Professional Documents

Culture Documents

Tutorial - Risk Management in (Bio) Pharmaceutical and Device Industry

Uploaded by

avinashonscribdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial - Risk Management in (Bio) Pharmaceutical and Device Industry

Uploaded by

avinashonscribdCopyright:

Available Formats

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

1 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Home | Contact Us | Newsletter | Usersclub | Books | Audio Seminars

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

2 of 63

Seminars

Literature

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Risk Management in the (Bio)Pharmaceutical and D

Industry

Usersclub

Tutorials

Risk Management

Practices

Computer Validation

Part11

Method Validation

ISO 17025

Lab Equipment Qualification

Good Laboratory Practices

About

Twelve 2-day In-person

Interactive GMP and

Validation seminars

available in America,

Europe and Asia

delivered by Dr. Ludwig

Huber.

Practical Risk

Assessment in

Laboratories:

Step-by-Step

With Risk Master Plan,

SOPs and Case Studies

for Easy Implementation

Recorded, available at

any time

Risk Based Validation

Links to specific sections of the

tutorial

Other information in the

Introduction and Literature

Overview

Regulations and Guidelines

Approaches for Risk

Management

Tools and Methodologies

Steps for Risk Management

Applications

References

Glossary

About Labcomplian

Tutorials

Forward this tutorial

Introduction and Literature Overview

Risk-based compliance is expected by regulatory agencies

recommended by industry task forces and private authors to balanc

efforts and costs vs. product quality and patient safety. Risk managem

history in the industry. For example, when car manufacturers have a q

with specific models in the market they will go through a thorough ris

process to decide whether to recall the cars or not. The cost of reca

the problem will be balanced against the cost that may potentially occ

doing anything and the effect this would have on the company imag

liability issues.

Risk assessment is also nothing new in our private life. We experie

day long before we start our daily work. Before we cross a busy road

our workplace, we look left and right because there is a risk that a ca

and run us over. By observing car traffic and stopping until the car h

looking for a pedestrian crossing or traffic lights we can eliminate th

car will hit us.

Objectives and Principles of Risk Management

Risk management is the process that helps to identify problems, ana

then to create an action plan to avoid or manage these problems. Th

risk management during pharmaceutical device and drug deve

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

3 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

of Software and

Computer Systems

manufacturing is to provide drugs and devices that are efficient and

spending too many resources, for example, for validating processes an

Strategies for FDA/EU

Compliance and Tools for

Implementation

All recommendations from official guidelines, from industry task for

private authors basically follow the same principles for risk assessmen

Recorded, available at

any time

Risk Management for

FDA/EU Regulated

Industries

Introduction and

Strategies for

Compliance and

Trouble-free Operation

Recorded, available at

any time

Developing a Risk

Management Master

Plan

A must for efficient and

consistent implementation

of risk management

projects

Recorded, available at

any time

Risk Based Computer

Validation and Part 11

Compliance

Recorded, available at

any time

1. Identify the risks: What can go wrong?

2. Analyze the risks: What is the likelihood or probability that somethi

and what are the consequences or what is the severity if somethin

wrong?

3. Estimate the risk priority number (RPN) and assess if the risk is ac

too high.

4. If the risk is too high develop and implement control steps to reduc

the risk.

5. Analyze the residual risk and assess if it is acceptable.

Let's look at the road traffic example we mentioned at the beginnin

same steps as above.

1. Risk or unwanted event: Car runs over a pedestrian crossing the r

2. Probability of occurrence: Depends on the road traffic - low for cou

medium for town roads and high for city streets.

Severity: Always high, because the accident may lead to permanen

death.

3. Risk level expressed by the risk priority number (RPN): Always high

high severity and some probability. The RPN increases from the co

the city street due to increasing probability.

4. Control steps to reduce probability: Depends on the risk priority nu

- Country road: Look left and right before crossing the road.

- Town road: Use pedestrian traffic lights or a pedestrian crossing.

- City street: Use pedestrian overpass or underpass.

5. Residual risk: Is acceptable because probability of occurrence has

reduced.

The effort to reduce the risk to an acceptable level increases with t

number. This is a simple example, but illustrates the steps that are r

safely across the road. The principles can be applied to most risk scen

The person crossing the road does not follow a formal and docume

She or he is using a practical approach which is only based on e

common sense. This way we can define risk management for compli

justified and documented common sense". Official guidelines and stan

ICH Q9, ISO 31000 and others have listed a couple of important prin

management.

Risk Assessment:

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

4 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Is an integral value of all organization processes, e.g., for complian

health and safety.

Is part of decision making, for example, whether to implement chan

Is systematic, structured and timely.

Is based on the best available information, for example, on historic

science.

Has the health and safety of patients in mind.

Is aligned with a company's culture, strategies, risk profile and perf

measures.

Decisions should always be justified, documented and communicat

everybody affected by the project.

Is an ongoing process to improve the efficiency of the organization

Benefits and Issues for the Regulated Industry

The value of risk assessment for the regulated industry becomes ob

diagram in Figure 1. On the x-axis it shows the level of quality,

compliance of a product or process. The y-axis shows decreasing ris

additional value and increasing costs for validation and compliance.

Figure 1: Risk Optimization vs. Quality and Cost

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

5 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Doing nothing about compliance, quality or validation is a high risk, for

may receive warning letters from the FDA, or when looking at equipm

have high failure rates. Or even worse, patients may get sick if a drug

adverse impurities because of insufficient quality or validation of p

systems. Of course, the advantage is that in this case there are no c

When going to the right side of the diagram everything is validated

stringent interpretation is used for compliance and the costs get expo

The risk decreases but so does the additional value, for example, f

validation efforts. One of the tasks of a risk management project

optimum which should be somewhere in the middle.

For each process or piece of equipment the company should decide

can be taken. General recommendations should come from the Risk

Master Plan or directly from management for a specific project. The q

much risk a company can or will take, or what is the acceptable risk

answer depends on which direct impact equipment or a process has

device product. For example, when looking at the drug value cha

research through preclinical and clinical development to manufactur

impact on consumers increases. Therefore, assuming everything is

validation effort for equipment used in manufacturing will be higher

same equipment is used in early development.

Similarly one can argue that the validation efforts during quality contr

pharmaceutical ingredient (API) can be lower than for finished drugs

quality problems can still be uncovered by the pharmaceutical manuf

the product reaches patients through incoming checks of the API and

control of finished drugs.

The main benefit of quality risk management is that the regulated

optimize resources towards high risk products, equipment and proces

resources for low or no risk systems. This increases the overall

improves product quality and patient safety. While in the past the reg

hesitated in applying risk management, this changed since the United

and Drug Administration (FDA) started promoting quality risk managem

its 21st century cGMP initiative along with some follow-up activities.

the word compliance can be eliminated from the x-axis in Figure 1

compliance is not always proportional to validation because with st

'The type and extent of validation depends on the risk on the drug p

compliance can be achieved at less than 100% validation.

The example used to illustrate the benefits of quality risk management

issues. QA and other professionals may disagree that development

manufacturing of API's don't require the highest focus on quality and v

is a good point as long as we understand that risk management is a

with objective criteria such as direct impact on product quality and

When looking at relative risks, quality control of finished products bear

than equivalent measures of API products or test samples from pre-clin

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

6 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Objectives of the Tutorial

This tutorial addresses risk management in the (bio)pharmaceutica

device industry. It is intended to give project managers and other prof

the (bio)pharmaceutical and medical device industry a good unders

objectives and principles of risk assessment and to guide them th

management process. Quality managers and staff as well as reg

professionals will also benefit through extensive discussions of releva

quality standards and guidelines. The tutorial will discuss tools and g

and specific recommendations for all steps of risk management

identification, risk evaluation, risk assessment and mitigation controls.

In less than one day readers will get:

An overview of regulatory and quality standard requirements and

recommendations.

Tools and common practices available for risk assessment and ma

Strategies for implementation with practical help on how to docume

outcome.

Recommendations for special applications, e.g., for laboratory sys

software and computer validation, equipment maintenance and qua

for process validation.

From our experience in attending risk management workshops and rea

and Risk Management Master Plans and procedures we realized tha

practical information available on how to identify, evaluate and d

together with documentation of failures, hazards, possible harms and

risk priority numbers based on severity, probability of occurrence and

detection. It seems that most authors describe conceptual steps with

help. Also, official documents such as ICH Q9 don't give detailed inf

tutorial tries to fill this gap.

Literature Overview

Risk management for the (bio)pharmaceutical and device industry ha

documented in regulatory guidance, by industry task forces and by pr

This chapter lists some literature publications with relevance to risk as

management in the (bio)pharmaceutical and medical device industry.

The European Council Directive 93/42/EEC of June 14 1993 Conc

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

7 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Medical Devices (1) was one of the first regulatory documents that

eliminate risks as much as possible during the design and manufac

medical devices when weighed against the benefits to the patient.

The US FDA Quality System Regulation (2) requested to validate t

medical devices and that design validation should include risk anal

appropriate.

The EU GMP Annex 15 for "Validation and Qualification" (3) reques

assessment approach to determine the scope and extent of valida

evaluate the impact of the change of facilities, systems and equipm

(medicinal) product including risk analysis.

Risk-based compliance was an important element of the FDA's Pha

cGMP Initiative for the 21st Century in 2002 (4).

Risk-based compliance was also a key component in the FDA's ne

for dealing with electronic records and signatures: 21 CFR Part 11

Probably the single most important document related to risk manag

pharmaceutical industry is the ICH Q9 "Guide on Quality Risk Mana

2005 (6). It describes a systematic approach for risk management

drug development and manufacturing including laboratories.

The World Health Organization Expert Committee on Specifications

Pharmaceutical Preparation published a paper entitled "Hazard and

Analysis in Pharmaceutical Products" (30). It provides general guid

use of Hazard Analysis and Critical Control Points (HACCP) to ens

of pharmaceuticals.

The Pharmaceutical Inspection Convention/Cooperation Scheme (

an example of a methodology for implementing ICH Q9 in the pharm

field (29).

Risk management is well known and practiced in many industries

industry task forces have developed guidance documents that

management.

In 2001 GAMP published the "Guide for Validation of Automated Sy

(GAMP 4)" (7). Appendix M3 was dedicated to risk assessment. It

focuses on risk-based validation of computer systems.

Its successor GAMP 5 was released in 2008 (8). The title: 'A RiskApproach to Compliant GxP Computerized Systems' indicates that

guide is focused on risk-based compliance of computerized system

The Global Harmonization Task Force (GHTF) has published a risk

guidance for the medical device industry titled: 'Implementation of R

Management Principles and Activities within a Quality Managemen

In 2000 ISO published a standard 14971:2000: 'Application of Risk

to Medical Devices'. Even though it was developed for medical dev

also recommended the approach for pharmaceutical applications. T

was updated in 2007 (10).

In 2009 ISO released two more standards: ISO 31000 on "Risk Ma

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

8 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Principles and Guidelines" (11) and ISO 31010 on "Risk Assessme

Techniques" (12). Both standards are applicable to all industries.

Private authors and professional service providers have published

general recommendations for risk management which are also relat

applications.

R. Jones (13) gave an overview of risk management for pharmace

development and manufacturing with an introduction to risk assess

techniques and with focus on probabilistic risk assessment (PRA).

Campbell (14) discussed how quality risk management principles c

to achieve a practical equipment verification strategy.

Several authors contributed to a book: "Risk Management in the Ph

Industry" (34). The book includes introductory chapters on regulato

requirements and risk management tools followed by a total of six c

J.L. Vesper (33) authored a book titled: "Risk Assessment and Ris

in the Pharmaceutical Industry: Clear and Simple". The book gives

of the risk management process and some of the more commonly u

assessment methods and tools. It also examines how the various t

applied to identifying hazards and evaluating their potential impact

Huber (15) applied the concepts of risk management to the validati

commercial off-the-shelf computer systems.

K. O'Donnel and A. Green described a risk management solution d

facilitate risk-based qualification, validation and change control act

GMP and the pharmaceutical regulatory compliance environment in

two parts. Part I (35) gave an overview on fundamental principles a

criteria outlined in the process and Part II (36) focused on tools, st

limitations, principle findings and novel elements.

Most literature publications give a general overview on risk managem

and also offer tools that help for easy implementation. For example, L

offers a "Risk Management Master Plan" (16), several SOPs (17studies (20).

Regulations, Guidelines and Quality Standards

Regulatory agencies expect (bio)pharmaceutical risk management to

associated with development and manufacturing of medicinal products

other task forces have developed guidelines and standards that he

understand and implement risk management processes. This cha

overview of the most important regulations, guidelines and quality stan

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

9 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

United States Food and Drug Administration (FDA)

FDA 21 CFR 820: Quality System Regulation (2)

This regulation was released for medical devices in 1996. The regula

risk-based design validation.

30(g): Design validation. Each manufacturer shall establish and

procedures for validating the device design. Design validation shal

under defined operating conditions on initial production units, lots, b

their equivalents. Design validation shall ensure that devices confo

user needs and intended uses and shall include testing of productio

actual or simulated use conditions. Design validation shall include s

validation and risk analysis, where appropriate.

FDA Guidance: General Principles of Software Validation (2002) (21

The guidance was developed for validation of software used in medica

FDA clearly spelled out the basic idea of risk-based compliance:

efforts should be commensurate with the complexity of the software d

risk associated with the use of the software.

This guidance recommends an integration of software life cycle ma

and risk management activities. Based on the intended use and the

associated with the software to be developed, the software develo

determine the specific approach, the combination of techniques to

the level of effort to be applied.

The selection of validation activities, tasks and work items should

commensurate with the complexity of the software design and the r

associated with the use of the software for the specified intended

For lower risk devices, only baseline validation activities may be c

the risk increases additional validation activities should be added t

additional risk.

Pharmaceutical cGMPs for the 21st Century: A Risk-Based Approa

With this document the FDA introduced risk management to the p

industry.

Risk-based orientation: In order to provide the most effective publi

protection, the FDA must match its level of effort against the magn

Resource limitations prevent uniformly intensive coverage of all ph

products and production. Although the agency has already been im

risk-based programs, a more systematic and rigorous risk-based a

be developed.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

10 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

FDA Guidance: Part 11, Electronic Records; Electronic Signatures

Application (2003) (5)

In this guidance the FDA documented the new approach for electroni

signatures. They recommended basing the decision on how to i

requirements of Part 11 on a justified and documented risk assessmen

We recommend that you base your approach on a justified and doc

assessment and a determination of the potential of the system to a

quality and safety and record integrity.

We recommend that your decision on whether to apply audit trails

based on "a justified and documented" risk assessment.

FDA Guidance: Quality Systems Approach to Pharmaceutical CGM

Regulations (2006) (22)

Risk management is one of the focuses of this guidance. Risk-base

are expected to be used for setting specifications and process

qualification of personnel, selection of quality unit (QU) personnel an

auditing.

Quality risk management is a valuable component of an effective q

framework. Quality risk management can, for example, help guide t

specifications and process parameters for drug manufacturing, ass

mitigate the risk of changing a process or specification and determ

of discrepancy investigations and corrective actions.

In a quality system, personnel should be qualified to do the tasks th

assigned to them in accordance with the nature of, and potential ris

operational activities.

Although QU personnel should not take on the responsibilities of ot

the organization, these personnel should be selected based on the

and technical understanding, product knowledge, process knowledg

assessment abilities to appropriately execute certain quality functio

quality systems feature is also found in the cGMP regulations, whic

specific qualifications, such as education, training and experience

combination thereof (see 211.25 (a) and (b)).

The quality systems approach also calls for periodic auditing of sup

on risk assessment.

Although the cGMP regulations (211.180(e)) require a product revi

annually, a quality systems approach calls for trending on a more fr

as determined by risk.

As with other procedures, audit procedures should be developed a

documented to ensure that the planned audit schedule takes into a

relative risks of the various quality system activities, the results of

audits and corrective actions, and the need to audit the complete s

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

11 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

European Regulations

The Council Directive 93/42/EEC of 14 June 1993 Concerning Med

(1) requires a risk-based design and manufacture validation and reducin

acceptable levels.

The devices must be designed and manufactured in such a way tha

under the conditions and for the purposes intended, they will not co

clinical condition or the safety of patients, or the health and safety

where applicable, other persons, provided that any risks which may

associated with their use constitute acceptable risks when weighe

benefits to the patient and are compatible with a high level of prote

and safety.

The solutions adopted by the manufacturer for the design and cons

devices must conform to safety principles, taking account of the ge

acknowledged state of the art.

In selecting the most appropriate solutions, the manufacturer must

following principles in the following order:

- Eliminate or reduce risks as far as possible (inherently safe desig

construction).

- Where appropriate take adequate protection measures including

necessary.

- In relation to risks that cannot be eliminated, inform users of the r

due to any shortcomings of the protection measures adopted.

Annex 15 to the EU GMPs Validation and Qualification (3) has legal

risk-based approaches to validation and for changes to facilities, system

equipment.

A risk assessment approach should be used to determine the scop

of validation.

The likely impact of the change of facilities, systems and equipmen

product should be evaluated, including risk analysis.

Annex 11 to the EU GMPs Using Computerized Systems (23)

controls for computerized systems on a justified and documented risk as

Once finalized the Annex will have legal status.

Extent of validation and data integrity controls should be based on

documented risk assessment.

Pharmaceutical Inspection Convention/Cooperation Scheme (PIC/

The PIC/S Good Practices Guide on using Computers in GxP Envir

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

12 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

(24) was developed for inspectors but it is also a good source documen

firms. Risk-based approaches are recommended throughout the life of a

system.

For GxP regulated applications it is essential for the regulated use

requirement specification prior to selection and carry out a properly

risk analysis for the various system options.

The inspector will consider the potential risks as identified and doc

the regulated user, in order to assess the fitness for purpose of the

system(s).

This risk-based approach is one way for a firm to demonstrate that

applied a controlled methodology to determine the degree of assur

computerized system is fit for its purpose. It will certainly be useful

consideration by an inspector.

Regulated users should be able to justify and defend their standard

acceptance criteria, procedures and records in the light of their ow

risk and complexity assessments, aimed at ensuring fitness for pur

regulatory compliance.

The business/GxP criticality and risks relating to the application wi

the nature and extent of any assessment of suppliers and software

The URS should also form the basis for a risk assessment of the s

compliance requirements, in addition to other risks such as safety.

analysis may be based on the FS, which is related to the URS (e.g

systems). The risk assessment and the results including the reaso

ranking as either: 'critical' or 'non-critical' should be documented. T

any GxP risks should be clearly stated.

The risk analyses and the results, together with reasoning for critic

non-critical classifications should be documented. Risks potentially

GxP compliance should be clearly identified.

Inspectors will be interested in the company's approach to identifyi

and the criteria for assessing the fitness for purpose of the system

An informal Working Group within PIC/S has developed an objective

example of methodology for implementing ICH Q9 (29). The documen

training purposes and will not have an impact on PIC/S inspections.

United States Pharmacopeia (USP)

USP develops methodology for specific applications and genera

different analytical aspects for FDA regulated industry. Most recently

and draft chapters recommend risk benefit approaches for testi

solvents.

<232> Elemental Impurities (Proposal)

The presence of unexpected elemental contaminants, as well as th

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

13 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

impurities likely to be present, should be considered in determining

and planning the risk-based extent of testing.

<467> Residual Solvents

Solvents that are known to cause unacceptable toxicities should be

the production of drug substances, excipients or drug products unle

can be strongly justified in a risk benefit assessment.

International Conference for Harmonization

ICH Q9: Quality Risk Management (6) is the single most important ref

document for risk management for the pharmaceutical industry. ICH focu

scientific knowledge and the link to the protection of the patients as a p

principle. The guide also gives recommendations for implementation.

Two primary principles of quality risk management are:

- The evaluation of the risk to quality should be based on scientific

and ultimately linked to the protection of the patient; and

- The level of effort, formality and documentation of the quality risk

process should be commensurate with the level of risk.

It is neither always appropriate nor always necessary to use a form

management process (using recognized tools and/or internal proce

standard operating procedures). The use of informal risk managem

(using empirical tools and/ or internal procedures) can also be cons

acceptable.

ICH Q9 has been adopted by the European Union and PIC/S in Annex

and PIC/S GMP Guides.

International Organization for Standardization (ISO)

ISO currently has three standards related to risk management: 1497

devices and 31000 and 31010 which are for general purpose risk

projects. ISO 31000 describes principles and guidelines and 31010 ris

techniques.

ISO 14971:2007 - Application of Risk Management to Medical Devi

This document was developed for medical devices but has also been

by FDA officials for pharmaceutical industry.

This International Standard specifies a process for a manufacturer

hazards associated with medical devices (including in vitro diagnos

medical devices), to estimate and evaluate the associated risks, to

risks and to monitor the effectiveness of the controls.

The requirements of this International Standard are applicable to a

life cycle of a medical device.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

14 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

This International Standard does not apply to clinical decision maki

This International Standard does not specify acceptable risk levels

This International Standard does not require that the manufacturers

quality management system in place. However, risk management c

integral part of a quality management system.

ISO 31000:2009 - Risk Management - Principles and Guidelines (11

This International Standard provides principles and generic guidelin

management. It can be used by any public, private or community e

association, group or individual. Therefore, this International Stand

specific to any industry or sector.

This International Standard can be applied throughout the life of an

and to a wide range of activities, including strategies and decisions

processes, functions, projects, products, services and assets.

This International Standard can be applied to any type of risk, wha

nature, whether having positive or negative consequences.

Although this International Standard provides generic guidelines, it

intended to promote uniformity of risk management across organiza

design and implementation of risk management plans and framewo

to take into account the varying needs of a specific organization, it

objectives, context, structure, operations, processes, functions, pr

products, services or assets and specific practices employed.

It is intended that this International Standard be utilized to harmoniz

management processes in existing and future standards. It provide

approach in support of standards dealing with specific risks and/or

does not replace those standards.

This International Standard is not intended for the purpose of certif

ISO 31010:2009 - Risk Assessment Techniques (12)

This International Standard is a supporting standard for ISO 31000

guidance on selection and application of systematic techniques for

assessment.

Risk assessment carried out in accordance with this International S

contributes to other risk management activities.

The application of a range of techniques is introduced, with specifi

to other International Standards, where the concept and application

techniques are described in greater detail.

This International Standard is not intended for certification, regulato

contractual use.

This International Standard does not provide specific criteria for id

need for risk analysis, nor does it specify the type of risk analysis

required for a particular application.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

15 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

This International Standard does not refer to all techniques and om

technique does not mean it is not valid. The fact that a method is a

particular circumstance does not mean that the method should nec

applied.

Approaches for Risk Management

Alternatives

Risk management can be very simple and straightforward but it can

complex. For example, risk assessment of equipment can be documen

paragraph with a simple statement such as: The risk level is low

equipment does not have any impact on the quality of the finished p

more complex computer system used in pharmaceutical manufactur

management may require an assessment of the criticality of each f

need for testing if the function has a high impact on the system perform

Similarly the vendor risk can be justified and documented on a sing

vendor meets all criteria as required for low risk vendors. This does

than five to ten minutes. On the other hand a full risk mana

pharmaceutical development or manufacturing process can take quite

can fill one hundred pages or more. Whether the process and doc

simple or complex it is always most important that it follows a formal

that the outcome and conclusion are justified and documented. The ris

process as applicable to the (bio)pharmaceutical and device indus

described in several official publications, for example ICH, GHTF and

10) and by private authors. All proposals for risk management include

risk initiation, risk assessment and evaluation, risk mitigation and co

communication and review. This chapter outlines the ICH Q9 proce

recommendations for estimating severity and probability.

The ICH Process

ICH Q9 is the most authentic document for risk manage

(bio)pharmaceutical industry. The guide describes quality risk mana

systematic process from the assessment, control, communication

risks to the quality of the drug along the product life cycle. The guide a

example model for quality risk management but includes a statem

models are also possible. The example model is illustrated in Figure 2.

Risk management projects can be proposed by anybody in an

whenever there is a need for such a project and the proposal is

proposal should describe any problem with background information and

data on potential hazards and harms.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

16 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Figure 2: Risk Management Process According to ICH Q9

The project is reviewed, approved and supported by management. Ma

identifies a project owner who, with the help of affected departme

assembles a risk management project team. The team develops a ris

project plan with information on process steps, required reso

deliverables and responsibilities. The plan should also include a prelimi

In the risk assessment phase the team identifies hazards and harms

severity and probability based on criteria as defined in the co

Management Master Plan.

Questions team members should ask are:

What might go wrong?

What is the likelihood (probability) that it will go wrong?

What are the consequences (severity) if something does go wrong

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

17 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

The outcome from this phase is a group of risk priority numbers (RP

from severity and probability. Alternatively ICH permits a qualitative

the terms, for example 'high', 'medium' or 'low'. The qualitative desc

number can be compared with risk acceptance criteria as generally

Risk Management Master Plan or by management specifically for the

risk number or corresponding qualitative description exceeds the acce

is reduced. After reduction the residual risk is evaluated again and a

resulting risk is lower than the acceptable risk.

The outcome of the risk management process is communicated t

makers and any others who might be affected by this process. T

reviewed for existing and possible new hazards on an ongoing basis

new hazards may be identified or the defined level for probability

Everybody affected by the project is encouraged to actively monitor th

give feedback for possible updates.

Criteria for Severity, Probability and Risk Acceptance

Defining a process and objective criteria for severity (S) and prob

criteria for risk acceptance is most important for risk assess

international standards nor regulatory guidance documents require th

method is used. Severity in general means: How big is the problem

Probability means: What is the likelihood that a problem occurs? For e

hazard the probability and severity factors are estimated and associa

categories. The number of categories is usually 3, 5 or 10 but can be

to or more than 10. ICH does not give any preference. The c

management should give recommendations on how to decide how

should be used. The number can be fixed in the master plan for all p

can allow two or three options. For example, the final number for a s

could be dependent on the confidence of the estimates.

The first part of this chapter suggests a procedure to estimate seve

and the overall risk of an identified hazard. The second part has rec

on how to define objective criteria and a process for assigning levels

and severity.

Procedure for Estimating Probability and Severity

The scales can be qualitative, quantitative or semi-quantitative. Unl

thorough statistical or other reliable data available, the scales should

qualitative. An example for a qualitative description of probability w

'medium' or 'low'. Equivalent semi-quantitative expressions would be

'once a day', 'once a week' or 'once a month'. Figure 3 shows more

qualitative and semi-quantitative descriptions for severity and Fig

equivalent examples for probability.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

18 of 63

Qualitative

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Semi-Quantitative

Quantitat

Very high

Frequent

Likely to happen

Every day

High

Probable

Every 3 days

Medium

Occasionally

Every week

Low

Can happen

Every 3 weeks

Very low

Improbable

Every 2 months

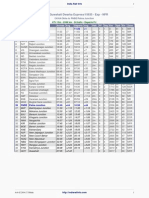

Figure 3: Examples for Qualitative, Semi-Quantitative and Qua

Categories for Probability

Qualitative

Semi-Quantitative

Very high

Catastrophic

Death or permanent injury

Loss > $50 million

High

Critical

Injury for up to 1 month

Loss $10-50 million

Medium

Serious

Temporary injury for 2 days requiri

professional medical treatment

Loss $2-10 million

Low

Minor

Temporary injury for 2 days not req

professional medical treatment

Loss $500 thousand / $2 million

Very low

Negligible

Temporary discomfort for 2 days

Loss < $500 thousand

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

19 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Figure 4: Examples for Qualitative and Semi-Quantitative Risk C

Severity

Probability of detection has also been suggested as a risk measu

option but it is not a must. One can argue that severity factors in

probability of detection is low. It should be considered under specific

decide whether the risk could be included or not.

It is most important to make the risk analysis and evaluation as

possible. A frequent mistake is that individual members tend to rate

high risk. One way to ensure objectivity across an organizatio

assessment criteria and examples for severity from the corporate Ris

Master Plan. The probability data should be derived from available em

the same or similar systems or processes. If such data are not ava

most unfavorable situation should be used for the initial risk assessme

Documentation of the severity factors should include a scientific just

all the risks have been discussed and rated, the team reviews the

comparison. Adjustments should be made for RPNs that are considere

order.

Graphical Determination of the Overall Risk

After values for severity and probability have been assigned, the

determined. This can be done graphically as shown in Figure 5. Seve

medium and high are drawn as columns and probability as rows. All cel

low risk, in yellow medium risk and cells in red are defined as high risk.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

20 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Figure 5: Graphical Determination of Risk

The equivalent graph including detectability is shown in Figure 6. Risk

Figure 5 is drawn using detectability as columns starting with high on th

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

21 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Figure 6: Graphical Determination of Risk including Detectability

Determination of the Overall Risk with Risk Priority Numbers

Levels for severity as described before can be converted to number

'low' becomes a 1, 'medium' a 2 and 'high' a 3. This is especially

assigning the risk for routine applications for the determination of the o

Risk priority numbers (RPNs) are calculated from severity and pro

using the formula:

RPN = Severity (S) x Probability (P)

Risk (RPN) is expressed as the multiplication of severity with occurren

RPN = S x O.

In the example in Figure 5 the RPN can go from 1 in the left lower cell t

upper cell. RPNs from 1 to 2 are equivalent to low, 3 to 5 are medium

high risk.

This procedure is much more flexible than the graphical determination

for specific situations weight factors can be added to probability and

this case the formula could look like:

RPN = 2S x P

This means the impact is double weighted compared to probability.

Another advantage of using numerical values is that multiple risk types

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

22 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

combined. For example, non-patient related business risk can be c

patient risk using the formula:

RPN = S x (P (Business) + S x P (Patient))

Again weight factors can be added, for example, if the patient risk is

be more important than non-patient related business risks.

This procedure also easily allows using detectability as a contributin

overall risk. But first, categories for the detectability have to be a

categories have to be converted to numbers. The resulting formula is:

RPN = S x P x 1/D

Working with calculated numbers is very easy but unless there is a go

about the meaning they don't tell us anything about the absolute ri

cause problems when values for severity, probability and detectabil

assigned. Therefore, a good practice is using qualitative or quantitativ

during initial ranking and then allocating numbers to the descriptions.

Estimating Severity of Potential Harms

There are several factors that contribute to the severity of potentia

(bio)pharmaceutical and device industry. The final ranking is derived

factors. ICH Q9 recommends using patient safety as the main criteri

the decision on estimating levels on a scientific judgment.

Factors contributing to severity typically include:

Impact on Product Quality

The question here is if the potential harm has a direct impact on p

which means that any failure cannot be corrected before a new dru

product is approved for marketing or before a batch is released for sh

case the probability of detecting the problem is low or zero. An e

analysis system used in a quality control laboratory where analysis re

as criteria whether to release a batch or not.

Impact on People's Health and Safety

Poor product quality as discussed in the previous paragraph only play

role if the poor quality can have an adverse impact on consumers. Thi

into health effects for patients. An example for high severity is when

quality can cause sickness that requires treatment in a hospital.

Impact on Business Continuity

This is related to a company's ability to timely market a new product a

the system and process uptime for continuous shipment of products. T

the level comes from the question: How big is the loss in $ due to

product approval or shipment stoppages?

Impact on Compliance

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

23 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

This is related to the risk of failing regulatory inspections and rece

multiple warning letters or inspectional observation reports. Consequ

shipment stops, substantial amounts of reengineering to fix problems

to implement corrective actions.

There are other indirect factors like claims by end-users, product l

product recalls and a company's reputation, e.g., if problems with pro

compliance become public.

Estimating Probability of Potential Harms

Probability should answer the question: What is the likelihood tha

hazard occurs? Probability should be expressed in occurrence per t

source for reliable probability data is experience with the same or sim

system. One important point is that we should look at the circu

complete sequence from the occurrence of the hazard through to the

the harm. A specific hazard may not always cause harm.

The probability should be estimated by subject matter experts. Possi

data are:

Historical data from using the same process or system.

Historical data from using a similar process or system.

For equipment and systems: Information from the vendor, for exam

estimates, costs for guaranteed uptime and extended warrantee.

Initial production data.

Sources can be used individually or jointly. Preferably multiple sour

used to increase the confidence level.

Estimates are very difficult to make when no historical data are a

workaround you can ask if within the same company either at the s

sites adequate data are available. Even if the information cannot be

you can look at similarities and differences and add uncertainties acco

Most critical is the situation for new systems. In this case estim

supplier can be used to judge what could possibly go wrong. Howeve

having a very good relationship based on trust with the supplier.

If no data are available the probability level should be based on th

estimates.

Risk Threshold

The risk threshold is a measure on how much risk a company is willin

expressed on a scale of very low risk tolerance to very high risk to

risk threshold means a company is not willing to take a risk and a

means the company is willing to accept a lot of risk. The RT is pro

project team for each risk management process and should be

management. For example, when looking at computer system valid

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

24 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

threshold is higher for a system used in early product development

same system is used in manufacturing control. Similarly processes

manufacturing can take higher risk factors than processes for manufac

because of additional quality control of finished drugs that can also r

problems of APIs. Recommendations on how to apply the RT and ex

be documented in the Risk Management Master Plan.

Figure 7: Risk Priority Number vs. Risk Threshold

The relationship between the RPN and the RT is shown on two exampl

On a scale of 0 to 10 the risk factor is determined as approximately 6

this RPN is higher than the RT (approximately 3) which means it shou

to below 3. In Example 2 the RPN is lower than the RT, so it is ac

procedure requires that the RPN and RT numbers should be normali

the same range.

Tools and Methodologies for Risk Management

Tools are important to make the entire risk management process

consistent. They can be as simple as templates in Microsoft Word or

be filled out by risk management team members and other individu

hazards and harms and to justify and document risk priority numbers

steps. Tools can also include software to guide risk management

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

25 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

through the full risk assessment process. The most well-established f

risk assessment are: Failure Mode Effect Analysis (FMEA), Fault

(FTA), Preliminary Risk Analysis (PRA), Hazard, Hazard Opera

(HAZOP) and Hazard Analysis and Critical Control Points (HACCP). Fo

be categorized into deductive and inductive tools. Inductive techniqu

question: What if something bad happens? Deductive techniques loo

problem and answer the question: What caused it to happen? An e

inductive tool is FMEA and an example for a deductive tool is FTA.

While these formal tools often proved to be efficient and reliable in ris

and risk control of specific projects, a systematic use of these tools

areas with requirement for risk assessment would generally be inc

existing resources. ICH Q9 also has a comment about using tools

always appropriate nor always necessary to use a formal risk manage

(using recognized tools and/or internal procedures e.g., stand

procedures). The use of informal risk management processes (using

and/or internal procedures) can also be considered acceptable". Wh

more empirical tools have been used there is a tendency nowadays

established formal tools.

All tools, whether they are simple or complex have one disadvantage

replace subject expert knowledge! The output is only as good as th

important is that inputs should not only come from single individuals b

risk management team that has all the required knowledge and expertis

This chapter will describe some of the most frequently used tools. Th

describes examples of informal tools that are mainly used to docume

They include tables, templates, forms and examples and also a Risk

Master Plan, internal procedures, a risk database and software tools.

part of the chapter we describe and move on to more soph

well-established methodologies. Figure 8 lists some of the mo

methodologies with advantages and limitations.

FTA

FMEA /

FMECA

HACCP

Principle

Graphical,

deductive,

structured tool.

Structured

inductive tool,

can be

qualitative and

quantitative.

Prevent known

hazards to

reduce risks at

specific CPs.

Advantages

Visual fault

tree diagrams

with

standardized

symbols to

Very universal

and scalable,

e.g., for high

level and

detailed risk

Full risk

management

process.

Specific and

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

26 of 63

Limitations

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

show the

pathway from

basic events

to the

undesired

event.

assessment.

Can quickly

become very

complex

because it

looks at one

failure at a

time.

Tool does not

consider

operational

issues or

operator

performance.

flexible.

Focus on

prevention.

Record

keeping

answers

product liability

and compliance

questions.

Requires

detailed

information on

the product and

process.

Does not show

interaction

between

events.

Tool

Graphics with

standardized

symbols.

Tables.

Tables.

Dedicated

software

recommended.

Main

Application

and Use

Used to define

a particular

undesired

event and

identify its

causes (basic

events).

For potential

problems with

serious

impact.

Detailed

process

diagrams.

Universal use,

e.g., medical

device,

hospitals.

Used to

identify known

and potential

failure modes

and impact on

processes,

facilities and

equipment.

Food and

chemical

industry.

Adapted for

pharmaceutical

industry by

WHO.

Covers full

product chain.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

27 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Used during

design and

operation.

Figure 8: Formal Risk Management Methodologies

Informal Tools

Informal tools are simple and easy to use. They are recommended

that are not so complex and if there is not much experience with ris

within a company. They are useful to make all risk assessment and

processes consistent and effective. They are also quite usefu

preliminary documentation which is used when making the decision to

moving a risk management project forward to a more detailed risk man

established methodologies.

The Importance of a Generic Risk Management Master Plan

One of the biggest challenges in risk management is to make assess

which means make it independent from subjective opinions of individ

look at risk from just one angle. Legislation does not give any solution

problem and different risk methods as well as private authors give diff

to the problem.

For example, recommended numbers for probability range from 0 to 1

and severity can vary from 1 to 3, 5 or 10. Some methods include "d

"discovery probability" in the formula and there is even inconsistency i

used for calculation. The subjectivity problem has also been brought

Each stakeholder might perceive different potential harms, plac

probability on each harm occurring and attribute different severities to

However, while it may be very difficult to get a common understandi

industry on the formal process and criteria to assess a risk, it should

get this understanding within a company. The outcome of the same ris

process should be consistent within a company, no matter who is doing

Master plans in general are excellent tools to get a common und

specific topics. For example, validation master plans are well

frequently used to ensure consistency and effectiveness of validation

Management Master Pans with specific examples are even more imp

ensure objectivity for criteria such as severity and probability. As

Management Master Plan provides a framework and practices for ris

of processes and equipment. It also ensures that risk assessment an

carried out efficiently and consistently throughout the organizatio

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

28 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

meeting regulatory, customer, quality and business requirements. Th

ensure that the company's risk management procedures are based o

that they are understood and followed throughout the organization.

The risk management document is the first and most important docume

be available when starting individual risk management processes. It i

individual Risk Management Project Plans and is the reference docum

management projects, no matter which risk management methodology

This master plan describes:

The company's risk management policy.

The links between the company's organizational objectives and pol

risk management policy.

Relationship of the risk management plans with other documents, e

master plans or quality manual.

The approach to the company's risk management process.

Members of risk management teams (by function).

Responsibilities of the project leader and team members.

Products and processes that should be covered by risk manageme

Contents of individual Risk Management Project Plan.

Detailed steps for risk management.

How the likelihood is defined.

How to identify risk levels.

Factors contributing to high and low severity.

Definition and determination of RPNs with examples.

Criteria and examples for acceptable risk thresholds.

How to make a high-level risk assessment.

Communication of project status and outcome of risk management

Frequency and procedures for ongoing review.

The Risk Management Master Plan should be developed by a cross-f

at the highest level possible. Preferably the corporate QA department s

project and also ensure that the concepts are implemented for individ

management projects.

Procedures

Step-by-step procedures should be developed for initiating, impl

updating individual application-specific risk management projects.

risk-based supplier assessment, risk-based computer system

risk-based testing of starting materials for drug manufacturing. Develop

of such procedures should be controlled by corporate quality assura

consistent use throughout the organization.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

29 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Templates and Forms

Templates and forms with examples and process flow charts are simp

tools to improve consistency and efficiency for risk identification, e

control. They can be part of SOPs or the Risk Management Master Pl

be individual documents. Examples are specifically important to gi

ranking risk elements such as probability, detectability and severity.

Examples and Case Studies

As organizations gain experience with risk management projects and

projects have been executed, a library with representative examp

developed. The examples help risk management project managers

identify, evaluate and control risks. The library should include both

examples. Each example should include recommendations on how to

similar projects.

Checklists

Checklists are lists of hazards, possible harms and controls tha

developed from experience either as a result of previous assessment

a result of past failures or from daily product or process support. For e

help desk can generate such a list for various computer systems.

checklists is not to forget common important hazards and control steps

Risk Database

A corporate database with examples for risk hazards and harms with

helps to facilitate the collection and maintenance of risk data. Relati

numbers for severity and probability and mitigation steps also help

assessment within a company. While initially there may be no or very l

a database will provide increased value over time when databases

with data from more risk management projects.

Software for Risk Assessment and Risk Manageme

To be added later

Failure Modes, Effects and Criticality Analysis (FMECA)

Failure Modes and Effects Analysis (FMEA) evaluates a produc

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

30 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

strengths and weaknesses, for potential problem areas, risks or failu

prevents failures before they occur. FMECA adds evaluation of

including severity, occurrence and detectability and tries to answer the

How can a product or process fail?

What is the likelihood that it fails and if so, what is the likelihood th

will be detected? and,

What will be the effect on the rest of the process or system if a fa

and is not detected such that it can be corrected?

FMEA has the highest impact and should be performed during design o

of a product or process when failures are less expensive to addres

powerful tool to improve product reliability and reduce design, dev

manufacturing costs. FMEA is a bottom up approach to failure mode a

be used to evaluate failures that can occur when designing or running

when designing, developing or operating equipment. FMEA helps

manufacture a trouble-free product. Identified failures in a product o

corrected before they occur to ensure trouble-free functioning and ope

Applications

FMEA and FMECA are the most generic risk management methodologi

applied to a large variety of applications.

For example, they can be used during design and manufacturing of equ

as to set up and optimize qualification and maintenance plans for equ

design FMEA can help to select the best design alternative and impro

of procedures and processes. Both methodologies are also used as

screening method for complex risk management before the project is m

to more time-consuming methodologies.

Advantages and Limitations

FMEA and FMECA have many advantages. They include:

Wide applicability from design to manufacturing, servicing and mai

mechanical and electronic equipment.

Identifies failure modes, their causes and effects on the system.

Ideal for simple to medium complex systems.

Limitations include:

Optimized for single individual failure modes, but they don't work we

combinations of failure modes.

Can be time-consuming for complex systems.

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

31 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Assessment Process

FMEA and FMECA require a very good knowledge of the product or

assessment process is the same as described in Figure 10.

1. Select a team and team leader. All team members must be subject

experts.

2. Select the FMECA form from the company's Risk Management Ma

not available, create one.

3. Train team members on the process and on criteria for ranking like

occurrence and impact of failure when it occurs.

4. Make the team members familiar with the design of the product or p

ensure that all team members have the same understanding. This c

distributing product and process documentation supported by flow d

5. Set up one or more brainstorming meetings. Multiple sessions are

for complex product/process designs. Individual sessions can focu

of the entire product/process.

6. Brainstorm the product or process design for possible failures. Doc

outcome on a flipchart.

7. Sort all suggested failures by categories.

8. Combine or remove similar or duplicate entries.

9. Document potential effects on the system, subsequent operation a

(e.g., patient).

10. Assign rating factors for each identified severity, occurrence and d

Definition and scale of rating factors should be taken from the com

Management Master Plan not only to ensure objectivity and consis

project team but also with other risk management projects. Justify

reference to the plan. For occurrence, historical data from the sam

projects can be used.

11. For each identified effect list all possible causes of failures with jus

and with all uncertainties.

12. Calculate the risk priority number using the formula from the Risk M

Master Plan. The RPN is a measure for the overall risk associated

project.

13. Take actions to reduce potential critical risks.

14. Assign owners, a schedule and deliverables for the actions.

15. After the action has been implemented make a new rating for seve

occurrence and detection and calculate the RPN.

In the brainstorming meeting the risk management team identifie

failures. Most important for new products and processes is informa

engineers who have designed the product or process even though they

in admitting that failures may occur. For products that have been in

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

32 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

time the user of the products and support engineers are excellent re

can not only provide good information on which failures may occur but

predict the likelihood of occurrence and the severity of a failure.

The overall risk number is calculated from the probability and sev

decision is made on which potential failures require risk reduction. Pos

actions could be redesign of products or processes such that either the

occurrence or severity factors are reduced such that the overall risk p

is also reduced.

Fault Tree Analysis (FTA)

Fault Tree Analysis is a deductive tool that assumes a failure of the fu

product or process. It can be used as a qualitative and quantitative str

is used to define a particular event and identify its causes. Results a

visualized in a tree of fault modes and this is where the name com

diagrams can be used to identify the pathways from the base

undesired events. The methodology is particularly useful to examine

equipment, facilities and operational conditions.

FTA identifies the potential root cause(s) ('basic events') of the spec

hypothetical event. Problems can be caused by design and engineerin

also by human factors. When it is unlikely that the root cause is not

single-base events, 'cut sets' of all scenarios can be defined which

top event.

Advantages and Limitations

FTA has advantages and limitations.

Advantages are:

Highly systematic but also flexible.

The 'top-down' approach focuses attention on the failure effects wh

directly related to the top event.

Useful for analyzing systems with many interfaces.

Pictorial representation helps to easily understand the system beh

Limitations are:

Uncertainties in the probability of the base events are included in t

calculations of the probability of the top event.

The static model does not address time interdependencies.

Fault trees can only deal with binary states (failed/not failed).

Steps for FTA Analysis

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

33 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Steps for FTA analysis include:

1. Form a Team and Determine a Team Leader

Team members should be experts in the application, and either have k

experience in FTA methodology or get trained; with emphasis on ho

standardized symbols used in a flow chart.

2. Definition of a Problem and Justification of the Project

Define the event or describe what it is that should be prevented.

amount of work for a complex FTA analysis can be significant, the prim

the project should be well justified. The definition should also clearly

scope and boundaries of the project. Most important is to clearly

event and to keep it in line with the project scope.

3. Construction of the Fault Tree

After team members have acquired all the information about the pr

possible root causes that could lead to the unwanted event. These

are linked through "intermediate" events to the top event in a flow

connection between top and basic events defined logical pathways sh

A basic event can cause the unlikely event (top event) on its own or

with others (cut sets).

4. Evaluate the Fault Tree

This step prioritizes basic events based on probability data. That kind o

is only useful if such data are available.

5. Prepare a Report

The report should include a description and scope of the proje

description, all relevant process flow diagrams, fault tree analysis li

FTA flow chart. It should also include a conclusion of the analysis

original question.

Hazard Analysis and Critical Control Points (HACCP)

The Hazard Analysis and Critical Control Points (HACCP) method ori

food management system. The objective is to ensure food safety thro

and preventing known hazards and risks as they may occur at specifi

food chain. As such it is a systematic method for identification, as

control of safety hazards. The methodology is not limited to the foo

has also been suggested for the pharmaceutical, chemical, aviation an

In the scope of this methodology hazards are defined as biologica

physical agents or operations that are likely to cause illness or

controlled. The purpose of HACCP in the pharmaceutical manufacturing

ensure products with quality as specified that are efficient and safe f

and HACCP are not contradictory but rather complementary. Implemen

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

34 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

Manufacturing Practices is facilitated through HACCP methodology wh

environment with well-structured procedures facilitates implementation

HACCP Principles and Methodology

HACCP principles and methodology are very well standardized wh

training and applying the HACCP system. The system addresses all s

material production, procurement and handling, to manufacturing, d

consumption of the finished product. HACCP principles were defined b

Advisory Committee on Microbiological Criteria for Foods (NACMCF)

document was reviewed and updated by the Committee in 1997 (32) a

HACCP was defined as a "systematic approach to evaluate, identi

food safety hazards". The HACCP system is based on seven principles

1.

2.

3.

4.

5.

6.

7.

Conduct a hazard analysis.

Determine critical control points (CCPs).

Establish critical limits for each CCP.

Establish a monitoring system for the CCPs.

Establish corrective actions when the CCP is not under control.

Establish verification procedure to confirm HACCP is working effec

Establish documentation concerning all procedures and records on

principles and their application.

Figures 9 show a flow diagram with steps for implementation of the HA

Some preparation work is needed before the hazard identification and

Preliminary Task

1. Develop a HACCP Plan

After the project has been initiated by management and after ma

defined a project leader a preliminary plan is drafted by the project le

be product or process specific to address specific situations in the

should also be in line and derived from a company's generic Risk

Master Plan or HACCP Master Plan to ensure efficiency and consisten

the company. The plan should include:

The scope of the project,

steps, tasks,

deliverables,

responsibilities and

a time line.

2. Assemble a HACCP Process Team and Define a Team Leader

Team members should include subject matter experts with specific k

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

35 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

expertise in pharmaceutical engineering. Preferably team members sh

all affected disciplines, e.g.

Research,

development,

production,

sanitation,

engineering,

maintenance,

quality control,

laboratories,

quality engineering and

members of other disciplines directly involved in the plan's day-to-d

The team should also include local personnel who are familiar with c

limitations of the operation. Team members should either have k

experience in HACCP methodology and product safety hazards

training. One of the first tasks of the team is to finalize the HACCP plan

3. Describe the Product or Process and Develop a Flow Diagram o

Process

The description should include the intended use and end users of the p

distribution method. The intended users of a food or drug product may

public or a particular segment of the population, e.g. infants and elder

product description should include a list of specifications e.g., physica

properties.

A flow diagram should be developed with the purpose of providing a

outline of the steps in the process which are under the control of the

It should include all process steps such as mixing, drying, cleaning, ble

packaging, labeling, storing and distribution.

4. Verify the Flow Diagram Onsite

This step compares in a walk-through, the actual operation with th

process documentation, such as product description and flow diagra

objectivity the verification should not be done by the same people

developed the flow diagram. Deviations should be corrected in the flo

documented.

Implementing HACCP Principles

After the preparation has been done, the seven HACCP principle

previously are implemented. Steps include:

1. Identify all Potential Hazards

All potential hazards and associated control measures, if available, are

8/13/2014 10:48 PM

Tutorial - Risk Management in (Bio)Pharmaceutical and Device Industry

36 of 63

http://www.labcompliance.com/tutorial/risk/default.aspx?sm=d_a

documented for each operational step from receipt of raw materia

release and distribution of the finished product.

2. Conduct a Hazard Analysis

The purpose of the hazard analysis is to develop a list of hazards whi

significance that they are reasonably likely to cause injury or illness if

controlled. Hazards that are not reasonably likely to occur would not

consideration. Potential hazards include:

Biological,

chemical and

physical compounds.

The analysis is done by the HACCP team in a brainstorming meet

identification followed by a workshop on hazard evaluation.

The process of conducting a hazard analysis involves two steps.

The first step, hazard identification, lists all potential hazards. This is

the brainstorming session. The team develops a list of potential biolog

or physical hazards.

After the list of potential hazards is assembled, step two the hazard