Professional Documents

Culture Documents

JSA-Water Proofing Works

Uploaded by

francis_e_tanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA-Water Proofing Works

Uploaded by

francis_e_tanCopyright:

Available Formats

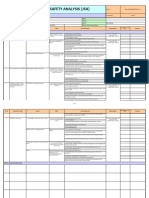

JOB SAFETY ANALYSIS

Roof Water Proofing Works

WORK ACTIVITY: ___________________________________

Each piece of equipment and crew are associated with known specific hazards that cause accidents to reoccur on one project

after another.

P123456

Mhd. Abdul Rahman LOCATION ;____________________

ARAB -D

SITE SUPERVISOR:___________________

PERMIT #:____________

Probability factors.

5

8

6

4

2

1

No

Evaluation Points

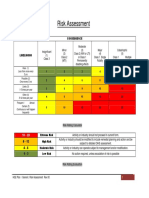

40-20High Risk

Severity Factors

8: Fatality, Permanent Disability

Probability Factors

5 : Extremely High

Abbreviation

E.P :Evaluation Points

1 9 12 Medium Risk

6: Serious Injury (LD>30 days)

4 : Highly Probable

S : Severity Factor

11-5 Low Risk

4: Major Injury (30>LD>4 days)

3 : Probable

P : Probability Factor

2: Minor Injury (4>LD>1 day)

2 : Rare

T : Total Points

1: Negligible

1 : Very Rare

4-1 Negligible

Activity ( Job Steps )

Potential Hazard

Arrival of personnel

and equipments on

site

Unfamiliar with plant

situation and with site

regulation

Work permit from

Client to be obtained.

Unauthorized

commencement of

works may result in

exposing workers and or

potential to harm or

danger

Who/ What Might

Be Harmed

Personnel &

Clients Property

Risk E.P.

SxP=T

4x2=8

Injury to IMCO

Personnel and or

client property.

2x3=6

LD : Lost Workdays

Control/ Recovery Measures

Ensure all personnel are fully

briefed on tasks and responsibilities

Ensure all workers that already

inducted prior to mobilization to

site.

Ensure, prior to work inside the

plant, all workers are having a valid

H2S card.

Authorized PTW holder shall

ensure obtaining and maintaining

valid work permit.

The worksite supervisor responsible

for this activity has to check the

PPE of his staff to ensure that all

required items are available and

properly used.

Target E.P. Responsible/ Action

SxP=T

By

2x1=2

Worksite supervisor

and Site Safety

Officer.

2x1=2

Site supervisor

and Site Safety

Officer.

No

Activity ( Job Steps )

Potential Hazard

Who/ What Might

Be Harmed

Risk E.P.

SxP=T

Pre-task briefing

toolbox talks.

The work force does not

understand the pre task

briefing therefore does

not understand the

potential dangers and

control measures to be

implemented. Some of

the workers could be

lacking PPE or using

defective PPE.

Personnel

2x4=8

Manual lifting of

materials

Cumulative disorders

due to gradual and

cumulative deterioration

of the musculoskeletal

system through

continuous lifting /

handling activities

IMCO personnel

4 x 3 = 12

Page 2 of 8

Control/ Recovery Measures

Inform all workers regarding permit

condition before work starts.

Worksite supervisor shall conduct

toolbox talks about nature of works

and associated potential hazards and

their essential precautionary

measure.

Ensure that the pre task briefing is

given out in a language understood

by the work force, have it

translated.

Ask question regarding the briefing

to get feedback from the staff, this

ensures full comprehension.

Issue required appropriate PPE and

replace PPE that has signs of defect.

PPE must include both hearing

protection as well as dust inhalation

protection.

Designing and organizing tasks to

avoid manual handling completely,

or at least restrict it.

Using automation and lifting

equipment.

Organizing manual handling tasks

in a safe way, with loads split into

smaller ones, and proper rest

periods provided.

Providing information and training

to workers on tasks, and the use of

equipment and correct handling

techniques.

Ensure taking the appropriate

Target E.P.

SxP=T

Responsible/

Action By

2x1=2

Site supervisor

and Site Safety

Officer.

2x1=2

Site supervisor

and Site Safety

Officer.

No

Activity ( Job Steps )

Handling of chemicals

Potential Hazard

Who/ What Might

Be Harmed

Signs of noise distracting IMCO personnel

people, interfering with

their ability to

communicate warnings,

or having the potential to

cause permanent hearing

loss.

IMCO personnel

Corrosive (burn skin or

eyes on contact) or

reactive (burn, explode,

or release hazardous

vapors on contact with

air, water, or other

chemicals)

Flammable or

IMCO personnel,

Risk E.P.

SxP=T

4x2=8

4 x 4 = 16

6 x 4 = 24

Page 3 of 8

Control/ Recovery Measures

organizational measures to reduce

the risk if manual handling cannot

be avoided

To ensure that workers receive

adequate information on the weight

of a load, the centre of gravity, or

the heaviest side when a package is

unevenly loaded

To provide proper training and

precise information on how to

handle loads correctly.

Ensure that personnel are wearing

appropriate hearing protection.

Before handling any chemical,

employees should read the container

label and material safety data sheet

(MSDS) for the chemical and be

sure about hazards and required

safety precautions.

Assemble and inspect personal

protective equipment (PPE)

recommended by the label and

MSDS, ensure to wear appropriate

PPE

Ensure workers have the proper

training and approval from their

supervisor to handle the particular

chemical.

Remove any items from the work

Target E.P.

SxP=T

Responsible/

Action By

2x1=2

Worksite supervisor

and Site Safety

Officer.

2x1=2

Worksite supervisor

and Site Safety

Officer.

2x1=2

Worksite supervisor

No

Activity ( Job Steps )

Potential Hazard

combustible (catch fire

and burn)

Who/ What Might

Be Harmed

Risk E.P.

SxP=T

Client property

damage

Control/ Recovery Measures

Inhalation problem due

to irritating to the

chemical fumes

IMCO personnel

4 x 4 = 16

Skin contact due to

contaminated clothing

IMCO personnel

4 x 4 = 16

Existing Insulation

Removal &

installation of new

insulation

Poor communication

between work parties

Inexperience person /

lack of safety awareness

and knowledge for the

area that could react with the

chemical.

Provide 2 nos. of 9kgs. fire

extinguisher in the area.

Ensure the availability of fire

blanket.

Ensure that all workers working in

this activity are know the location

of fire extinguishers, alarms, firstaid kits, eyewash stations,

emergency showers, and emergency

exits in case of emergency.

Ensure workers have the proper

training and approval from their

supervisor to handle the particular

chemical.

Check adequate ventilation.

Ensure to wear appropriate PPE

Ensure to know the symptoms of

exposure and the appropriate first

aid.

Remove contaminated protective

clothing and PPE carefully to avoid

skin contact with the chemical.

Wash thoroughly after removing

PPE and work clothes.

Target E.P.

SxP=T

Responsible/

Action By

and Site Safety

Officer.

2x1=2

Worksite supervisor

and Site Safety

Officer.

2x1=2

Worksite supervisor

and Site Safety

Officer.

IMCO personnel

and or other

personnel working

nearby

4 x 4 = 16

All operatives persons to have

received site Induction & additional

appropriate training

2x1=2

Worksite supervisor

and Site Safety

Officer.

IMCO personnel

and or other

4 x 4 = 16

Secure apply all PTW and all

supporting document prior to start

2x1=2

Worksite supervisor

and Site Safety

Page 4 of 8

No

Activity ( Job Steps )

Potential Hazard

task

Airborne dust of

insulation materials

Who/ What Might

Be Harmed

Risk E.P.

SxP=T

personnel working

nearby

Control/ Recovery Measures

Target E.P.

SxP=T

the job

Responsible/

Action By

Officer.

Conduct safety tool box talked

meeting and discuss the JSA &

work procedure prior to start a job

Full time supervision is necessary to

ensure the task done in a safe

manner as per MS and JSA

procedure.

IMCO personnel

4 x 4 = 16

Sharp objects

IMCO personnel

4 x 4 = 16

Airborne dust potential

for skin and eye

irritation

IMCO personnel

4 x 4 = 16

Page 5 of 8

Ensure to use full face organic with

HEPA cartridge and Neoprene

gloves recommended

Refer to MSDS of insulation and

take special precaution that may be

specified in the same

Ensure no authorized entry in the

work area / isolate with warning

tapes barricades and warning signs

Full compliance use proper PPE.

Store remove cladding materials at

the designated location and remove

at the area as soon practicable

Remove any other installed object

that may pose a cut hazard while

removal of cladding

Only trained personnel will execute

the job under able supervision

Use sufficient hand protection ( cut

resistant leather gloves)

Keep away and cautions person

allergic to chemical materials

Proper body protection and long

sleeve glove to avoid skin contact

2x1=2

Worksite supervisor

and Site Safety

officer

2x1=2

Worksite supervisor

and Site Safety

officer

2x1=2

Worksite supervisor

and Site Safety

officer

No

Activity ( Job Steps )

Manual handling

Potential Hazard

Who/ What Might

Be Harmed

Risk E.P.

SxP=T

Fire and explosion

IMCO personnel

and or Client

property damage

6 x 4 = 24

Lower back injury

IMCO personnel

4 x 3 = 12

Hand injury due to sharp

edges/corners/ caught

under the load

IMCO personnel

3x3=9

Page 6 of 8

Control/ Recovery Measures

Refer to MSDS of insulation

materials and take any special

precaution that may be specified in

the same

Ensure that the flammable liquids

should be handled in well ventilated

areas.

Effective ventilation should be

applied to prevent accumulation of

flammable aerosol or vapors.

Ensure that flammable liquids

should be stored in safety

containers. The safety containers

should be properly labeled and kept

in a properly constructed fireproof

store when not in use

Spark proof or non-sparking tools

and materials should be used in

areas where flammable dust

accumulation.

Proper lifting technique shall be

applied:

Body shall be kept as close as

possible to the load;

Back straight, bend the knees not

the back when lifting the load

Avoid twisting the body while

lifting the load.

Ask help when necessary

Use adequate hand gloves

Get a better feel of the object when

picking it up by gripping it with the

palm of the hand and the base of the

Target E.P.

SxP=T

Responsible/

Action By

2x1=2

Worksite supervisor

and Site Safety

officer

1x2=2

Worksite supervisor

and Site Safety

officer

1x2=2

Worksite supervisor

and Site Safety

officer

No

Activity ( Job Steps )

Potential Hazard

Who/ What Might

Be Harmed

Risk E.P.

SxP=T

Control/ Recovery Measures

Slips, trips and fall

IMCO personnel

3x3=9

IMCO personnel

2x4=8

Work during extreme

weather/ climate

conditions.

IMCO personnel

Heat Stress, stroke,

exhaustion and or fatigue

6 x 4 = 24

Housekeeping

Construction materials

causing slips, trips and

3 x 4 = 12

Object too heavy for

manual handling

8

IMCO personnel

Page 7 of 8

fingers

Set blocks or spacers underneath the

load to prevent fingers from getting

caught when putting it down.

Know the location where to transfer

the object;

Survey the route and ensure area is

clear of obstructions and tripping

hazards;

Keep a clear vision of your way;

Do not carry bulky objects that

blocks your eyesight;

Take the shortest possible route.

DO NOT DO IT! Use mechanical

equipment to do the job.

Ensure 100% availability of

drinking water at site

Encourage and remind workers to

drink water or rehydration juices

frequently

Frequent rest cycle is highly

recommended during high humidity

index

Resting shed shall be provided for

the workers and shall be

strategically located near the actual

working area.

Worksite supervision/ HSE

personnel shall closely monitor the

condition of workers, intervene as

the need arises.

Regular clearing of worksite

Target E.P.

SxP=T

Responsible/

Action By

1x2=2

Worksite supervisor

and Site Safety

officer

1x2=2

Worksite supervisor

and Site Safety

officer

Worksite supervisor

and Site Safety

officer

1x2=2

1x2=2

Worksite supervisor

and Site Safety

No

Activity ( Job Steps )

Potential Hazard

Who/ What Might

Be Harmed

Risk E.P.

SxP=T

falls

Materials falling from

IMCO personnel

3 x 4 = 12

height

Adequate stacking of materials

Regular inspection and corrective

actions

Regular housekeeping, inspection

and corrective action;

Ensure toe boards are properly

installed on platforms; Adequate

stacking/ storage of materials at

height;

Do not overload platforms

PREPARED BY (HSE)

Name

Target E.P.

SxP=T

Control/ Recovery Measures

Responsible/

Action By

officer

1x2=2

Worksite supervisor

and Site Safety

officer

REVIEWED BY (QP)

----------------------------------------

Name

----------------------------------------

Signature ---------------------------------------

Signature ---------------------------------------

Date

Date

---------------------------------------

Page 8 of 8

---------------------------------------

You might also like

- Job Safety Analysis for Concrete WorksDocument8 pagesJob Safety Analysis for Concrete Worksfrancis_e_tan93% (27)

- Job Hazard Analysis DemolitionDocument2 pagesJob Hazard Analysis DemolitionvinothNo ratings yet

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- JSA For False CeilingDocument4 pagesJSA For False CeilingJaved100% (3)

- JSA For Asphalt Concrete PavingDocument10 pagesJSA For Asphalt Concrete PavingRAMIL75% (4)

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyNo ratings yet

- HIRA, TCS-ACP Sheet FixingDocument2 pagesHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- Cement Plaster JSADocument4 pagesCement Plaster JSAMohammed Minhaj50% (2)

- False CeilingDocument1 pageFalse CeilingChandru67% (3)

- Jsa For Tile FixingDocument4 pagesJsa For Tile FixingMohammed Minhaj100% (1)

- JOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKDocument3 pagesJOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKba ratnaparkheNo ratings yet

- JSA MasnoryDocument4 pagesJSA Masnorysubhanmusadiq100% (1)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- JSA CarpentryDocument2 pagesJSA Carpentrysubhanmusadiq91% (11)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Risk Assessment For WaterproofingDocument5 pagesRisk Assessment For Waterproofingnoufal2780% (10)

- Manual Excavation JSADocument1 pageManual Excavation JSATausif Khan100% (2)

- JSA for Grinding WorkDocument5 pagesJSA for Grinding WorkM M PRADHANNo ratings yet

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Risk Assessment - Finishing Work (Brick, Plaster, Skim, Tiles, Screeding)Document17 pagesRisk Assessment - Finishing Work (Brick, Plaster, Skim, Tiles, Screeding)Muhd Izzat Iskandar Safarudin100% (3)

- Assess and Manage Construction RisksDocument1 pageAssess and Manage Construction RisksAnonymous goXrLOI33% (3)

- JSA For Vegetation ClearingDocument4 pagesJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Job Safetyanalysis: Traffic Control & FlaggingDocument2 pagesJob Safetyanalysis: Traffic Control & Flaggingnasrul draco100% (1)

- JSA Roof Sheeting V3 16 July 06Document6 pagesJSA Roof Sheeting V3 16 July 06Walt Flowers80% (5)

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- Job Safety Analysis PlumbersDocument5 pagesJob Safety Analysis Plumbersallen2912100% (1)

- Job Safety Analysis For Scaffolding 1Document3 pagesJob Safety Analysis For Scaffolding 1Arshad Khan100% (5)

- Job Safety Analysis for Trench WorksDocument1 pageJob Safety Analysis for Trench Worksmurali100% (3)

- Jha RoofingDocument4 pagesJha Roofingahmadhatake100% (1)

- JSA For Brick WorkDocument3 pagesJSA For Brick Workwahyu nugroho83% (6)

- Risk Assessment: N C Tucker LTD Plastering 17/06/2019 NTDocument4 pagesRisk Assessment: N C Tucker LTD Plastering 17/06/2019 NTAngela DaveyNo ratings yet

- Jsa For Installation of Fence & Area GradingDocument11 pagesJsa For Installation of Fence & Area GradingKhuda Buksh80% (10)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works Jsarashid zaman76% (17)

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- 7 - Civil WorkDocument12 pages7 - Civil WorkPerwez21100% (1)

- Structure Dismantling JSADocument2 pagesStructure Dismantling JSAtnssbhaskar69% (13)

- Job Safety Analysis for Shuttering and Deshuttering Form WorkDocument3 pagesJob Safety Analysis for Shuttering and Deshuttering Form Workba ratnaparkhe83% (12)

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Job Hazard Analysis for SurveyingDocument1 pageJob Hazard Analysis for SurveyingYogesh Gowda100% (1)

- BYDP-JHA-05 Erection of ScaffoldingDocument4 pagesBYDP-JHA-05 Erection of ScaffoldingAhmad Shauqi100% (6)

- Job Safety Analysis For Concrete Casting (R-01)Document13 pagesJob Safety Analysis For Concrete Casting (R-01)Suju RajanNo ratings yet

- WMS-02 - Material Unloading & Shifting by Farana & MannuallyDocument5 pagesWMS-02 - Material Unloading & Shifting by Farana & MannuallySufiyan Khedekar100% (2)

- Job Hazard Analysis FormDocument10 pagesJob Hazard Analysis FormJayson Escamillan100% (1)

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- JSA G20 Scaffolding (Erection, Dismantling)Document4 pagesJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Concrete Surface Coating JSA-027Document5 pagesConcrete Surface Coating JSA-027shivgovind pal100% (1)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- JSA - Cable Trench ExcavationDocument9 pagesJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- JSA DOWNLOADING RELAY CONFIGURATIONDocument4 pagesJSA DOWNLOADING RELAY CONFIGURATIONfrancis_e_tan100% (1)

- Job Safety Analysis for Relay ConfigurationDocument4 pagesJob Safety Analysis for Relay Configurationfrancis_e_tan100% (2)

- Job Safety Analysis for Relay ConfigurationDocument4 pagesJob Safety Analysis for Relay Configurationfrancis_e_tan100% (2)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- IMCO Engineering HSE Non-Conformance ReportDocument1 pageIMCO Engineering HSE Non-Conformance Reportfrancis_e_tan100% (1)

- JSA - Cable Trench ExcavationDocument9 pagesJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- JSA-Cable P 112 QDocument11 pagesJSA-Cable P 112 Qfrancis_e_tanNo ratings yet

- HSE Non Compliance Report Log SheetDocument1 pageHSE Non Compliance Report Log Sheetfrancis_e_tan100% (2)

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDocument9 pagesJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Weekly HSE Report GC11110100Document4 pagesWeekly HSE Report GC11110100francis_e_tan100% (2)

- Wind Speed ConvertionDocument1 pageWind Speed Convertionfrancis_e_tanNo ratings yet

- Principle On Risk Assessment and ControlDocument45 pagesPrinciple On Risk Assessment and Controlfrancis_e_tanNo ratings yet

- Work Method Statement PHASEDocument1 pageWork Method Statement PHASEfrancis_e_tanNo ratings yet

- JSA DOWNLOADING RELAY CONFIGURATIONDocument4 pagesJSA DOWNLOADING RELAY CONFIGURATIONfrancis_e_tan100% (1)

- General Work in Khatiyah North - Main StationDocument6 pagesGeneral Work in Khatiyah North - Main Stationfrancis_e_tanNo ratings yet

- Rigger Duties & ResponsibilitiesDocument1 pageRigger Duties & Responsibilitiesfrancis_e_tan100% (9)

- Jsa For KahsDocument3 pagesJsa For Kahsfrancis_e_tan100% (2)

- Sodium Chloride MSDSDocument5 pagesSodium Chloride MSDSIbaharmovic LpuNo ratings yet

- Self-Adhesive Resin Cements Ph-Neutralization, HydrophilicityDocument7 pagesSelf-Adhesive Resin Cements Ph-Neutralization, HydrophilicityCarolina Rodríguez RamírezNo ratings yet

- 2022 Intro To Process and Plant Safety NewDocument163 pages2022 Intro To Process and Plant Safety Newdavid gabriel100% (2)

- Penicillin G Benzathine-Drug StudyDocument2 pagesPenicillin G Benzathine-Drug StudyDaisy Palisoc50% (4)

- Cobb 500 PDFDocument14 pagesCobb 500 PDFNeil Ryan100% (1)

- As en 540-2002 Clinical Investigation of Medical Devices For Human SubjectsDocument8 pagesAs en 540-2002 Clinical Investigation of Medical Devices For Human SubjectsSAI Global - APACNo ratings yet

- Common Safety Method GuidanceDocument66 pagesCommon Safety Method GuidanceDiego UngerNo ratings yet

- 5 (Jeremy Stranks) Health and Safety Pocket BookDocument10 pages5 (Jeremy Stranks) Health and Safety Pocket BookTuralNo ratings yet

- Flexo Uv Ink TroubleshootingDocument22 pagesFlexo Uv Ink TroubleshootingHiba Naser100% (1)

- 2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryDocument5 pages2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryJulio Cesar Velasco CastroNo ratings yet

- Chapter 1: Abnormal Behavior in Historical ContextDocument22 pagesChapter 1: Abnormal Behavior in Historical ContextEsraRamos100% (2)

- Spoiled and Improper PackingDocument4 pagesSpoiled and Improper PackingshirvenaNo ratings yet

- Aripiprazole medication guideDocument3 pagesAripiprazole medication guidemissayayaya100% (1)

- Chapter 3 NotesDocument10 pagesChapter 3 Notesmjamie12345No ratings yet

- Maxicare Individual and Family ProgramDocument43 pagesMaxicare Individual and Family Programbzkid82No ratings yet

- Arthropods: A Guide to the Diverse PhylumDocument10 pagesArthropods: A Guide to the Diverse Phylumpkkalai112No ratings yet

- Computed Tomography (CT) - BodyDocument7 pagesComputed Tomography (CT) - Bodyfery oktoraNo ratings yet

- Atlas Tool Specs SummaryDocument3 pagesAtlas Tool Specs SummaryWaleed Barakat MariaNo ratings yet

- Work, Energy Power RevDocument31 pagesWork, Energy Power RevRency Micaella CristobalNo ratings yet

- Hybridization Review WorksheetDocument6 pagesHybridization Review WorksheetRejed VillanuevaNo ratings yet

- Annotated Bibliography Graphic OrganizerDocument4 pagesAnnotated Bibliography Graphic Organizerapi-348035481No ratings yet

- Texture Crystallisation and Freezing Point DepressionDocument18 pagesTexture Crystallisation and Freezing Point DepressionJán PeterNo ratings yet

- BSN-2D 1st Semester ScheduleDocument2 pagesBSN-2D 1st Semester ScheduleReyjan ApolonioNo ratings yet

- Summative Test in Respiratory SystemDocument2 pagesSummative Test in Respiratory SystemEden Manlosa100% (4)

- SPR MAN 4 14 ET Operating ManualDocument24 pagesSPR MAN 4 14 ET Operating ManualJason WeeksNo ratings yet

- Acute Atelectasis Prevention & TreatmentDocument9 pagesAcute Atelectasis Prevention & TreatmentmetabolismeproteinNo ratings yet

- Employment Law Lubs 3915Document4 pagesEmployment Law Lubs 3915ogunsatoNo ratings yet

- Us Errata Document 11-14-13Document12 pagesUs Errata Document 11-14-13H VNo ratings yet

- Statistics of Design Error in The Process IndustriesDocument13 pagesStatistics of Design Error in The Process IndustriesEmmanuel Osorno CaroNo ratings yet

- Narrative Poetry 6305Document14 pagesNarrative Poetry 6305Siti AisyahNo ratings yet