Professional Documents

Culture Documents

Speed Queen Hub+Seal Kit Installation PDF

Uploaded by

MacSpares0 ratings0% found this document useful (0 votes)

3K views3 pagesOriginal Title

Speed Queen Hub+Seal Kit installation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3K views3 pagesSpeed Queen Hub+Seal Kit Installation PDF

Uploaded by

MacSparesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

iad Ors Holey Sock

Important Instruc

Subject Installing No. 39508P Drive Bell and Seal Kit

Use With Topload Washers

i mac@mecsperes.co.za Tel O11 665 4990

‘A WARNING

This kit Is to be Installed in accordance with the manufacturer's Instructions and all codes and

requirements of the authority having Jurisdiction. In Canada, this conversion/Installation shall

be carried out in accordance with the requirements of the provincial authorities having

jurisdiction and in accordance with the requirements of the CAN/CGA-B149.1 and CAN/CGA-

149.2 installation code. Failure to follow instructions could result in serious injury, death or

property damage. The qualified agency performing this work assumes all responsibility for this

kit installation.

To reduce the risk of electric shock, fire, explosion, serious injury or death: :

* Disconnect electric power to the washer before servicing.

* Never start the washer with any guards/panels removed.

‘+ Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded,

Kit 39508P consists of the following: NOTE: Drive Bell Tool, No. 253P4, must be

i ited with Jaws, No, 294P4A, and Bolt, No.

Qty. PartNo. — Deseription upd °

1 = 36425 Seat 294P4B, to remove drive bell.

1 - 36511 Plug 3. Back bolt out of 294P4 Drive Bell Toot

1 -36765P Grease approximately three quarters of the way. Refer to

1 - 39432 Shoulder Screw Figure 1

1 - 39508 Drive Bell

1 - 10-97-81R1 Instructions

IMPORTANT: If water is present in wasbtub, spin

and pump out before attempting to remove drive

Pe Indent.

1. Refer to appropriate service manual and remove

agitator.

2, Remove plug (if present) from drive bell. Then saws:

remove screw (and o-ring if present) from drive

bell. i

NOTE: Use No, 294P4 Drive Bell Tool to remove Lip awe

drive bell from transmission shaft.

Figure 1

RSPCo

P.O. Box 990

Ripon, WI.54971-0990 Page 1 of 3

mac@macspares.co.za Tel 011 665 4990

4, Place tool over drive bell, making sure indent on jaws

line up with wide slots on drive bell, Refer to

Figure 2.

5. Thread bolt down through hole in top of drive bell

until it bottoms out,

6. Place tip of each jaw under bottom edge of drive bell,

‘making sure indent on jaws line up with wide slots on

drive bell. Tighten wing nuts on tool to hold jaws

firmly against drive bell. Refer to Figure 2.

8

10.

i

Spek Dram oloa Sek ge Z|

‘After drive bell has been pulled, remove tool and

drive bell by turning quarter inch bolt out of

transmission output sbaft.

Loosen wing nuts and remove drive bell from tool.

Remove old seal from hub assembly by:

a. Placing a flat bladed screwdriver between bottom

edge of seal and hub.

b. Using washtub bolts as a pry atea pop off lower

seal bead. |

©. Grasping bottom of seal pull straight up freeing

upper seal bead.

‘Thoroughly clean all foreign material from seal

mounting area of hub assembly, bronze bearing and |

washer. Refer to Figure 4.

Figure 2

7. Using an adjustable wrench, turn large nut on tool

COUNTERCLOCKWISE to pull drive bell from

transmission output shaft, Refer to Figure 3.

IMPORTANT: If large nut is turned clockwise when

pulling drive bell, you will twist off the quarter inch,

bolt.

‘Turn Adjustable Wrench

‘Counterclockwise

‘To Remove Drive Bell

Hex

Nut Transmission

sos

12,

Figure 4

Lubricate new seal with liquid soap or soapy water to

aid in assembly. Refer to Figure 5.

Apply Grease To

Inside Sealing Lips f=

Page 2013

(ioer-tRt)

mac@macspares.co.za Tel 011665 4990

send

13. Apply a small amount of supplied grease, No.

36765P, to inside sealing lips of seal. Refer to

Figure 5

IMPORTANT: DO NOT allow any luhricants to come

in contact with outside surface of seal.

14, Apply remainder of supplied grease, No. 36765P, to

exposed surface of washer between transmission

‘output shaft and seal

IMPORTANT: Using a small pocket mirror, check

entire circumference of bottom seal flange to make sure

seal is pressed down against shoulder on hub; there

should he no gap!

293P4

‘Seal Tool

Figure 6

Hub

‘Shoulder

‘Apply

36765P

Grease

(Step 14)

Bottom

Oman (delor Sek Pease s

15, Place new drive bell seal onto hub and carefully push.

into position using large end of No, 293P4 Seal Tool

Refer to Figure 6.

16. Turn the No. 293P4 Seal Tool upside-down and place

the small end over transmission output shaft and onto

the seal. Refer to Figure 7.

17. Push down on tool with a quick motion until it

bottoms out and the top of seal is fully seated. Refer

to Figure 7.

Installing Drive Bell

18, Position new drive bell over transmission output

shaft, Rotate drive bell until splines in drive bell line

up with splines on transmission output shaft.

19, Place No, 294P4 Bell Tool over top of drive bell

‘Screw bolt into transmission output shaft until it

bottoms out

NOTE: It is not necessary to clamp tool jaws on drive

hell during this operation.

20. Using an adjustable wrench, tum large nut on tool

CLOCKWISE to force drive bell down onto

transmission shaft until drive bell bottoms out on

shaft

21, Turn quarter inch bolt out of transmission shaft and

remove tool

NOTE: Tighten new shoulder serew to approximately

60 to 80 inch-pounds.

22, Place new plug over hole in drive bell and firmly press

into place using palm of your hand.

NOTE; It may he necessary to insert the end of a paper

clip along side of plug as it is pressed into drive hell to

release entrapped air.

IMPORTANT: When fully seated plug should not

extend ahove drive hell more than 1/8 in, (3.2 mm).

23, Place agitator on top of drive bell. Slowly rotate

agitator until fingers on underside of agitator line up

witb large slots on drive bell

24, A sharp blow on top of agitator, with palm of your

hand, will force agitator down onto drive bell,

allowing fingers on underside of agitator to lock under

oe lenge ea: bottom edge of drive bell

Figure 7 NOTE: Do not push agitator onto drive hell any further

than necessary.

Page dot

. (odrainiy

mac@macspares.co.za Tel 011 665 4990

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 71th Defy Gemini Wiring Diagram PDFDocument1 page71th Defy Gemini Wiring Diagram PDFMacSpares100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

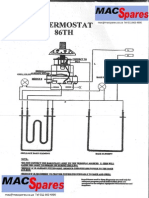

- Thermostat 86 TH Wiring Diagram PDFDocument1 pageThermostat 86 TH Wiring Diagram PDFMacSpares67% (3)

- Maneurop NTZ Low Temp - Refrigeration CompressorsDocument32 pagesManeurop NTZ Low Temp - Refrigeration CompressorsMacSparesNo ratings yet

- Refrigeration Orrifice Selection Chart PDFDocument2 pagesRefrigeration Orrifice Selection Chart PDFMacSpares100% (1)

- Refrigeration System ProtectionDocument3 pagesRefrigeration System ProtectionMacSparesNo ratings yet

- Defy Dishmaid Eton Timer PDFDocument1 pageDefy Dishmaid Eton Timer PDFMacSparesNo ratings yet

- Refigeration U-Tube Riser For Rooftop CompressorsDocument1 pageRefigeration U-Tube Riser For Rooftop CompressorsMacSparesNo ratings yet

- Connection 6 Position - 5 Heat Stove SwitchDocument1 pageConnection 6 Position - 5 Heat Stove SwitchMacSpares100% (1)

- Identifying Refrigeration Compressor FailuresDocument2 pagesIdentifying Refrigeration Compressor FailuresMacSparesNo ratings yet

- Refrigeration System Protection PDFDocument3 pagesRefrigeration System Protection PDFMacSparesNo ratings yet

- Speed Queen Hub+Seal Kit Installation PDFDocument3 pagesSpeed Queen Hub+Seal Kit Installation PDFMacSparesNo ratings yet

- Identifying Refigeration Compressor Failures PDFDocument2 pagesIdentifying Refigeration Compressor Failures PDFMacSparesNo ratings yet

- Refigeration U-Tube Riser For Rooftop CompressorsDocument1 pageRefigeration U-Tube Riser For Rooftop CompressorsMacSparesNo ratings yet

- Connection 5+6 Position Stove SwitchesDocument1 pageConnection 5+6 Position Stove SwitchesMacSparesNo ratings yet

- Speed Queen Brake Pad InstallationDocument1 pageSpeed Queen Brake Pad InstallationMacSparesNo ratings yet

- Whirlpool Tumble Drier Belt Installation PDFDocument2 pagesWhirlpool Tumble Drier Belt Installation PDFMacSparesNo ratings yet

- MS-SIRAIR-Portable-Air Conditioner PDFDocument2 pagesMS-SIRAIR-Portable-Air Conditioner PDFMacSparesNo ratings yet

- Compressor Connection DiagramsDocument2 pagesCompressor Connection DiagramsMacSparesNo ratings yet

- MS-SIRAIR Under Ceiling PDFDocument2 pagesMS-SIRAIR Under Ceiling PDFMacSparesNo ratings yet

- MS-SIRAIR Solar Geyser PDFDocument2 pagesMS-SIRAIR Solar Geyser PDFMacSparesNo ratings yet

- MS-Maneurop Catalogue PDFDocument8 pagesMS-Maneurop Catalogue PDFMacSparesNo ratings yet

- MS-SIRAIR Pool Heat Pump PDFDocument2 pagesMS-SIRAIR Pool Heat Pump PDFMacSparesNo ratings yet

- MS Maneurop Refigeration Compressor Range PDFDocument1 pageMS Maneurop Refigeration Compressor Range PDFMacSparesNo ratings yet

- MS-SIRAIR Midwall SplitDocument2 pagesMS-SIRAIR Midwall SplitMacSparesNo ratings yet

- MS Maneurop Refigeration Compressor Range PDFDocument1 pageMS Maneurop Refigeration Compressor Range PDFMacSparesNo ratings yet

- MS Alliance Air Atlantic AirconditionersDocument2 pagesMS Alliance Air Atlantic AirconditionersMacSparesNo ratings yet

- MS Maneurop Refigeration Compressors Spec SheetsDocument32 pagesMS Maneurop Refigeration Compressors Spec SheetsMacSparesNo ratings yet

- MS Alliance Air 4way Compact Cassette PDFDocument2 pagesMS Alliance Air 4way Compact Cassette PDFMacSparesNo ratings yet

- MS Alliance Air Air Curtain PDFDocument1 pageMS Alliance Air Air Curtain PDFMacSparesNo ratings yet