices properly stored

inspected. Visible inspection tags in place.

&

Usable lifting cables mixed with defective ones, not

properly stored

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poor procedure to mount lifting devices.

Site Standards Lifting Devices

Hoists and lifting devices properly hooked at the

mandated spot.

Rope WILL slide

during lifting

Lifting device

mounted on a duct

Fatalities: In Morocco, a mechanic working at the extension site of the Ttouan plant killed by a falling

crane block.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poor procedure to mount lifting devices.

Site Standards Lifting Devices

;

Lifting device mounted on a

frame latch become useless

Fatalities: In Morocco, a mechanic working at the extension site of the Ttouan plant killed by a falling

crane block.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Free moving hoisting

unsecured hook.

equipment

Site Standards Lifting Devices

with

Secured hoisting equipment & hook with a

safety latch.

Free swinging hook

Secured hook to

prevent swinging

during vehicle

movement

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Compressed Gases & Hoses

; Secured Cylinder Bottles

from heat sources..).

(e.g., proper parking, segregation, stored away

; Labeling & Signage.

; Quality of Rubber Hose.

; Quality of Cylinders (e.g., free of dents, corrosion..).

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Unsecured cylinder bottles.

Site Standards Compressed Gases

;

Secured cylinder bottles

Proper segregation of filled

cylinders, chained and gated.

and

empty

Free-standing cylinders

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Poor quality of rubber hoses.

Site Standards Hoses and Cables

;

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Laboratory

; Restricted Access.

; Storage of Hazardous Chemicals.

; Emergency Eye Wash & Body Shower.

; Safety Equipments For Hot Material, Fume Hood.

; Radiation & X-Ray Protection.

; Secured Gas Cylinder.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Specific Shops Laboratory Access

;

Laboratory can be assessed by anybody.

No clear policy for entry / access to restricted

areas such as sampling room, hot room,

chemical storage room, X-ray room etc.

Restricted Access to the laboratory

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Unlabeled chemical bottles

Specific Shops Laboratory Storage & labelling

;

Chemical

bottles

properly

segregated,

labeled and stored in a safe place.

Dangerous chemicals

stored in a safe cabin

All bottles are labeled, even if it contains just

water.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Laboratory eye wash station without

water supply

Specific Shops Laboratory Eye Washer

Well maintained eye wash station with reliable

water supply

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Specific Shops Laboratory Equipment

;

Safety equipment to handle Hot material in the

laboratory

Well maintained Fume Hood.

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Specific Shops Laboratory X-ray radiation

;

Radiation

Dosi-badge

laboratory personnel

are

available

to

/asa

Safety Pictorial Guide: East & South West Asia Region Cement Audits

Gas cylinder inside laboratory building

Specific Shops Laboratory Gas Cylinders

;

Gas cylinder outside of laboratory building

ATC Guideline - Laboratory Safety 5.4.3.4 - Gas Cylinders

Individual gases should be kept securely in separate bays outside the laboratory. Gas cylinders should be used inside the

laboratory only under exceptional circumstances, because they present a real danger in the event of a fire, whether they are

empty or full. The size of cylinders temporarily used in the laboratory should be kept to a minimum, preferably 5 litres or less.

Cylinders should be color-coded and bear an unambiguous description of their contents. They should be regularly inspected

and tested.

Pipe work between the supply cylinders and the point of usage should have a minimum of couplings and connections, but should be