Professional Documents

Culture Documents

Spigot Socket

Uploaded by

kmmansafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spigot Socket

Uploaded by

kmmansafCopyright:

Available Formats

Spigot & Socket Pipes

Product Range

G = Overall Length

1. All S&S Pipes designed and

meet the requirements of

BS 5911pt.100

Irish Standard IS 6.1974.

F = Effective Length

Spigot End

also known

as male end

Socket End

also known

as bell end

or female

end

2. All dimensions in mm.

H

3. All weights in Kgs based on

density of concrete at 2450

kg/m3

4.

A=DN

D

B

Arrow indicates

flow direction

Indicates pipe reinforced

E

Flexible Jointed Spigot and Socket Pipe

A DN:Inside diam of pipe

Minimum

B Wall

Thickness

Light =

225

300

375

450

525

600

675

750

900 1050 1200 1350 1500 1800 2100

52

55

62

65

70

82

87

95

100

115

140

150

165

190

245

Medium =

52

55

62

65

70

82

87

95

100

115

140

150

165

190

245

Heavy =

52

55

62

65

70

82

87

95

100

115

140

150

165

190

245

C Overall pipe diam

329

410

499

580

665

764

849

940

1100 1280

1490 1658 1838

2188

2598

D Overall socket diam

445

530

645

715

800

910

1005

1100 1280 1380

1640 1800 1980

2270

2598

E Projection of socket

58

60

73

68

68

73

78

46

F Effective length

2000

2500

2500 2500 2500 2500 2500

2500 2500 2500

2500 2500

2500

2500 2500

G Overall pipe length

2100

2600

2600 2600 2600 2600 2620

2620 2620 2620

2640 2640

2640

2645 2645

H Circumference on centre line

870

1115

1373 1618 1869 2158 2394

2655 3142 3660

4210 4710

5230

6250 7360

230

400

550

1640 2100 2650

3660 4300

5200

7400 10500

Approx weight/pipe in kgs

680

850

80

1150 1425

90

50

80

80

80

J Approx no off pipes/21 ton load

90

52

38

30

25

18

15

13

10

K No of meters /21 ton load

180

130

95

75

62.5

45

37.5

32.5

25

20

15

12.5

10

7.5

Length varies

Length varies

BUTT END

SOCKET

BUTT END

SPIGOT

Effective Length

Effective Length

DOUBLE SPIGOT

ROCKER PIPE

Butt End or square end

pipes can be cut on site

or supplied if requested.

Rocker pipes are as

full length pipes

except length.

Made only to order.

Rocker Pipe D.N.

225

300

375

450

525

600

675

750

900

Effective length of S&S Rocker

620

620

620

825

825

825

825

1245 1245

1050 1200 1350 1500

1245

Rockers not recommended see

C.P.S.A. Article on use of Rockers

Ref: TC11/1

Date: 1/12/03

Arrow indicates

flow direction

BUTT END SPIGOT

or double spigot only

where M/H base used

Full length pipes

ROCKER

TRACEY CONCRETE

Limited

Old Rossorry

Sligo Road

Enniskillen

Co.Fermanagh

BUTT END SOCKET

CHANNEL

BENCHING

TYPICAL MANHOLE DETAIL

MANHOLE

RING

ROCKER

As short as possible, but not exceed 600 mm

Minimum 100 mm

(where rocker pipes may be used)

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

Spigot & Socket Pipes

Bends and Junctions

Bends are manufactured by cutting pipes into

two or three segments and joining them

together at the required angle using an epoxy

resin.

Bends

The centre line effective length on bends vary depending on

diameter of pipe.

221/20

111/40

900

450

111/40 degree bend

221/20 degree bend

Although manufactured from class H pipes,

Bends are not load bearing structures and

should be encased in concrete surround to

carry any applied load.

450 degree bend

Offset Distance per meter

900 degree bend

Angle

0

17.46 mm

1 deflection

34.92 mm

20 deflection

98.49 mm

5 /8 deflection

198.91 mm

111/40 deflection

1

414.21 mm

22 /2 deflection

1000.00 mm

450 deflection

e.g. 90 or 45 bends immediately outside a

drop manhole

111/4 Bend placed immediately outside a

manhole

Various Bends in Drains carrying only

rainwater

150 Diameter Bends on pipes from road

gully to main drain.

Junctions are normally attached to full length pipes,

inlet part always being the female or socket end.

Junctions

Inlet pipe may be PVC, clay or concrete.

D1 Not more than D

Concrete surround should always be placed around a

junction.

Square or T junction

D = Inside

Diam

45

Manholes are normally required for inspection

purposes over bends in sewers, however, there

may be occasions where bends are permitted

without a manhole.

Manholes are normally required at intersection of

junctions for inspection purposes, however there may

be occasions where junctions are permitted without the

use of a manhole

D1 Not more

than D

D = Inside

Diam

e.g. smaller diameter pipes from road gullies or one off

houses to main drain which are usually 100 or 150

Diameter and may be P.V.C. clay pipe, or concrete

pipe.

Oblique or Y junction

Tumbling Bay Junctions which are used outside

Drop Manholes are normally attached to full length

pipes which can be provided with Butt End if requested.

Tumbling Bay Junctions

Used in drop manholes.

The male or spigot end is always used as outlet on

Tumbling Bay junctions.

Butt End if requested

The Outlet Diameter Pipe is always the same as the

main pipe.

Square or T tumbling bay

junction

Date: 1/12/03

as D

Oblique or Y tumbling

bay junction

Ref: TC11/2

Tumbling Bay Junctions and associated bends, used

to transfer drain from incoming invert to lower invert

level, must be surrounded in concrete.

450

as D

Customers are asked to give adequate notice of

their requirements for junctions or bends as they

are usually made to order, this is due to the vast

range and type for each diameter of pipe.

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

TRACEY CONCRETE

Limited

Old Rossory

Sligo Road

Enniskillen

Co.Fermanagh

Spigot & Socket Pipes

WATER

14 m

Laboratory Tests in Brief

WATER

Tracey Concrete Ltd have their own modern laboratory

where our technicians carry out the various testsWATER

briefly

described below, to ensure the products meet the strict

Pressure Pads To Seal Pipe Ends

WATER

requirements of BS 5911 pt 100.

List of tests to be carried out on Spigot pipes to

meet the requirements of BS 5911 Pt100

14 m

14 m

14 m

Hydrostatic Test

Fill pipe with water

and pressurize to

20psi. Hold for one

minute, Pipe to show

no signs of leaks

Joint Straight

Draw Test

After pressurizing

hold for 5 minutes,

Joint to show no

sign of leaks

Pipe diam

Test

14 m

Pressure Pads To Seal Pipe Ends

Pressure Pads To Seal Pipe Ends

All sizes

Surface voids

Water

Joint Withdrawn 20mm

7m

Pressure Pads To Seal Pipe Ends

Joint Withdrawn 20mm

Water

7m

Pressure Pads To Seal Pipe Ends

Joint Withdrawn 20mm

7m

Water

Expanding

Stoppers

Of

Joint Withdrawn

20mm To Seal Ends

7m

Expanding Stoppers To Seal Ends Of Pipes

Pipes

Water

Water

Joint Withdrawn 20mm

Expanding Stoppers To Seal Ends Of Pipes

7m

Expanding Stoppers To Seal Ends Of Pipes

Water

Expanding Stoppers To Seal Ends Of Pipes

Water

7m

Joint Deflection

Test

After pressurising

hold for 5 minutes,

Joint to show no

sign of leaks

Water7 m

7m

Water

7m

20 Up to DN 600

10 DN 675 - 1200

0

.5

DN 1350 - 1800

200Up to DN 600

0 Up to DN 600

675 - 1200

120DN

10 DN

DN1350

675- 1800

- 1200

.5

Water

7m

0

.50 DN 1350 - 1800

Joint Shear Test

After pressurizing

and load applied,

hold for 5 minutes.

Joint to show no

sign of leaks

2 Up to DN 600

10 DN 675 - 1200

.50 DN 1350 - 1800

20 Up to DN 600 Load

10 DN 675 - 1200

.50 DN 1350 - 1800

Load

Load

This Pipe

Held Ridget

This Pipe

Held Ridget

Water

This Pipe

Ref: TC11/3

Date: 1/12/03

TRACEY CONCRETE

Limited

Old Rossorry

Sligo Road

Enniskillen

Co.Fermanagh

Water absorption

Hydrostatic

Works proof load

Maximum load

Cover to reinforcement

Straightness

Surface evenness

Joint deflection

Joint straight draw

Joint sheer

up to and

incl. DN 300

Bending moment

resistance (BMR)

Normal routine tests: carried out on samples for each

batch whilst manufacturing, refer to BS 5911 Pt100

Type test: Carried out initially on new joint design or if

any changes occur due to wear or new design, but in

any case at least once per year.

Crushing Test Loads in kN/M

Water

7m

Water

Load

7m

7m

Support At

Balance Point

Load

Support At

Balance

2 Point

Water

7m

Support At

Balance Point

This

Pipe

Support

All of the above tests Held

areRidget

carried out

with

pipeAt

HeldThis

Ridget

Balance

Pipethe pipe or

Support

AtPoint

filled water and pressurized,

joint

Held Ridget

Balance Point

should withstand this test with no sign of leaks.

Crushing Test

See crushing table

for applied loads

per metre, pipe to

sustain its applied

work load for 1

minute without

developing a crack

width greater than

0.25mm.

7m

14m Head of Water = 1.4 BAR = 0.14N/mm = 20 P.S.I.

Bending Moment

Resistance Test

For pipes up to and

including DN 300

which are longer

than 1.25m

Normal

Type

Routine Test Test

WATER

LOAD

LOAD

Refer to BS 5911 Pt100 for full details of above tests.

Water

L = Light

M = Medium

H = Heavy

DN =

Works

Max

Work

Max

Work

Max

Diam

Load

Load

Load

Load

Load

Load

150

20

25

23

29

225

20

25

23

29

300

20

25

23

29

375

20

25

31

39

36

45

450

20

25

35

44

41

52

525

20

25

38

48

46

58

600

20

25

46

58

54

68

675

20

25

50

63

60

75

750

38

48

53

67

65

81

900

46

58

67

84

85

106

1050

51

64

76

95

96

120

1200

58

72

87

109

110

138

1350

63

79

96

120

122

153

1500

69

87

104

130

132

165

1800

82

103

124

155

158

198

2100

96

120

146

183

184

230

Note: For information on the application of the above

pipe crushing test load to design of pipelines, reference

should be made to Simplified tables of external loads on

buried pipelines (HMSO 1986) and A guide to design

loadings for buried rigid pipes (HMSO 1983).

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

Spigot & Socket Pipes

Water test

General Site Testing

Water Test

Air and water tests

All lengths of sewer drain up to DN 750 should be tested

for leakage by means of air or water tests.

A water test is the more logical and conclusive method

of testing a completed pipeline but problems of

availability and disposal of the quantity of water involved

may cause difficulty. Before backfilling, leakage can be

clearly located, its amount assessed and where

necessary appropriate remedies applied.

These tests should be applied after laying and before

backfilling. Some backfill may be placed at the centre of

each pipe to prevent movement during testing.

We strongly recommend that air testing be

undertaken periodically during the laying process,

say every fourth pipe, so as to facilitate

rectification if any defect is found. Short branch

drains connected to a main sewer between manholes

should be tested as one system with the mains sewer.

Long branches should be separately tested.

Man entry sizes of pipeline can be physically inspected

while smaller diameters can be visually inspected from

manholes by means of T.V. cameras.

Visual inspection: Check for1. obstructions and debris,

2. structural soundness of pipes,

3. joints properly sealed,

4. line and level within tolerance

Pipeline under Water Test

(diagram)

Level of water for test

To test the pipeline:1. Insert plugs in both ends of the drain or sewer and in

connections if necessary. Precautions should be

taken by strutting or otherwise to prevent movement

of the drain or sewer during testing.

2. Fill the system with water ensuring all the air has

been expelled.

3. Allow at least two hours before test readings are

taken to allow conditions to stabilise, adding water to

maintain the test head.

It may be necessary to extend this period for large

diameter pipes, up to twenty-four hours or more

before a stable condition is reached.

4. Apply required test head at the upper end by means

of a flexible pipe leading from a graduated container

or stand pipe.

5. Apply the test pressure of 1.2m head of water above

the soffit of the drain or sewer at the high end with a

maximum of 6m head at the low end. If it exceeds

6m test the drain or sewer in stages.

6. Measure the loss of water over a period of 30

minutes by adding and metering quantities of water

at intervals of 5 minutes to maintain original water

level in the standpipe.

Over this 30 minute period the quantity of water added

should not exceed 0.05 litre per 100 linear meters per

millimetre of nominal size of the drain or sewer, i.e. for

a 150m length of DN 800 the allowable leakage

would be:

1.2m Head of

Water (6.0m Max

at lower end)

0.05 x 150 x 800 = 60 litres

----100

Should the pipeline not comply with these

requirements it will probably be attributable to

one of the following:1. leakage from test equipment

2. trapped air,

3. leakage from joints, e.g., displaced ring,

4. leakage from damaged or defective pipe.

Ref: TC11/4

Pipeline Under Water Test

Date: 1/12/03

1.2m

6.0m Max

Plug Strutted if necessary

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

TRACEY CONCRETE

Limited

Old Rossory

Sligo Road

Enniskillen

Co.Fermanagh

Spigot & Socket Pipes

Air testing

Air Test

The air test is very searching and is more convenient

than the water test, but the leakage rate cannot be

measured accurately. An excessive drop in pressure in

the air test may indicate a fault in line such as a

displaced sealing ring. It may be due to faults in the

testing apparatus. Therefore the first check must be on

the apparatus, especially the seals of the stop ends and

all connections. The point of any leakage may be difficult

to detect but spraying with soap solution could indicate

such leakage by the presence of bubbles.

Failure to pass this test in not conclusive and, when

marginal failure does occur, a water test as described

should be made and the leakage rate determined before

a decision as to rejection is made.

Air test requirements are currently specified in British

Standard Codes of Practice BS 8301 Building Drainage

and BS 8005 Sewerage. (5 minute test 100mm on U

tube to drop no more than 25mm). However current

practice in many other European Countries confirms the

research by CPA that the introduction of a higher

pressure test to 1000mm rather than the current 100mm

would overcome most of the shortcomings in BS test.

These may be summarised as follows:1. The BS air test specifies a constant requirement

regardless of diameter and length of the pipeline.

2. The air test is relatively more severe on smaller pipe

diameters.

3. Pipe wall dampness affects air test results,

particularly on smaller diameter pipes and at the low

pressure specified.

Ref: TC11/5

Nominal size of pipe

(DN)

Minimum time for head to

fall from 900mm to 800mm

225

0.9 minutes

300

1.3

375

1.7

450

2.3

525

3.0

600

3.8

675

4.6

750

5.5

900

7.5

1050

10.0

The following air test procedure is consistent

with that described in BS 8301 and the Water

Authorities Association publication Sewers for

Adoption.

1. Seal the ends of the pipeline by means of expanding

or inflatable drain stoppers.

2. Connect a U gauge (manometer) to the test nipple

of the drain stopper by means of rubber tubing.

3. Raise the internal pressure of the system until the U

gauge indicates slightly more than 100mm. Purpose

made drain testing equipment is so calibrated that

the scale indicates the actual pressure in mm water

gauge. (See figure below)

4. Allow about 5 minutes for stabilisation of the air

temperature (a 1 change in temperature is reflected

in a change in pressure of about 38mm on the

gauge).

5. Adjust the pressure to 100mm by either introducing

further air or by bleeding off any excess pressure.

6. Observe the fall in indicated pressure over a 5

minute test period. The residual pressure should be

not less than 75mm.

75

100

90

80

70

60

50

40

30

20

10

0

10

20

30

40

50

60

70

75

75mm 100mm

80

90

100

'U' Gauge

(Manometer)

EXPANDING

STOPPERS

Date: 1/12/03

TRACEY CONCRETE

Limited

Old Rossorry

Sligo Road

Enniskillen

Co.Fermanagh

To test the pipeline, fit strutted plugs at each end and

pump air until a pressure of 1m head is shown on the U

tube. Allow the pressure to drop recording the time for

the head to fall from 900mm to 800mm. This time should

not be less than that shown in the table above for the

appropriate nominal pipe size. These modifications to

the BS test incorporating these higher pressures are

illustrated above.

Air pump or Compressor

Inflatable stoppers etc available from Causeway

Equipment, Belfast Road, Saintfield, Co. Down.

Fax/Phone (028) 9081 2627

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

Spigot & Socket Pipes

Jointing & Laying

Jointing Procedure

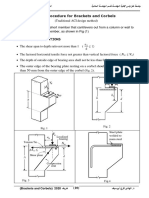

Forsheda 140 Lamell Sliding Rubber seal permits

installation with very little force as there is lubricant

enclosed within the seals sliding layer, thus there is no

friction between concrete pipe and rubberseal.

The sliding layer, when in final position locates itself in

the gap between spigot and socket and then prevents

concrete to concrete contact if pipe is deflected.

Installation

Fit the seal onto spigot as shown on Fig.1.

Centre the spigot in the socket as Fig. 1.

Slide the pipes together and the lubricated flap will

move over top of the compressed rubber seal as

Fig. 2 and finish as shown on Fig. 3.

SOCKET

SPIGOT

Fig 1

rings are compatible with the pipes to be laid, then the

following procedure should be followed:

Clean the Pipe Ends

Brush or wipe with rag to

remove adhering part or water.

Ice may be removed with

methylated or a gas torch. Take care not to damage the

concrete.

Inspect Joint Surfaces

Inspect the joint faces for

damage which may affect the

performance of the joint.

Handle Pipes with Care

Use only proper lifting equipment, eg woven

slings. Make sure the pipe is balanced so that it

is horizontal.

Fit the Ring

Fit the correct ring in the correct

position and equalise the tension

by lifting out intervals at its length

and letting it snap back against the

socket (see Joint details)

Clean the Socket End

Brush and wipe the end of

the pipe fitted previously to

remove any particles or

water, ensure that the receiving socket is clean and

undamaged.

Fig 2

Prepare the

Trench Bed

Make a recess in the bed

to accommodate the pipe.

Line Up the Pipes

Carefully centre the spigot

within the socket.

Fig 3

The relevant pipe diameter is stamped on each rubber

ring. Rubber rings should be carefully stored and

protected from sunlight, oils, greases and heat, if rings

have been tied they should be separated a few days

before using in order to eliminate minor impressions the

tying may have caused.

Joint rings are normally Styrene Butadiene Rubber (SBR)

complying with EN 681-1. Nitrile and Ethylene Propylene

Rubber (EPDM) can be supplied if specifically ordered to

meet special conditions, but are not normally available

from stock.

Make the Joint

The jointing procedure

should develop a steady

controlled push or pull

until joint is in final

position. Method of

jointing will depend on

size of pipe. Ensure timber blocks are used to prevent

damage to socket of pipe.

Ref: TC11/6

Mechanical plant should not be used to push pipes

down to their correct level.

When jointing pipes the last pipe laid sometimes has a

tendency to reassert therefore it should be proped and

checked before laying commences.

Laying Pipes

After ensuring that you are using the correct bedding,

Diameter and class of pipe as specified and that jointing

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

Date: 1/12/03

TRACEY CONCRETE

Limited

Old Rossory

Sligo Road

Enniskillen

Co.Fermanagh

Spigot & Socket Pipes

Recommended Trench width and Bedding pipes

When laying pipes, to attain its full potential as a load

bearing structure, trench width, proper bedding and

backfilling are equally as important as the actual pipe

strength. In fact, almost 50% of the completed structure

is attributed to proper design and good workmanship.

Any increase in trench

width above that

Recommended Maximum

specified will increase

Trench Widths

the load on the pipe

measured at crown of

and a narrower trench

may impede the

pipe = Bd

proper placing and

Pipe

Trench

consolidation of

bedding.

Width

Diam.

150

.600

225

.700

300

.750

375

1.050

450

1.150

525

1.200

600

1.350

675

1.450

750

1.500

900

1.900

1050

2.050

1200

2.300

1350

2.450

1500

2.600

1800

2.950

2100

3.200

2400

3.500

2700

3.800

The trench should be

dug so that the line,

gradient and

dimensions are as

specifications or as

agreed with site

engineer.

The bedding is

intended to level out

any irregularities in the

formation and ensure

uniform support along

the barrell of pipe.

The drawing below generally shows a typically bedding

detail, however contractors should adhere to the type of

bedding details specified which will vary depending on

certain conditions for a particular project.

Typical Bedding Detail

Surface finishing

Normal backfill, degree

of compression will

depend on surface

design requirements

Ground level

Cover to

pipe H

H = Cover

to pipe

Bd

300

Lightly

Compacted

300 above

crown of pipe

Well

compacted

in layers

especially

under

haunches

of pipes

Trench width

maintained to

300 above

crown of pipe

Y

Lightly compacted

under pipe

Temporary drain

where necessary

It is recommended that were pipes have to be airtested,

it should be done every fourth pipe and prior to back

filling.

Cover to pipes (H) laid in fields for agricultural purposes

only = 600mm.

However, it is advisable that pipes laid under roads

carrying traffic or grass verges adjacent to such roads,

should have a minimum 1200mm cover.

Never drive across a pipeline with minimum cover

unless at prepared crossings.

min

of 100

under Barrells

and 50 and

under sockets.

Y = min Y=

of In

100

under

Barrells

50 under

rock, 200 min under Barrell and 150 under socket.

sockets. In rock, 200 min under Barrell and 150

under socket

Ref: TC11/7

Date: 1/12/03

TRACEY CONCRETE

Limited

Old Rossorry

Sligo Road

Enniskillen

Co.Fermanagh

The selections of bedding material and bedding class is

influenced by many factors which include the nature of

the ground, the loads acting on pipeline, availability of a

particular type of bedding material. The ideal is crushed

rock or gravel that is compatible and provides stable

embedment.

Ground water should be kept below the bottom of

trench by use of temporary drains and not allowed to

rise before backfilling is complete.

Special care should be taken with the bedding material

immediately surrounding the pipes to minimise the

possibility of lumps or others coming into direct contact

with pipes thus causing point loading.

Never bulldose backfill directly into trench.

For more details on bedding and pipe specifications see

C.P.S.A. (Concrete Pipe Systems Association)

publications.

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

Spigot & Socket Pipes

Specification, Handling and Storage

C.P.S.A.

60 Charles Street, Leicester

England LE1 1FB

Phone: +44 (0) 116 253 6161

Fax: +44 (0) 116 251 4568

Website: www.concretepipes.co.uk

1. Loads on Buried pipelines in trenches simplified

tables.

2. Hydraulic calculations for sewer and surface water.

3. Laying concrete pipelines in trenches.

4. Jacking Concrete Pipes.

Below describes the markings which the

manufacturer puts on pipes to identify them.

L = Light Duty

see the crushing tables which

M = Medium Duty

shows the load a particular

H = Heavy Duty

diameter of pipe or class

should sustain

R =

Reinforced

Unreinforced

is not identified

SR = Sulphate

Resistant Cement

pipes below DN 900 do not

have to be reinforced

provided they sustain the

relevant loads applied

may be specified for

} this

certain ground conditions.

Handling & Storage

Time and place of loading should be agreed before units

arrive on site. The pipe line contractor should provide

suitable equipment for offloading, stacking and stringing

out pipes and other accessories on site.

Offloading should take place at the nearest hard road to

the point of installation provided it is accessible for

delivery trucks. All units must be left in a stable

condition well clear of the edge of trench.

Pipes should be handled horizontally using a properly

designed c hook or other purpose designed equipment,

but not unprotected chains. For safety reasons always

know the weight of pipe to be lifted.

Fig. 1

Fig. 2

Fig. 3

Never Lift pipes or accessories as shown in Fig. 3

which is likely to cause damage to spigot or

socket.

Where stacking is necessary, this must be on level

ground and the bottom layer of pipes securely chocked

to prevent pipes from rolling or stack from collapsing.

Pipes should be supported under the barrell of the pipe

so that the sockets are free from load, they should

preferably be stacked barrell to barrell with sockets

overhanging alternative sides.

Fig. 4

Fig. 5

2.0M MAX.

Specifying

Spigot & Socket pipes and accessories are manufactured

in accordance with BS 5911 pt 100. This is the relevant

British Standard which sets out the complete

specification including manufacturing tolerances and the

various strength and hydrostatic tests which the final

product must comply with. However it does not include

guidelines on the use if pipes for particular situations.

For Guidelines on specifying the use of pipes including

Diameter, Class, Bedding details etc. refer to Concrete

Pipe Systems Association Publications or your engineers

details.

PC = Portland Cement is not identified

CHOCKES

BS5911 pt100 =

The British Standard to which

the pipe is manufactured.

British Kitemark =

This indicates that the BS

institution, following initial on

site tests and continuous site

assessments, have been

satisfied that the product

meets the relevant standard

and grant the manufacturer a

licence to use the Kitemark

on product.

Manufacturers name, date of manufacture and

internal diam are also marked on pipes

There may be other

marking on pipes such

as colours or batch

number which is solely

for the manufacturers

purposes.

EQUAL

EQUAL

80mm

BALANCE POINT FOR

LIFTING PURPOSES

SOCKET CLEAR OF GROUND

Mainly for safety reasons Diam of Pipe No. of layers

pipes should not be

150-225

6

stacked in greater

4

300-375

numbers of layers than

3

450-600

shown in table.

Generally the height of

675-750

2

stack should not exceed

1

900 and above

2.0m high.

Carefully inspect during off loading to verify that

products comply with order and are not damaged. If a

product fails to meet these conditions notify the

company immediately and record details on delivery

docket.

Pipes or other units which have to be moved, should

never be dragged. If pipes have to be rolled, beware of

rocks or boulders which may damage joint profiles. See

joint details for storage of rubber rings.

T: 028 6632 6437 F: 028 6632 4908( From ROI (048) W: traceyconcrete.com E: headoffice@traceyconcrete.com

Whilst all information was correct at time of printing, the company reserves the right, without notice to the purchaser, to alter or change any dimension or illustration.

Ref: TC11/8

Date: 1/12/03

TRACEY CONCRETE

Limited

Old Rossory

Sligo Road

Enniskillen

Co.Fermanagh

You might also like

- 2007 11 Concrete Pipe 101Document112 pages2007 11 Concrete Pipe 101Hussain MirNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- PVC c900 HP Water PipeDocument8 pagesPVC c900 HP Water Pipeyeli878No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 13 Precast Concrete DrainageDocument20 pages13 Precast Concrete DrainageArun Vaithyanathan100% (1)

- Awwa c900 y c905Document4 pagesAwwa c900 y c905Angel LopezNo ratings yet

- ANSI Post Insulators: Design, Production and Performance of High Voltage Ceramic InsulatorsDocument20 pagesANSI Post Insulators: Design, Production and Performance of High Voltage Ceramic InsulatorsElectricEngineeringNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Sample BOQ Central HVACDocument7 pagesSample BOQ Central HVACbookjaman92% (12)

- FL AWWA Steel Pipelines - 0Document42 pagesFL AWWA Steel Pipelines - 0Francis DhanarajNo ratings yet

- Catalogo Tubería PVC Blue BruteDocument24 pagesCatalogo Tubería PVC Blue Bruteyeli878No ratings yet

- Marley Underground Drainage Aug 08Document17 pagesMarley Underground Drainage Aug 08David Shanks 1No ratings yet

- Technical Manual: Couple With ConfidenceDocument16 pagesTechnical Manual: Couple With Confidencescribd99190No ratings yet

- Series 510 Specification SheetDocument2 pagesSeries 510 Specification SheetFEBCONo ratings yet

- Circular Pipes 1.1.1 and 1.1.2Document2 pagesCircular Pipes 1.1.1 and 1.1.2mohib_mohammedNo ratings yet

- Specifications of Sanitary and Plumbing Works Part 1 ProductDocument12 pagesSpecifications of Sanitary and Plumbing Works Part 1 ProductderekNo ratings yet

- Horseley Bridge Tanks BrochureDocument12 pagesHorseley Bridge Tanks BrochureObinna OkaforNo ratings yet

- uPVC Pipes - Saudi Plastic ProductsDocument3 pagesuPVC Pipes - Saudi Plastic Productsjayh88No ratings yet

- PVC Awwa c900 BluebruteDocument20 pagesPVC Awwa c900 BluebruteRicardo LugoNo ratings yet

- AVK Repair-Clamps BrochureDocument12 pagesAVK Repair-Clamps BrochureAnonymous LfeGI2hMNo ratings yet

- Trenchless Pipe Rehab with Durability of New InstallDocument9 pagesTrenchless Pipe Rehab with Durability of New Installdstefan24No ratings yet

- Conex Cuprofit TechnicalDocument24 pagesConex Cuprofit TechnicalLawrence FoxNo ratings yet

- Ductile Iron CastingsDocument6 pagesDuctile Iron CastingsSusan Sue Berrospi MerinoNo ratings yet

- La Royal LaborDocument7 pagesLa Royal LaborDEVSHILPI ARCHITECTSNo ratings yet

- SoR 2015-16 (PART-IV)Document98 pagesSoR 2015-16 (PART-IV)Srinivasa KavitamNo ratings yet

- Sisteme de ZavorareDocument32 pagesSisteme de ZavorareGabi CristacheNo ratings yet

- Water Distribution System Materials and TestingDocument1 pageWater Distribution System Materials and TestingAhmad Ramin AbasyNo ratings yet

- Aveng INFRASTRUCTURE Brochure 11-14 - Technical DataDocument2 pagesAveng INFRASTRUCTURE Brochure 11-14 - Technical DataChristineNyambeNo ratings yet

- Submittal73 74Document2 pagesSubmittal73 74Sushant GuptaNo ratings yet

- Pipe Drainage Systems for RoadwaysDocument5 pagesPipe Drainage Systems for Roadwaysذوالفقار كريم الابراهيميNo ratings yet

- Tower ParticularsDocument20 pagesTower ParticularsStephen BridgesNo ratings yet

- DAMANSARA CITY MIXED DEVELOPMENT PIPE SUPPORT SPECSDocument4 pagesDAMANSARA CITY MIXED DEVELOPMENT PIPE SUPPORT SPECSjames_chan2178No ratings yet

- 8th Floor Plumbing BOQDocument6 pages8th Floor Plumbing BOQsathish virupaksheNo ratings yet

- Spec - ACODocument5 pagesSpec - ACOReza MohebbiNo ratings yet

- Poly Pipe Rural 2aDocument2 pagesPoly Pipe Rural 2aSarah DeanNo ratings yet

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- ANSI Post Insulators Technical OverviewDocument28 pagesANSI Post Insulators Technical OverviewMateo AlvezNo ratings yet

- (LR) Rainwater System Gyrojoint 04062015Document32 pages(LR) Rainwater System Gyrojoint 04062015sungshinnNo ratings yet

- Ductworks - RevDocument6 pagesDuctworks - RevLuis Gabriel BautistaNo ratings yet

- Concrete Encased Duct Bank PDFDocument8 pagesConcrete Encased Duct Bank PDF101079No ratings yet

- Drill String DesignDocument12 pagesDrill String DesignAsaadgz100% (1)

- Hepworth BG Plastics TPL 040711Document90 pagesHepworth BG Plastics TPL 040711Nick VincentNo ratings yet

- Water Distribution Systems (Sistem Agihan Air)Document49 pagesWater Distribution Systems (Sistem Agihan Air)Hafizuddin HanafiNo ratings yet

- Kent Plumbing - XLSX 231229Document2 pagesKent Plumbing - XLSX 231229purchasehydNo ratings yet

- Bonna Sabla Concrete PipesDocument19 pagesBonna Sabla Concrete Pipesst_calvoNo ratings yet

- En ArpolDocument44 pagesEn ArpoldenemeuserNo ratings yet

- Analysis Book CompleteDocument235 pagesAnalysis Book CompleteparminderNo ratings yet

- Beany Block: Kerb Drainage at Its Most EfficientDocument2 pagesBeany Block: Kerb Drainage at Its Most EfficientMihaela TodiricaNo ratings yet

- Water ReticulationDocument49 pagesWater ReticulationMuhammad Hanafi50% (2)

- Pipe and Pipe JointsDocument11 pagesPipe and Pipe Jointsنور جمال عبدالحليمNo ratings yet

- Reliable Protection for Electrical SystemsDocument9 pagesReliable Protection for Electrical SystemsMadyNo ratings yet

- Water PipeDocument8 pagesWater PipeThanhquy NguyenNo ratings yet

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocument3 pagesSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNo ratings yet

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Plumbing Estimation 1Document2 pagesPlumbing Estimation 1kmmansafNo ratings yet

- Fine tuning estimates by location factorsDocument2 pagesFine tuning estimates by location factorskmmansafNo ratings yet

- The Engineers Toolbox 1Document1 pageThe Engineers Toolbox 1kmmansafNo ratings yet

- Engineer's Guide to Standard Sizes & CalculationsDocument1 pageEngineer's Guide to Standard Sizes & CalculationskmmansafNo ratings yet

- Pages From Research2012 2016 ForWebDocument1 pagePages From Research2012 2016 ForWebkmmansafNo ratings yet

- 13 1Document1 page13 1kmmansafNo ratings yet

- Sewerage Manual Part 1 - With Eurocodes 9Document1 pageSewerage Manual Part 1 - With Eurocodes 9kmmansafNo ratings yet

- Collection of Construction Cost Data Workbook Modified Bills of Quantity FormatDocument2 pagesCollection of Construction Cost Data Workbook Modified Bills of Quantity FormatkmmansafNo ratings yet

- Sewerage Manual Part 1 - With Eurocodes 9Document1 pageSewerage Manual Part 1 - With Eurocodes 9kmmansafNo ratings yet

- The Engineers Toolbox 4Document1 pageThe Engineers Toolbox 4kmmansafNo ratings yet

- The Engineers Toolbox 5Document1 pageThe Engineers Toolbox 5kmmansafNo ratings yet

- The Engineers Toolbox 6Document1 pageThe Engineers Toolbox 6kmmansafNo ratings yet

- Swales Paper - 06-01887 17Document1 pageSwales Paper - 06-01887 17kmmansafNo ratings yet

- Construction Cost Model and Value Engineering StudyDocument1 pageConstruction Cost Model and Value Engineering StudykmmansafNo ratings yet

- Water 2014, 6: 12.0 All Swales-TD-TP Data All Swales-TC-TP Data All Swales-TB-TP Data All Swales-TA-TP DataDocument1 pageWater 2014, 6: 12.0 All Swales-TD-TP Data All Swales-TC-TP Data All Swales-TB-TP Data All Swales-TA-TP DatakmmansafNo ratings yet

- Water 2014, 6: 1902 6. ConclusionsDocument1 pageWater 2014, 6: 1902 6. ConclusionskmmansafNo ratings yet

- Water 2014, 6 - Effectiveness of swales in removing sediment and nutrientsDocument1 pageWater 2014, 6 - Effectiveness of swales in removing sediment and nutrientskmmansafNo ratings yet

- Water 2014, 6: 1902 6. ConclusionsDocument1 pageWater 2014, 6: 1902 6. ConclusionskmmansafNo ratings yet

- Particle Size Distribution Along Swale LengthDocument1 pageParticle Size Distribution Along Swale LengthkmmansafNo ratings yet

- Particle Size Distribution Along Swale LengthDocument1 pageParticle Size Distribution Along Swale LengthkmmansafNo ratings yet

- Swales Paper - 06-01887 9Document1 pageSwales Paper - 06-01887 9kmmansafNo ratings yet

- Removal of Total Suspended Solids and Sediment Particle Sizes by Vegetated SwalesDocument1 pageRemoval of Total Suspended Solids and Sediment Particle Sizes by Vegetated SwaleskmmansafNo ratings yet

- Water 2014, 6: 1892 3. Study ObjectivesDocument1 pageWater 2014, 6: 1892 3. Study ObjectiveskmmansafNo ratings yet

- Water 2014, 6: 900 All Swales-TD-TSS Data All Swales-TC-TSS Data All Swales-TB-TSS Data All Swales-TA-TSS DataDocument1 pageWater 2014, 6: 900 All Swales-TD-TSS Data All Swales-TC-TSS Data All Swales-TB-TSS Data All Swales-TA-TSS DatakmmansafNo ratings yet

- Water 2014, 6: Test Name Swale Name Experiment Inflow Ivmc (%) Outflow (%) WQ TestsDocument1 pageWater 2014, 6: Test Name Swale Name Experiment Inflow Ivmc (%) Outflow (%) WQ TestskmmansafNo ratings yet

- Swales Paper - 06-01887 3Document1 pageSwales Paper - 06-01887 3kmmansafNo ratings yet

- Water 2014, 6: 1896 Figure 2. Conceptual Swale Testing SetupDocument1 pageWater 2014, 6: 1896 Figure 2. Conceptual Swale Testing SetupkmmansafNo ratings yet

- Swales Paper - 06-01887 7Document1 pageSwales Paper - 06-01887 7kmmansafNo ratings yet

- Swales Paper - 06-01887 5Document1 pageSwales Paper - 06-01887 5kmmansafNo ratings yet

- Swales Paper - 06-01887 4Document1 pageSwales Paper - 06-01887 4kmmansafNo ratings yet

- Brackets and Corbels ACI 318 L # 1Document7 pagesBrackets and Corbels ACI 318 L # 1soran azizNo ratings yet

- 10C0003X0 Anixter Wire&Cable Catalog 2010 Sec14 High Tempurature Cable en USDocument16 pages10C0003X0 Anixter Wire&Cable Catalog 2010 Sec14 High Tempurature Cable en USAziz HassanNo ratings yet

- Metals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze ShapesDocument14 pagesMetals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze Shapesrekyts31No ratings yet

- Duplex Stainless SteelDocument17 pagesDuplex Stainless SteelthunderNo ratings yet

- Data Sheet Soundsoak Walls PDFDocument2 pagesData Sheet Soundsoak Walls PDFSameera LakmalNo ratings yet

- MPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7Document1 pageMPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7GauravNo ratings yet

- Multi-Use Product: Technical DataDocument2 pagesMulti-Use Product: Technical Datacorsini999No ratings yet

- Aluminum Mig Wires PDFDocument16 pagesAluminum Mig Wires PDFlemuel bacsaNo ratings yet

- Austenitic Alloy Hardness ConversionDocument1 pageAustenitic Alloy Hardness ConversiongoggerNo ratings yet

- CASTING Design GuideDocument54 pagesCASTING Design GuideXin Yu75% (4)

- CLASS 11450: DEP 31.38.01.15-Gen Class 11450, Rev. I Page 1 of 13Document13 pagesCLASS 11450: DEP 31.38.01.15-Gen Class 11450, Rev. I Page 1 of 13SaguesoNo ratings yet

- Eva Foam SpecificationsDocument1 pageEva Foam SpecificationsachmadnizarNo ratings yet

- Catalogue Surface Electric Pumps 50HzDocument32 pagesCatalogue Surface Electric Pumps 50HzHenry SNo ratings yet

- MCE 541 - Cement Replacement Materials Pozzolanic ReactionsDocument46 pagesMCE 541 - Cement Replacement Materials Pozzolanic ReactionsatousazakariaeiNo ratings yet

- Ring Hangers: (Formerly Afcon Fig. 300) Adjustable Swivel Ring, Tapped Per NFPA StandardsDocument1 pageRing Hangers: (Formerly Afcon Fig. 300) Adjustable Swivel Ring, Tapped Per NFPA StandardsANTONIO GUTIERREZ MIRANDANo ratings yet

- Clash Detection in BIM ModelingDocument63 pagesClash Detection in BIM ModelingSantosh RaiNo ratings yet

- Highly stressed die forgings technical termsDocument22 pagesHighly stressed die forgings technical termsLeo AislanNo ratings yet

- Phase Diagram of Fe-Fe3CDocument25 pagesPhase Diagram of Fe-Fe3CIram MustaviNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- Cracks Phenomenonon HousesDocument22 pagesCracks Phenomenonon HousesSarah MendezNo ratings yet

- 6-17-0002 STD Spec For Steel Work of Fired Heater & APH SystemDocument13 pages6-17-0002 STD Spec For Steel Work of Fired Heater & APH Systemvmraj2001No ratings yet

- 092116Document7 pages092116kupaloidNo ratings yet

- ACE Hammer CatalogueDocument8 pagesACE Hammer CatalogueAgung NgurahNo ratings yet

- Soleal PYn Door Brochure /PUIGMETAL®Document9 pagesSoleal PYn Door Brochure /PUIGMETAL®PUIGMETAL®No ratings yet

- Acid PipingDocument1 pageAcid Pipinghasan_676489616No ratings yet

- SS005-Waterproofing Rev 0Document23 pagesSS005-Waterproofing Rev 0obieNo ratings yet

- 01-1 Spanstress Floor SystemDocument14 pages01-1 Spanstress Floor SystemJohn GaringNo ratings yet

- MIx Design by Shakib SirDocument9 pagesMIx Design by Shakib SirSAUMIK HASAN TANIMNo ratings yet

- Civil Engineering Objective Type Questions by S.S.bhavi - by Civildatas - Blogspot.inDocument764 pagesCivil Engineering Objective Type Questions by S.S.bhavi - by Civildatas - Blogspot.inSuir IsahuNo ratings yet

- OJT-Initial-Report (2) As of Sept 16Document50 pagesOJT-Initial-Report (2) As of Sept 16Ralph GalvezNo ratings yet