Professional Documents

Culture Documents

501 985 1 SM

Uploaded by

gem68megOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

501 985 1 SM

Uploaded by

gem68megCopyright:

Available Formats

Nigerian Journal of Technology, Vol. 23, No.

1, March 2004

Maduako, Mikailu and Maunde

34

DEVELOPMENT OF A MOTORIZED KNEADER FOR GROUNDNUT OIL

EXTRACTION

J.N. Maduako; J. Mikailu; F.A. Maunde

Department of Agricultural Engineering

Yola- Nigeria,

ABSTRACT

A motorized groundnut-kneading machine was designed, based on the principle of a rotational

viscometer, in which the viscous flow drag of rotating a body .immersed in a liquid is measured as a

function of speed. The machine was constructed, and evaluated for its performance in terms of, its

kneading time and throughput capacity. In addition to eliminating the drudgery involved in the

existing manual kneading tools, test result reveals substantial savings in kneading time. Kneading time

.kneading time was reduced by 80% and the throughput capacity of the machine in terms of weight of

oil extracted per unit time was found to be 46.3 kg/hr. The machine promises a big relief from

drudgery for groundnut processors.

INTRODUCTION

In Nigeria, a survey study conducted in some

northern states (Kano, Kaduna, Adamawa, Niger,

Bauchi; and Taraba) showed that. traditional

groundnut oil extraction is a profitable business,

and mosly done by women. It was also found that

out of 436 processors of groundnut oil in three of

the states (Kana, Niger and Kaduna), 74% said

that they were processing for Income generation

[I]. Groundnut is of course a very important raw

material for industries, but it is presently underutilized, in spite of its potential for conversion

into various edible and commercial products, such

as, shelled groundnuts, roasted groundnuts, butter,

groundnut oil and groundnut cake.

Preliminary studies showed that groundnut

seeds contain 42% to 52% oil, and most of the

world groundnut processing is done for that oil. It

is a desirable cooking and salad oil, because of its

quality, containing about 80% unsaturated fatty

acids, such as oleic and linoneic acids and so

much protein [2].

The traditional use of mortar and pestle

manually to process groundnut seeds for oil is a

serious problem to the women that are engaged in

the groundnut oil extraction business. The

method is not only tedious and time consuming,

but also a serious drudgery to the women.

It involves the following sequence of

operations: shelling, sieving, sorting, roasting,

cooling, skinning, winnowing, milling, (grinding

to paste), kneading (oil extraction), frying the

residue to cake locally called Kuli-Kuli and

cooking the oil to refine it [3]. Kneading was

then identified as the most tasking and energy

consuming among these operations, which

underscores the need to develop a motorized

machine.

The Institute for Agricultural Research

(I.A.R) at Ahmadu Bello University, Zaria

developed a traditional model for groundnut oil

extraction in 1995. The model was operated

manually, but the mortar was installed and

cemented to the ground for stability, and the

pestle was clamped on the mortar such that it

could pivot on the casing as it kneaded the

groundnut paste in the mortar [3].

Another work done at National Agricultural

Extension and Research Liaison Services (

NAERLS) Ahmadu Bello University, Zaria [4]

attempted to replace the traditional mortar and

pestle with manually operated drum chamber and

a stirring shaft-and-finger mechanism.

Also a motorized model of groundnut oil

extractor was designed, constructed and tested at

Agricultural Engineering Department, A.B.U,

Zaria [5]. The main features of the oil extractor

include the kneading head, the conventional

mortar, the transmission unit and the supporting

frame. The intended quantity of paste is poured

into the mortar and the machine is set up for

kneading. Once the electric motor is switched on,

rotary power is transmitted to the kneading shaft

through the intermediate shaft to the input shaft

on which the kneading shaft is hooked. Kneading

is accomplished by the centrifugal effect of the

rotating fingers on the oil molecules in the paste,

with water added gradually as the process

progresses until the end. It was observed that the

average kneading time per unit weight decreased

Nigerian Journal of Technology, Vol. 23, No. 1, March 2004

with an increase in paste quantity for all the

speeds, and slightly decreased with increase in

speed for all paste quantities [5]. This paper

presents another motorized prototype, which

achieves higher throughput capacity within a

shorter kneading time.

2. MA TERIALS AND METHODS

2.1 Design of the Motorized

Kneader.

The design method of the machine was based on

the principle of a rotational viscometer. In this

instrument, the viscous flow drag of rotating a

body immersed in a liquid is measured as a

Maduako, Mikailu and Maunde

35

function of speed [6]. Using this principle, the

shear stress and shear diagram could be

established for a rotational concentric-cylinder

viscometer (6). Therefore, by applying it to the

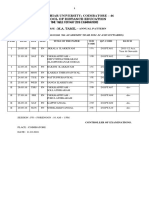

kneading mortar and stirrer shown in figure 1,

the following parametes were calculated: angular

velocity of the stirrer shaft and the number of

revolutions per minute (rpm),diameter of the

stirrer shaft, radius of the stirrer fingers (Rs),

torque acting on the stirrer shaft, radius of

mortar (Rm), power requirement of the kneading

operation and the height of groundnut paste

inside the mortar (H).

Stirrer shaft

Groundnut paste

Stirrer finger

Mortar

Figure 1: kneading mortar and stirrer

and passes the drive to the stirrer shaft through

the pulleys. The shaft has six stirrer fingers (7)

2.2 Description of the Motorized Kneader.

Figure 2 shows the main features of the

welded on to it for effective stirring of the paste

motorized groundnut paste kneading machine,

inside the mortar. The shaft, the shaft bushing

which are the conventional mortar, the

and the shaft fingers form the kneading head,

transmission unit, the power unit, the kneading

and this replaces the traditional pestle.

head and the supporting frames.

The power unit consists of a 1.492 kW

The conventional mortar (8) has an

(2.0 hp) single-phase electric motor and its small

internal diameter of 280mm at the top and

pulley from where the V-belt obtains its drive.

internal depth of 300mm with an oil drainpipe

The electric motor is bolted to the upper part of

(9) inserted at the bottom for draining the

the frame in a vertically downward position and

extracted oil into the oil container. The mortar is

supplies the necessary power for the rotation of

held to the main frame (5) by four supporting

the shaft. The positioning of the motor vertically

members such that the base of the mortar is just

downward was considered to be convenient for

touching the ground as shown in figure 2.Thc

lack of space underneath and for operator's

transmission unit consists of one V-belt, (3) two

safety. The frame consists of angle iron bars

pulleys (2 and 4) and the stirrer shaft (6). The Vconstructed to support all the components of the

belt obtains its drive from the electric motor (I)

machine.

Nigerian Journal of Technology, Vol. 23, No. 1, March 2004

Maduako, Mikailu and Maunde

36

For the operation of the machine, the

paste quantity of known weight is poured into

the mortar and the machine is set up as shown in

figure 2. Once the electric motor is switched on,

rotary power is transmitted to the kneading shaft

through the V -belt. Kneading is accomplished

by the centrifugal effect of the rotating fingers

on oil molecules in the paste, with hot clean

water added gradually as the process progresses

until the kneading ends. Figure: 3 (a, b, c) shows

some views of the kneading machine. At the end

of kneading by the machine, the residue is

further pressed manually and deep- fried to

extract the residual oil.

2.3 Performance Testing

The groundnut-kneading machine was fabricated

and tested at the Centre for Equipment.

Maintenance and Industrial Training (CEMIT),

Federal University of Technology, Yola.

A free-rotation test was first carried out

on the machine to see how it functioned with

empty mortar. Afterwards the machine was

tested again under full load, with 8.0kg of

groundnut paste poured into the mortar. To

facilitate the oil extraction, as usual in traditional

kneading, 16.0g of salt was added to it. When

the machine was operated at a constant speed of

450 rpm, the stirrer shaft kneaded the paste with

its fingers. As the process continued, 1.2kg of

hot water was added to the paste gradually. The

hot water diffused into the groundnut cells and

displaced the lighter oil molecules. The kneading

operation came to an end when the paste

changed colour to brown and became sticky

within eight (8) minutes. Afterwards, the residue

was packed to one side in the mortar and the oil

outlet pipe was opened. This allowed the oil to

flow into the oil collector through the pipe. The

amount of oil collected was measured and found

to be 3.0 kg within eight (8) minutes of

operation. The test was repeated five times. The

time taken (t) for each kneading operation was

recorded with a stopwatch. The extracted oil

collected through the oil outlet after each

operation, plus the oil obtained during the

manual pressing of the residual meal and deepfrying of the shaped and sized meal were

weighed and recorded. The formulae used for

computing the yield of oil (Yo), and throughput

capacity Tc are expressed in equations (I), and

(2), respectively;

( )

(1)

(2)

Where Yo= Yield of oil extracted from

groundnut paste in each batch (%).

Wo = weight of oil obtained after each kneading

operation (kg).

Wp= weight of groundnut paste kneaded (kg).

Tc, = throughput capacity (kg/hr).

tk = kneading time (hr).

3. RESUL TS AND DISCUSSION

The results obtained in the testing of the

motorized kneader are shown in Table I.

Nigerian Journal of Technology, Vol. 23, No. 1, March 2004

Maduako, Mikailu and Maunde

Figure 3: detailed drawing of the motorized kneader (a) front elevation (b) side elevation (c) plan

Table 1: testing result for the motorized kneader.

S/N

Paste quality

Kneading

Weight of oil Yield of oil

Wp (kg)

time tk (mm) obtained Wo

Yo (%)

(kg)

1

8.00

8.00

3.00

37.5

2

8.00

12.00

3.00

37.5

3

8.00

11.20

3.16

39.5

4

8.00

10.30

3.20

40.0

5

8.00

11.40

3.40

42.5

X

8.00 0.00

10.58 1.56

3.15 0.16

39.402.07

Note: X = mean value of Samples sample standard deviation

Throughput

capacity

(kg/hr)

60.00

40.00

42.86

46.60

42.11

46.318,01

37

Nigerian Journal of Technology, Vol. 23, No. 1, March 2004

3.1 Yield of Oil (%)

The oil yield obtained from the Manipinta

variety of groundnuts used for testing the

kneading machine ranged from 37.5% to

42.5%, with an average of 39.4%, as shown in

Table I. The significance of the yield of oil lies

mainly in using it to estimate the quantity of

oil to expect from kneading a specified

quantity of groundnut paste. In this case. it

averaged 3.15 kg of oil from 8.00kg groundnut

paste.

3.2 Kneading Time (mins)

Table I shows a range of 8-12 minutes of

kneading time for 8.00 kg groundnut paste.

The average kneading time of 10.58 mins for

8.00 kg of groundnut paste compares

favourably with the 11.25 mins used for 6.6kg

of groundnut paste, as earlier reported [51. It is

also faster than the 25 mins spent by three

operators exchanging hands in using manual

rotary tools for kneading the same quantity

(6.6kg) of groundnut paste [7].

Now, we have about 80% savings in kneading

time for 8.00kg of groundnut paste with this

motorized

kneader,

which

compares

favourably

with the 45-76% savings of time recorded by

some [5], and the 35% savings of time

recorded by others [4].

3.3 Throughput Capacity (kg/hr)

The throughput capacity of the motorized

kneader was found to range from 40.0 kg/hr to

60.0 kg/hr. which averaged 46.3 kg/hr. as

shown in Table I. This is certainly better than a

situation where 6.6 kg/hr of groundnut paste

was kneaded in 25 mins (i.e15.84 kg/hr), as of

one [7], or 6.6kg of groundnut paste kneaded

in I 1.25 mins (i.e. 35.2 kg/hr), as of another

[5].

4. CONCLUSION.

This work has shown that there is always room

for improvement in the development of

processing machines. The achievement of

faster kneading and oil extraction from

groundnut paste by this machine is certainly a

big relief from drudgery for groundnut

processors. It is also an invention of the

Maduako, Mikailu and Maunde

38

farmer's dream of a more profitable and

pleasurable agricultural business in groundnut

production and processing. With 80% savings

in kneading time and throughput capacity of

46.3 kg/hr. this motorized kneader is quite

promising.

REFERENCES

1. Nalumansi , S.R: Kaul, R.N. "Studies on

the traditional system of groundnut oil

extraction and possible improvements."

IAR/Ford

Foundation

Project

on

Technology for Women In Agricultural

Mechanization

Research

programme.

IAR/ABU. Zaria. 1992: 45-48.

2. Young. T.S. "Field crop production in

tropical Africa Macmillan, New York,

1982.

3. Eke. A.B; Maigida, D.N Groundnut oil

extraction:

tools

and

Processing."

Commonwealth Training Programme on

Technology. Tools and Processing for

Women. IAR/ABU, Zaria. 1995:

4. Abubakar, S.Z: Yiljep, Y.D. Design and

development of a groundnut kneader."

NSAE Proceedings, 1996, 18:245-250.

5. Ola. F.A; Suleiman, M.L; El-Okene,

A.M.I; Oricha. I.M. "Development and

performance evaluation of a motorized

groundnut paste kneading machine."

Proceedings of the Nigerian Institution of

Agricultural Engineers, 2001.23 103-109.

6. Mohsenin, N.N. " Physical properties of

plant and animal materials: structure,

physical characteristics and mechanical

properties." Gordon and Breach Science

Publishers, New York 1980.

7. Sanda, M.A. "Improved tools and methods

of groundnut oil extraction system".

Unpublished M.Sc Thesis, Department of

Agricultural Engineering, Ahmadu Bello

University. Zaria, 1997.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Sterlization of Water Using Bleaching Powder PDFDocument20 pagesSterlization of Water Using Bleaching Powder PDFradha krishnanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Power Electronics - MITDocument210 pagesPower Electronics - MITVasco RodriguesNo ratings yet

- ATR 72 - Flight ManualDocument490 pagesATR 72 - Flight Manualmuya78100% (1)

- List of Study Center 2016-2017Document12 pagesList of Study Center 2016-2017gem68megNo ratings yet

- Bio PharmaceuticsDocument48 pagesBio PharmaceuticsRajan Kashyap100% (2)

- FirmcusbDocument123 pagesFirmcusbAndry1975No ratings yet

- SOP's For All Digital Marketing ActivitesDocument3 pagesSOP's For All Digital Marketing ActivitesSavijeet Singh50% (2)

- CO2 Production PlantsDocument4 pagesCO2 Production PlantsBoojie Recto100% (1)

- Ugc-Rc Oc Fro 2017-18 PDFDocument8 pagesUgc-Rc Oc Fro 2017-18 PDFAYSHAMOHD88No ratings yet

- Application Form 2016-2017Document2 pagesApplication Form 2016-2017gem68megNo ratings yet

- Service Manual Minolta PP1380/1390Document178 pagesService Manual Minolta PP1380/1390OcaziiNo ratings yet

- Gen Ins Arr 16decDocument2 pagesGen Ins Arr 16decgem68megNo ratings yet

- Website:: Www.b-U.ac - inDocument2 pagesWebsite:: Www.b-U.ac - inmahethiruNo ratings yet

- DDE - List of Course - Eligibility Criteria and Fee Structure 2016Document4 pagesDDE - List of Course - Eligibility Criteria and Fee Structure 2016gem68megNo ratings yet

- Bharathiar University Coimbatore - 46 Time Table For May 2016 ExaminationsDocument24 pagesBharathiar University Coimbatore - 46 Time Table For May 2016 Examinationsgem68megNo ratings yet

- Seven Largest Countries of The World': Source: WWW - India.gov - inDocument8 pagesSeven Largest Countries of The World': Source: WWW - India.gov - inPriyank NegiNo ratings yet

- Bharathiar University Coimbatore - 46 Time Table For May 2016 ExaminationsDocument24 pagesBharathiar University Coimbatore - 46 Time Table For May 2016 Examinationsgem68megNo ratings yet

- PG 2016 DecDocument25 pagesPG 2016 Decgem68megNo ratings yet

- Unige 11985 Attachment01Document25 pagesUnige 11985 Attachment01gem68megNo ratings yet

- ShakespeareDocument1 pageShakespearegem68megNo ratings yet

- TNPESU - DDE - Advertisement 16-17Document1 pageTNPESU - DDE - Advertisement 16-17gem68megNo ratings yet

- The Greatest English Dramatist in The Largest Asian Country: A Complex Cross-Cultural EncounterDocument17 pagesThe Greatest English Dramatist in The Largest Asian Country: A Complex Cross-Cultural Encountergem68megNo ratings yet

- Makita Power Tools India Distributors Locations Contact DetailsDocument2 pagesMakita Power Tools India Distributors Locations Contact Detailsgem68megNo ratings yet

- Unige 11985 Attachment01Document25 pagesUnige 11985 Attachment01gem68megNo ratings yet

- ShakespeareDocument1 pageShakespearegem68megNo ratings yet

- Endosulfan: Fact Sheet & Answers To Common QuestionsDocument16 pagesEndosulfan: Fact Sheet & Answers To Common QuestionsVaishnavi JayakumarNo ratings yet

- Representing Shakespeare The Dramatist: A Study of The Early Title-PagesDocument9 pagesRepresenting Shakespeare The Dramatist: A Study of The Early Title-Pagesgem68megNo ratings yet

- The Greatest English Dramatist in The Largest Asian Country: A Complex Cross-Cultural EncounterDocument17 pagesThe Greatest English Dramatist in The Largest Asian Country: A Complex Cross-Cultural Encountergem68megNo ratings yet

- MNT Ta Ppklkoprget02 343621 541328 WWW - Makemegenius.com Web Content Uploads Education Computer Basics For KidsDocument61 pagesMNT Ta Ppklkoprget02 343621 541328 WWW - Makemegenius.com Web Content Uploads Education Computer Basics For KidsnilaNo ratings yet

- EnglishDocument14 pagesEnglishamitsinghbdnNo ratings yet

- Conomics: Textbook For Class IXDocument10 pagesConomics: Textbook For Class IXveeruNo ratings yet

- Makita Power Tools India Distributors Locations Contact DetailsDocument2 pagesMakita Power Tools India Distributors Locations Contact Detailsgem68megNo ratings yet

- Compatibility StudyDocument5 pagesCompatibility Studygem68megNo ratings yet

- Problem 13.3Document2 pagesProblem 13.3kannyNo ratings yet

- HMT Data Book-kothandaramanDocument2 pagesHMT Data Book-kothandaramanNikhil T G0% (1)

- PAI Industries, Inc. - Catalog Polea de MotorDocument2 pagesPAI Industries, Inc. - Catalog Polea de MotorAlexis ValleNo ratings yet

- HP Application Lifecycle Management Readme: What's New Installation InstructionsDocument36 pagesHP Application Lifecycle Management Readme: What's New Installation InstructionsBrandon GarciaNo ratings yet

- Cavalieri Principle (Kin Y. Li)Document4 pagesCavalieri Principle (Kin Y. Li)Hicham ElyassamiNo ratings yet

- STI0903 - PSD Postprocessing 2Document7 pagesSTI0903 - PSD Postprocessing 2choprahariNo ratings yet

- SK EngineeringDocument16 pagesSK EngineeringOmkar waghuleNo ratings yet

- Maths EnglishDocument26 pagesMaths EnglishmeenasarathaNo ratings yet

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDocument4 pages19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RNo ratings yet

- RMI Verif NAFEMS 3 2 PDFDocument28 pagesRMI Verif NAFEMS 3 2 PDFFernando MartinezNo ratings yet

- G4pc50ud-Fd IgbtDocument10 pagesG4pc50ud-Fd IgbtMiguel DuranNo ratings yet

- Thermal DiffusivityDocument3 pagesThermal DiffusivityPrincess_Ira_E_2471No ratings yet

- Ae53 Ac53 At53Document4 pagesAe53 Ac53 At53M Taher BamyaniNo ratings yet

- Practical 4 - Signpost 2011Document4 pagesPractical 4 - Signpost 2011Percy Percival50% (2)

- Clients Class Workbook v5.1 CBTDocument192 pagesClients Class Workbook v5.1 CBTmich0pNo ratings yet

- 0580 w13 QP 41Document20 pages0580 w13 QP 41Haider AliNo ratings yet

- CS610 Final Term Past Papers Mega FileDocument35 pagesCS610 Final Term Past Papers Mega Filehowtoplaygames38No ratings yet

- Faculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVDocument7 pagesFaculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVhasmikaNo ratings yet

- CSC4212 Lecture 3 - 3D Viewing - Projection TransformationDocument31 pagesCSC4212 Lecture 3 - 3D Viewing - Projection TransformationAhmad AbbaNo ratings yet

- Simple Backup/Restore Utility With SQL-: Introduction To SQL-DMODocument8 pagesSimple Backup/Restore Utility With SQL-: Introduction To SQL-DMOZaeni Marjiyanto, A.mdNo ratings yet

- Financial Modelling Assignment - Ghizal Naqvi (Attock Petroleum Limited)Document13 pagesFinancial Modelling Assignment - Ghizal Naqvi (Attock Petroleum Limited)Ghizal NaqviNo ratings yet

- 20-SDMS-02 Overhead Line Accessories PDFDocument102 pages20-SDMS-02 Overhead Line Accessories PDFMehdi SalahNo ratings yet

- ES Q2 Mod8Document26 pagesES Q2 Mod8maacovsNo ratings yet