Professional Documents

Culture Documents

E 233 05

Uploaded by

shashikanth79Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E 233 05

Uploaded by

shashikanth79Copyright:

Available Formats

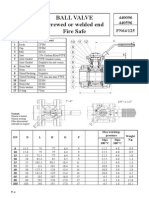

KITZ Butterfly Valves

E-233 = 05

TECHNICAL SPECIFICATIONS

Maximum

service pressures

10UB

1.4MPa

16UB (Size 14 to 24)

1.4MPa

16UB (Size 2 to 12)

150UB

Service

Wall

temperature range

Coupling

PTFE seat

29 to 160

Carbon filled PTFE seat

29 to 200

ASME B 16.34 Class 150

dimensions

6 and smaller

ISO 5752 Short

10UB

JIS 10K

150UB

ASME Class 150

8 and larger

flanges

Size

NPS

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

ISO 5752 Midium

16UB

Flow coefficient (Cv)

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

1.9MPa

thickness

Face-to-face

P-T rating of seats

Valve opening

45

60

33

54

69

112

101

164

182

295

285

462

465

756

883

1440

1450

2350

2230

3610

2790

4520

3700

6010

4850

7880

6030

9800

9030

14700

30

17

36

52

94

147

240

455

743

1150

1440

1910

2500

3110

4650

JIS 16K

MPa

90

83

175

255

460

722

1180

2240

3660

5640

7060

9390

12300

15300

22900

16UB

2.0

1.9

PTFE

0

29

Min.

60

73

88

108

136

162

213

266

312

342

389

444

493

594

ID

Max.

61

77

90

116

143

170

220

275

326

359

410

460

513

615

OD

Min.

90

115

126

146

181

211

257

322

367

410

470

530

580

688

mm

Thickness

Min.

3

3

3

3

3

3

3

3

3

3

3

3

3

3

100 120

Temperature

150 160

200

Pressure Loss (for handling static clean water)

kPa

20

2

21/2

3

4

10

12 14 16 18 20 24

1

0.5

0.2

4.0

10

50

100

500

Flow volume

m3/h

1000

8000

Flow characteristics

100

90

80

70

Cv%

For mounting Valves onto pipes, be sure to use gaskets* specified below:

*Asbestos joint sheet or PTFE sheet

38

Contact KITZ for technical advice when service conditions may exceed the P-T

rating range limited here.

Pressure drop

CAUTION

UB

10UB

1.4

1.3

0.3

0.1

0

Carbon filled PTFE

150

10

Size

NPS

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

Stainless Steel

Butterfly Valves

2.0MPa

60

50

40

30

20

10

0 10 20 30 40 50 60 70 80 90 100

Close

Valve opening

%

Open

1402KPC

KITZ Butterfly Valves

KITZ Butterfly Valves

KITZ Type UB 10K/16K & Class 150

Stainless Steel Butterfly Valves

KITZ Butterfly Valves

LEVER OPERATED

LONG SPINDLE GEAR OPERATED

*KITZ valve codes shall be suffixed with M in case of SCS14A stainless steel body and trim.

*KITZ valve codes shall be suffixed with M in case of SCS14A stainless steel body and trim.

10UB*: Class 10K150UB: Class 150

Double-eccentric kinematics, and all stainless steel bodies and trims guarantee high performance

corrosion resistant service for application of KITZ Type UB butterfly valves to chemical industries.

GL-10UB*: Class 10KGL-16UB: Class 16KGL-150UB: Class 150

DESIGN FEATURES

L1

Rigid SUS304N2 stainless steel stem

D1

D1

H3

Gland can be retightened without lever

or gear disassembly

H1

Low-friction V shape PTFE gland packing rings

Lubrication-free, friction-resistant stem

bearing made of SUS316 and PTFE

Flow

direction

H1

d D

Rigidly built SCS13A* body with ASME

Class 150 wall thickness

Flow

direction

H2

H2

Corrosion resistant PTFE seat ring built

in SUS304* seat retainer

Integral disc stopper to protect seat

ring from damage

E

F

Rigid SCS13A stainless steel disc

Dimensions

SUS304* ring for provision of blowout-proof stem

DN

Size

50

Corrosion resistant PTFE gasket

65

80

100

125

150

Double-eccentric kinematics

The valves stem is designed eccentric to both the center

of the seat ring (by X) and the center of the valve body

(by Y), which makes the clearance C between the seat

ring and the disc seat surface on its fully open position

(Fig.1). Disc seating surface is spherically machined

and contacts PTFE seat tightly thorough 360 for

leak-free service. All these help minimize frictional

wear of seat rings and reduce the valve operating

torque considerably.

Fig.1

Seat ring

X

Close

Stem Axis

Double eccentric design

Single eccentric design

Open

Stem center

Durable seat rings

H1

H2

50

176

138

64

43

78

208

167

82

NPS

2 1/2

4

5

6

Parts

Retightening of gland packing

Gland packing

Fig.2

Gland

Gland bolt

Valve center

Disc

Gland packing

186

98

222

123

241

148

264

148

74

181

92

202

115

225

126

46

52

56

90

115

126

146

181

211

D1

230

280

350

10K

L1

150

120

120.5

150

152.5

140

139.5

175

D1

H3

190.5

210

216.0

240

H1

241.5

Flow

direction

Materials

Seat rings are made of PTFE with stainless steel

supporter. Furthermore, double-eccentric kinematics

relieve seat ring from damage or wear which is a rather

usual problem of conventional butterfly valves, This

makes the service life twice as long as rubber seated

butterfly valves.

There is a room between the gland and the lever or

gear to allow retightening of gland boltings without

trouble of disassembly of the lever or gear during plant

operation. Another feature of KITZ Type UB butterfly

valves (Fig.2).

65

*SCS14A or SUS316 is available as an option

unit : mm

Body

Stem

Disc

Gland

Seat ring

Seat retainer

Gasket

ASTM Materials

JIS Materials

SUS304 N2

SUS304 N2

A351 GR.CF8*1

SCS13A*1

A351 GR.CF8*1

A351 GR.CF8*1

PTFE*

SCS13A*1

SCS13A*1

PTFE*2

A276 TYPE304

SUS304

PTFE

PTFE

PTFE

PTFE

Parts

Set bolt

Taper pin

ASTM Materials

A193 GR.B8

A276 TYPE316

Stem bearing

METAL BACKED PTFE

Thrust washer

PTFE

Gland bolts

End plate

End plate bolts

A193 GR.B8

A351 GR.CF8

A193 GR.B8

JIS Materials

H2

SUS304

SUS316

METAL BACKED PTFE

SUS304

PTFE

SCS13A

SUS304

CF8M(316) /SCS14A(SUS316) is available as an option.

*1.

*2. carbon filled PTFE seat rings are optionally available.

Dimensions

DN

50

The following gaskets should be used for the installation of the valves into pipelines.

[Type of Gasket]

Reinforced PTFE gasket (Jacketed gasket, Spiral Wound gasket or Metal gasket cannot be installed.)

[Dimension of Gasket]

The dimensions of the gasket should comply with ASME B16.21. (Minimum gasket thickness is 3 mm.)

The valves cannot be installed to stub ends.

UB is a unidirectional valve. The valve must be installed according to an arrow, provided on the side of the operator mounting

flange. The arrow must point from the higher pressure side to the lower pressure side in the valve closed position.

NPS

2

65

2 1/2

100

80

CAUTION

Size

125

150

200

600

H2

50

191

138

64

65

78

98

197

14

500

H1

350

450

123

10

400

250

300

unit : mm

12

16

18

20

24

148

243

295

325

371

421

470

569

201

225

239

260

283

350

417

444

476

572

606

622

758

148

167

181

202

74

92

115

126

315

235

342

374

408

442

458

558

25

82

225

263

H3

28

L

43

46

52

280

71

258

60

83

370

95

475

170

398

195

204

47

315

150

56

164

294

L1

76

92

102

114

127

154

310

363

377

D

90

115

126

146

181

211

257

322

367

D1

140

35

42

170

60

310

54

66

360

69

89

70

93.5

200

410

470

530

580

688

500

10K

16K

140

140

120

150

42

90

134

105

213

175

210

240

290

355

400

445

510

565

620

730

150

120

120.5

160

152.5

185

225

260

305

380

430

480

540

605

660

770

139.5

190.5

216.0

241.5

298.5

Gear

type

No.1

No.2

No.3

No.4

No.5

No.6

No.7

KITZ Butterfly Valves

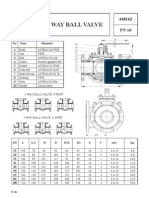

E-233 = 05

TECHNICAL SPECIFICATIONS

Maximum

service pressures

10UB

1.4MPa

16UB (Size 14 to 24)

1.4MPa

16UB (Size 2 to 12)

150UB

Service

Wall

temperature range

Coupling

PTFE seat

29 to 160

Carbon filled PTFE seat

29 to 200

ASME B 16.34 Class 150

dimensions

6 and smaller

ISO 5752 Short

10UB

JIS 10K

150UB

ASME Class 150

8 and larger

flanges

Size

NPS

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

ISO 5752 Midium

16UB

Flow coefficient (Cv)

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

1.9MPa

thickness

Face-to-face

P-T rating of seats

Valve opening

45

60

33

54

69

112

101

164

182

295

285

462

465

756

883

1440

1450

2350

2230

3610

2790

4520

3700

6010

4850

7880

6030

9800

9030

14700

30

17

36

52

94

147

240

455

743

1150

1440

1910

2500

3110

4650

JIS 16K

MPa

90

83

175

255

460

722

1180

2240

3660

5640

7060

9390

12300

15300

22900

16UB

2.0

1.9

PTFE

0

29

Min.

60

73

88

108

136

162

213

266

312

342

389

444

493

594

ID

Max.

61

77

90

116

143

170

220

275

326

359

410

460

513

615

OD

Min.

90

115

126

146

181

211

257

322

367

410

470

530

580

688

mm

Thickness

Min.

3

3

3

3

3

3

3

3

3

3

3

3

3

3

100 120

Temperature

150 160

200

Pressure Loss (for handling static clean water)

kPa

20

2

21/2

3

4

10

12 14 16 18 20 24

1

0.5

0.2

4.0

10

50

100

500

Flow volume

m3/h

1000

8000

Flow characteristics

100

90

80

70

Cv%

For mounting Valves onto pipes, be sure to use gaskets* specified below:

*Asbestos joint sheet or PTFE sheet

38

Contact KITZ for technical advice when service conditions may exceed the P-T

rating range limited here.

Pressure drop

CAUTION

UB

10UB

1.4

1.3

0.3

0.1

0

Carbon filled PTFE

150

10

Size

NPS

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

Stainless Steel

Butterfly Valves

2.0MPa

60

50

40

30

20

10

0 10 20 30 40 50 60 70 80 90 100

Close

Valve opening

%

Open

1402KPC

KITZ Butterfly Valves

KITZ Butterfly Valves

KITZ Type UB 10K/16K & Class 150

Stainless Steel Butterfly Valves

KITZ Butterfly Valves

LEVER OPERATED

LONG SPINDLE GEAR OPERATED

*KITZ valve codes shall be suffixed with M in case of SCS14A stainless steel body and trim.

*KITZ valve codes shall be suffixed with M in case of SCS14A stainless steel body and trim.

10UB*: Class 10K150UB: Class 150

Double-eccentric kinematics, and all stainless steel bodies and trims guarantee high performance

corrosion resistant service for application of KITZ Type UB butterfly valves to chemical industries.

GL-10UB*: Class 10KGL-16UB: Class 16KGL-150UB: Class 150

DESIGN FEATURES

L1

Rigid SUS304N2 stainless steel stem

D1

D1

H3

Gland can be retightened without lever

or gear disassembly

H1

Low-friction V shape PTFE gland packing rings

Lubrication-free, friction-resistant stem

bearing made of SUS316 and PTFE

Flow

direction

H1

d D

Rigidly built SCS13A* body with ASME

Class 150 wall thickness

Flow

direction

H2

H2

Corrosion resistant PTFE seat ring built

in SUS304* seat retainer

Integral disc stopper to protect seat

ring from damage

E

F

Rigid SCS13A stainless steel disc

Dimensions

SUS304* ring for provision of blowout-proof stem

DN

Size

50

Corrosion resistant PTFE gasket

65

80

100

125

150

Double-eccentric kinematics

The valves stem is designed eccentric to both the center

of the seat ring (by X) and the center of the valve body

(by Y), which makes the clearance C between the seat

ring and the disc seat surface on its fully open position

(Fig.1). Disc seating surface is spherically machined

and contacts PTFE seat tightly thorough 360 for

leak-free service. All these help minimize frictional

wear of seat rings and reduce the valve operating

torque considerably.

Fig.1

Seat ring

X

Close

Stem Axis

Double eccentric design

Single eccentric design

Open

Stem center

Durable seat rings

H1

H2

50

176

138

64

43

78

208

167

82

NPS

2 1/2

4

5

6

Parts

Retightening of gland packing

Gland packing

Fig.2

Gland

Gland bolt

Valve center

Disc

Gland packing

186

98

222

123

241

148

264

148

74

181

92

202

115

225

126

46

52

56

90

115

126

146

181

211

D1

230

280

350

10K

L1

150

120

120.5

150

152.5

140

139.5

175

D1

H3

190.5

210

216.0

240

H1

241.5

Flow

direction

Materials

Seat rings are made of PTFE with stainless steel

supporter. Furthermore, double-eccentric kinematics

relieve seat ring from damage or wear which is a rather

usual problem of conventional butterfly valves, This

makes the service life twice as long as rubber seated

butterfly valves.

There is a room between the gland and the lever or

gear to allow retightening of gland boltings without

trouble of disassembly of the lever or gear during plant

operation. Another feature of KITZ Type UB butterfly

valves (Fig.2).

65

*SCS14A or SUS316 is available as an option

unit : mm

Body

Stem

Disc

Gland

Seat ring

Seat retainer

Gasket

ASTM Materials

JIS Materials

SUS304 N2

SUS304 N2

A351 GR.CF8*1

SCS13A*1

A351 GR.CF8*1

A351 GR.CF8*1

PTFE*

SCS13A*1

SCS13A*1

PTFE*2

A276 TYPE304

SUS304

PTFE

PTFE

PTFE

PTFE

Parts

Set bolt

Taper pin

ASTM Materials

A193 GR.B8

A276 TYPE316

Stem bearing

METAL BACKED PTFE

Thrust washer

PTFE

Gland bolts

End plate

End plate bolts

A193 GR.B8

A351 GR.CF8

A193 GR.B8

JIS Materials

H2

SUS304

SUS316

METAL BACKED PTFE

SUS304

PTFE

SCS13A

SUS304

CF8M(316) /SCS14A(SUS316) is available as an option.

*1.

*2. carbon filled PTFE seat rings are optionally available.

Dimensions

DN

50

The following gaskets should be used for the installation of the valves into pipelines.

[Type of Gasket]

Reinforced PTFE gasket (Jacketed gasket, Spiral Wound gasket or Metal gasket cannot be installed.)

[Dimension of Gasket]

The dimensions of the gasket should comply with ASME B16.21. (Minimum gasket thickness is 3 mm.)

The valves cannot be installed to stub ends.

UB is a unidirectional valve. The valve must be installed according to an arrow, provided on the side of the operator mounting

flange. The arrow must point from the higher pressure side to the lower pressure side in the valve closed position.

NPS

2

65

2 1/2

100

80

CAUTION

Size

125

150

200

600

H2

50

191

138

64

65

78

98

197

14

500

H1

350

450

123

10

400

250

300

unit : mm

12

16

18

20

24

148

243

295

325

371

421

470

569

201

225

239

260

283

350

417

444

476

572

606

622

758

148

167

181

202

74

92

115

126

315

235

342

374

408

442

458

558

25

82

225

263

H3

28

L

43

46

52

280

71

258

60

83

370

95

475

170

398

195

204

47

315

150

56

164

294

L1

76

92

102

114

127

154

310

363

377

D

90

115

126

146

181

211

257

322

367

D1

140

35

42

170

60

310

54

66

360

69

89

70

93.5

200

410

470

530

580

688

500

10K

16K

140

140

120

150

42

90

134

105

213

175

210

240

290

355

400

445

510

565

620

730

150

120

120.5

160

152.5

185

225

260

305

380

430

480

540

605

660

770

139.5

190.5

216.0

241.5

298.5

Gear

type

No.1

No.2

No.3

No.4

No.5

No.6

No.7

KITZ Butterfly Valves

KITZ Butterfly Valves

KITZ Type UB 10K/16K & Class 150

Stainless Steel Butterfly Valves

KITZ Butterfly Valves

LEVER OPERATED

LONG SPINDLE GEAR OPERATED

*KITZ valve codes shall be suffixed with M in case of SCS14A stainless steel body and trim.

*KITZ valve codes shall be suffixed with M in case of SCS14A stainless steel body and trim.

10UB*: Class 10K150UB: Class 150

Double-eccentric kinematics, and all stainless steel bodies and trims guarantee high performance

corrosion resistant service for application of KITZ Type UB butterfly valves to chemical industries.

GL-10UB*: Class 10KGL-16UB: Class 16KGL-150UB: Class 150

DESIGN FEATURES

L1

Rigid SUS304N2 stainless steel stem

D1

D1

H3

Gland can be retightened without lever

or gear disassembly

H1

Low-friction V shape PTFE gland packing rings

Lubrication-free, friction-resistant stem

bearing made of SUS316 and PTFE

Flow

direction

H1

d D

Rigidly built SCS13A* body with ASME

Class 150 wall thickness

Flow

direction

H2

H2

Corrosion resistant PTFE seat ring built

in SUS304* seat retainer

Integral disc stopper to protect seat

ring from damage

E

F

Rigid SCS13A stainless steel disc

Dimensions

SUS304* ring for provision of blowout-proof stem

DN

Size

50

Corrosion resistant PTFE gasket

65

80

100

125

150

Double-eccentric kinematics

The valves stem is designed eccentric to both the center

of the seat ring (by X) and the center of the valve body

(by Y), which makes the clearance C between the seat

ring and the disc seat surface on its fully open position

(Fig.1). Disc seating surface is spherically machined

and contacts PTFE seat tightly thorough 360 for

leak-free service. All these help minimize frictional

wear of seat rings and reduce the valve operating

torque considerably.

Fig.1

Seat ring

X

Close

Stem Axis

Double eccentric design

Single eccentric design

Open

Stem center

Durable seat rings

H1

H2

50

176

138

64

43

78

208

167

82

NPS

2 1/2

4

5

6

Parts

Retightening of gland packing

Gland packing

Fig.2

Gland

Gland bolt

Valve center

Disc

Gland packing

186

98

222

123

241

148

264

148

74

181

92

202

115

225

126

46

52

56

90

115

126

146

181

211

D1

230

280

350

10K

L1

150

120

120.5

150

152.5

140

139.5

175

D1

H3

190.5

210

216.0

240

H1

241.5

Flow

direction

Materials

Seat rings are made of PTFE with stainless steel

supporter. Furthermore, double-eccentric kinematics

relieve seat ring from damage or wear which is a rather

usual problem of conventional butterfly valves, This

makes the service life twice as long as rubber seated

butterfly valves.

There is a room between the gland and the lever or

gear to allow retightening of gland boltings without

trouble of disassembly of the lever or gear during plant

operation. Another feature of KITZ Type UB butterfly

valves (Fig.2).

65

*SCS14A or SUS316 is available as an option

unit : mm

Body

Stem

Disc

Gland

Seat ring

Seat retainer

Gasket

ASTM Materials

JIS Materials

SUS304 N2

SUS304 N2

A351 GR.CF8*1

SCS13A*1

A351 GR.CF8*1

A351 GR.CF8*1

PTFE*

SCS13A*1

SCS13A*1

PTFE*2

A276 TYPE304

SUS304

PTFE

PTFE

PTFE

PTFE

Parts

Set bolt

Taper pin

ASTM Materials

A193 GR.B8

A276 TYPE316

Stem bearing

METAL BACKED PTFE

Thrust washer

PTFE

Gland bolts

End plate

End plate bolts

A193 GR.B8

A351 GR.CF8

A193 GR.B8

JIS Materials

H2

SUS304

SUS316

METAL BACKED PTFE

SUS304

PTFE

SCS13A

SUS304

CF8M(316) /SCS14A(SUS316) is available as an option.

*1.

*2. carbon filled PTFE seat rings are optionally available.

Dimensions

DN

50

The following gaskets should be used for the installation of the valves into pipelines.

[Type of Gasket]

Reinforced PTFE gasket (Jacketed gasket, Spiral Wound gasket or Metal gasket cannot be installed.)

[Dimension of Gasket]

The dimensions of the gasket should comply with ASME B16.21. (Minimum gasket thickness is 3 mm.)

The valves cannot be installed to stub ends.

UB is a unidirectional valve. The valve must be installed according to an arrow, provided on the side of the operator mounting

flange. The arrow must point from the higher pressure side to the lower pressure side in the valve closed position.

NPS

2

65

2 1/2

100

80

CAUTION

Size

125

150

200

600

H2

50

191

138

64

65

78

98

197

14

500

H1

350

450

123

10

400

250

300

unit : mm

12

16

18

20

24

148

243

295

325

371

421

470

569

201

225

239

260

283

350

417

444

476

572

606

622

758

148

167

181

202

74

92

115

126

315

235

342

374

408

442

458

558

25

82

225

263

H3

28

L

43

46

52

280

71

258

60

83

370

95

475

170

398

195

204

47

315

150

56

164

294

L1

76

92

102

114

127

154

310

363

377

D

90

115

126

146

181

211

257

322

367

D1

140

35

42

170

60

310

54

66

360

69

89

70

93.5

200

410

470

530

580

688

500

10K

16K

140

140

120

150

42

90

134

105

213

175

210

240

290

355

400

445

510

565

620

730

150

120

120.5

160

152.5

185

225

260

305

380

430

480

540

605

660

770

139.5

190.5

216.0

241.5

298.5

Gear

type

No.1

No.2

No.3

No.4

No.5

No.6

No.7

KITZ Butterfly Valves

E-233 = 05

TECHNICAL SPECIFICATIONS

Maximum

service pressures

10UB

1.4MPa

16UB (Size 14 to 24)

1.4MPa

16UB (Size 2 to 12)

150UB

Service

Wall

temperature range

Coupling

PTFE seat

29 to 160

Carbon filled PTFE seat

29 to 200

ASME B 16.34 Class 150

dimensions

6 and smaller

ISO 5752 Short

10UB

JIS 10K

150UB

ASME Class 150

8 and larger

flanges

Size

NPS

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

ISO 5752 Midium

16UB

Flow coefficient (Cv)

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

1.9MPa

thickness

Face-to-face

P-T rating of seats

Valve opening

45

60

33

54

69

112

101

164

182

295

285

462

465

756

883

1440

1450

2350

2230

3610

2790

4520

3700

6010

4850

7880

6030

9800

9030

14700

30

17

36

52

94

147

240

455

743

1150

1440

1910

2500

3110

4650

JIS 16K

MPa

90

83

175

255

460

722

1180

2240

3660

5640

7060

9390

12300

15300

22900

16UB

2.0

1.9

PTFE

0

29

Min.

60

73

88

108

136

162

213

266

312

342

389

444

493

594

ID

Max.

61

77

90

116

143

170

220

275

326

359

410

460

513

615

OD

Min.

90

115

126

146

181

211

257

322

367

410

470

530

580

688

mm

Thickness

Min.

3

3

3

3

3

3

3

3

3

3

3

3

3

3

100 120

Temperature

150 160

200

Pressure Loss (for handling static clean water)

kPa

20

2

21/2

3

4

10

12 14 16 18 20 24

1

0.5

0.2

4.0

10

50

100

500

Flow volume

m3/h

1000

8000

Flow characteristics

100

90

80

70

Cv%

For mounting Valves onto pipes, be sure to use gaskets* specified below:

*Asbestos joint sheet or PTFE sheet

38

Contact KITZ for technical advice when service conditions may exceed the P-T

rating range limited here.

Pressure drop

CAUTION

UB

10UB

1.4

1.3

0.3

0.1

0

Carbon filled PTFE

150

10

Size

NPS

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

Stainless Steel

Butterfly Valves

2.0MPa

60

50

40

30

20

10

0 10 20 30 40 50 60 70 80 90 100

Close

Valve opening

%

Open

1402KPC

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 320C PDFDocument160 pages320C PDFApri Alhaddad100% (1)

- 7 Hydraulic System, Digging, Handling, Grading Equipment, Misc Equipment-1 PDFDocument561 pages7 Hydraulic System, Digging, Handling, Grading Equipment, Misc Equipment-1 PDFMichael Pearson BungcarasNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- V-103 HAZOP Study Nodes and ParametersDocument15 pagesV-103 HAZOP Study Nodes and ParametersEdna TanNo ratings yet

- Nozzle LoadDocument14 pagesNozzle LoadOluwachidi100% (3)

- SWIMMING POOL HYDRAULIC ANALYSISDocument6 pagesSWIMMING POOL HYDRAULIC ANALYSISdcoveNo ratings yet

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHSathish LingamNo ratings yet

- Analysis of Piping System Used in Chemical PlantDocument7 pagesAnalysis of Piping System Used in Chemical Plantpipestress100% (1)

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Gate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12Document1 pageGate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- PN 16 Flanged Ball Valve with ISO Top FlangeDocument1 pagePN 16 Flanged Ball Valve with ISO Top Flangeshashikanth79No ratings yet

- Ball Check Valve: 4740 47401 PN 16 PN 10Document1 pageBall Check Valve: 4740 47401 PN 16 PN 10shashikanth79No ratings yet

- Resilient Seated Gate Valve: 620302 620301 PN 16 PN 10Document1 pageResilient Seated Gate Valve: 620302 620301 PN 16 PN 10shashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 Body No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 Body No Materialshashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Ball Valve Full Bore - Compact: No MaterialDocument1 pageBall Valve Full Bore - Compact: No Materialshashikanth79No ratings yet

- Ball Check Valve Dimensions and SpecificationsDocument1 pageBall Check Valve Dimensions and Specificationsshashikanth79No ratings yet

- Full Bore Flanged Ball ValveDocument1 pageFull Bore Flanged Ball Valveshashikanth79No ratings yet

- Brass Full Bore Screwed End Ball ValveDocument1 pageBrass Full Bore Screwed End Ball Valveshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- 3-Way Gland Cock: No Material 1Document1 page3-Way Gland Cock: No Material 1shashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: No MaterialDocument1 pageBall Valve Full Bore - Flanged End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- Screwed End Stainless Steel Ball Valve Technical SpecificationsDocument1 pageScrewed End Stainless Steel Ball Valve Technical Specificationsshashikanth79No ratings yet

- Full Bore Butt Weld Ball ValveDocument1 pageFull Bore Butt Weld Ball Valveshashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- 3-Way Ball Valve Full Bore - Screwed End: No MaterialDocument1 page3-Way Ball Valve Full Bore - Screwed End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Butt Weld End: 1 No MaterialDocument1 pageBall Valve Full Bore - Butt Weld End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Parts & SpecsDocument1 pageBall Valve Parts & Specsshashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- 3-Way Ball Valve Flanged ISO PN16 Stainless SteelDocument1 page3-Way Ball Valve Flanged ISO PN16 Stainless Steelshashikanth79No ratings yet

- 3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- 3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- Calculating Two-Phase Pressure DropDocument8 pagesCalculating Two-Phase Pressure DroprondonjjNo ratings yet

- 10 819 Astro Express LF Valve IODocument2 pages10 819 Astro Express LF Valve IOHary FadlyNo ratings yet

- Pulsa Series 680 IomDocument26 pagesPulsa Series 680 IomAgung Pramu AjiNo ratings yet

- Gas Pipe Line DesignDocument31 pagesGas Pipe Line DesignRajnikant DehariaNo ratings yet

- Mold Engineering - How To Calculate The Pressure Drop Through An OrificeDocument3 pagesMold Engineering - How To Calculate The Pressure Drop Through An OrificeCicel JaimaniNo ratings yet

- Schneider Documentation - Hook-Up11sDocument1 pageSchneider Documentation - Hook-Up11sgenih44348No ratings yet

- Thermodynamic and Fluid Flow Equations from Perry's Chemical Engineers' HandbookDocument2 pagesThermodynamic and Fluid Flow Equations from Perry's Chemical Engineers' HandbookSolidWattiesNo ratings yet

- Sistema Diesel 1 PDFDocument13 pagesSistema Diesel 1 PDFstalin vNo ratings yet

- Cat2545145 Cat938hDocument6 pagesCat2545145 Cat938hRafael RodriguezNo ratings yet

- Increasing Pump CapacityDocument3 pagesIncreasing Pump Capacitydk4monjureNo ratings yet

- Interplant Standard - Steel IndustryDocument10 pagesInterplant Standard - Steel IndustryVishal Singh PatelNo ratings yet

- Free Vent For Tank Sizing PDFDocument5 pagesFree Vent For Tank Sizing PDFoppila100No ratings yet

- Standard Dimensions of Spectacle Blind - 8 Blind - EnggCyclopedia PDFDocument12 pagesStandard Dimensions of Spectacle Blind - 8 Blind - EnggCyclopedia PDFMohamed AdelNo ratings yet

- Penn underground utility designDocument2 pagesPenn underground utility designssinda123No ratings yet

- Chapter 5 Lecture 2Document30 pagesChapter 5 Lecture 2burhanuddinNo ratings yet

- Daftar Besi BajaDocument30 pagesDaftar Besi BajaMailbox AditNo ratings yet

- 11 Open ChannelDocument13 pages11 Open ChannelshahqazwsxNo ratings yet

- Principles of convection heat transfer in fluidsDocument6 pagesPrinciples of convection heat transfer in fluidsMhamedNo ratings yet

- Turbo Machinery: Donga Ramesh KumarDocument19 pagesTurbo Machinery: Donga Ramesh KumarxyzNo ratings yet

- Boiler Feedwater PumpDocument2 pagesBoiler Feedwater PumpTHEOPHILUS ATO FLETCHERNo ratings yet