Professional Documents

Culture Documents

Base Plate Verification Example

Uploaded by

Karthikeyan VediOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate Verification Example

Uploaded by

Karthikeyan VediCopyright:

Available Formats

8.

2.

Determine required plate thickness:

Note: Since the Mpl is expressed in units of kip-in./in.,

the plate thickness expressions can be formatted without the plate width (B) as such:

tu req =

Verification Example

LRFD

ASD

AISC Design Guide 1, 2nd Edition

4 MPlate

Base

4 M a crit

u crit and Anchor Rod Design

Fy

411.1 kip-in.

0.9036 ksi

= 1.17 in.

=

9.

ta req =

LRFD

ASD

e = 720 kip-in./90 kips = 8.00 in.

e = 480 kip-in./60 kips = 8.00 in.

Then, e > ekern; therefore, anchor rods are required to

resist the tensile force. The anchor rods are assumed to

be 1.5 from the plate edge.

Fy

4 7.68 kip-in.1.67

36 ksi

= 1.19 in.

=

Assume a 14-in. 14-in. base plate. The effective eccentricity is

3.

Determine the length of bearing.

LRFD

ASD

3.06 ksi 14 in.12.5 in. 2.04 ksi 14 in.12.5 in.

f =

2

2

= 178 kips

= 268 kips

f=

Use plate size:

N = 19 in.

B = 19 in.

thus,

t = 14 in.

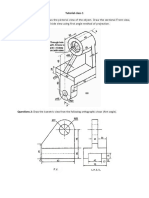

B.5.2 Example: Large Moment Base Plate Design,

Triangular Pressure Distribution Approach

Design the base plate shown in Figure B.4 for an ASD and

LRFD required strength of 60 and 90 kips, respectively, and

moments from the dead and live loads equal to 480 and 720

kip-in., respectively. The ratio of the concrete to base plate

area (A2/A1) is 4.0. Bending is about the strong axis for the

wide ange column W831 with d = bf = 8 in.; Fy of the

base plate and anchor rods is 36 ksi and fc of the concrete

is 3 ksi.

LRFD

ASD

3.0614

2682 4

6

268

(905.5) + 720

A=

3.0614

2.0414

1782 4

6

178

(605.5) + 480

A=

2.0414

= 5.27 in.

= 5.27 in.

1.

LRFD

Pu = 90 kips

M u = 720 kip-in.

Pp

A1

= 0.60(0.85)(3.0)(2)

ASD

Pa = 60 kips

M a = 480 kip-in.

Pp

A1

0.60(1.7)((3.0)

Pp

A1

= 3.06 ksi

Pp

A1

(0.85)(3.0)(2)

2.50

(1.7)(3.0)

2.50

= 2.04 ksi

Figure B.4. Design example with large eccentricity.

60 / DESIGN GUIDE 1, 2ND EDITION / BASE PLATE AND ANCHOR ROD DESIGN

4.

Anchor rods are placed at a 12-in. edge distance. The

required moment strength, Mu pl or Ma pl, for a 1-in. strip

of plate due to the tension in the anchor rods is

Determine the required tensile strength of the anchor

rod.

LRFD

ASD

2.04 ksi 5.27 in.14 in.

3.06 ksi 5.27 in.14 in.

60 kips

90 kips Ta =

2

2

= 15.2 kips

= 22.8 kips

Trod = Ta / 2 = 7.660 kips

= Tu / 2 = 11.4 kips

LRFD

Tu =

Trod

5.

22.8 kips(3.2 in. 1.5 in.)

2(3.2 in. 1.5 in.)

= 11.4 in.-kips/in.

M u pl =

ASD

M a pl

15.2 kips(3.2 in. 1.5 in.)

=

2(3.2 in. 1.5 in.)

= 7.60 in.-kips/in.

Determine the required plate thickness.

The moment for this determination is to be taken at the

critical plate width. This is determined by assuming that

the load spreads at 45 to a location 0.95d of the column. The width is then taken as twice the distance from

the bolt to the critical section for each bolt, provided

that the critical section does not intersect the edge of the

plate.

The critical section, as shown in Figure B.5, is at 14

0.95(8)/2 = 3.2 in.

The required moment strength, Mu pl or Ma pl, for a 1-in.

strip of plate, determined from the bearing stress distribution in Figure B.4, is

LRFD

The required plate thickness is:

LRFD

tp =

4(12.5 in.-kips)

= 1.24 in.

0.9036 ksi

ASD

tp =

4(8.33 in.-kips)(1.67)

= 1.24

36 ksi

Use a 14 14 1-in. base plate.

ASD

2

M u pl =

The required moment strength due to the bearing stress

distribution is critical.

1.20 ksi (3.2 in.)

2

2 (3.06 ksi 1.20 ksi) (3.2 in.) 2

+ 3

2

= 12.5 in-kips/in.

M a pl =

0.80 ksi (3.2 in.)

2

2 ( 2.04 ksi 0.80 ksi) (3.2 in.) 2

3

+

2

= 8.33 in-kips/in.

Figure B.5. Critical plate width for anchor bolt (tension side).

DESIGN GUIDE 1, 2ND EDITION / BASE PLATE AND ANCHOR ROD DESIGN / 61

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

ASDIP Steel 3.2.5

STEEL BASE PLATE DESIGN

GEOMETRY

Column Section .................

W8X31

Width

Length

Column ..........

8.0

8.0

Plate ..............

14.0

14.0

Concrete Wp1 14.0 Lp1 14.0

Support

Wp2 14.0 Lp2 14.0

Rod Offset .....

5.5

5.5

Thickness of Grout ............

1.5

in

in

in

in

in

in

OK

OK

OK

OK

Page # ___

7/20/2014

www.asdipsoft.com

SERVICE LOADS (ASD)

Vertical Load P ................

60.0

Bending Moment M .........

40.0

Horizontal Load V ............

0.0

Design Eccentricity e .......

8.0

Design Eccentricity Is > L/2

MATERIALS

Plate Steel Strength Fy ....

36.0

Pier Concrete Strength f'c

3.0

kip

k-ft

kip

in

ksi

ksi

AXIALLY LOADED PLATES

Cantilever Model

Bearing Stress fp .............

0.31

Critical Section @ Long m

3.20

Critical Section @ Short n

3.80

Plate Thickness tp ..........

0.64

ksi

in

in

in

OK

Thornton Model

Bearing Strength Fp/ .....

2.04

Critical Section @ Int n' .

0.81

Design Moment @ Plate ...

0.10

Plate Thickness tp ............

0.14

ksi

in

k-in/in

in

BASE PLATES WITH MOMENT

Blodgett Method

Max. Bearing Stress fp ...... 1.64

Bearing @ Critical Section

0.88

Moment @ Critical Section

7.11

Moment due to Rod Tension 4.86

Design Moment @ Plate .... 7.11

Plate Thickness tp ............. 1.15

ksi

OK

ksi

k-in/in

k-in/in

k-in/in

in

DeWolf Method

Max. Bearing Stress fp ...... 2.04

Bearing @ Critical Section

0.80

Moment @ Critical Section

8.34

Moment due to Rod Tension 3.86

Design Moment @ Plate .... 8.34

Plate Thickness tp ............. 1.24

ksi

OK

ksi

k-in/in

k-in/in

k-in/in

in

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

ASDIP Steel 3.2.5

STEEL BASE PLATE DESIGN

ANCHORAGE DESIGN

Rod Material Specification .........

F1554-36

(4) Rods , fya = 36.0 ksi, futa = 58.0 ksi

Anchor Rod Size ..

1" diam. x 16.0 in emb.

Concrete Is Cracked at Service Load Level

Tension Analysis (kip)

Total Tension Force N ..........

15.4 kip

Tension Force per Rod Ni ....

7.7 kip

Anchor Reinf: Use 2 Bars #5 per Rod

Failure Mode

Nn N / Nn/

Steel Strength Nsa

2.00

35.1

0.44

Rebars Strength Nrg

2.00

74.4

0.41

Conc. Breakout Ncbg

2.00

N.A.

N.A.

Pullout Strength Npn

2.00

36.0

0.43

Side Blowout Nsbg

2.00

N.A.

N.A.

N / Nn/ Tension Design Ratio ....

0.44 OK

Page # ___

7/20/2014

www.asdipsoft.com

SUMMARY OF RESULTS

Design Moment @ Plate ...

8.3 k-in/in

Plate Thickness tp ............

1.24 in

Max. Bearing Stress fp .....

2.04 ksi

Bearing Strength Fp/ ......

2.04 ksi

fp / Fp/ Design Ratio ..............

1.00 OK

DESIGN IS DUCTILE

Shear Analysis (kip)

Shear Taken by Anchor Rods only

Total Shear Force V ...........

0.0 kip

Shear Force per Rod Vi ......

0.0 kip

All Anchor Rods Are Effective

No Reinforcing Bars Provided

Failure Mode

Vn V / Vn/

Steel Strength Vsa

2.31

16.9

0.00

Rebars Strength Vrg

2.31

N.A.

N.A.

Conc. Breakout Vcbg

2.14

11.9

0.00

Conc. Pryout Vcpg

2.14

52.8

0.00

V / Vn/ Shear Design Ratio ......

0.00 OK

Tension-Shear Interaction

Combined Stress Ratio ...........

0.25

OK

DESIGN CODES

Steel design .............

AISC 360-10 (14th Ed.)

Base plate design ....

AISC Design Series # 1

Anchorage design ...

ACI 318-11 Appendix D

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

ASDIP Steel 3.2.5

STEEL BASE PLATE DESIGN

Tension Breakout

Page # ___

7/20/2014

www.asdipsoft.com

Shear Breakout

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

STEEL BASE PLATE DESIGN

ASDIP Steel 3.2.5

Column Section .................

Width

Length

Column ..........

in

Plate ..............

in

OK

Wp1

Lp1

in

OK

Wp2

Lp2

in

OK

Rod Offset .....

in

OK

Thickness of Grout ............

in

Concrete

Support

Bearing stress

Page # ___

7/20/2014

www.asdipsoft.com

Vertical Load P ................

kip

Bending Moment M .........

k-ft

Horizontal Load V ............

kip

Design Eccentricity e .......

8.0

in

Design Eccentricity Is > L/2

Plate Steel Strength Fy ....

ksi

Pier Concrete Strength f'c

ksi

60.0 / (14.0 * 14.0) = 0.3 ksi

Bearing strength

= 0.85 * 3.0 *

= 5.1 ksi

Under-strength factor = 2.50

Bearing strength ratio =

ACI 9.3.2.4

=

0.3

2.0 / 2.50

= 0.15

< 1.0 OK

Critical section m =

0.5 * (14.0 - 0.95 *8.0) = 3.2 in

Critical section n =

0.5 * (14.0 - 0.80 *8.0) = 3.8 in

[

+

=

Controlling section

ACI 10.14.1

4 * 8.0 * 8.0

(8.0 + 8.0)

] * 0.15 = 0.15

AISC-DG#1 3.1.2

AISC-DG#1 3.1.2

= 0.40

= 2.0 in

Max (3.2, 3.8, 0.40 * 2.0) = 3.8 in

Plate moment

0.3 * 3.8 / 2 = 2.2 k-in/in

Plate thickness

= 3.8 *

= 0.64 in

AISC-DG#1 3.1.2

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

STEEL BASE PLATE DESIGN

ASDIP Steel 3.2.5

Eccentricity

40.0 * 12 / 60.0 = 8.0 in

Page # ___

7/20/2014

www.asdipsoft.com

> L / 6 = 14.0 / 6 = 2.3in

Bearing length

Y = 1.5 * (14.0 / 2 + 5.5) - 0.5 *

Max bearing stress

]-

= 5.3 in

AISC-DG#1 B.4.2

2.0 ksi

Tension

2.0 * 5.3 * 14.0 / 2 - 60.0 = 15.4 kip

Bearing at critical section

2.0 * (1 - 3.2 / 5.3) = 0.8 ksi

Moment due to bearing

AISC-DG#1 B.4.2

AISC-DG#1 3.1.2

Mb = 0.8 * 3.2 / 2 + (2.0 - 0.8) * 3.2 / 3 = 8.3 k-in/in

Moment due to tension

Mt = 7.7 * [3.2 - (14.0 / 2 - 5.5)] / [2 * (3.2 - (14.0 / 2 - 5.5))] = 3.9 k-in/in

Plate thickness

= 1.24 in

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

STEEL BASE PLATE DESIGN

ASDIP Steel 3.2.5

Page # ___

7/20/2014

www.asdipsoft.com

Rod Material Specification ...... F1554-36 , Use (4) Rods , fya = 36.0 ksi, futa = 58.0 ksi

Anchor Rod Size .... 1" diam. x 16.0 in emb. ,

Ase = 0.61 in , Abrg = 1.50 in

ACI D.5

Total tension force N = 15.4 kip ,

# of tension rods = 2 , Tension force per rod Ni = 7.7 kip

- Steel strength of anchors in tension

Steel strength

ACI D.5.1

0.606 * 58.0 = 35.1 kip

ACI Eq. (D-2)

Under-strength factor = 2.00

Steel strength ratio =

ACI D.4.3

=

7.7

= 0.44 < 1.0 OK

35.1 / 2.00

ACI D.4.1.1

- Concrete breakout strength of anchors in tension

ACI D.5.2

Anchor reinforcement: Use 2 bars #5 per rod

Bar strength

0.31 * 2 * 2 * 60 = 74.4 kip

Under-strength factor = 2.00

Bar strength ratio =

ACI D.5.2.9

=

15.4

= 0.41 < 1.0 OK

74.4 / 2.00

Effective embedment

ACI D.4.1.1

19.50 / 1.5 = 13.00 in

ACI D.5.2.3

Anchor group area

Anc = (19.5 + 8.5) * (8.5 + 11.0 + 8.5) = 784.0 in

Single anchor area

Single anchor strength

Eq. (D-5)

= 24

Eccentricity factor

= 61.6 kip

1.00 (No eccentric load)

Edge effects factor

Cracking factor

ACI D.5.2.1

9 * (13.0) = 1521.0 in

= 0.7 + 0.3

1.00

Eq. (D-6)

ACI D.5.2.4

8.5

= 0.83

1.5 * 13.0

(Cracked concrete at service load level)

ACI D.5.2.5

ACI D.5.2.6

Breakout strength

784.0

1.00 * 0.83 * 1.00 * 61.6 = 26.4 kip

1521.0

Eq. (D-4)

Under-strength factor = 2.00

ACI D.4.3

Breakout strength ratio =

15.4

= 1.17 > 1.0 NG

26.4 / 2.00

Bar strength ratio controls (0.41 < 1.17)

ACI D.5.2.9

- Concrete pullout strength of anchors in tension

Single anchor strength

Cracking factor

ACI D.5.3

8 * 1.50 * 3.0 = 36.0 kip

1.00

(Cracked concrete at service load level)

Pullout strength

1.00 * 36.0 = 36.0 kip

ACI Eq. (D-14)

ACI D.5.3.6

ACI Eq. (D-13)

Under-strength factor = 2.00

Pullout strength ratio =

ACI D.4.1.1

ACI D.4.3

=

7.7

= 0.43

36.0 / 2.00

< 1.0 OK

ACI D.4.1.1

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

STEEL BASE PLATE DESIGN

ASDIP Steel 3.2.5

- Concrete side-face blowout strength of anchors in tension

Page # ___

7/20/2014

www.asdipsoft.com

ACI D.5.4

Side-face blowout Nsbg = N.A. (Embed < 2.5 Ca , 16.0 < 2.5 * 8.5 = 21.3)

ACI D.5.4.1

Tension Design Ratio =

ACI D.4.1.1

= 0.44 < 1.0 OK

ACI D.5

Shear resisted by Anchor Rods only

Total shear force V = 0.0 kip ,

(anchor rods are welded to the base plate)

Shear per rod Vi = 0.0 kip , (all anchor rods are effective)

- Steel strength of anchor rods in shear

Steel strength

0.6 * 0.61 * 58.0 * 0.80 = 16.9 kip

Under-strength factor = 2.31

Steel strength ratio =

ACI D.6.1.2

ACI D.4.3

0.0

= 0.00

16.9 / 2.31

< 1.0 OK

- Concrete breakout strength of anchors in shear

ACI D.4.1.1

ACI D.5.2

No Reinforcing bars provided

Anchor group area

Avc = (1.5 * 8.00) * (8.50 + 11.00 + 8.50) = 336.0 in

Single anchor area

ACI D.6.2.1

4.5 * (8.00) = 288.0 in

Eq. (D-32)

Single anchor strength

Vb =

Vb = 11.2 kip

Eccentricity factor

1.00 (No eccentric load)

Edge effects factor

Cracking factor

= 0.7 + 0.3

1.00

Eq. (D-33)

ACI D.6.2.5

8.50

= 0.91

1.5 * 8.0

(Cracked concrete at service load level)

Thickness factor

ACI D.6.2.6

ACI D.6.2.7

ACI D.6.2.8

Breakout strength

336.0

288.0

1.00 * 0.91 * 1.00 * 1.00 * 11.2 = 11.9 kip

Under-strength factor = 2.14

Breakout strength ratio =

Eq. (D-31)

ACI D.4.3

0.0

= 0.00 < 1.0 OK

11.9 / 2.14

Breakout strength ratio controls (0.00 < 0.00)

ACI D.4.1.1

ACI D.6.2.9

Project: Verification Example

Engineer: Javier Encinas, PE

Descrip: Base Plate Verification

STEEL BASE PLATE DESIGN

ASDIP Steel 3.2.5

Page # ___

7/20/2014

www.asdipsoft.com

- Concrete pryout strength of anchors in shear

Pryout strength

2.0 * 11.9 = 52.8 kip

ACI D.6.3.1

Under-strength factor = 2.14

ACI D.4.3

Pryout strength ratio =

Shear Design Ratio =

0.0

= 0.00

52.8 / 2.14

< 1.0 OK

= 0.00 < 1.0 OK

ACI D.4.1.1

ACI D.4.1.1

Combined Stress Ratio =

Combined Stress Ratio =

= 0.25

< 1.0 OK

ACI RD.7

Anchorage design is ductile

Steel design ...................

AISC 360-10 (14th Ed.)

Base plate design ..........

AISC Design Series # 1

Anchorage design .........

ACI 318-11 Appendix D

You might also like

- F - Deludge SystemDocument11 pagesF - Deludge Systemkelvin_totNo ratings yet

- Structural Requirements For EquipmentDocument11 pagesStructural Requirements For EquipmentJDGM01No ratings yet

- PILE FDN DESIGN For NMD TOWERDocument12 pagesPILE FDN DESIGN For NMD TOWERraj mNo ratings yet

- Hilti - Factored Loads in The Context of Anchor DesignDocument21 pagesHilti - Factored Loads in The Context of Anchor DesignPatrice AudetNo ratings yet

- LRFD AsdDocument9 pagesLRFD Asdshilpijain0504No ratings yet

- Shear Key or Shear Lug Design - US AISC SectionDocument4 pagesShear Key or Shear Lug Design - US AISC SectionJun AtienzaNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- GS. Load Types in STAAD - ProDocument2 pagesGS. Load Types in STAAD - ProFrancis CayananNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionDocument3 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionVenu GopalNo ratings yet

- SP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96Document200 pagesSP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96santhosh kumar BudiNo ratings yet

- 10753-Ep 4-1-1Document37 pages10753-Ep 4-1-1FcosmeNo ratings yet

- 1090-Structural Design Basis For Brazil ProjectDocument7 pages1090-Structural Design Basis For Brazil Projectask.kulkarni KulkarniNo ratings yet

- 3.1 - General Principles of Dynamic DesignDocument36 pages3.1 - General Principles of Dynamic DesignKevin OzNo ratings yet

- Appendix-2 Seismic "G" Load CalculationDocument2 pagesAppendix-2 Seismic "G" Load Calculationkemo10No ratings yet

- Wind Loads For High-Solidity Open-Frame StructuresDocument14 pagesWind Loads For High-Solidity Open-Frame StructuresEric Chien100% (1)

- PEC EN STN C 13619 17 Mar 2014Document169 pagesPEC EN STN C 13619 17 Mar 2014Raja RamNo ratings yet

- Imp Design GuideDocument32 pagesImp Design GuideRahulNo ratings yet

- Circular Footing (HUGO2)Document89 pagesCircular Footing (HUGO2)nelsonhugoNo ratings yet

- WeldDocument7 pagesWeldMuhammad Akbar Faereza NugrahaNo ratings yet

- AASHTO-2009 Highway Signs 159 PDFDocument1 pageAASHTO-2009 Highway Signs 159 PDFer_rahmansNo ratings yet

- Practical Design Stepped ColumnsDocument12 pagesPractical Design Stepped ColumnstaosyeNo ratings yet

- Seismic Coefficients Non Building StructuresDocument3 pagesSeismic Coefficients Non Building StructuresBunkun15No ratings yet

- 00calculation Sheet For MMII Compressor Shed1Document31 pages00calculation Sheet For MMII Compressor Shed1clarkgaguiNo ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- 420 Transformer FDN For Panjarpur-6.0mtr26.5.06Document21 pages420 Transformer FDN For Panjarpur-6.0mtr26.5.06Zulkifli BasriNo ratings yet

- Pipe Rack 1803-Pr-01 Calculation For Pilings & Pile Caps: Megha Engineering & Infrastructure LTD Intecsa IndustrialDocument1 pagePipe Rack 1803-Pr-01 Calculation For Pilings & Pile Caps: Megha Engineering & Infrastructure LTD Intecsa IndustrialphanikrishnabNo ratings yet

- 1613.8 ASCE 7-10, Table 12.2-1 SesmicDocument4 pages1613.8 ASCE 7-10, Table 12.2-1 Sesmiclaila. areebNo ratings yet

- 01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFDocument75 pages01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFkapilNo ratings yet

- Day 2 S3 BNBC 2020Document75 pagesDay 2 S3 BNBC 2020November RainNo ratings yet

- BY Pooja Pingle: Structwel Designers & ConsultantsDocument23 pagesBY Pooja Pingle: Structwel Designers & ConsultantssachinapkarNo ratings yet

- Anchor Design HILTIDocument14 pagesAnchor Design HILTIRohit GadekarNo ratings yet

- QES PEVC-ENG262 - Checklist For Tower Foundation Design & DrawingDocument2 pagesQES PEVC-ENG262 - Checklist For Tower Foundation Design & DrawingRupesh KhandekarNo ratings yet

- USD T BeamDocument10 pagesUSD T BeammanowarNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- Bentley Q&ADocument35 pagesBentley Q&AinnovativekarthiNo ratings yet

- Reinforcement Detailing BrochureDocument2 pagesReinforcement Detailing BrochureAbd Al-Gaffar BajouriNo ratings yet

- Section Modulus 012004Document2 pagesSection Modulus 012004dakidofdaboomNo ratings yet

- Calculation Note For Removeable Side - Rev ADocument28 pagesCalculation Note For Removeable Side - Rev AmaniaxpdfNo ratings yet

- Excel Sheet 2007Document20 pagesExcel Sheet 2007Muhammad ImranNo ratings yet

- Chapter J Design of ConnectionsDocument16 pagesChapter J Design of Connectionsghosh73No ratings yet

- Bosch Motorsport ECU MS 15 Sport Calibration GuideDocument107 pagesBosch Motorsport ECU MS 15 Sport Calibration GuideMauricio Navarro santanaNo ratings yet

- RAILWAY Geogrid DesignDocument11 pagesRAILWAY Geogrid DesignPetrucio José Dos Santos JuniorNo ratings yet

- Civil Layout DrawingsDocument2 pagesCivil Layout DrawingsAnonymous IwqK1NlNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- Pile Cap Design 3 PilesDocument1 pagePile Cap Design 3 PilesdantevariasNo ratings yet

- Vessel Side Shell Check CalculationsDocument5 pagesVessel Side Shell Check CalculationsShahir MeledathNo ratings yet

- GB1516 Sac 240 CV RP 0004 - BDocument69 pagesGB1516 Sac 240 CV RP 0004 - BkkkkNo ratings yet

- BSPL 1242 Iot2 Me Cal 0004 Rev.a1Document70 pagesBSPL 1242 Iot2 Me Cal 0004 Rev.a1SachinNo ratings yet

- As Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjaDocument32 pagesAs Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjajaffnaNo ratings yet

- Skid Resistance For Paved Surfaces (Full Scale Tire)Document6 pagesSkid Resistance For Paved Surfaces (Full Scale Tire)Kongsak AkkharawongwhatthanaNo ratings yet

- Structures of Gas Station in Saint PetersburgDocument97 pagesStructures of Gas Station in Saint PetersburgassdaNo ratings yet

- Seminar Wind LoadDocument18 pagesSeminar Wind LoadKaustubh JadhavNo ratings yet

- Fillet Weld Strength Calculation Example For Welded Connection Subjected To BendingDocument6 pagesFillet Weld Strength Calculation Example For Welded Connection Subjected To BendingpipestressNo ratings yet

- Stepped Columns - A Simplified Design MethodDocument23 pagesStepped Columns - A Simplified Design MethodwrayroNo ratings yet

- ASDIP Steel - Base Plate Verification ExampleDocument4 pagesASDIP Steel - Base Plate Verification ExampleEdwin VizueteNo ratings yet

- One Way Slab DesignDocument16 pagesOne Way Slab DesignAssad Mohammed AliNo ratings yet

- Steel Beam DesignDocument26 pagesSteel Beam DesignWazini D. Izani100% (1)

- Pile Cap DesignDocument25 pagesPile Cap DesignGanesh Konar100% (5)

- XL InterpolatorsDocument6 pagesXL InterpolatorsKarthikeyan VediNo ratings yet

- Steel TableDocument288 pagesSteel TableKarthikeyan VediNo ratings yet

- 9013Document14 pages9013Sujoy RoyNo ratings yet

- One Layer Theory ChartsDocument9 pagesOne Layer Theory ChartsKarthikeyan VediNo ratings yet

- WP-3r0 Urban StreetsDocument37 pagesWP-3r0 Urban StreetsKarthikeyan VediNo ratings yet

- IS: 73 - 1992 Paving Bitumen - SpecificationDocument7 pagesIS: 73 - 1992 Paving Bitumen - SpecificationKarthikeyan Vedi83% (6)

- Tutorial Class 1 Questions 1Document2 pagesTutorial Class 1 Questions 1Bố Quỳnh ChiNo ratings yet

- 9C606C.64 To 65Document24 pages9C606C.64 To 65SHIRISHA YADAVNo ratings yet

- Reading Material CH 14 Other Artificial Lift MethodsDocument18 pagesReading Material CH 14 Other Artificial Lift MethodsSagar DadhichNo ratings yet

- Winter Internship Report (23/09/2016 - 31/01/2017)Document56 pagesWinter Internship Report (23/09/2016 - 31/01/2017)AyushNo ratings yet

- DRM Transmitter PresentationDocument22 pagesDRM Transmitter PresentationJuan Jose PerezNo ratings yet

- Technical Owner Manual Nfinity v6Document116 pagesTechnical Owner Manual Nfinity v6Tom MondjollianNo ratings yet

- Apple A9Document10 pagesApple A9Savithri NandadasaNo ratings yet

- Iso 9974-2Document4 pagesIso 9974-2willianNo ratings yet

- TIL 1881 Network Security TIL For Mark VI Controller Platform PDFDocument11 pagesTIL 1881 Network Security TIL For Mark VI Controller Platform PDFManuel L LombarderoNo ratings yet

- Cloud Computing - Feb-Mar 2017Document40 pagesCloud Computing - Feb-Mar 2017Abhishek SinghNo ratings yet

- Sd-1-Parts-Book Manual Propietario SpreaderDocument30 pagesSd-1-Parts-Book Manual Propietario Spreadergabriel sanchezNo ratings yet

- Pre-Spud Checklist # 4Document2 pagesPre-Spud Checklist # 4Yougchu LuanNo ratings yet

- Battery Power Management For Portable Devices PDFDocument259 pagesBattery Power Management For Portable Devices PDFsarikaNo ratings yet

- Jun SMSDocument43 pagesJun SMSgallardo0121No ratings yet

- Experiment SCDocument5 pagesExperiment SCnitinmgNo ratings yet

- Wrights Mushroom ColumnDocument33 pagesWrights Mushroom ColumnKeithy GandhiNo ratings yet

- Fundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiDocument818 pagesFundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiMohit Verma85% (20)

- Libeskind Daniel - Felix Nussbaum MuseumDocument6 pagesLibeskind Daniel - Felix Nussbaum MuseumMiroslav MalinovicNo ratings yet

- OTM Reports FTI Training ManualDocument78 pagesOTM Reports FTI Training ManualAquib Khan100% (2)

- Desmophen 1200 - en - 00134597 17947398 20766463Document3 pagesDesmophen 1200 - en - 00134597 17947398 20766463Sabri AeroChemNo ratings yet

- EM000039Rev1 PDFDocument1 pageEM000039Rev1 PDFGustavo RiveraNo ratings yet

- JAVA Stack Installation in ERPDocument2 pagesJAVA Stack Installation in ERPsai_balaji_8No ratings yet

- Misc Forrester SAP Competence CenterDocument16 pagesMisc Forrester SAP Competence CenterManuel ParradoNo ratings yet

- E Insurance ProjectDocument10 pagesE Insurance ProjectChukwuebuka Oluwajuwon GodswillNo ratings yet

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- FHV19 - Exhibitor Manual - 10 DECEMBER - Manual PDFDocument50 pagesFHV19 - Exhibitor Manual - 10 DECEMBER - Manual PDFHien Hien NguyenNo ratings yet

- Electrical 02Document10 pagesElectrical 02Hary Kriz33% (3)

- Chap 08Document63 pagesChap 08Sam KashNo ratings yet

- CambuzaDocument45 pagesCambuzaMia Marin Pâslaru100% (2)

- Final Upcat Mock ExamDocument24 pagesFinal Upcat Mock Examjbgonzales8No ratings yet