Professional Documents

Culture Documents

13-8 Mo

Uploaded by

fedaquiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13-8 Mo

Uploaded by

fedaquiCopyright:

Available Formats

DATA SHEET

LESCALLOY 13-8 Mo VIM-VAR

PRECIPITATION HARDENING STAINLESS STEEL

Typical

Composition

C

0.04

Cr

12.60

Ni

8.30

Mo

2.15

Al

1.00

GENERAL CHARACTERISTICS

LESCALLOY 13-8 Mo VIM-VAR steel is a precipitation hardening martensitic stainless steel offering excellent

fracture toughness and transverse mechanical properties coupled with the resistance to stress-corrosion cracking

and high strength characteristics common to the family of precipitation hardening steels. A wide range of

mechanical properties can be realized by selecting various single cycle low temperature aging treatments. The

alloy is double vacuum melted (VIM-VARvacuum induction melted followed by vacuum arc remelting) to

consistently assure low gas content, improved homogeneity and superior cleanliness.

PHYSICAL PROPERTIES*

(H1000 CONDITION)

Density: 0.279 lb./in3 (7.76 g/cm3)

Modulus of Elasticity: 28.3x106 psi (195.1 GPa)

Poissons Ratio: 0.278

COEFFICIENT OF THERMAL EXPANSION

Temp Range

F

C

70 - 200

21 - 93

70 - 400

21 - 204

70 - 600

21 - 316

70 - 800

21 - 427

in / in / F

( x 10-6 )

5.8

6.0

6.2

6.3

mm / mm / C

( x 10-6 )

10.4

10.8

11.2

11.3

*A more extensive presentation of physical properties is available

in the Aerospace Structural Metals Handbook and other industry

reference publications.

HEAT TREATMENT

Lescalloy 13-8 Mo VIM-VAR steel is solution heat

treated by heating to 1700F (927C) 15F (8C),

holding 15-30 minutes at temperature, followed by an

air cool. The austenite to martensite transformation

starts at about 250F (121C) and is completed for all

practicality at approximately 60F (16C). Therefore,

for optimum property response it is important the

alloy be cooled to below 60F (16C) following

solution treatment.

Precipitation hardening (aging) is conducted at a

variety of temperatures with in the 950-1150F (510621C) temperature range. See the tensile property

section for details.

COPYRIGHT 2007 by Latrobe Specialty Steel Co.

A dimensional change during aging can be

anticipated. Shrinkage of approximately 0.00040.0006 in/in (mm/mm) is normal for the H950

condition. Up to 0.0030 in/in (mm/mm) can occur

when aging to the H1150 condition.

HARDNESS INFORMATION

The following lists the hardness range that can be

expected in the several thermal conditions.

Condition

Solution Treated

H950

H1000

H1050

H1100

H1150

H1150M*

Hardness HBW

363 Max

430 Min

400 Min

372 Min

313 Min

283 Min

302 Max

*Overaged for sawing and cold forming

WORKABILITY

Hot Working: Lescalloy 13-8 Mo VIM-VAR steel is

readily forged from 2150-2200F (1177-1204C). To

favorably control grain size the final 50% of reduction

should be completed below 1900F (1038C). This

alloy should be air cooled to room temperature after

forging.

Cold Working: For severe cold forming operations it

is recommended the material be in the H1150 or

H1150M (overaged) condition.

Registered Trademark of Latrobe Specialty Steel Co.

LESCALLOY 13-8 Mo VIM-VAR

Welding: Lescalloy 13-8 Mo VIM-VAR steel has

excellent weldability. It requires no preheating or

special cooling and can be welded using any of the

usual electric arc or resistance welding techniques.

Welding can be readily done in either the solution

treated or any of the aged conditions. Smaller sections

may be aged directly after welding; however, for

optimum post weld properties the component should

be solution treated and precipitation hardened after

welding.

Machining: This alloy can be machined in any of the

several thermal conditions. Machining is easiest in the

H1150M overaged condition, which involves the

following thermal cycle:

1400F (760C) - 2 hours - air cool

1150F (621C) - 4 hours/air cool

The rate of machining possible for the various

thermal conditions relates to the hardness typical of

each condition; see the Heat Treatment section for

hardness information.

CORROSION RESISTANCE

The general corrosion resistance of Lescalloy 13-8 Mo

VIM-VAR steel approaches that of Type 304 stainless

steel in most media and is superior to the 400 series

stainless steels. Corrosion resistance of the alloy is

greatest in the H950 condition and decreases slightly

with increasing aging temperatures.

MECHANICAL PROPERTY DATA

A convent way to appreciate the tensile property capabilities of Lescalloy 13-8 Mo VIM-VAR steel is to consider

the minimum guarantees of the popular AMS 5629 document. The following has been extracted from AMS 5659.

The solution treated product, 12 in (300mm) and

under in nominal diameter or maximum crosssectional dimension, when precipitation heat treated

for 4 hours 0.25 to a particular condition at the

temperatures shown here and cooled in air, shall have

the properties specified here for that particular

condition.

Condition

H950

H1000

H1025

H1050

H1100

H1150

Specimen

Orientation

Longitudinal

Transverse

Longitudinal

Transverse

Longitudinal

Transverse

Longitudinal

Transverse

Longitudinal

Transverse

Longitudinal

Transverse

Tensile Strength (min)

ksi

MPa

220

1515

220

1515

205

1415

205

1415

185

1275

185

1275

175

1205

175

1205

150

1035

150

1035

135

931

135

931

Temperature

F 10

C 5

950

510

1000

540

1025

550

1050

565

1100

595

1150

620

Condition

H950

H1000

H1025

H1050

H1100

H1150

0.2% Yield Strength (min)

ksi

MPa

205

1415

205

1415

190

1310

190

1310

175

1205

175

1205

165

1140

165

1140

135

931

135

931

90

620

90

620

El in 4D (min)

%

10

10

10

10

11

11

12

12

14

14

14

14

RA (min)

%

45

35

50

40

50

45

50

45

50

50

50

50

APPLICATIONS

SPECIFICATIONS

Typical applications for Lescalloy 13-8 Mo VIMVAR steel include aircraft and nuclear reactor

components, fasteners, gears, valves and jet engine

parts. This alloy should be considered for applications

requiring a combination of stress-corrosion resistance

and high strength properties.

Industry specifications for this alloy include:

AMS 5629, ASTM A564

BMS 7-332, BMS 7-349 (Boeing)

DMS 2100 (McDonnell-Douglas)

HMS 6-1105 (Boeing-Mesa)

RMS 150 (Rohr)

STM05-602 (Lockheed Georgia)

STO 160 LB 0013 (Rockwell International)

Latrobe, Pennsylvania 15650-0031 U.S.A.

Phone: (724) 537-7711 Fax: (724) 532-6316

www.latrobesteel.com

COPYRIGHT 2007 by Latrobe Specialty Steel Co.

04/07

You might also like

- 13-8 PHteDocument1 page13-8 PHtegeorgeNo ratings yet

- Modern Alloys: Figure 1. Schematic of A Gas Turbine EngineDocument3 pagesModern Alloys: Figure 1. Schematic of A Gas Turbine EngineFauzi Oki100% (1)

- High-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickDocument2 pagesHigh-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickSadashiva sahooNo ratings yet

- Performance of Hadfield's Manganese Steel and How Manufacturing Affects ItDocument22 pagesPerformance of Hadfield's Manganese Steel and How Manufacturing Affects ItFelipe ZanellaNo ratings yet

- Pneumatic Steelmarking - Chapter IV AOD ProcessingDocument6 pagesPneumatic Steelmarking - Chapter IV AOD Processinggau3koNo ratings yet

- Aisi 305Document3 pagesAisi 305Aditya PratapNo ratings yet

- BG42 Data SheetDocument0 pagesBG42 Data SheetTroy AshcraftNo ratings yet

- Nickel Base Alloys LectureDocument15 pagesNickel Base Alloys LectureMuhammad Zam-zamNo ratings yet

- 19830024895Document15 pages19830024895SunnyNo ratings yet

- Amp16304p036 PDFDocument3 pagesAmp16304p036 PDFMarius Alin LupașcuNo ratings yet

- Nano Coating For Cutting ToolDocument26 pagesNano Coating For Cutting Toolisirajudeen17100% (1)

- Nickel Based SuperalloysDocument20 pagesNickel Based SuperalloysKarthik 029CSK100% (1)

- Ti 6al 4v Grade 5Document1 pageTi 6al 4v Grade 5Angga Kurniawan DharmaNo ratings yet

- Duplex Stainless Steel 329 Round Bars ManufacturerDocument2 pagesDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- Effect of heat treatment on spring steel microstructures and propertiesDocument7 pagesEffect of heat treatment on spring steel microstructures and propertiesMahmood KhanNo ratings yet

- LIBRO3Document43 pagesLIBRO3Camilo LacoutureNo ratings yet

- Electroplating Handbook GuideDocument13 pagesElectroplating Handbook GuideAbeerNo ratings yet

- Material Definitions & TermsDocument3 pagesMaterial Definitions & TermsDr_M_SolimanNo ratings yet

- Master ThesisDocument61 pagesMaster ThesisManoj K NaikadeNo ratings yet

- Steel IndexDocument24 pagesSteel IndexAnonymous AlhzFE9EVNNo ratings yet

- AISI 1040 Carbon Steel OverviewDocument4 pagesAISI 1040 Carbon Steel Overviewعابد زاهدNo ratings yet

- Heat Treatment of SuperalloysDocument15 pagesHeat Treatment of SuperalloysJ JhansibaiNo ratings yet

- Ferrous Alloys: Revised: March 1970 Author: S. S. MansonDocument17 pagesFerrous Alloys: Revised: March 1970 Author: S. S. MansonsunsirNo ratings yet

- PH 13-8 MoDocument34 pagesPH 13-8 MosunsirNo ratings yet

- Stainless Steel 410Document2 pagesStainless Steel 410Suriyachai NiamsornNo ratings yet

- Flame HardeningDocument29 pagesFlame Hardeningzaid sulaimanNo ratings yet

- On The Tensile Strength and Hardness Relation For MetalsDocument5 pagesOn The Tensile Strength and Hardness Relation For MetalsHammadNo ratings yet

- Bearing Steel Material Specification Sheet SAE52100Document1 pageBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryNo ratings yet

- Metrode Welding Consumables For P92 and T23 Creep Resisting SteelsDocument17 pagesMetrode Welding Consumables For P92 and T23 Creep Resisting SteelsClaudia MmsNo ratings yet

- Precipitation-Hardening Stainless Steels: Properties and Types (Martensitic, Austenitic, SemiausteniticDocument3 pagesPrecipitation-Hardening Stainless Steels: Properties and Types (Martensitic, Austenitic, SemiausteniticClaudia MmsNo ratings yet

- Stainless Steel GX4CrNi13-4 Material Data SheetDocument5 pagesStainless Steel GX4CrNi13-4 Material Data SheetAlex007No ratings yet

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy DetailAdrian LimantoNo ratings yet

- 410 CBDocument8 pages410 CBsunsirNo ratings yet

- Aisi 4340 Alloy Steel (Uns g43400)Document4 pagesAisi 4340 Alloy Steel (Uns g43400)Muhamad Ikbal TrismanaNo ratings yet

- Effects of MN Content and Heat TreatmentDocument5 pagesEffects of MN Content and Heat TreatmentTrần Xuân VịnhNo ratings yet

- Mil STD 1312BDocument44 pagesMil STD 1312BgreatsteelNo ratings yet

- Gear Reference Guide: Types, Applications & Strength CalculationsDocument15 pagesGear Reference Guide: Types, Applications & Strength CalculationsXuan Phuong HuynhNo ratings yet

- Assignment 2Document1 pageAssignment 2Laura RobayoNo ratings yet

- Gunmetal Melting ProcessDocument3 pagesGunmetal Melting Processdom250% (2)

- 8630Document24 pages8630sunsirNo ratings yet

- Si and Ni As Alloying Elements To Vary Carbon Equivalent of Austenitic Ductile Cast Iron - Microstructure and Mechanical Properties-2Document9 pagesSi and Ni As Alloying Elements To Vary Carbon Equivalent of Austenitic Ductile Cast Iron - Microstructure and Mechanical Properties-2Chun-Yi LinNo ratings yet

- A723A723M-18a 1.05 PDFDocument5 pagesA723A723M-18a 1.05 PDFist93993No ratings yet

- Filter NotesDocument46 pagesFilter Notestanzil10100% (1)

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationTennis Mathew100% (1)

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocument4 pagesA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterNo ratings yet

- GSC Steam Turbine CastingsDocument10 pagesGSC Steam Turbine CastingsJozsef MagyariNo ratings yet

- CD4 PDFDocument1 pageCD4 PDFMayrym Rey ConNo ratings yet

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Document5 pagesSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNo ratings yet

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- Heat Treatment Grossmann Hardenability PDFDocument11 pagesHeat Treatment Grossmann Hardenability PDFsivajirao70100% (2)

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Document6 pagesAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNo ratings yet

- Experimental and Numerical Investigations On The Leakage Flow Characteristics of The Labyrinth Brush SealDocument10 pagesExperimental and Numerical Investigations On The Leakage Flow Characteristics of The Labyrinth Brush SealНиколайNo ratings yet

- Steel CleanlinessDocument22 pagesSteel CleanlinessfondershellNo ratings yet

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- Sae Ams5837f 1999Document7 pagesSae Ams5837f 1999이연지No ratings yet

- Ni-Resist Alloy Properties and Applications GuideDocument40 pagesNi-Resist Alloy Properties and Applications GuidePrasad Aher100% (1)

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- Workbench Under Stair Storage PlansDocument20 pagesWorkbench Under Stair Storage PlansKeleen WrightNo ratings yet

- ASM Cross Reference For NonferrousDocument17 pagesASM Cross Reference For Nonferrousfedaqui100% (2)

- Photomicrographs of Iron and Steel, ReedDocument288 pagesPhotomicrographs of Iron and Steel, Reedfedaqui100% (1)

- 4340Document2 pages4340fedaquiNo ratings yet

- Alloy20 PennSDainlessProductsDocument2 pagesAlloy20 PennSDainlessProductsfedaquiNo ratings yet

- Cross Reference Ro SteelsDocument17 pagesCross Reference Ro SteelsJosé SilvérioNo ratings yet

- 4340M or 300MDocument2 pages4340M or 300MfedaquiNo ratings yet

- Nickel Maraging Steel PropertiesDocument30 pagesNickel Maraging Steel PropertiesRobert NatasorpNo ratings yet

- 15-5 PHDocument2 pages15-5 PHfedaquiNo ratings yet

- ASCII TableDocument7 pagesASCII TableSheriff SammyNo ratings yet

- 17 4Document2 pages17 4fedaquiNo ratings yet

- As/400 Modernization FujitsuDocument10 pagesAs/400 Modernization FujitsuKapur_dineshNo ratings yet

- Wednesday - 12.45 - Michael - Wiesinger CALIBRATE FUEL PUMP PDFDocument17 pagesWednesday - 12.45 - Michael - Wiesinger CALIBRATE FUEL PUMP PDFDoDuyBacNo ratings yet

- Everything You Need to Know About AspirinDocument3 pagesEverything You Need to Know About AspirinMaria Louiza Victoria AllauiganNo ratings yet

- July 2012Document104 pagesJuly 2012Swati AmarNo ratings yet

- Redundancy Pdu PDFDocument21 pagesRedundancy Pdu PDFPrem Singh MehtaNo ratings yet

- Axial AngularDocument9 pagesAxial AngularAlejandroInostrozaNo ratings yet

- Funds ManagementDocument3 pagesFunds ManagementSowmyaNo ratings yet

- SCHEDULE BASIS Procedure and TemplateDocument3 pagesSCHEDULE BASIS Procedure and TemplateAmydchic100% (1)

- Case Study Venus Performance TwillDocument2 pagesCase Study Venus Performance TwillRohit KumarNo ratings yet

- Quotation TejasDocument2 pagesQuotation TejasNedlloyd IndiaNo ratings yet

- 1550 LNA1087404 LTE L11 Performance and Optimization PDFDocument3 pages1550 LNA1087404 LTE L11 Performance and Optimization PDFRiverNo ratings yet

- Sap Ittoolbox Com Groups Technical Functional Sap Acct AccouDocument4 pagesSap Ittoolbox Com Groups Technical Functional Sap Acct AccouAmaranathreddy YgNo ratings yet

- An Application of SMED MethodologyDocument4 pagesAn Application of SMED MethodologyIng Raul OrozcoNo ratings yet

- Robotic and Automation AssignmentDocument34 pagesRobotic and Automation AssignmentEffa Fazierah LufiasaffeNo ratings yet

- CSR Activities Carried Out by Indian Oil Corporation LTDDocument16 pagesCSR Activities Carried Out by Indian Oil Corporation LTDAmar ItagiNo ratings yet

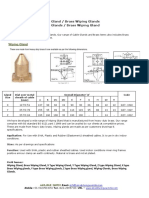

- Wiping Gland Brass Wiping Glands ManufacturerDocument3 pagesWiping Gland Brass Wiping Glands ManufacturerUjjwal ShahNo ratings yet

- Production Supervisor/ Dairy Companies /milk, Cheese, YougourtDocument2 pagesProduction Supervisor/ Dairy Companies /milk, Cheese, YougourtkaramzahiNo ratings yet

- 7583 313435g Husky 1050 Graco EnglishDocument32 pages7583 313435g Husky 1050 Graco EnglishAgus YulfizarNo ratings yet

- SAP RFC vs BAPI, ABAP Objects AdvantagesDocument7 pagesSAP RFC vs BAPI, ABAP Objects AdvantagesImtiyaz khanNo ratings yet

- Royal Wolf Product CatalogueDocument24 pagesRoyal Wolf Product Cataloguelouza8No ratings yet

- Standard Pipe SupportsDocument73 pagesStandard Pipe SupportsSaad Ahmad Siddiqui100% (1)

- Scaleform Unity - Plug-In ReadMe For PCDocument8 pagesScaleform Unity - Plug-In ReadMe For PCVictor FrancoNo ratings yet

- General Description: 4Q TriacDocument13 pagesGeneral Description: 4Q Triachuudk51No ratings yet

- B31 1 1967Document89 pagesB31 1 1967Salvatore CimorelliNo ratings yet

- ABC Analysis Reveals True Costs of Wine ProductsDocument11 pagesABC Analysis Reveals True Costs of Wine ProductsShelly ElamNo ratings yet

- Ankur GuptaDocument2 pagesAnkur GuptaChandan MondalNo ratings yet

- Vintage Airplane - Feb 1987Document32 pagesVintage Airplane - Feb 1987Aviation/Space History LibraryNo ratings yet

- Sap TablesDocument45 pagesSap TablesPrateek PatelNo ratings yet

- Article - BWP HydrocoolingDocument5 pagesArticle - BWP Hydrocoolingmahmoud mohamedNo ratings yet

- Non Disclosure Agreement - Beta TesterDocument3 pagesNon Disclosure Agreement - Beta TesterRocketLawyer100% (3)