Professional Documents

Culture Documents

Fluid Flow and Heat Transfer Characteristics of Nanofluids in Heat Pipes

Uploaded by

Dr NallusamyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluid Flow and Heat Transfer Characteristics of Nanofluids in Heat Pipes

Uploaded by

Dr NallusamyCopyright:

Available Formats

International Communications in Heat and Mass Transfer 56 (2014) 5062

Contents lists available at ScienceDirect

International Communications in Heat and Mass Transfer

journal homepage: www.elsevier.com/locate/ichmt

Fluid ow and heat transfer characteristics of nanouids in heat pipes:

A review

Omer A. Alawi, Nor Azwadi Che Sidik , H.A. Mohammed, S. Syahrullail

Department of Thermouids, Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, 81310 UTM Skudai, Johor Bahru, Malaysia

a r t i c l e

i n f o

Available online 14 May 2014

Keywords:

Heat pipe

Nanouid

Heat transfer enhancement

a b s t r a c t

Comprehensive research work on heat transfer in heat pipe using traditional working uids has been carried out

over the past decade. Heat transfer in heat pipes using suspensions of nanometer-sized solid particles in base

uids have been experimentally and theoretically investigated in recent years by various researchers across

the world. The suspended nanoparticles effectively enhance heat transfer characteristics and the transport

properties of base uids in heat pipes. The objective of this paper is to present an overview of literature dealing

with recent developments in the study of heat transfer using nanouids in heat pipes and some important

inferences from the various papers are also highlighted. It also discusses the mechanism of heat transfer enhancement or degradation, the existing problems for various heat pipes utilizing nanouids, and explores the possible

application prospects.

2014 Elsevier Ltd. All rights reserved.

Contents

1.

2.

3.

Introduction . . . . . . . . . . . . . . . . . . . .

Preparation of nanouids . . . . . . . . . . . . . .

Fundamental studies of nanouids in heat pipes . . . .

3.1.

Micro-grooved heat pipe . . . . . . . . . . .

3.2.

Mesh wick heat pipe . . . . . . . . . . . . .

3.3.

Sintered metal wick heat pipe . . . . . . . . .

3.4.

Oscillating heat pipe . . . . . . . . . . . . .

3.5.

Two-phase closed thermosyphon . . . . . . .

4.

Heat transfer characteristics of nanouids in heat pipes .

4.1.

Experimental investigations . . . . . . . . . .

4.2.

Theoretical investigations . . . . . . . . . . .

5.

Conclusions . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1. Introduction

With the increase of work frequency and heat ux of electronic components, the dissipation problem of the high heat ux components

becomes one of the key technologies of the electronic device design.

Up to now, heat pipe technology has been widely applied in the eld

of microelectronics cooling, as the improved construction of the general

heat pipes, at heat pipe has now become a hotspot technology of heat

pipe research and development [1,2] and has been widely applied in

many elds, such as spacecraft thermal control, high heat ux electronic

Communicated by W.J. Minkowycz.

Corresponding author.

E-mail address: azwadi@fkm.utm.my (N.A.C. Sidik).

http://dx.doi.org/10.1016/j.icheatmasstransfer.2014.04.014

0735-1933/ 2014 Elsevier Ltd. All rights reserved.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

50

51

52

52

53

54

55

57

59

59

60

61

61

equipment cooling, medical and health undertakings, and household

appliances. Heat pipe is a device used to transfer the heat from one

place to the other. The heat pipe consists of evaporator section, adiabatic

section and condenser section (Fig. 1). Heat absorption takes place

in the evaporator section and heat rejection at the condenser section.

Adiabatic section is fully insulated. The heat pipe is evacuated using a

vacuum pump and is lled up with the working uid. The working

uid absorbs the heat at one end of the heat pipe called evaporator

and releases the heat at the other end called condenser. Due to the

capillary action, the condensed working uid through the mesh wick

structure returns to the evaporator, on the inside wall of the pipe. Normally conventional uids are used in heat pipes to remove the heat [3].

For the time being, nanouids play an important role in heat

pipes to increase the heat transfer compared to conventional uids.

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

Fig. 1. Schematic diagram of heat pipe [3].

Thermal conductivity is an important parameter in enhancing the heat

transfer performance of a heat transfer uid. Researchers have also

tried to increase the thermal conductivity of base uids by suspending

nanometer-sized solid particles in uids since the thermal conductivity

of solid is typically higher than that of liquids, as seen from Table 1.

Many researchers have presented the heat transfer characteristics of

heat pipe using nanouids [3]. The concept of nanouid has rstly

proposed by Choi and Eastman [4]. That is, adding nanoscale metal or

metal oxide particles in the liquid with a certain way and proportion,

which forms a new class of heat transfer and cooling working uid. Because of its stability and high thermal conductivity, the nanouid shows

a promising prospect in the heat transfer enhancement. Keblinski et al.

[5] made an interesting review to discuss the properties of nanouids

and future challenges. Weerapun and Somchai [6] summarized the

published experimental and numerical investigations of forced convective heat transfer of nanouids. Bahrami et al. [7] provided an overview

on the effective thermal conductivity of nanouids. Cheng et al. [8] carried out an overview on the studies of nanouids boiling and two phase

ow. The application of nanouid research in heat pipes was rstly

published by Chien et al. [9]. Over 20 relevant articles have been published since then, involving mesh wicked heat pipes [10] and [11],

micro-grooved heat pipes [9,1217], sintered metal wicked heat pipes

[18] and so on.

An experiment concerning a cylindrical mesh wicked heat pipe was

performed by Tsai et al. [10]. The working uid was an aqueous suspension of various-sized gold nanoparticles. The inner diameter and

the length of the tested copper tube were 6 mm and 170 mm, respectively. A 200 mesh screen was distributed on the inner wall. The experimental results showed that the total thermal resistance of the heat

pipe reduced a lot due to the addition of nanoparticles under the

same cooling condition. The experiment also found that the best way

to use nanouids in the heat pipe was using a well dispersed nanouid.

The mechanism of the heat transfer enhancement was explained as

follows: a major thermal resistance of heat pipe was caused by the

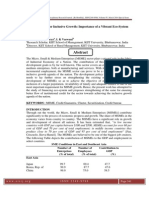

Table 1

Thermal conductivities of various solids and liquids [3].

Thermal conductivity (W/m-K)

Material

401

237

148

40

72.3

0.613

0.253

0.145

Metallic solid copper

Aluminum

Nonmetallic solid silicon

Alumina (Al2O3)

Metallic liquid sodium (644 K)

Nonmetallic liquid water

Ethylene glycol (EG)

Engine oil (EO)

51

formation of vapor bubbles at the liquidsolid interface; the suspended

nanoparticles tended to bombard the vapor bubbles during the bubble

formation; therefore, it was expected that the nucleation size of vapor

bubbles was much smaller for the uid with suspended nanoparticles

than that without them. Chen et al. [11] studied the performance of

axially at mesh wicked heat pipe (FHP) using water-based silver

nanouids with different nanoparticle concentrations under the

input power of 2040 W. The average diameter of nanoparticles was

35 nm. The height and the length of the FHP used in the experiment

were 3 mm and 200 mm, respectively. It was found that the total

thermal resistance of the heat pipe using nanouids was reduced compared with that of the heat pipe using deionized water under the same

cooling condition. In the volume concentration range tested, the larger

the volume concentration of nanoparticles was, the more reduction

of the thermal resistance could be. The mechanisms of heat transfer

enhancement were given by authors as: (1) the increase of the wettability increased the critical heat ux; (2) the mutual increases of the

liquid thermal conductivity and the wick conductivity increased the

heat transfer.

Some steady heat transfer experiments under several steady operation pressures conducted to investigate the heat transfer performance

of a cylindrical micro-grooved copper heat pipe. Water-based CuO

nanouids and water-based carbon nanotubes without dispersant

were used as the working uids [15]. All experiments show that adding

nanoparticles into the base liquid can enhance both the heat transfer

performance and the maximum input power of heat pipes [9,1217].

Analytical models carried out to investigate the thermal performance of rectangular and disk-shaped heat pipes using nanouids.

Some of the more widely utilized nanoparticles, such as Al2O3, CuO

and TiO2 with a range of nanoparticle diameters were considered.

Results show that the presence of nanoparticles in the working uid

leads to a reduction in the speed of the liquid, smaller temperature difference along the heat pipe and the possibility of reduction in size under

the same operational conditions. It is similar to what has been observed

experimentally that using a nanouid will reduce the thermal resistance

of the at-shaped heat pipe. The maximum heat removal capability of

the at-shaped heat pipe was displayed for a range of wick thicknesses

and nanoparticle concentration levels. The existence of an optimum

nanoparticle concentration level and wick thickness in maximizing

the heat removal capability of the at-shaped heat pipe was established

[19]. Alizad et al. [20] studied the thermal performance, transient

behavior and operational start-up characteristics of at-shaped heat

pipes using nanouids. Three different nanouids (CuO, Al2O3, and

TiO2) were utilized in their analysis. A comprehensive analytical

model, which accounts in detail the heat transfer characteristics within

the pipe wall and the wick within the condensation and evaporation

sections, was utilized. The results illustrate the enhancement in the

heat pipe performance while achieving a reduction in the thermal resistance for both at-plate and disk-shaped heat pipes throughout the

transient process. It was shown that a higher concentration of nanoparticles increases the thermal performance of either the at-plate or diskshaped heat pipes. The study has also established that for the same heat

load a smaller size at-shaped heat pipe can be utilized when using

nanouids.

The papers presented on the study of heat transfer and ow characteristics of the heat pipe with nanouids have rarely been reported. The

objective of this paper is to present an overview of literature dealing

with recent developments in the study of heat transfer using nanouids

in heat pipes and some important inferences from the various papers

are also highlighted by the following studies.

2. Preparation of nanouids

The powder form nanoparticles which disperse in host liquids are

called nanouids. Nanouids can be produced by two techniques; the

two-step (double-step) method, and one-step (single-step) method.

52

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

These methods have been utilized using different types of chemical and

physical techniques to make sure that the solidliquid mixture is stable

to avoid agglomeration, additional ow resistance, possible erosion and

clogging, poor thermal conductivity, and poor heat transfer. The twostep method is done by producing the nanoparticle powder initially as

introduced in the previous section, and then disperses them into a

host liquid. However, in one-step method the nanoparticles are simultaneously made and directly dispersed into the base uid [21]. It is noticed

in the literature that nanouids with oxide nanoparticles and carbon

nanotubes are produced well by the two-step method, while it is not

suitable for nanouids with metallic nanoparticles. The summary of results reported by various researchers in the area of nanouid preparation is provided in Table 2.

3. Fundamental studies of nanouids in heat pipes

3.1. Micro-grooved heat pipe

An experimental study on the application of nanouids in FHP rstly

carried out by Chien et al. [9]. They studied a disk-shaped aluminum

miniature micro-grooved heat pipe. The diameter and the thickness

were 9 mm and 2 mm, respectively. A total number of 18 microgrooves were evenly distributed on the aluminum base to provide the

capillary force. The depth and the width of rectangular micro-grooves

were 0.4 mm and 0.35 mm, respectively. The nanouid consisted of

gold nanoparticles with a diameter of 17 nm and DI water. The experimental data of the nanouids were compared with those of DI water including the wall temperatures and the total heat resistances of the heat

pipe. Experimental results showed that the total heat resistance of the

heat pipe using nanouids was less than that of the heat pipe using DI

water at different lling ratios. The use of the nanouids made the

heat resistance reduces by an average of 40%.

Wei et al. [38] used a cylindrical micro-grooved heat pipe with

the inner diameter and the length of 6 mm and 200 mm, respectively.

The width and the depth of the rectangular groove were 211 m

and 217 m, respectively. The working uid consisted of silver nanoparticles with an average particle size of 10 nm and pure water. They

mainly measured the total heat resistance of the heat pipe lled

with pure water and nanouids at the same lling volume of 0.51 mL

( = 10%). Nanoparticle volume fractions of 1 ppm to 100 ppm were

used in the tests. The total heat resistance of the heat pipe using

nanouids could decrease by 28%44% compared with that of the heat

pipe using water. Researchers did not explain the mechanism of the

heat transfer enhancement.

Kang et al. [13] also carried out experiments using nanouids

consisting of silver nanoparticles and pure water. The silver nanoparticle sizes were 10 nm and 35 nm, respectively. The experimental results

showed that the total heat resistance of the heat pipe using nanouids

decreased by 1080% comparing with that using water in the heating

power range of 3060 W. The total heat resistance decreased with the

increase in both the nanoparticle concentration and the nanoparticle

size. Fig. 2 shows that the thermal resistance of a heat pipe containing

10 nm nanoparticles was 52% lower than that using DI-water at 50 W.

They considered that the improvement of thermal performance is

mainly due to the reduction of uid temperature gradient in nanouids.

An experimental study was performed by Zhen-hua Liu et al. [39] to

understand the nucleate boiling heat transfer of waterCuO nanoparticle suspension at different operating pressures and different nanoparticle mass concentrations. The experimental apparatus is a miniature

at heat pipe (MFHP) with micro-grooved heat transfer surface of its

evaporator. The experimental results indicate that the heat transfer

coefcient and the critical heat ux (CHF) of nanouids increase greatly

with decreasing pressure as compared with those of water. The heat

transfer coefcient and the CHF of nanouids can increase about 25%

and 50%, respectively, at atmospheric pressure whereas about 100%

and 150%, respectively, at the pressure of 7.4 kPa. The heat transfer

coefcient and the CHF increase slowly with the increase of the nanoparticle mass concentration at low concentration conditions. However,

when the nanoparticle mass concentration is over 1.0 wt.%, the CHF

enhancement is close to a constant number and the heat transfer coefcient deteriorates.

Liu and Lu [15] and Yang et al. [17] carried out some steady heat

transfer experiments under several constant operating temperatures

to investigate the heat transfer performance of a cylindrical microgrooved heat pipe. Water-based CuO nanouids and water-based carbon nanotubes (CNTs) without dispersants were used as the working

uids. The length and the inner diameter of the heat pipe were

350 mm and 8 mm, respectively. Sixty rectangular grooves with the

depth of 0.2 mm and the width of 0.25 mm were uniformly fabricated

on the inner wall of the heat pipe. The experiments were carried out at

three xed operating pressures of 7.45 kPa, 12.38 kPa and 19.97 kPa,

with respectively corresponding operating temperatures of 40 C,

50 C and 60 C. Data of evaporation and condensation heat transfer

were investigated and the impacts of the nanoparticle mass concentration, the operating temperature on the heat transfer characteristics

was discussed. Fig. 3 indicates the effect of the nanoparticle mass concentration on the total heat resistance of the heat pipe using CuO

nanouids. It is shown in [15,17,40] and [41] that there existed an optimal CuO nanoparticle mass concentration of 1.0 wt.% and an optimal

Table 2

Summary of nanouid preparation methods.

System

Synthesis process

Particle

size (nm)

Heat transfer

enhancement (%)

Ref.

Cu/EG

Cu/H2O

Cu/H2O

Fe/EG

Ag/toluene

Cu2O/H2O

Au/ethanol

Fe3O4/H2O

TiO2/H2O

Al2O3/H2O

CuO/H2O

SiC/H2O

NCTs/engine oil

NCTs/poly oil

NCTs/EG

NCTs/H2O

NCTs/decene

H2O/FC-72

Single-step

Single-step

Two-step

Single-step

Two-step

Single-step

Two-step

Single-step

Two-step

Two-step

Two-step

Two-step

Two-step

Two-step

Two-step

Two-step

Two-step

Two-step

10

75100

100

10

6080

200

4

10

15

20

33

25

2050

25

15

15

15

9.8

40

23.8

78

18

16.5

24

1.3 0.8

38

3033

20

11.5

15.9

30

160

19.6

7.0

12.7

52

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

[33]

[34]

[35]

[36]

[36]

[36]

[37]

Fig. 2. Experimental data of heat resistances using both nanouid and water at different

heating powers [13].

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

Fig. 3. Effect of mass concentration of nanoparticles on the heat resistance [17].

inclination angle of 75. In addition, the heat transfer enhancement

decreased with increasing operating temperature. And substituting

nanouids for deionized water as the working liquid can reduce the

startup time of heat pipe. For both water and the nanouid, the maximum heat removal capacity in the unsteady startup procedure is much

lower than that in the steady operating procedure. The mechanisms

of the heat transfer enhancement were thought to be the increase of

the heat conductivity of the nanouids, the disturbance effect of nanoparticles in the base liquid, as well as the reduction of solidliquid contact angle in the liquid lm.

A mathematical model was developed by Do and Jang [16] for quantitatively evaluating the thermal performance of a water-based Al2O3

nanouid heat pipe with a rectangular grooved wick. For the purpose,

the axial variations of the wall temperature, the evaporation and condensation rates are considered by solving the one-dimensional conduction equation for the wall and the augmented YoungLaplace equation

for the phase change process. From the comparison of the thermal performance using both DI water and nanouids, it is found that the thin

porous coating layer formed by nanoparticles suspended in nanouids

is a key effect of the heat transfer enhancement for the heat pipe

using nanouids. Also, the effects of the volume fraction and the size

of nanoparticles on the thermal performance are studied. The results

shows the feasibility of enhancing the thermal performance up to

100% although water-based Al2O3 nanouids with the concentration

less than 1.0% are used as working uid. The thermal resistance of the

nanouid heat pipe tends to decrease with increasing the nanoparticle

size, which corresponds to the previous experimental results.

A two-dimensional model modied by Shafahi et al. [19] to simulate

the thermal performance of a cylindrically grooved heat pipe utilizing

nanouids. The mathematical model adopted in this work was based

on the following assumptions: the process was steady state; radiative

and gravitational effects were negligible and the uid was considered

Newtonian and incompressible. Also, the wick was assumed to be isotropic and saturated with the working uid. The liquid ow within the

porous wick was modeled using the generalized momentum equation.

The analysis incorporated the presence of nanouid within the heat

pipe. Three of the most common nanoparticles, namely Al2O3, CuO,

and TiO2 were applied. The simulation found that the nanoparticles

within the base liquid enhance the thermal performance of the heat

pipe by reducing the heat resistance while enhancing the maximum

heat load. In theory, there exists an optimum nanoparticle mass concentration corresponding to the maximum heat transfer enhancement. The

model assumed that vapor and liquid ow are steady and laminar and

transport properties of the vapor and liquid are considered to be constant; the vapor injection and suction rates are considered to be uniform

in the evaporator and condenser, respectively. Operating temperature,

53

liquid velocity prole, wall temperature distribution of the heat pipe,

heat resistance and maximum heat load were investigated for the heat

pipes utilizing both the base liquid and nanouids.

Zhen-hua Liu et al. [42] carried out an experimental investigation to

study the heat transfer performance of a cylindrically micro-grooved

heat pipe using aqueous nanouids as the working uids. The base

liquid was distilled water, while, the ve kinds of nanoparticles: Cu

with two mean diameters of 40 nm and 20 nm, CuO with two mean

diameters of 50 nm and 20 nm and SiO with a mean diameter of

30 nm were added respectively into the base liquid to compose different

kinds of nanouids. Experiments were performed under three steady

operating pressures of 7.45 kPa, 12.38 kPa and 19.97 kPa, respectively.

Effects of nanoparticle kind, nanoparticle size, nanoparticle mass concentration and operating pressure on the evaporation and condensation

heat transfer coefcients, the maximum heat ux and the total heat resistance of the heat pipe were investigated, compared and discussed.

Experimental results show that adding Cu and CuO nanoparticles into

the base uid can apparently improve the thermal performance of the

heat pipe and there is an optimal nanoparticle mass concentration to

achieve the maximum heat transfer enhancement. However, adding

SiO nanoparticles into the base uid will contrarily deteriorate the

heat transfer performance.

3.2. Mesh wick heat pipe

Tsai et al. [10] performed an experiment concerning a cylindrical

mesh wick heat pipe. The working uid was an aqueous solution

of various-sized gold nanoparticles. The inner diameter and the length

of the test copper tube were 6 mm and 170 mm, respectively. A

200 mesh screen was distributed on the inner wall. The experimental

results showed that the total heat resistance of the heat pipe reduced

20%37% due to the addition of nanoparticles. Fig. 4 shows the total resistance of the heat pipe for nanouids of various particle sizes. The

mechanism of the heat transfer enhancement was explained as follows:

a major heat resistance of heat pipe was caused by the formation of

vapor bubbles at the liquidsolid interface; the suspended nanoparticles

tended to bombard the vapor bubbles during the bubble formation;

therefore, it was assumed that the release diameter of vapor bubbles

was much smaller for the uid with suspended nanoparticles than

that without them.

The heat transfer characteristics of a cylindrical mesh wick heat pipe

using CuOwater nanouids investigated by Liu and Shu [43]. The inner

diameter and the length of the test tube were 10 mm and 350 mm,

respectively. Two layers of 160 mesh screen were distributed on the

inner wall. It was found that the nanoparticle mass concentration had

Fig. 4. Measured value of heat resistance of a mesh wick heat pipe using nanouids of

various particle sizes [10].

54

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

signicant impact on both the heat pipe evaporation and condensation

heat transfer. There was an optimal mass concentration of 1.0% under a

variety of operating temperature. An enhancement of the evaporation

and condensation heat transfer and the maximum heat ux was

obtained at lower operating temperature. Fig. 5 shows that the total

heat resistance of the heat pipe using nanouids is signicantly smaller

than without nanoparticles.

Chen et al. [11] discussed the performance of at mesh wick heat

pipe using water-based silver nanouids with different nanoparticle

concentrations in the input power range of 2040 W. The average

diameter of nanoparticles was 35 nm. The height and the length of the

FHP used in the experiment were 3 mm and 200 mm, respectively.

The size and the number of mesh layers were unknown. As shown in

Fig. 6, the total heat resistance of the heat pipe using nanouids is

reduced compared with that of the heat pipe using pure water. In the

volume concentration range tested, the larger the volume concentration

of nanoparticles, the higher the reduction of the heat resistance will

be. The authors assumed that the mechanisms of heat transfer enhancement were: (1) the increase of the wettability increases the critical heat

ux; (2) the increase of the liquid thermal conductivity and the wick

conductivity enhance the heat transfer.

Do et al. [44] and Liu and Zhu [45] experimentally observed the thin

porous coating layer formed by nanoparticles suspended in nanouids

at wick structures. Based on the observation, it is shown that the primary mechanism on the enhancement of the thermal performance for the

heat pipe is the coating layer formed by nanoparticles at the evaporator

section because the layer can not only extend the evaporation surface

with high heat transfer performance but also improve the surface wettability and capillary wicking performance.

Putra et al. [46] manufactured and tested screen mesh wick heat

pipes were to determine the thermal resistance of nanouids such as

Al2O3water, Al2O3ethylene glycol, TiO2water, TiO2ethylene glycol

and ZnOethylene glycol charged in the screen mesh wick heat pipes.

The concentration of the nanoparticles was varied from 1% to 5% of

the volume of the base uid. The screen mesh wick heat pipe with the

best performance was that which used Al2O3water nanouid with 5%

volume concentration. Using nanouids in the heat pipes resulted in

the formation of a thin coating on the screen mesh surface from the

element of the nanoparticles. However, the thin coating promotes

good capillary structure. The higher thermal performance of heat pipes

charged with nanouids proved the potential of nanouids as a substitute for conventional working uids. This nding makes nanouids attractive as working uids in screen mesh wick heat pipes.

Kole and Dey [47] prepared fairly stable surfactant free copperdistilled water nanouids by using prolonged sonication and homogenization. Thermal conductivity of the prepared nanouid displays a

Fig. 6. Inuence of particle concentration on the heat resistance of FHP under various input

powers [11].

maximum enhancement of ~15% for 0.5 wt.% of Cu loading in distilled

water at 30 C. The wall temperature distributions and the thermal

resistances between the evaporator and the condenser sections of a

commercial screen mesh wick heat pipe containing nanouids are investigated for three different angular positions of the heat pipe. The results are compared with those for the same heat pipe with water as the

working uid. The wall temperatures of the heat pipes decrease along

the test section from the evaporator section to the condenser section

and increase with input power. The average evaporator wall temperatures of the heat pipe with nanouids are much lower than those of

the heat pipe with distilled water as shown in Fig. 7. The thermal resistance of the heat pipe using both distilled water and nanouids is high

at low heat loads and reduces rapidly to a minimum value as the applied

heat load is increased. The thermal resistance of the vertically mounted

heat pipe with 0.5 wt.% of Cu-distilled water nanouid is reduced by

~ 27%. The observed enhanced thermal performance is explained in

light of the deposited Cu layer on the screen mesh wick in the evaporator section of the heat pipe.

Asirvatham et al. [48] presented the improvement in heat transfer

performance of a heat pipe using silver nanoparticles dispersed in DI

(De-Ionized) water. The nanoparticles suspended in conventional uids

have superior heat transfer capability due to improved thermal conductivity. The heat pipes are tested for heat inputs ranging from 20 W to

100 W in ve steps, which is suitable for removing heat from power

transistors in electronics and processors in computers. The effect of

various operational limits and test parameters such as heat inputs,

volume fraction, vapor temperature on the thermal resistance, evaporation and condensation heat transfer coefcients, are experimentally

investigated. The tested silver nanoparticle volume concentration

ranged from 0.003% to 0.009% with average nanoparticle diameter

of 58.35 nm. The experimental results are evaluated in terms of performance metrics by direct measurement of vapor temperatures in

the center core of heat pipe. A substantial reduction in thermal resistance of 76.2% is observed for 0.009 vol.% concentration of silver nanoparticles. Further an enhancement in the evaporation heat transfer

coefcient of 52.7% is observed for the same concentration. The use

of nanoparticles enhances the operating range of heat pipe by 21%

compared with that of DI water.

3.3. Sintered metal wick heat pipe

Fig. 5. Effect of mass concentration of particles on the total heat resistance for a mesh wick

heat pipe using CuO nanouids [43].

Riehl [49] performed an experimental study on the thermal performance of the sintered metal wick miniature loop heat pipe (LHP)

using nickelwater nanouid. A simple wettability test of the nanouids

was rstly carried out in various wick materials, which were hydrophilic

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

55

Fig. 7. Distribution of wall temperatures in heat pipes for an input power of 100 W in the evaporator containing (a) distilled water and (b)(d) different nanouids inclined at different

angles [47].

polyethylene, sintered nickel and copper. It was found that the water

nickel nanouids did not present good wettability in the sintered

copper; and solid nanoparticles were separated even if the wick pore radius was greater than that of the nanoparticles. Only sintered nickel

wick could be applied in the LHP using waternickel nanouids. However, the thermal performance was reduced. The authors explained

the mechanism of heat transfer reduction as follows: the increase

of the density and the viscosity of the nanouids would increase

the ow drag and reduce the capillary force in the sintered metal wick

channels.

Kang et al. [18] studied the total heat resistance of a cylindrical

sintered wick heat pipe with the outer diameter and the length of

6 mm and 200 mm, respectively. The heat pipe contained a 1 mm-thick

sintered-wick made of copper powders. The nanouids were made

of pure water and silver nanoparticles with the particle sizes of 10 nm

and 35 nm, respectively. The tested nanouid concentrations were

1 mg/L, 10 mg/L and 100 mg/L. The investigated power range was

30 W70 W. The condenser section of the heat pipe was maintained

at 40 C in all runs. The experimental results showed that the maximum

heat loads of the heat pipe using nanouids increased by 40% and the

temperature distributions of the evaporator section were more uniform

compared with those of the heat pipe using water. The total heat resistance decreased by 88% for the 60 W heat loads. They considered that

the reason for the heat transfer enhancement could be explained as follows. The maximum heat ux could be enhanced by higher wettability;

nanoparticles could atten the transverse temperature gradient of

the working uid and reduce the boiling limit because of the increase

of the effective liquid conductance in the heat pipe. The heat resistance

of the heat pipe was reduced for the same reason.

3.4. Oscillating heat pipe

Nanouid studies used in a vertical closed loop oscillating heat pipes

(OHPs) were performed by Ma's research team [50] and [51]. They used

alloy 122 copper tube with an inside diameter of 1.65 mm, an outer diameter of 3.18 mm and 12 turns. The experiment was carried out with

the heat load ranging between 0 and 336 W, the ambient temperature

maintained at 1070 C and the internal lling ratio xed at 50%. The

nanouids consisted of the high-performance liquid chromatography

(HPLC) grade water and 1.0 vol.% diamond nanoparticles with the

diameter of 550 nm. The comparison of the total heat resistance

between water charged OHP and nanouid charged OHP is shown in

Fig. 8. It is evident that diamond nanoparticles signicantly increase

the heat transport capability. The enhanced heat transfer mechanism

was considered as below: higher thermal conductivity, lower viscosity

of nanouids, and stronger oscillating motion of nanoparticles might

be the primary factors enhancing the heat transport capability in

nanouid charged oscillating heat pipe.

Shang et al. [52] investigated the heat transfer characteristics of

a closed loop OHP with Cuwater nanouids as the working uid

under different lling ratios. The results were compared with those

of the same heat pipe with distilled water as the working uid. The

56

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

Fig. 8. Heat resistance comparison between a water charged OHP and a nanouid charged

OHP, lling ratio = 50%, vertical, top = 20 C [50].

experimental results conrmed that the use of Cuwater nanouids in

the heat pipe could enhance the maximum heat removal capacity by

83%. It was conrmed that directly adding nanoparticles into distilled

water without any stabilizing agents had greater heat transfer enhancement compared to the case where a stabilizing agent was added to the

distilled water.

An experiment on the heat transport capability in a closed loop wellbalanced oscillating heat pipe using nanouids carried out by Park and

Ma [53]. The well-balanced OHP was dened as a perfectly round ring

with no turns. The OHP was fabricated from copper tube with an inside

diameter of 1.6 mm. It had six heating sections and six cooling sections

spaced along the circumference. Between the heating section and

the cooling section was adiabatic section. The nanouids consisted of

HPLC water and 1.0 vol.% CuNi nanoparticles with the diameters of

40 nm to 150 nm. The heat pipe was tested in two situations: (1) without oscillating motions and (2) with oscillating motions. Although the

heat transfer performance was improved after substituting nanouids

for the base uid, the heat transfer enhancement effect was not signicant for the rst situation when the input power increased from 0 to

20 W. The primary reason for this was that the CuNi nanoparticles in

the HPLC water settled on the bottom of the heat pipe due to the lack

of oscillating motion. For the second situation, oscillating motions

occurring in the heat pipe were very irregular and were different from

those occurring in common OHP. The nanouids could signicantly

enhance the heat transfer in the heat pipe when the oscillating motions

existed. Also, the impact of the nanouids on the heat transport capability depended on the lling ratio. As shown in Fig. 9, the thermal

performances of the OHP using both nanouids and water have no differences for a power input of 30 W and a lling ratio below 40% and

above 70%. The heat pipe has its best heat transfer performance when

the lling ratio is 50%.

Lin et al. [54] investigated experimentally the thermal performance

of a closed loop oscillating heat pipe using nanouids. They applied

water-based silver nanouids at different volume fractions (100 ppm

and 450 ppm) and various lling ratios (20%, 40%, 60%, and 80%). The

silver nanoparticle had a diameter of 20 nm. Results showed that the

thermal performance of the oscillating heat pipe using nanouids was

better than that using water. The best lling ratio was reported to be

60%. As shown in Fig. 10, there exists a best volume concentration of

100 ppm. When the input power was 85 W, the average temperature

difference between the inner wall of evaporator and the saturated

vapor decreased by 7.8 K, which is equivalent to a decrease of the

total heat resistance of the heat pipe by 15%. The authors considered

that the mechanism for the existing optimal volume fraction of silver

nanouids could be explained as follows: although the nanouids

Fig. 9. Thermal performances of the OHP using both nanouid and water [53].

with higher concentration had higher thermal conductivity, higher

nanoparticle concentration resulted in higher viscosity; this caused

more difculty to the bubbles growing and generated larger obstruction

of the liquid slug, hence an optimal concentration would exist.

Bhuwakietkumjohn and Rittidech [55] investigated the internal ow

patterns and heat transfer characteristics of a closed-loop oscillating

heat-pipe with check valves. The ratio of number of check valves to

meandering turns was 0.2. Ethanol and a silver nano-ethanol mixture

were used as working uids with a lling ratio of 50%. Results show

that the main ow pattern changes from a bubble ow with slug ow

and annular ow to a dispersed bubble ow.

An experimental investigation was performed by Jian Qu et al. [56]

on the thermal performance of an oscillating heat pipe (OHP) charged

with base water and spherical Al2O3 particles of 56 nm in diameter.

The effects of lling ratios, mass fractions of alumina particles, and

power inputs on the total thermal resistance of the OHP were investigated. Experimental results showed that the alumina nanouids significantly improved the thermal performance of the OHP, with an optimal

mass fraction of 0.9 wt.% for maximal heat transfer enhancement. Compared with pure water, the maximal thermal resistance was decreased

by 0.14 C/W (or 32.5%) when the power input was 58.8 W at 70% lling

ratio and 0.9% mass fraction. By examining the inner wall samples, it

was found that the nanoparticle settlement mainly took place at the

evaporator. The change of surface condition at the evaporator due to

nanoparticle settlement was found to be the major reason for the enhanced thermal performance of the alumina nanouid-charged OHP.

Fig. 10. Heat input vs. average heat resistance for 60% lling ratio [54].

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

An experimental investigation has been carried out by Qu and Wu

[57] to compare and analyze the different thermal performances of

the oscillating heat pipes, which were charged with SiO2/water and

Al2O3/water nanouids, respectively. Both the average evaporator wall

temperature and the overall thermal resistance of the OHPs at different

nanoparticle mass concentrations (00.6 wt.% for silica nanouids

and 01.2 wt.% for alumina nanouids) and at the volume lling ratio

of 50% were tested and compared. Results showed that different

nanouids caused different thermal performances of OHPs. Within the

experimental range, using the alumina nanouid instead of pure water

enhanced the heat transfer of the OHP (reductions in the evaporator

wall temperature and thermal resistance of the OHP of about 5.6 C (or

8.7%) and 0.057 C/W (or 25.7%), respectively, were obtained), while

using the silica nanouid instead of pure water deteriorated the thermal

performance of the OHPs. A preliminary analysis was conducted for the

different effects induced by the addition of different nanoparticles to

pure water, and it was found that the change of surface condition at

the evaporator and condenser due to different nanoparticle deposition

behaviors was the main reason for the thermal performance improvement or deterioration of the OHPs charged with different nanouids.

The Al2O3 particle effect on the heat transfer performance of an oscillating heat pipe (OHP) was investigated experimentally by Ji et al. [58].

Four size particles with average diameters of 50 nm, 80 nm, 2.2 m, and

20 m were studied, respectively. Fig. 11 shows that the Al2O3 particles

added in the OHP signicantly affect the heat transfer performance and

it depends on the particle size. When the OHP was charged with water

and 80 nm Al2O3 particles, the OHP can achieve the best heat transfer

performance among four particles investigated herein. In addition, it is

found that all particles added in the OHP can improve the startup performance of the OHP even with 20 m Al2O3 particles.

Tanshen et al. [59] investigated an inuence of multi-walled carbon

nanotube (MWCNT) based aqueous nanouids with different concentrations on the heat transport and the relevant pressure distribution

in oscillating heat pipe (OHP). They described the heat transfer phenomena in terms of thermal resistance, pressure and frequency of pressure uctuation in multi-loop oscillating heat pipe (OHP) charged by

aqueous nanouids with MWCNT loadings of 0.05 wt.%, 0.1 wt.%,

0.2 wt.% and 0.3 wt.%. The multi-loop OHP with 3 mm inner diameter

has been conducted in the experiment at 60% lling ratio. Experimental

results show that thermal characteristics are signicantly inter-related

with pressure distribution and strongly depend on the number of pressure uctuations with time. The investigation shows that the 0.2 wt.%

MWCNT based aqueous nanouids obtain maximum number of the

uctuation frequency and low thermal resistance at any evaporator

57

power input. Based on the experimental results, we discuss the reasons

for enhancement and decrement of thermal characteristics of the

nanouids.

3.5. Two-phase closed thermosyphon

Xue et al. [60] carried out an investigation about the interface effect

of carbon nanotube (CNT) suspension with surfactant on the thermal

performance of a closed two-phase thermosyphon. The test section

was a copper tube with an inner diameter of 20 mm. The lling ratio

of the closed two-phase thermosyphon was 20%. The experimental results in Fig. 12 show that the total heat resistance of the heat pipe

using CNT is higher than those of the heat pipe using water. It is also

obvious that adding CNT in the base liquid deteriorated the thermal

performance of the heat pipe. It was found in this experiment that the

CNT was broken to chips due to the addition of some acid liquids in

the CNT suspension to improve the stability of the suspension. The

chips of CNT settled on the evaporator surface formed a coating layer

and signicantly diminished the density and number of the active

nucleation sites, the release frequency and the coalesced patches of

vapor bubbles.

Liu et al. [61] investigated the effect of nanoparticle parameters on the

thermal performance in a miniature closed two-phase thermosyphon

using CuO nanouids without surfactant. The test tube diameter, the

lengths of the evaporation section, the insulation section and the condensation section were 8 mm, 100 mm, 100 mm and 150 mm, respectively. The experiment was carried out at three operating pressures of

7.45 kPa, 12.38 kPa and 19.97 kPa, respectively and the corresponding

saturation operating temperatures were 40 C, 50 C and 60 C, respectively. The experimental results showed that adding nanoparticles in

the heat pipe could enhance both the heat transfer and the critical

heat ux. The operating temperature could signicantly affect the

heat transfer enhancement. The enhancement effect of nanouids

increased with the decrease of the operating temperature. For the CuO

nanouids heat pipe, the heat transfer coefcient increased by a maximum of 160%, and the critical heat ux increased by 120% when an

optimal nanoparticle mass concentration of 1% was applied. The total

heat resistance can decrease about 30%90% by substituting the

nanouids for water as the work liquid as shown in Fig. 13. At low

heat uxes, the heat transfer enhancement is especially remarkable.

They also [62] investigated the thermal performance in the same miniature closed two-phase thermosyphon using carbon nanotube (CNT)

suspensions without surfactant. The experimental results are similar

to those using CuO nanouids.

Fig. 11. Particle size effect on (a) temperature difference and (b) thermal resistance (lling ratio: 50%) [58].

58

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

Fig. 12. Heat resistances of closed two-phase thermosyphon using both CNT suspension

and water at different heating powers [60].

Khandekar et al. [63] investigated the total heat resistance of a

closed two-phase thermosyphon using pure water and various waterbased nanouids containing nanoparticles of Al2O3 (4047 nm), CuO

(8.613.5 nm) and laponite clay (disks of diameter 25 nm and thickness

1 nm). The length and the inner diameter of the test closed two-phase

thermosyphon were 720 mm and 16 mm, respectively. The experimental results illustrate that the heat transfer performance of the closed

two-phase thermosyphon using nanouids was worse than that of the

closed two-phase thermosyphon using pure water. They considered

that nanouids had better surface wettability than water in the copper

closed two-phase thermosyphon and the improvement in wettability

along with entrapment of nanoparticles in the grooves caused the decrease of Peclet number in evaporator section. These factors nally

leaded to poor thermal performance.

Noie et al. [64] combined two mentioned techniques for heat transfer

enhancement. Nanouids of aqueous Al2O3 nanoparticle suspensions

were prepared in various volume concentrations of 13% and used in a

two-phase closed thermosyphon (TPCT) as working media. Different

volume concentrations of nanoparticles (13%) in suspension within

the TPCT were experimentally examined and results were compared

with pure water. Nanouids in all concentration studied showed better

thermal performance than pure water. They improved efciency of the

TPCT up to 14.7% as shown in Fig. 14. Temperature distributions on the

TPCT were lower level using nanouid compared to pure water. Temperature differences between the evaporator and condenser sections

with nanouids were less that pure water, i.e. thermal resistance of

Fig. 13. Total heat resistances of closed two-phase thermosyphon using water and

nanouid [61].

the TPCT when charged with nanouids was less. The higher thermal

performance TPCTs loaded with nanouid proved its potential as substitute for conventional ones with pure water. This nding makes

nanouid attractive as working uid in heat pipe and thermosyphon

technologies noting further investigation are needed.

Parametthanuwat et al. [65,66] investigated the effect of using silver

nanouid (de-ionized water mixed with silver nano and particles less

than 100 nm) on the thermal characteristics of a two-phase closed

thermosyphon. The thermosyphon was made with copper tubes with

7.5, 11.1 and 25.4 mm ID. The lling ratios of 30%, 50% and 80% by evaporator length and aspect ratios of 5, 10, and 20 with an inclination angle

90. Temperatures were controlled so that the temperature measured at

the adiabatic section was constant at 40 4 C, 50 4 C and 60 4 C.

It was found that the lling ratio has no effect on the ratio of heattransfer characteristics in the vertical position, but the properties of

the working uid affected the heat-transfer rate. In addition a correlation for predicting the heat ux for the two-phase closed thermosyphon

in the vertical position has been established.

Huminic and Huminic [67] and Huminic et al. [68] presented the

heat transfer characteristics of two-phase closed thermosyphon

(TPCT) with iron oxide-nanouids. The TPCT is fabricated from the copper tube with the outer diameter and length of 15 and 2000 mm, respectively. The TPCTs with the de-ionic water and nanouids (water

and nanoparticles) are tested. The iron oxide nanoparticles with mean

diameter of 45 nm were obtained by the laser pyrolysis technique

and the mixtures of water and nanoparticles are prepared using an ultrasonic homogenizer. Effects of TPCT inclination angle, operating temperature and nanoparticle concentration levels on the heat transfer

characteristics of TPCT are considered. The nanoparticles have a signicant effect on the enhancement of heat transfer characteristics of TPCT.

In Fig. 15, the heat transfer characteristics of TPCT with the nanouids

are compared with that the based uid.

Lu at al. [69] designed an especial open thermosyphon device used in

high-temperature evacuated tubular solar collectors. The indoor experimental research was carried out to investigate the thermal performance of the open thermosyphon using respectively the deionized

water and water-based CuO nanouids as the working liquid. The

effects of lling rate, kind of the base uid, nanoparticle mass concentration and operating temperature on the evaporating heat transfer

characteristics in the open thermosyphon were discussed. Experiment

results show the optimal lling ratio to the evaporator is 60% and the

thermal performance of the open thermosyphon increase generally

with the increase of the operating temperature. Substituting waterbased CuO nanouids for water as the working uid can signicantly

Fig. 14. Efciency of TPCT versus input power and concentration of nanouid [64].

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

59

Fig. 15. Heat transfer rate distributions for different concentration levels at inclination angle of 90 [67].

enhance the thermal performance of the evaporator and evaporating

heat transfer coefcients may increase by about 30% compared with

those of deionized water. The CuO nanoparticle mass concentration

has remarkable inuence on the heat transfer coefcient in the evaporation section and the mass concentration of 1.2% corresponds to the

optimal heat transfer enhancement.

Yang and Liu [70] carried out an experimental study to understand

the ow boiling heat transfer of water based CuO nanouids in the

evaporator of a thermosyphon loop under steady sub-atmospheric

pressures. Experimental results show that both the heat transfer coefcient (HTC) and the critical heat ux (CHF) of ow boiling in the evaporator of the thermosyphon loop could be enhanced by substituting

nanouids for water. The operating pressure has apparent impact on

the HTC enhancement of nanouids. However, the operating pressure

has negligible effect on the CHF enhancement. There exists an optimal

mass concentration of nanoparticles corresponding to the best enhancement effect. Experimental results show that the CHF enhancement

results mainly from the existing of the coating layer on the heated surface formed by the sediment of nanoparticles. However, the HTC enhancement results from the effects of both the existing of the coating

layer and the change of thermophysical properties of the working uid.

Kamyar et al. [71] examined the effects of using nanouids on the

performance of a two-phase closed thermosyphon. Different concentrations (0.01%, 0.02%, 0.05% and 0.075%) of Al2O3 as well as TiSiO4 particles

were dispersed in distilled water as base uid. They focused on the resulted changes in temperature distribution, overall thermal resistance

of the thermosyphon and the heat transfer coefcient of the evaporator

section. Various input powers (40210 W) were applied in the evaporator to see the behavior of nanouid-lled thermosyphon in low and

high heat loads. Compared with pure water, both nanouids showed

lower temperature distribution along the heat pipe. Reductions of up

to 65% in thermal resistance were obtained for Al2O3 at the optimum

value of 0.05 vol.%. However, for TiSiO4 the best performance was explored to be at 0.075 vol.% where a reduction of 57% was found. Evaporation heat transfer coefcient also increased after using nanouids. The

relative enhancement in boiling heat transfer coefcient was more signicant at low powers. Although heat transfer coefcient improved by

increasing particle concentration for TiSiO4/water, it had the highest

value at 0.05 vol.% for Al2O3/water showing a limit for increments in

particle concentration.

Huminic and Huminic [72] a 3D analysis is used to investigate the

heat transfer of thermosyphon heat pipe using water and nanouids

as the working uid. The study focused mainly on the effects of volume

concentrations of nanoparticles and the operating temperature on

the heat transfer performance of the thermosyphon heat pipe using

the nanouids. The analysis was performed for water and -Fe2O3

nanoparticles, three volume concentrations of nanoparticles (0 vol.%,

2 vol.% and 5.3 vol.%) and four operating temperatures (60, 70, 80 and

90 C). The numerical results show that the volume concentration

of nanoparticles had a signicant effect in reducing the temperature

difference between the evaporator and condenser. Experimental and

numerical results show qualitatively that the thermosyphon heat pipe

using the nanouid has better heat transfer characteristics than the

thermosyphon heat pipe using water.

Buschmann and Franzke [73] presented study aims to make

nanouids applicable for thermosyphons. Experiments employing a

vertical thermosyphon are carried out utilizing deionized water, water

based titanium dioxide and gold nanouids with different concentrations as working uids. A maximal reduction of the thermal resistance

of about 24% can be achieved when nanouids are employed. An optimum is reached at concentrations between 0.2 vol.% and 0.3 vol.%,

whereas at higher concentrations the thermal resistance remains either

unchanged or increases again. A nanoparticle layer on the evaporator

surface seems to cause the found changes. Experiments with the gold

nanouid indicate that no nanoparticles are transported with the

vapor phase and deposited on the condenser surface. Long-term experiments carried out with 0.3 vol.% indicate a massive aging of the porous

layer built of nanoparticles on the evaporator surface.

Over 70 relevant articles have been published since then involving

miniature micro-grooved heat pipe, mesh wick heat pipe, sintered

metal wick heat pipe, oscillating heat pipe (OHP), and two-phase closed

thermosyphon (TPCT).

4. Heat transfer characteristics of nanouids in heat pipes

4.1. Experimental investigations

Many researchers have reported experimental studies on the thermal conductivity of nanouids in heat pipes, thermal resistance and

thermal efciency of heat pipe. The heat pipe thermal efciency can

be calculated from the ratio of cooling capacity rate of water at the condenser section and supplied power at the evaporator section. The results

from all the available experimental studies indicated that nanouids

containing a small amount of nanoparticles have substantially higher

thermal conductivity than those of base uids and also there is an increase in the thermal efciency of heat pipe.

Naphon et al. [74] investigated the enhancement of heat pipe thermal efciency with TiO2-alcohol nanouids. The test section is fabricated from the straight copper tube with the outer diameter 15 mm

and length 600 mm. In this, working uids of heat pipe such as deionized water, alcohol, and nanouids (alcohol and TiO2 nanoparticles)

are tested. The diameter of TiO2 nanoparticles with 21 nm are used, in

which the mixtures of alcohol and nanoparticles are prepared using

an ultrasonic homogenizer. The parameters considered are the effects

of percentage charge amount of working uid, percentage nanoparticle

volume concentrations, and heat pipe tilt angle on the thermal efciency of heat pipe. The nanoparticles added with the base uid have a signicant effect on the enhancement of thermal efciency of heat pipe.

60

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

The variation of heat pipe thermal efciency with heat pipe tilt angle at

66% charge amount of de-ionic water and alcohol has been calculated.

The absorption heat capacity depends on the charge amount of working

uid and more space for the vapor of working uid. Due to that, the heat

pipe thermal efciency increases with increasing charge amount of

working uid. Maximum heat pipe thermal efciency is attained at

the optimum condition of 45 tilt angle and 66% charge amount of alcohol. The thermal efciency of heat pipe is 10.60% higher than the base

working uid, with 0.10% nanoparticle volume concentration.

Chen [75] investigated the effect of at heat pipe thermal performance using silver nano-uid. The silver nanoparticles of size 35 nm

and the pure-water as base working uid were used. At the same charge

volume, the thermal resistance of heat pipe lled nano-uid was lower

than DI water. The reason for enhancement in the thermal performance

of FHP by using nano-uid is higher wettability that enhances the capability and attens the temperature difference of FHP. The temperature

difference and the thermal resistance of FHP with silver nano-particle

solution were lower than that with pure water. The result showed

that the silver nano-uid not only enhanced the thermal performance

of traditional circular heat pipes but also increased the thermal performance at heat pipe. This investigation concluded that further studies

will focus on the effect of the thickness of FHP, nano-uid concentration

and the wettability effect of the nano-uids on various geometry of the

heat pipe wick to get the optimum thermal performance of heat pipe.

Ji et al. [76] experimentally investigated the alumina nanoparticle

shape effect on the heat transfer performance of an OHP. A binary mixture of ethylene glycol (EG) and deionized water (50/50 by volume)

was used as the base uid for the OHP. Four types of nanoparticles

with shapes of platelet, blade, cylinder, and brick were studied. The results showed that the alumina nanoparticles used in the OHP signicantly enhance the heat transfer performance and it depends on the

particle shape and volume fraction. In the four types, cylinder-like alumina nanoparticles with EG can give the best heat transfer performance

of OHP. The previous research found that these alumina nanouids

were not benecial in laminar or turbulent ow mode; they can enhance the heat transfer performance of an OHP.

Mousa [77] experimentally studied the effect of Al2O3water based

nanouid concentration on the performance of a circular heat pipe.

The operating parameters considered are working uid lling ratio,

volume fraction of nano-particle in the base uid, and heat input. Thermal resistance decreases with increasing Al2O3water based nanouid

compared to that of pure water. The results showed that the optimum

lling ratio of charged uid in heat pipe was about 0.45 to 0.50

for both pure water and Al2O3water based nanouid, respectively,

and that the thermal performance of heat pipe can be decreased by increasing concentration of the nanouid.

Yang and Liu [78] investigated the thermal performance of functionalized nanouid (silica nanoparticles) and traditional nanouid (water

and same silica nanoparticles without functionalized) in a thermosyphon

and observed that functionalized nanouid can maintain long-term stability and without any sedimentation. Traditional nanouids enhance

the maximum heat ux. Further, it was found that both functionalized

and traditional nanouids have no effects on the condenser of the

thermosyphon. It can be concluded that there are no meaningful

nanouid effects on the thermal performance of thermosyphon.

Liu and Li [79] studied the effect of characteristics and mass concentrations of nanoparticles on the thermal performance of heat pipes. the

effect of different nanouids on the thermal performance of different

heat pipes like micro-grooved heat pipe, mesh wick heat pipe, sintered

metal wick heat pipe, oscillating heat pipe and closed two-phase

thermosyphon have been carried out. In miniature micro-grooved

heat pipe, the effect of different nanoparticle sizes and nanoparticle

concentrations enhances the thermal performance of heat pipe. The

boiling heat transfer may occur at high heat uxes in heat pipes with

micro-grooves, but it cannot occur in the mesh and sintered metal

heat pipes. In oscillating heat pipes, the temperature gradient makes

a different volumetric distribution of the working uid and causes pressure waves and uid pulsations in each of the individual tube sections. In

closed two-phase thermosyphon, the driving force of the uid ow is

the buoyancy generated by the boiling two-phase ow. They concluded

that in majority of micro-grooved heat pipe, mesh wick heat pipe, oscillating heat pipe and most closed two-phase thermosyphon addition of

nanoparticles to the working liquid signicantly enhances the heat

transfer, reduces the total heat resistance and increases maximum

heat removal capacity.

Saleh et al. [80] used a straight copper heat pipe with an outer diameter of 8 mm, an inner diameter of 7.44 mm and the length of 200 mm.

A stainless steel wire screen mesh with a diameter of 56.5 m and 67.42

strands per mm was used. ZnO nanouids were prepared using a twostep procedure with base uid ethylene glycol (EG). They mainly measured the temperature distribution and thermal resistance of the heat

pipe lled with pure EG and ZnO nanouids at concentrations from

0.025 vol.% to 0.5 vol.%. The experimental data revealed that nanouids

containing a small fraction of nanoparticles had higher thermal conductivities compared to the base uid. The conductivity ratio could be enhanced by approximately 5.3% until 15.5%. In addition, it was observed

that the temperature distribution and the heat pipe thermal resistance

were varied with the particle volume fraction and the size of the ZnO

particles.

Kole and Dey [47] experimentally investigated the thermal performance of screen mesh wick heat pipes using water-based copper

nanouids. In this study, no surfactant is added to the copper-distilled

water nanouids. The different concentrations of Cu nanoparticles like

0.0005 wt.%, 0.005 wt.%, 0.05 wt.% and 0.5 wt.% were prepared by

using ultrasonicator followed by magnetic stirring process. The dimensions of heat pipe are length 300 mm, outer diameter 10 mm and wall

thickness 0.6 mm and material used is copper. The evaporator section,

adiabatic section and condenser section of the heat pipe are 70 mm,

80 mm and 150 mm, respectively. Thermal conductivity shows an enhancement of approximately 15% with 0.5 wt.% loading of Cu nanoparticles. The results show that vertical heat pipes are found to perform

better than other inclinations. Cu-distilled water nanouid of 0.5 wt.%

reduced the thermal resistance by approximately 27%.

4.2. Theoretical investigations

Do and Jang [16] numerically investigated the effect of water-based

Al2O3 nanouids as working uid on the thermal performance of a at

micro-heat pipe with a rectangular grooved wick. The axial variations

of the wall temperature and the evaporation and condensation rates

are considered by solving the one dimensional conduction equation

for the wall and the augmented YoungLaplace equation for the phase

change process. The thermophysical properties of nanouids as well

as the surface characteristics formed by nanoparticles such as a thin

porous coating are considered. The thin porous coating layer formed

by nanoparticles suspended in nanouids is a key effect of the heat

transfer enhancement for the heat pipe using nanouids. The effects

of the volume fraction and the size of nanoparticles on the thermal

performance were studied and the results showed that the feasibility

of enhancing the thermal performance up to 100% although waterbased Al2O3 nanouids with the concentration less than 1.0% is used

as working uid. Finally, it could be concluded that the thermal resistance of the nanouid heat pipe tends to decrease with increasing the

nanoparticle size compared with the previous experimental results.

Shafahi et al. [81] theoretically studied the thermal performance

of cylindrical heat pipe with Al2O3, CuO and TiO2 by using two dimensional analyses. When using nanouids, there is substantial change

in the heat pipe thermal resistance, temperature distribution and

maximum capillary heat transfer of the heat pipe observed. By utilizing

nanouid resistance decreases as the concentration increases or as

the particle diameter decreases for the smaller size of the cylindrical

heat pipe. In this study, the inuence of nanouid and the geometrical

O.A. Alawi et al. / International Communications in Heat and Mass Transfer 56 (2014) 5062

characteristics of the wick on the maximum heat load carrying capability of the cylindrical heat pipe are investigated. The existence of

an optimum mass concentration and smaller particle in size providing

the highest thermal performance had been established.

The observations based on the reviewed literature on the heat pipes

showed that the thermal performance of heat pipe using nanouid

is higher than that of the base uid. A majority of the results that are

available are of experimental ndings and the theoretical investigations

are limited. It is obvious that more research is needed in future in order

to validate the simulation model with the experimental ndings.

5. Conclusions

This review describes the research results of heat transfer characteristics of various types of heat pipes using nanouids as working uids.

The limited number of available references has shown that nanouids

have great application prospects in various heat pipes. For the majority

of micro-grooved heat pipes, mesh wick heat pipes, oscillating heat

pipes and most closed two-phase thermosyphon, adding nanoparticles

to the working liquid can signicantly enhance the heat transfer, reduce

the total heat resistance and increase the maximum heat removal

capacity. At the same time, there are still some problems and challenges

on the mechanisms of the heat transfer enhancement and the actual

applications. The present research of nanouids in heat pipes is still at

its initial stage and needs further development.

References

[1] D. Wu, G.P. Peterson, Investigation of the transient characteristics of a micro heat

pipe, J. Thermophys. Heat Transf. 5 (2) (1991) 129134.

[2] Jeong-Se Suh, Young Sik Park, Analysis of thermal performance in a micro at

heat pipe with axially trapezoidal groove, Tamkang J. Sci. Eng. 6 (4) (2003)

201206.

[3] R. Sureshkumar, S. Tharves Mohideen, N. Nethaji, Heat transfer characteristics of

nanouids in heat pipes: a review, Renew. Sust. Energ. Rev. 20 (2013) 397410.

[4] S.U.S. Choi, J.A. Eastman, Enhancing Thermal Conductivity of Fluids with Nanoparticles, No. ANL/MSD/CP-84938; CONF-951135-29 Argonne National Laboratory, IL

(United States), 1995.

[5] Pawel Keblinski, Jeffrey A. Eastman, David G. Cahill, Nanouids for thermal transport, Mater. Today 8 (6) (2005) 3644.

[6] Weerapun Daungthongsuk, Somchai Wongwises, A critical review of convective

heat transfer of nanouids, Renew. Sust. Energ. Rev. 11 (5) (2007) 797817.

[7] Majid BahramiMichael, M. Yovanovich, Richard J. Culham, Assessment of relevant

physical phenomena controlling thermal performance of nanouids, J. Thermophys.

Heat Transf. 21 (4) (2007) 673680.

[8] Lixin Cheng, Filho Bandarra, P. Enio, John R. Thome, Nanouid two-phase ow

and thermal physics: a new research frontier of nanotechnology and its challenges,

J. Nanosci. Nanotechnol. 8.7 (2008) 33153332.

[9] Hsin-Tang Chien, Chien-In Tsai, Ping-Hei Chen, Po-Yeh Chen, Improvement on thermal performance of a disk-shaped miniature heat pipe with nanouid, Electronic

Packaging Technology Proceedings, 2003, ICEPT 2003, Fifth International Conference IEEE, 2003, pp. 389391.

[10] C.Y. Tsai, H.T. Chien, P.P. Ding, B. Chan, T.Y. Luh, P.H. Chen, Effect of structural character of gold nanoparticles in nanouid on heat pipe thermal performance, Mater.

Lett. 58 (9) (2004) 14611465.

[11] YuTang Chen, Wei Chiang Wei, Shung Wen Kang, Chun Sheng, Effect of nanouid on

at heat pipe thermal performance, Semiconductor Thermal Measurement and

Management Symposium 2008 Semi-therm 2008, Twenty-fourth Annual IEEEIEEE,

2008, pp. 1619.

[12] Y. Wang, K. Vafai, An experimental investigation of the thermal performance of an

asymmetrical at plate heat pipe, International Journal of Heat and Mass Transfer

43.15 (2000) 26572668.

[13] Shung-Wen Kang, Wei-Chiang Wei, Sheng-Hong Tsai, Shih-Yu. Yang, Experimental

investigation of silver nano-uid on heat pipe thermal performance, Appl. Therm.

Eng. 26 (17) (2006) 23772382.

[14] Balram Suman, Sirshendu De, Sunando DasGupta, Transient modeling of microgrooved heat pipe, International journal of heat and mass transfer 48.8 (2005)