Professional Documents

Culture Documents

77000

Uploaded by

shashikanth79Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

77000

Uploaded by

shashikanth79Copyright:

Available Formats

Control Valves

n

Accessories

MIL 77000

High Pressure Drop Control Valves with

Multiple Stage Labyrinth Lo-dB Trim

TABLE OF CONTENTS

Introduction ........................................... 1

Model Numbering System ................... 2

Available Sizes & Ratings ................... 2

Cv Chart ................................................. 2

Generala Data ....................................... 3

Seat Leakage Class / Temp. Range .. 3

37-38 Series Actuator Selection ......... 3

Construction .......................................... 4-5

Dimensions ............................................ 6

Typical Applications.............................. 6

MIL 77000 - Introduction

FOREWORD

The 77000 Series Lo-dB valve is designed to reduce

fluid velocities and the resultant noise generation to

tolerable levels, while diminishing metal fatigue and

erosion due to high fluid velocities and vibration, at low

initial installation costs.

Anti-Clog Design

The 77000 Series Lo-dB valves provide control of high

pressure compressible fluids without the erosion,

vibration and high noise levels associated with

conventionally designed control valves. Because of their

relatively large flow passages and a shearing action

provided by their multiple step plug and seat ring

designs, these valves are particularly well suited for

applications involving gases with entrained liquids/solids

or liquids with entrained solids.

Adiabatic Flow with Friction

The principle of Adiabatic Flow with Friction is to

reduce pressure much like the pressure loss which

occurs in a long pipeline. This effect is produced by

letting the fluid pass through a number of restrictions

providing a tortuous flow pattern dissipating energy

through high head loss rather than through shock

waves.

The flow area of the valve trim is gradually increased

toward the downstream section. This compensates for

expansion of the gas with pressure drop and insures a

nearly constant fluid velocity throughout the complete

throttling process.

The reduced velocity thus minimizes the impact erosion

of entrained liquids. The acoustical performance of

77000 series valves is optimal when pressure ratio does

not exceed trim expansion ratio. For higher pressure

ratios, Lo-dB cartridges in the outlet are recommended.

For liquid service, special trim with multiple linear stages

followed by expanding stages provides the optimum in

cavitation and erosion control.

Installation Costs Minimized

The size of the outlet flange is purposely enlarged to

reduce outlet velocity and to eliminate the need for pipe

reducers between the valve and the larger downstream

piping. The outlet flange connection is available in lower

ratings (see specifications). Additional cost savings are

found in the omission of expensive silencers.

Quiet Operation

The multiple step, labyrinth type plug and seat ring

1

incorporate a Stellite faced seating surface at the top

to provide tight shut-off. The rest of the steps do not

touch. The intermeshing flow pattern between the steps

results in a large number of sharp turns for the fluid.

This develops a high velocity head loss (pressure

drop) and therefore a reduced velocity. The shape of

the plug steps is designed to prevent the deposit and

trapping of solids entrained in the liquid stream. Low

velocity also ensures longer trim life due to less

abrasion.

Low Cost Operation and Maintenance

The relatively short stroke of the Lo-dB valve keeps

installation and operation costs low by permitting use

of standard, pneumatic spring diaphragm actuators.

These actuators, used with a ratio lever, provide

sufficient force to close the valve at pressure drops up

to 6000 psi with the spring alone.

Due to integral bonnets, the deep packing box is the

only high pressure seal in the valve. The oversize stem

and plug are welded together to form a sturdy, vibrationproof subassembly having a high natural frequency. The

plug and stem are guided top and bottom for additional

rigidity.

The removable seat ring is clamped against a shoulder

in the valve body by the lower flange. Since the shoulder

is near the bottom flange, the long seat ring is free to

expand and contract with changes in fluid temperature.

Leakage between the seat ring and body is prevented

with a high pressure O-ring seal for near ambient

temperature fluids and the lapped shoulder for high

temperature applications. Raised lips are machined on

the seat ring and body for a possible seal weld.

Smooth, Stable Control, Fail Safe Action

The high rangeability (100: 1) of the Lo-db valve allows

wide variations in controlled flow. Operation is stable

because the low static unbalanced is achieved by

supporting the plug on the lower guide, which acts as a

piston. By admitting a selected intermediate pressure

through internal plug porting, a balance force exists

within the plug which reduces the unbalance force to a

minimum. The valve will fail in the proper direction by

the actuator spring on air failure.

Auxiliary Equipment

A variety of optional pneumatic and electro-pneumatic

positioners, solenoid valves, limit and position switches

and handwheels are available to suit each process

application.

MIL 77000 - General Infor mation

NUMBERING SYSTEM

Trim

Characteristic

Trim Type

Body Series

Trim Type

0.

77

0. Undefined

0.

Undefined

7. Labyrinth Lo-dB

7.

Mod. Linear

Undefined

7-A. Reduced Area

7-B. Full Area

7-C. High Capacity

Single Step

SIZES / RATINGS

INLET

VALVE SIZE (Inch)

OUTLET

(nominal)

Size

(inch)

Rating

ANSI Class

1500# & 2500#

1500# & 2500#

1500# & 2500#

1500# & 2500#

Size

(in)

Maximum Rating

ANSI Class

2500#

900#

2500#

600#

2500#

600#

2500#

: Not available with C Trim

FLOW COEFFICIENTS - RATED Cv

VALVE SIZE (inch)

** Cf factor = 0.99

Trim A (for lowest noise values)**

(nominal)

Area

Ratio

*** Cf factor = 0.9

Trim B**

Trim C*** (single step)

Cv*

Area

Ratio

Cv*

Cv*

4.2

15

1.9

25

45

3.4

35

1.8

50

110

4.0

60

2.4

80

185

3.5

85

2.0

125

260

* : Use in conjunction with Cy factor. Refer MIL Noise Control Manual.

*** : Use Standard Valve SPL prediction method with Cf factor = 0.9.

MIL 77000 - General Information

GENERAL DATA

Body

Trims

Type: Cast with Integral bonnet and bolted outlet flange

Plug & Seat Type : Expanding Labyrinth

Recommended Flow Directions:

Rangeability

: 100 : 1

Characteristic :

Side Inlet Connection - Bottom Outlet

Standard

Connections:

: Modi. Linear

Special Application : Customised

Flanged or Butt welded

Actuator

Gland Packing

Type: 37/38 Series Pneumatic Spring Diaphragm Actuators

Type: With Teflon (<180 C ) or Graphite (>180 C )

with optional Hand Wheels.

moulded split rings.

Options: Electrical, Piston Cylinder

Option: Teflon V Rings, Eco-Lock (Low Emission)

LEAKAGE CLASS / TEMPERATURE RANGE

VALVE TYPE

SEAT

TEMPERATURE

SEAT LEAKAGE

RANGE (C)

(As per ANSI/FCI 70.2)

TYPE

Min.

Max.

Standard

Optional

Metal

-27

566

IV

Soft Seat

-27

149

2 - 6

VI

PRESSURE DROP LIMITATION (Spring - Diaphragm Actuator)

AIR - TO - OPEN

VALVE

STROKE

ACTUATOR

SPRING

ALLOWABLE

Spring

ALLOWABLE

SIZE

(inch)

SIZE

RANGE

PRESSURE DROP

Range

PRESSURE DROP

(psi)

(psi)

(bar)

(psi)

(psi)

(bar)

1.5

15

11-30

5000

345

3-15

5000

345

2.5

18L

12-30

4000

275

3-15

6000

415

3.5

24

9-30

3000

205

3-15

5000

345

3.5

24

19-46

4000

275

3-15

4000

275

Note: Supply pressure 35 psig for all sizes except 50 psig required with 6 valve

AIR - TO - CLOSE

MIL 77000 - Construction

4

17

16

15

7

1

10

13

11

12

14

MIL 77000 STANDARD CONSTRUCTION

4

MIL 77000 - Construction

MATERIAL OF CONSTRUCTION

DRAWING

REF. NO.

TEMPERATURE

PART NAME

-29 0C

+2320C

+4270C

+5660C

STANDARD MATERIAL

17-4 PH St.St. ASTM A564 Gr 630 Condition H1075

1

Valve Plug & Stem

316 St. St. ASTM A479 TP 316 with hard faced guiding area

Packing Flange Stud

Alloy Steel ASTM A 193 Gr B7

Packing Flange Nut

304 St. St. ASTM A 194 Gr B

Packing Flange

Guide Bushng

Carbon Steel ASTM A668 CI B Cadmium Plated

440 C St.St. ASTM 276 TP 440 C Heat Treated

316St. St. ASTM A479TP 316 W hardfacing

Carbon Steel ASTM A216 Gr WCC

Body

316 St. St. ASTM A351 Gr. CF8M.

Chrome Molybdenum Steel ASTM A 217 Gr. C5

Seat Ring

O-Ring Upper & Lower

10

Guide Bushing Plug

316 St.St. ASTM A 351 Gr CF8M W hardfacing

Inconel X750 Silver Plated

Solid Stellite No.6

440C St. St. ASTM 276 TP 440 C Heat Treated

Carbon Steel ASTM A 194 Gr 2H

11

Body Nut

Alloy Steel ASTM A 194 Gr8

Alloy Steel ASTM A 193 Gr B7

12

Body Stud

ASTM A 320 Gr B8

13

Bottom Flange

Same as Body Material

14

Pipe Plug

316 St. St. ASTM A 479 TP 316

15

Packing Spacer/Lantern Ring

304 St. St. ASTM A 479 TP 304

16

Packing

17

Packing Follower

PTFE Graphite

304 St.St. ASTM A479 TP 304

For other material or NACE compliant Material, consult MIL, MIL reserves right to provide superior material, owing to constant

product upgradation.

MIL 77000 - Dimensions/ Applications

APPROXIMATE DIMENSIONS (mm) FOR MIL 77000

APPROXIMATE

VALVE

VALVE DIMENSIONS (mm)

C

INLET

OUTLET

TRIM A& B

460

4

3

570

215

241

365

352

565

280

445

880

300

292

410

430

838

485

526

1120

368

540

475

851

478

686

1210

406

641

560

1050

450

686

1450

730

8

6

6

4

D

TRIM C

395

-

954

508

TYPICAL APPLICATIONS

MIL 77000 Series Multi-stage Control Valve is designed primarily for high-pressure Compressible Fluid Application. These valves effectively controls erosion, vibration and high noise conditions and also allows entrained particles to pass through. This makes 77000 series, an ideal solution for High Pressure, High Temperature, Flashing Liquid Hydrocarbons.

High Pressure Superheated Steam

Turbine Bypass

Steam Vent

Oil & Natural Gas Production

Gas Pressure Reduction

Hydro Carbon processing

High Pressure Hot-Separator Letdown of Flashing Liquid Hydrocarbons

Choke Valves

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Relative MotionDocument14 pagesRelative MotionSunil DasNo ratings yet

- Battery Manual en-GAZ1Document24 pagesBattery Manual en-GAZ1Anonymous eOWJ2HNo ratings yet

- Radiation Physics: Meynard Y. Castro, RRTDocument84 pagesRadiation Physics: Meynard Y. Castro, RRTCyrlle Miranda100% (1)

- Using Excel For Soil TestingDocument18 pagesUsing Excel For Soil TestingQaiser Abbas100% (3)

- Setting Out Circular CurvesDocument21 pagesSetting Out Circular CurvesvpmohammedNo ratings yet

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Gate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12Document1 pageGate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

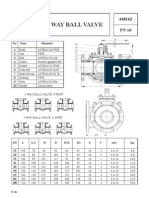

- PN 16 Flanged Ball Valve with ISO Top FlangeDocument1 pagePN 16 Flanged Ball Valve with ISO Top Flangeshashikanth79No ratings yet

- Ball Check Valve: 4740 47401 PN 16 PN 10Document1 pageBall Check Valve: 4740 47401 PN 16 PN 10shashikanth79No ratings yet

- Resilient Seated Gate Valve: 620302 620301 PN 16 PN 10Document1 pageResilient Seated Gate Valve: 620302 620301 PN 16 PN 10shashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 Body No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 Body No Materialshashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Ball Valve Full Bore - Compact: No MaterialDocument1 pageBall Valve Full Bore - Compact: No Materialshashikanth79No ratings yet

- Ball Check Valve Dimensions and SpecificationsDocument1 pageBall Check Valve Dimensions and Specificationsshashikanth79No ratings yet

- Full Bore Flanged Ball ValveDocument1 pageFull Bore Flanged Ball Valveshashikanth79No ratings yet

- Brass Full Bore Screwed End Ball ValveDocument1 pageBrass Full Bore Screwed End Ball Valveshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- 3-Way Gland Cock: No Material 1Document1 page3-Way Gland Cock: No Material 1shashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: No MaterialDocument1 pageBall Valve Full Bore - Flanged End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- Screwed End Stainless Steel Ball Valve Technical SpecificationsDocument1 pageScrewed End Stainless Steel Ball Valve Technical Specificationsshashikanth79No ratings yet

- Full Bore Butt Weld Ball ValveDocument1 pageFull Bore Butt Weld Ball Valveshashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- 3-Way Ball Valve Full Bore - Screwed End: No MaterialDocument1 page3-Way Ball Valve Full Bore - Screwed End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Butt Weld End: 1 No MaterialDocument1 pageBall Valve Full Bore - Butt Weld End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Parts & SpecsDocument1 pageBall Valve Parts & Specsshashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- 3-Way Ball Valve Flanged ISO PN16 Stainless SteelDocument1 page3-Way Ball Valve Flanged ISO PN16 Stainless Steelshashikanth79No ratings yet

- 3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- 3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- Chemical Basbvbms of Pharmacology An Introduction To Pharmacodynamics 1000160027Document394 pagesChemical Basbvbms of Pharmacology An Introduction To Pharmacodynamics 1000160027Andres ZareNo ratings yet

- Chromatographic Techniques WORDDocument56 pagesChromatographic Techniques WORDhelion45No ratings yet

- Ch5 - 2 Relative VelocityDocument22 pagesCh5 - 2 Relative Velocitym_er100No ratings yet

- Models - Mixer.centrifugal PumpDocument22 pagesModels - Mixer.centrifugal Pumpcarlos tNo ratings yet

- Mimonitu PHD 2010 PDFDocument371 pagesMimonitu PHD 2010 PDFMujtabaNo ratings yet

- Physics Ssc-I: Answer Sheet No.Document6 pagesPhysics Ssc-I: Answer Sheet No.Mohsin SyedNo ratings yet

- Alkohol, Eter Dan EpoksidaDocument72 pagesAlkohol, Eter Dan EpoksidaAdi Kurniawan EffendiNo ratings yet

- All Physics Formulae Panorama FrazMallick PDFDocument57 pagesAll Physics Formulae Panorama FrazMallick PDFSiyar AhmadNo ratings yet

- Fluid Flow in Pipes - Lecture 1Document4 pagesFluid Flow in Pipes - Lecture 1amin_corporationNo ratings yet

- Electrical and Optical PropertiesDocument26 pagesElectrical and Optical PropertiesReinhard Dapot ManurungNo ratings yet

- 05.01 - Intraoperative MRI DevelopmentsDocument223 pages05.01 - Intraoperative MRI DevelopmentsBivolaru AlinNo ratings yet

- GD&TDocument33 pagesGD&TDgreatarunNo ratings yet

- The Initial Stall in Span Wise DirectionDocument8 pagesThe Initial Stall in Span Wise DirectionpareshnathNo ratings yet

- 01 - Cryogenics - Nakai PDFDocument63 pages01 - Cryogenics - Nakai PDFSaumya RanjanNo ratings yet

- Fault Analysis: Prof.O.V.Gnana SwathikaDocument18 pagesFault Analysis: Prof.O.V.Gnana SwathikaSarthak VatsNo ratings yet

- History of Laplace TransformDocument4 pagesHistory of Laplace TransformnishagoyalNo ratings yet

- Differential Thermal Analysis (DTA) and Differential Scanning CalorimetryDocument27 pagesDifferential Thermal Analysis (DTA) and Differential Scanning CalorimetryAgustynho MagimbaNo ratings yet

- Light absorption of iron thiocyanate complexDocument5 pagesLight absorption of iron thiocyanate complexErnesto LecuonaNo ratings yet

- Chapter 03 - Flow in PipesDocument83 pagesChapter 03 - Flow in PipesSamnang HangNo ratings yet

- The PENCIL Inspired by Ohm Micro Walsh TallDocument48 pagesThe PENCIL Inspired by Ohm Micro Walsh TallJinu JacobNo ratings yet

- Som 4Document11 pagesSom 4Ronaldo Ulisi100% (1)

- Moment of Force Calculation - Definition, Formula & Examples"TITLE"Principle of Moments - Definition & Equilibrium Examples" TITLE"Calculating Moments: See-Saw, Plank & Weight ProblemsDocument5 pagesMoment of Force Calculation - Definition, Formula & Examples"TITLE"Principle of Moments - Definition & Equilibrium Examples" TITLE"Calculating Moments: See-Saw, Plank & Weight ProblemsPhilip MooreNo ratings yet

- AICTE Model Curriculum Ist YearDocument44 pagesAICTE Model Curriculum Ist YearPushpendra ShuklaNo ratings yet

- 24029962Document269 pages24029962smrndrdasNo ratings yet

- Mikavukasaragod Physics PDFDocument148 pagesMikavukasaragod Physics PDFRaj SinhaNo ratings yet