Professional Documents

Culture Documents

Lea - 5S

Uploaded by

allanjules0 ratings0% found this document useful (0 votes)

39 views1 page5S

Original Title

LEA - 5S

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document5S

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views1 pageLea - 5S

Uploaded by

allanjules5S

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Learning Enrichment Activity

5S Visual Management System

What is the 5S System?

Seeing as a Group

Production status

Inventory levels

The 5S visual management system is designed to create a

visual workplace a work environment that is selfexplaining, self-ordering, self-improving. A good 5S

condition is a clean, well-ordered workplace that is the

foundation of improvement.

Knowing as a Group

Delivery

commitments

Goals and schedules

Management rules

Principles of the 5S System:

Sort (S1) sort out what you dont need (when in doubt,

throw it out). Use the Red Tagging tool to

identify unneeded items during the sort phase of

5S. Listed on the red tagged items:

Item classification

Item ID and quantity

Reason for red tagging

Work section

Date

Take the red tag items to a removal location. Anyone can

plead the case for the item to stay. The team makes the

final decision.

Set in order (S2) organize whats left so as to minimize

wasted motion (a place for everything, and

everything in its place). Keep in mind how to place

machines, storage shelves, equipment, etc. to

reduce the waste of motion.

Shine (and Inspect) (S3) Nothing raises a teams spirit

like a clean, well-ordered workplace. This involves:

What to clean

How to clean

Who will do the cleaning

How clean is clean

Develop checklists of what should be cleaned

Cleaning responsibilities and schedules should

be prominently posted

5S stations should be set up and stocked with

cleaning supplies

Oakland University

Pawley Lean Institute

6633 18 Mile Road

Sterling Heights, MI 48314

Acting as a Group

Consensus on

rules and

objectives

Involvement in

improvement

activities

The Visual Management Triangle

Benefits of 5 Ss:

Problem identification: spot abnormal conditions

quickly

Standardization: one way, one place, one level of

cleanliness

Waste elimination: reduce walking, waiting, searching,

etc.

Morale: less clutter, darkness and frustration

Examples:

Use wall charts instead of computers for group

communications. Wall charts or schedules involve the

team and compel action. Computers lack public

interface.

The Detroit Zoo uses elephant paw prints to visually

direct visitors to various animal attractions.

Standardize (S4) maintain the good condition by

applying standards for S1 to S3.

Remember that the best standards are clear,

simple and visual.

Effective standards make the out-of-standard

condition obvious.

Example: an office equipment board tells us

What equipment should be there

What equipment currently are there

Who has taken equipment and when they

will return it.

Sustain (S5) ensure that 5S develops deep roots

through involvement. 5S must belong to each team

member through:

Promotion and Communication (report boards,

contests, 5S core group)

Training

5S Game:

This is a powerful way of demonstrating the benefits of

organized workplaces.

Break into teams.

Each team is to build the same house from two different

boxes of parts.

The first box has unclear instructions and a

disorganized set of parts (to which the 5S methodology

can be applied).

The second box has clear instruction and an organized

set of parts.

Build two houses with legos, one from each box.

What have we discovered?

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Overhead Water Tank Structural AnalysisDocument28 pagesOverhead Water Tank Structural Analysiscollins unanka100% (3)

- Dball-Gm5 en Ig Cp20110328aDocument18 pagesDball-Gm5 en Ig Cp20110328aMichael MartinezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Love Your Design Getting Started GuideDocument14 pagesLove Your Design Getting Started GuideOnalevel100% (9)

- 5S PrincipleDocument53 pages5S PrincipleAmir M. VillasNo ratings yet

- Empowerment Technologies: Quarter 1 - Module 3: Online NavigationDocument20 pagesEmpowerment Technologies: Quarter 1 - Module 3: Online NavigationMark Marasigan87% (38)

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- 5S workplace organization systemDocument1 page5S workplace organization systemallanjulesNo ratings yet

- Electrical Installation and Maintenance NC IiDocument25 pagesElectrical Installation and Maintenance NC Iiallanjules100% (1)

- Operation 490BDocument60 pagesOperation 490BYe Min Htike100% (1)

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document44 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Angel David ChavezNo ratings yet

- Okto Engineering Experience ShareDocument66 pagesOkto Engineering Experience Sharecengiz kutukcuNo ratings yet

- Language Culture and ThoughtDocument24 pagesLanguage Culture and ThoughtLý Hiển NhiênNo ratings yet

- Install and configure computer systemsDocument6 pagesInstall and configure computer systemsallanjulesNo ratings yet

- Column and Thin Layer ChromatographyDocument5 pagesColumn and Thin Layer Chromatographymarilujane80% (5)

- Technical Drafting NC II: Quarter 1 - Module 3Document26 pagesTechnical Drafting NC II: Quarter 1 - Module 3allanjulesNo ratings yet

- Kompyuteran: Other ProblemsDocument2 pagesKompyuteran: Other ProblemsallanjulesNo ratings yet

- Empowerment Technologies Q1-M1 RevisedDocument16 pagesEmpowerment Technologies Q1-M1 Revisedallanjules100% (3)

- Snhs Comlab Rules 15 2Document1 pageSnhs Comlab Rules 15 2allanjulesNo ratings yet

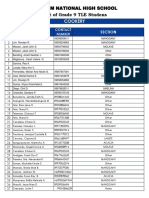

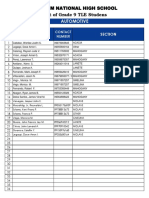

- Sibalom National High School List of Grade 9 TLE Studens: Beauty CareDocument2 pagesSibalom National High School List of Grade 9 TLE Studens: Beauty CareallanjulesNo ratings yet

- Members of Division Development Teams Allowed to Report to Antique Division OfficeDocument5 pagesMembers of Division Development Teams Allowed to Report to Antique Division OfficeallanjulesNo ratings yet

- Sibalom National High School List of Grade 9 TLE Studens: CookeryDocument2 pagesSibalom National High School List of Grade 9 TLE Studens: CookeryallanjulesNo ratings yet

- CSS 9.11 Q1.W1 WD Pages SNHS OnlyDocument40 pagesCSS 9.11 Q1.W1 WD Pages SNHS OnlyallanjulesNo ratings yet

- OFFICE of The Academic Affairs: TOPIC: Introduction To Information and Communication TechnologiesDocument8 pagesOFFICE of The Academic Affairs: TOPIC: Introduction To Information and Communication TechnologiesJhunella Mae Collera SapinosoNo ratings yet

- Sibalom National High School List of Grade 9 TLE Studens: Crop ProductionDocument1 pageSibalom National High School List of Grade 9 TLE Studens: Crop ProductionallanjulesNo ratings yet

- Sibalom National High School Automotive Grade 9 ListDocument2 pagesSibalom National High School Automotive Grade 9 ListallanjulesNo ratings yet

- Sibalom National High School List of Grade 9 TLE Studens: Ict (CSS)Document1 pageSibalom National High School List of Grade 9 TLE Studens: Ict (CSS)allanjulesNo ratings yet

- Room Utilization SNHSDocument2 pagesRoom Utilization SNHSallanjulesNo ratings yet

- SHS Immersion Handbook-SKYEDocument16 pagesSHS Immersion Handbook-SKYEallanjulesNo ratings yet

- 5S PrincipleDocument3 pages5S PrincipleallanjulesNo ratings yet

- Revised Collection Kompyuteran of MARCHDocument83 pagesRevised Collection Kompyuteran of MARCHallanjulesNo ratings yet

- E Tech LectureDocument5 pagesE Tech LectureallanjulesNo ratings yet

- E-Tech LectureDocument5 pagesE-Tech LectureallanjulesNo ratings yet

- Electronic Class Program For TVL IctDocument10 pagesElectronic Class Program For TVL IctallanjulesNo ratings yet

- Sibalom Internet Café Owners' Meeting: Lanz Pizza Hauz Erlinda Arcade, Sibalom, Antique 8-Jun-18Document1 pageSibalom Internet Café Owners' Meeting: Lanz Pizza Hauz Erlinda Arcade, Sibalom, Antique 8-Jun-18allanjulesNo ratings yet

- Contract of Lease Jonalyn2Document2 pagesContract of Lease Jonalyn2allanjulesNo ratings yet

- Down Syndrome: WebsiteDocument2 pagesDown Syndrome: WebsiteallanjulesNo ratings yet

- ICT Tool Cabinet: Depth 0.40MDocument1 pageICT Tool Cabinet: Depth 0.40MallanjulesNo ratings yet

- Kompyuteran: Friza Bebe Date Cashier TotalDocument1 pageKompyuteran: Friza Bebe Date Cashier TotalallanjulesNo ratings yet

- 6 Main Rotor Config DesignDocument44 pages6 Main Rotor Config DesignDeepak Paul TirkeyNo ratings yet

- Lower Congo Basin 3D SurveyDocument2 pagesLower Congo Basin 3D SurveyTalis TemNo ratings yet

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

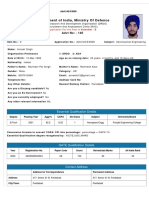

- DrdoDocument2 pagesDrdoAvneet SinghNo ratings yet

- Seminar - Review 2 FinalDocument12 pagesSeminar - Review 2 FinalBhaskaruni Sai TarunNo ratings yet

- Critical Thinking Essay-Animal Testing: Rough DraftDocument10 pagesCritical Thinking Essay-Animal Testing: Rough Draftjeremygcap2017No ratings yet

- Understanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeDocument1 pageUnderstanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeAgus RiyadiNo ratings yet

- CH 11 & CH 12 John R. Schermerhorn - Management-Wiley (2020)Document16 pagesCH 11 & CH 12 John R. Schermerhorn - Management-Wiley (2020)Muhammad Fariz IbrahimNo ratings yet

- Writing A Spooky Setting DescriptionDocument4 pagesWriting A Spooky Setting DescriptionAayan AnjumNo ratings yet

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocument2 pagesNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiNo ratings yet

- Fort St. John - Tender Awards - RCMP Building ConstructionDocument35 pagesFort St. John - Tender Awards - RCMP Building ConstructionAlaskaHighwayNewsNo ratings yet

- Chemical Engineering Assignment SubmissionDocument10 pagesChemical Engineering Assignment SubmissionFahad KamranNo ratings yet

- TSR Cyl Tilt Cab LD 110Document2 pagesTSR Cyl Tilt Cab LD 110Ferry AndisNo ratings yet

- TCBE - Conversation Skills TemplateDocument10 pagesTCBE - Conversation Skills TemplateAryoma GoswamiNo ratings yet

- Vega Plus 69Document3 pagesVega Plus 69yashNo ratings yet

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Mindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicDocument13 pagesMindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicGABRIELNo ratings yet

- Mohammad Abu-Radi ResumeDocument4 pagesMohammad Abu-Radi ResumeMohammad Abu-RadiNo ratings yet

- Adb Wind ConeDocument4 pagesAdb Wind ConeSulistyo WidodoNo ratings yet

- 1136 E01-ML01DP5 Usermanual EN V1.2Document11 pages1136 E01-ML01DP5 Usermanual EN V1.2HectorNo ratings yet

- DRM 25Document14 pagesDRM 25Anantha RajanNo ratings yet

- AR Adjustments: Details, Setup, Flow, Accounting and API: September 5th, 2008Document5 pagesAR Adjustments: Details, Setup, Flow, Accounting and API: September 5th, 2008John SmithNo ratings yet