Professional Documents

Culture Documents

Quality 1.4021 Chemical Composition: Lucefin Group

Uploaded by

mohamedbadawyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality 1.4021 Chemical Composition: Lucefin Group

Uploaded by

mohamedbadawyCopyright:

Available Formats

Quality

X20Cr13

Number

1.4021

Martensitic

Stainless Steel

Technical card

Lucefin Group

Chemical composition

Si%

Mn%

P%

S% a)

Cr%

max

max

max

max

EN 10088-1: 2005

0,16-0,25

1,00

1,50

0,040

0,015

12,0-14,0

0.01

+ 0.05

+ 0.04

+ 0.005

+ 0.003

0.15

Product deviations are allowed

a) for improving machinability, it is allowed a controlled sulphur content of 0,015 % - 0,030; for polishability, it is suggested a controlled

sulphur content of max 0,015 %

C%

Temperature C

Melting range

Hot-forming

Recrystallization

Soft annealing

Full annealing

1510-1460

1100-800

not

suitable

Tempering

825-745

air

Stress-relieving

900-870 cooling

15 C/h to 590,

then air

MMA welding AWS electrodes

pre-heating annealing after w.

250-200

750

Isothermal

Quenching

joint with steel

carbon CrMo alloyed

annealing

E60 xx E8018-B 2

885-830

1050-950

700-650

250-150

controlled cooling oil/polymer/air air

air

cosmetic welding

to 705, then air

(HRC 46 ~)

E420 E410

Transformation temperature during heating Ac1 ~ 790, Ac3 ~ 850 and during cooling Ms ~ 240, Mf ~ 90

stainless

E309

Mechanical properties

Hot--formed EN 10088-3: 2005 in conditions 1C, 1E, 1D, 1X, 1G, 2D

size

Testing at room temperature

mm

R

Rp 0.2

A%

Kv +20 C

from

to

N/mm2

N/mm2

min

J min

min

760 max

160

700-850

500

13

25

160

800-950

600

12

20

HB a)

max

a) for

information only

230

+A annealed

+QT700 quenched and tempered

+QT800 quenched and tempered

Cold-processed EN 10088-3: 2005 in conditions 2H, 2B, 2G, 2P

size

Testing at room temperature

mm

R

HB a)

R

Rp 0.2

A%

Kv +20 C

from

to

N/mm2 max

max

N/mm2

N/mm2 min min

J min

10 b)

910

290

750-1000

600

8

10

16

910

290

750-1000

550

8

16

40

850

260

700-950

500

10

25

40

63

800

230

700-900

500

12

25

63

160

760

220

700-850

500

13

25

+A annealed material

+QT700 quenched and tempered material

a) for information only

b) in the range of 1 mm < d < 5 mm, values are valid only for rounds the mechanical properties of non round bars of < 5 mm of

thickness have to be agreed at the time of request and order

Forged EN 10250-4: 2001

size

Testing at room temperature

mm

R

Rp 0.2 A%

from

to

N/mm2

N/mm2

min

min

760 max

160

700-850

500

13

160

800-950

600

12

C%

min

Kv +20 C

J min

HB

max

230

Table of tempering values at room temperature on rounds of 10 mm after quenching at

R

N/mm2

1650

1550

1540

1530

1530

1500

Rp 0.2 N/mm2

1320

1280

1260

1250

1230

1180

A

%

12

11

10.5

10.5

11

12

Kv

J

25

22

18

12

10

12

Tempering C 200

300

350

400

450

500

Effect of cold-working (hot-rolled +A+C). Approximate values

R

N/mm2 580

650

670

680

Reduction %

0

8

10

12

+A annealed

+QT700 quenched and tempered+QT800 quenched and tempered

25

20

685

14

690

16

970C in oil

1200

980

15

18

550

720

18

900

680

17

32

600

790

600

18

36

650

745

20

760

22

600

560

20

60

700

Lucefin Group

X20Cr13 n 1.4021 martensitic stainless steel

Effect of cold-working (hot-rolled +QT+C). Approximate values

R

N/mm2

760

810

830

840

Rp 0.2

N/mm2

570

740

770

780

A

%

18

16

15

15

Reduction %

0

8

10

12

855

795

14

14

870

800

13

16

880

820

12

18

895

830

11

20

Minimum values at high temperatures EN 10088-3: 2005

Rp 0.2 N/mm2

460

445

430

Rp 0.2 N/mm2

515

495

475

Test at

C

100

150

200

395

440

300

365

405

350

330

355

400

material +QT700

material +QT800

Thermal expansion

10.5

11.0

11.5

10-6 K-1

Modulus of elasticity

longitudinal GPa 215

212

205

200

Poisson number

v 0.235

0.210

Electrical resistivity

mm2/m 0.60

Electrical conductivity

Siemensm/mm2 1.67

Specific heat

J/(KgK) 460

Density

Kg/dm3 7.70

Thermal conductivity

W/(mK) 30

Relative magnetic permeability

r 950 1)

Temperature

C 20

100

200

300

The symbol indicates temperatures between 20 C and 100 C, 20 C and 200 C ..

1) max 950 for full annealed material

12.0

190

415

460

250

400

Corrosion resistance

Atmospheric

Chemical

Fresh water

x

industrial

Magnetic

Machinability

Hardening

Service temperature in air

yes

good

by quenching

continuous service up to 650 C; intermittent service up to 750 C

marine

medium

oxidizing

reducing

600

800

x aggressive

atmosphere lacking

chlorine-derived

substances

Europe

USA

USA

China

Russia

Japan

India

Republic of Korea

EN

UNS

ASTM

GB

GOST

JIS

IS

KS

X20Cr13

S42000

420A

2Cr13

20Ch13

SUS 420J1

AISI 420 steel - T.T.T. diagram (Transformation Time Temperature)

STS 420J1

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 1.4125 440c PDFDocument2 pages1.4125 440c PDFsuntansueNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- AISI304Document2 pagesAISI304tony_abNo ratings yet

- 1 4571a316ti69Document2 pages1 4571a316ti69Admir TalicNo ratings yet

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- 1 4305a30365Document2 pages1 4305a30365skidanjeNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Material 1.2379 - X153CrMoV12Document1 pageMaterial 1.2379 - X153CrMoV12johnnydoe90No ratings yet

- Ceramics for Energy Conversion, Storage, and Distribution SystemsFrom EverandCeramics for Energy Conversion, Storage, and Distribution SystemsThomas PfeiferNo ratings yet

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin GroupSonNguyenNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Material 1.2312 - 40CrMnMoS8-6Document1 pageMaterial 1.2312 - 40CrMnMoS8-6johnnydoe90No ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Quality 42crmo4: Lucefin GroupDocument1 pageQuality 42crmo4: Lucefin GroupAnonymous Gbers2ENo ratings yet

- En10083-2 - 1996 - C35eDocument3 pagesEn10083-2 - 1996 - C35ealextentwentyNo ratings yet

- 1330 Crni Mo 831Document2 pages1330 Crni Mo 831sajay_suryaNo ratings yet

- Material 1.2738 - 40CrMnNiMo8-6-4Document1 pageMaterial 1.2738 - 40CrMnNiMo8-6-4johnnydoe90100% (1)

- 42 Crmo 4Document2 pages42 Crmo 4Shiva Kumar MNo ratings yet

- 42CrMo4 Datos Tecnicos PDFDocument2 pages42CrMo4 Datos Tecnicos PDFjlplazaolaNo ratings yet

- Material 1.2379 - X153CrMoV12Document2 pagesMaterial 1.2379 - X153CrMoV12johnnydoe90No ratings yet

- C45EDocument3 pagesC45ETrương Định100% (1)

- 18 Ni CR Mo 5Document2 pages18 Ni CR Mo 5lavius_mNo ratings yet

- Quality 18nicrmo5: Applications: High-Stress Gearwheels Components and CamshaftsDocument1 pageQuality 18nicrmo5: Applications: High-Stress Gearwheels Components and Camshaftslavius_mNo ratings yet

- SAE1018Document1 pageSAE1018arunas1081No ratings yet

- 100Cr6 PropertiesDocument1 page100Cr6 PropertiesRudrendu ShekharNo ratings yet

- Quality SAE 1018: Lucefin GroupDocument1 pageQuality SAE 1018: Lucefin GrouponeakshayNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4niladriprasadrNo ratings yet

- 39 Ni CR Mo 3Document2 pages39 Ni CR Mo 3Lokesh Krishnappa100% (1)

- 1.4305 Sae303 DatasheetDocument2 pages1.4305 Sae303 Datasheetehudingram6535No ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4Stefan GhNo ratings yet

- Quality X20Cr13: Lucefin GroupDocument2 pagesQuality X20Cr13: Lucefin GroupRajeev ChandelNo ratings yet

- Thyrodur 2379Document1 pageThyrodur 2379Türker AstarlioğluNo ratings yet

- E295 PDFDocument1 pageE295 PDFNunoAfonsoNo ratings yet

- Quality 23Mnb4: Lucefin GroupDocument1 pageQuality 23Mnb4: Lucefin GrouppgltuNo ratings yet

- Quality E335Document1 pageQuality E335Sivanaga DantuluriNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Material 1.2767 - 45NiCrMo16Document1 pageMaterial 1.2767 - 45NiCrMo16johnnydoe90No ratings yet

- Material 1.1723 - C45UDocument1 pageMaterial 1.1723 - C45Ujohnnydoe90No ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Sae1045 1018Document2 pagesSae1045 1018kevinjunNo ratings yet

- Astm A1Document1 pageAstm A1shahid khanNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- Quality 16Mncr5: Lucefin GroupDocument2 pagesQuality 16Mncr5: Lucefin GroupPrasadNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105lavius_mNo ratings yet

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- 1 8159-51CrV4Document2 pages1 8159-51CrV4black_absynthNo ratings yet

- Quality 1.2329 Chemical Composition: Lucefin GroupDocument0 pagesQuality 1.2329 Chemical Composition: Lucefin Groupramelow1982No ratings yet

- 1.7225 enDocument0 pages1.7225 enPavle StevanovicNo ratings yet

- 20 MN CR 5Document2 pages20 MN CR 5sansmgNo ratings yet

- SS 1.4122Document2 pagesSS 1.4122Bipin Sadasivan100% (2)

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservedmal singhNo ratings yet

- Caihe ch1Document30 pagesCaihe ch1dwaraganathan100% (1)

- Activated Sludge MathDocument21 pagesActivated Sludge Mathmohamedbadawy100% (1)

- Design Calculation For Softener UnitDocument12 pagesDesign Calculation For Softener Unitaraikun74775% (8)

- TN5Document57 pagesTN5OlgalycosNo ratings yet

- The Mathematics of Pumping Water PDFDocument9 pagesThe Mathematics of Pumping Water PDFOualid LamraouiNo ratings yet

- Chapter 3 PenstocksDocument29 pagesChapter 3 PenstocksmohamedbadawyNo ratings yet

- ww16 Sludge 2 WB PDFDocument114 pagesww16 Sludge 2 WB PDFmohamedbadawyNo ratings yet

- Large Diameter Manhole Sizing GuidelineDocument1 pageLarge Diameter Manhole Sizing GuidelinemohamedbadawyNo ratings yet

- Service Interval Extension: Self-Study Programme 224Document32 pagesService Interval Extension: Self-Study Programme 224ภูเก็ต เป็นเกาะNo ratings yet

- 2011-06-06 - Technical Service Bulletin - Audi Oil Quality StandardDocument18 pages2011-06-06 - Technical Service Bulletin - Audi Oil Quality StandardkidhokiNo ratings yet

- Octavia AccessoriesDocument23 pagesOctavia AccessoriesmohamedbadawyNo ratings yet

- Amsoil EnglishDocument6 pagesAmsoil EnglishmohamedbadawyNo ratings yet

- Basics of Sensors - Siemens WW (Industrial Automation Sensors)Document112 pagesBasics of Sensors - Siemens WW (Industrial Automation Sensors)VanNinh TNNo ratings yet

- Approved Oil List WVDocument17 pagesApproved Oil List WVBorislavNo ratings yet

- DVG Grammatik GeogrNamen enDocument3 pagesDVG Grammatik GeogrNamen enmohamedbadawyNo ratings yet

- Section 1. Identification: Safety Data SheetDocument10 pagesSection 1. Identification: Safety Data SheetmohamedbadawyNo ratings yet

- Robuschi Design TableDocument28 pagesRobuschi Design TablemohamedbadawyNo ratings yet

- KSB Selecting Centrifugal Pumps En, Property FileDocument92 pagesKSB Selecting Centrifugal Pumps En, Property Filevisitabhinav100% (7)

- Ust Drawing Typical EN12285-1Document1 pageUst Drawing Typical EN12285-1vonipkoNo ratings yet

- Robuschi Main CataloguesDocument23 pagesRobuschi Main CataloguesmohamedbadawyNo ratings yet

- Immobilizer: What Is Immobilizer and Why Is It Important?Document6 pagesImmobilizer: What Is Immobilizer and Why Is It Important?mohamedbadawyNo ratings yet

- DVG - Grammatik Plural-Regeln - enDocument3 pagesDVG - Grammatik Plural-Regeln - enmohamedbadawyNo ratings yet

- DVG GRammatik KasusFunktion enDocument6 pagesDVG GRammatik KasusFunktion enmohamedbadawyNo ratings yet

- Storage Tanks Made of SteelDocument6 pagesStorage Tanks Made of SteelHakan Şahinoğlu100% (1)

- Heat TracingDocument10 pagesHeat TracingmuahdibNo ratings yet

- Awwa c900 y c905Document4 pagesAwwa c900 y c905Angel LopezNo ratings yet

- Heat TracingDocument10 pagesHeat TracingmuahdibNo ratings yet

- Litmus Paper Acidity Alkalinity PH Value: PH Values of Water Completely ExplainedDocument3 pagesLitmus Paper Acidity Alkalinity PH Value: PH Values of Water Completely ExplainedmohamedbadawyNo ratings yet

- Chapter 5Document21 pagesChapter 5mohamedbadawyNo ratings yet

- Aquaponics IntegrationofhydroponicswaquacultureDocument28 pagesAquaponics IntegrationofhydroponicswaquacultureDimas Urip SNo ratings yet

- "Promotional Activity of RCF Fertilizers Through Print Media (RCF Sheti PatrikaDocument26 pages"Promotional Activity of RCF Fertilizers Through Print Media (RCF Sheti PatrikagirishtorawaneNo ratings yet

- Electrozincados en 10152 (2009)Document18 pagesElectrozincados en 10152 (2009)joaopedrosousaNo ratings yet

- Mixture RequirementsDocument11 pagesMixture Requirementsrajesh0% (1)

- Filtration of AluminiumDocument218 pagesFiltration of AluminiumNico Agung NugrahaNo ratings yet

- (T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterDocument214 pages(T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterANTENOR JOSE ESCUDERO GÓMEZNo ratings yet

- Surgical Sutures & BandagesDocument49 pagesSurgical Sutures & BandagesAnni Sholihah100% (1)

- CADD Unit 4 TPDocument7 pagesCADD Unit 4 TPmohitNo ratings yet

- Cell Wall: Presented by M. Vijaya LakshmiDocument9 pagesCell Wall: Presented by M. Vijaya LakshmiATCHUNALA SAINo ratings yet

- Biochemistry WorksheetDocument5 pagesBiochemistry WorksheetTyh tytNo ratings yet

- Soda AshDocument10 pagesSoda Ashdr chatti hanumantha rao0% (1)

- Zatamaru Cjenovnik PregledatiDocument8 pagesZatamaru Cjenovnik PregledatiNemanja StrkicNo ratings yet

- Determination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Document11 pagesDetermination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Irvine MupambaNo ratings yet

- Dehydrated Culture MediaDocument92 pagesDehydrated Culture MediaTitan Biotech Ltd.0% (1)

- Chocolate: Chocolate Is A Raw or Processed Food Produced From The Seed of The TropicalDocument7 pagesChocolate: Chocolate Is A Raw or Processed Food Produced From The Seed of The TropicalNyimas Irina SilvaniNo ratings yet

- Gravimetric Analysis Laboratory ReportDocument9 pagesGravimetric Analysis Laboratory ReportShawn RizalNo ratings yet

- Oleic Acid TechnologiesDocument11 pagesOleic Acid Technologiessoham kawaleNo ratings yet

- Salting-Out Crystallisation Using NH Ina Laboratory-Scale Gas Lift ReactorDocument10 pagesSalting-Out Crystallisation Using NH Ina Laboratory-Scale Gas Lift ReactorChester LowreyNo ratings yet

- MK1977 CongressDocument173 pagesMK1977 CongressGodshalllaughNo ratings yet

- McQuay WHS ChillerDocument28 pagesMcQuay WHS ChillerYorkist100% (1)

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- Biocomposites Guide PDFDocument40 pagesBiocomposites Guide PDFShirah CoolNo ratings yet

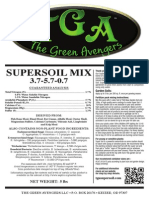

- TGA Supersoil 5lbDocument1 pageTGA Supersoil 5lbKatherine CampbellNo ratings yet

- Who We Are: Case Study-Mahindra ChlorisDocument25 pagesWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMANo ratings yet

- Detailed Storage Tank SizingDocument18 pagesDetailed Storage Tank SizingBooLat Johorean100% (3)

- Biological Nitrogen FixationDocument24 pagesBiological Nitrogen FixationRam Nivas Ahirwar100% (2)

- Iso 14687 3 2014Document11 pagesIso 14687 3 2014Tatiana Sainara Maia FernandesNo ratings yet

- Air Conditioning EquipmentsDocument31 pagesAir Conditioning EquipmentsamarparimiNo ratings yet

- Drug Education: September 9, 2017 Mati Davao OrientalDocument119 pagesDrug Education: September 9, 2017 Mati Davao OrientalYem Binobo NantesNo ratings yet

- Multiparticulate Delayed Release Drug Delivery SystemDocument24 pagesMultiparticulate Delayed Release Drug Delivery SystemAarti koramNo ratings yet