Professional Documents

Culture Documents

Computational Modeling of Irregular Masonry Failure

Uploaded by

Rony BetzerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computational Modeling of Irregular Masonry Failure

Uploaded by

Rony BetzerCopyright:

Available Formats

Computational Modeling of Irregular Masonry Failure

DECLARATION

Name:

Rony Betzer

Email:

rony.be@gmail.com

Title of the

Computational Modeling of Irregular Masonry Failure

Msc Dissertation:

Supervisor(s):

Prof. Ing. Milan Jirsek, DrSc. & Doc. Ing. Jan Zeman, Ph.D.

Year:

2014

I hereby declare that all information in this document has been obtained and presented in accordance

with academic rules and ethical conduct. I also declare that, as required by these rules and conduct, I

have fully cited and referenced all material and results that are not original to this work.

I hereby declare that the MSc Consortium responsible for the Advanced Masters in Structural Analysis

of Monuments and Historical Constructions is allowed to store and make available electronically the

present MSc Dissertation.

University:

Czech Technical University

Date:

21.07.2014

Signature:

___________________________

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

ii

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

To my family

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

iii

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

iv

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

ACKNOWLEDGEMENTS

First and foremost I wish to express my deepest appreciation and gratitude to my supervisors, Prof.

Milan Jirsek and Prof. Jan Zeman, who have supported, guided and encouraged me throughout my

thesis with their impeccable knowledge and unmatched patience. One could not wish for better or

friendlier supervisors.

I must also acknowledge my thanks and appreciation to Dr. Petr Havlsek for the technical support

and suggestions.

I would like to thank Prof. Paulo Loureno, Prof. Pere Roca, Prof. Claudio Modena, Prof. Petr Kabele,

Prof. Daniel Oliveira and Prof. Lus Ramos for their professional and personal commitment to the

SAHC program.

A very special thanks goes to Eng. Yaacov Schaffer and Eng. Meir Ronen, for their continued support

and mentoring.

My sincere gratitude goes to the Erasmus Mundus program and the MSc consortium for the generous

scholarship. I am truly fortunate to have had this opportunity.

Last but not least, I wish to thank my extended international family of SAHC students, for being the

highlight of this amazing year.

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

vi

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

ABSTRACT

The study discusses the potential influence of material and geometrical randomness on the behavior

of masonry walls. Accumulated knowledge and modeling approaches as well as documented

experimental studies from the literature are considered in the process of definition, validation and

calibration of the adopted finite element models. A typical stones and joints arrangement of an existing

masonry wall is defined as reference geometry. Statistical data are then collected by performing

numerical simulations of compression and shear tests, taking into account the natural randomness of

the various material properties on both meso and macro scale, as well as the 'semi-randomness' of

the geometrical parameters, which are mainly dominated by construction technology, available

building materials and somewhat by the masons' building technique. These parameters are randomly

generated in these simulations, while complying with the overall arrangement of the reference

geometry.

The objectives of the research are to characterize, depict and quantitatively investigate the structural

behavior of masonry walls, focusing on the possible sensitivity to random material and geometrical

factors on both local and global scales. For the in-plane loading conditions considered, the results

indicate that random distribution of material properties has fairly limited influence on global behavior,

whereas geometrical arrangement is dominant in the failure mechanism triggered and in post-failure

behavior.

Keywords: Masonry; random; stochastic; failure; simulation

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

vii

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

viii

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

NUMERICK MODELOVN PORUEN NEPRAVIDELNHO ZDIVA

ABSTRAKT

Tato studie pojednv o monm vlivu nhodnho charakteru materilovch a geometrickch

vlastnost na chovn zdnch stn. Pi tvorb, oven a kalibraci pouitch konenprvkovch

model se vyuv znalost, model a experimentlnch studi pevzatch z literatury. Typick

uspodn kamen a spr ve skuten zdn stn je definovno jako referenn geometrie. Pot

jsou shromdna statistick data zaloen na numerickch simulacch tlakovch a smykovch

zkouek, kter berou v vahu pirozenou nhodnost rznch materilovch vlastnost v mezo- a

makromtku, jako i stenou nhodnost geometrickch parametr, kter jsou ovlivnny zejmna

technologi vstavby, dostupnmi stavebnmi materily a do jist mry i specifickou stavebn technikou

konkrtnch zednk. Tyto parametry jsou v simulacch nhodn generovny, pi respektovn

celkovho uspodn referenn geometrie.

Clem provedenho vzkumu je charakterizovat, zobrazit a kvantitativn prozkoumat konstrukn

chovn zdnch stn, se zamenm na ppadnou citlivost na nhodn materilov a geometrick

faktory na lokln i globln rovni. Vsledky ukazuj, e pi zatovn ve stednicov rovin m

nhodn rozloen materilovch vlastnost jen omezen vliv na globln chovn, zatmco

geometrick uspodn je pro vznikl mechanismus poruen a pro chovn v postkritickm reimu

rozhodujc.

Klov slova: Zdivo; nhodnost; stochastick; poruen; simulace

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

ix

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

x

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

. ,

. .

,

, , '-' ,

, .

, .

, ,

.

,

, .

: ; ; ; ;

Erasmus Mundus Programme

xi

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

xii

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

TABLE OF CONTENTS

1.

INTRODUCTION ............................................................................................................................. 1

2.

ADOPTED MESO MODELING ....................................................................................................... 5

3.

4.

2.1

Finite element mesh ................................................................................................................ 5

2.2

Constitutive material models ................................................................................................... 7

2.3

Modeling of uncertainties ...................................................................................................... 12

FEM SIMULATIONS AND RESULTS ........................................................................................... 15

3.1

Deterministic validation model ............................................................................................... 15

3.2

Random input models ........................................................................................................... 18

3.3

Random geometry models .................................................................................................... 28

3.4

Periodic geometry models ..................................................................................................... 36

CONCLUSIONS ............................................................................................................................ 47

REFERENCES ...................................................................................................................................... 49

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

xiii

Computational Modeling of Irregular Masonry Failure

LIST OF TABLES

Table 1 Input parameter of SBETA material......................................................................................... 7

Table 2 Input parameter of Interface material .................................................................................... 11

Table 3 Input material parameters of the validation model ................................................................ 16

Table 4 - Elastic and inelastic properties of the material models .......................................................... 18

Table 5 Mean and standard deviation of random fields in material sample DG2RB1 ....................... 19

Table 6 Input variables of material properties in simulations 1-30 ..................................................... 20

Table 7 Input variables of material properties in simulations 31-41 ................................................... 20

Table 8 Input variables of material properties in simulations 42-47 ................................................... 23

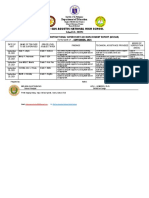

Table 9 Results summary for simulations performed with a vertical load equal to -80 kN................. 29

Table 10 Results summary for simulations 61-66 .............................................................................. 35

Table 11 Results summary for simulations 67 and 69 ....................................................................... 37

Table 12 Results summary for simulations 68 and 70 ....................................................................... 37

Erasmus Mundus Programme

xiv

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

LIST OF FIGURES

Figure 1 Modeling strategies for masonry structures: (a) detailed micro-modeling; (b) simplified

micro-modeling; and (c) macro-modeling, Loureno (2002). .......................................................... 1

Figure 2 Masonry wall defined as reference geometry, Cavalagli, Cluni and Gusella (2013). ............ 3

Figure 3 Blocks and interfaces representation of reference geometry. ............................................... 3

Figure 4 Representative 1mx1m specimens from reference geometry. .............................................. 3

Figure 5 Geometry of CCISOQUAD quadrilateral element, adapted from ervenka, Jendele and

ervenka (2013). ............................................................................................................................. 5

Figure 6 Geometry of CCISOGAP 2D interface element, ervenka, Jendele and ervenka (2013). . 6

Figure 7 Uniaxial stress-stain law, adapted from ervenka, Jendele and ervenka (2013) ............... 8

Figure 8 Exponential crack opening law, ervenka, Jendele and ervenka (2013) ........................... 8

Figure 9 Biaxial failure function, adapted from ervenka, Jendele and ervenka (2013) .................. 9

Figure 10 Interface element failure surface, adapted from ervenka, Jendele and ervenka (2013)

....................................................................................................................................................... 11

Figure 11 Division of the variable domain into intervals, Novk, Tepl, Kerner and Voechovsk

(2002) ............................................................................................................................................ 12

Figure 14 Geometry and schematic loading arrangement, Loureno, Oliveira, Roca and Ordua

(2005) ............................................................................................................................................ 15

Figure 15 Geometry and finite element mesh of the validation model ............................................... 15

Figure 16 Load-displacement diagrams, Loureno, Oliveira, Roca and Ordua (2005) on the left,

validation model on the right ......................................................................................................... 16

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

xv

Computational Modeling of Irregular Masonry Failure

Figure 17 Principal compressive stresses (N/mm2) depicted on the incremental deformed mesh for a

horizontal displacement equal to (mm): (a) 1.0; (b) 2.0; (c) 3.0; and (d) 15.0, Loureno, Oliveira,

Roca and Ordua (2005). .............................................................................................................. 17

Figure 18 Principal compressive stresses (N/mm2) depicted on the deformed mesh of the validation

model for a horizontal displacement equal to (mm): (a) 1.0; (b) 2.0; (c) 3.0; and (d) 15.0 ............ 17

Figure 19 Random fields of material sample DG2RB1 ...................................................................... 19

Figure 20 Load-displacement diagram for simulations 1-30 .............................................................. 21

Figure 21 Load-displacement diagram for simulations 31-41 ............................................................ 21

Figure 22 Load-displacement diagram for simulations 1 and 31 ....................................................... 22

Figure 23 Load-displacement diagram for simulations 42-47 ............................................................ 23

Figure 24 Load-displacement diagram for simulations 1 and 42 ....................................................... 24

Figure 25 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 1 for a horizontal displacement equal to 0.2 mm ................................................................ 25

Figure 26 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 42 for a horizontal displacement equal to 0.2 mm .............................................................. 25

Figure 27 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 1 for a horizontal displacement equal to 0.4 mm ................................................................ 26

Figure 28 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 42 for a horizontal displacement equal to 0.4 mm .............................................................. 26

Figure 29 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 1 for a horizontal displacement equal to 0.8 mm ................................................................ 27

Figure 30 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 42 for a horizontal displacement equal to 0.8 mm .............................................................. 27

Figure 31 Load-displacement diagram for simulations 1, 42 and 48-60 ............................................ 28

Figure 32 Load-displacement diagram for simulations 53 and 55 ..................................................... 30

Figure 33 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 53 for a horizontal displacement equal to 0.5 mm .............................................................. 31

Erasmus Mundus Programme

xvi

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Figure 34 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 55 for a horizontal displacement equal to 0.5 mm.............................................................. 31

Figure 35 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 53 for a horizontal displacement equal to 1.0 mm.............................................................. 32

Figure 36 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 55 for a horizontal displacement equal to 1.0 mm.............................................................. 32

Figure 37 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 53 for a horizontal displacement equal to 1.45 mm............................................................ 33

Figure 38 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 55 for a horizontal displacement equal to 1.45 mm............................................................ 33

Figure 39 Load-displacement diagram for simulations 61-66 ............................................................ 34

Figure 40 Peak response versus applied vertical load for samples RG1-RG6 .................................. 35

Figure 41 Geometries of the stack bond and running bond models .................................................. 36

Figure 42 Load-displacement diagram for simulations 1, 42, 48, 67 and 69 ..................................... 37

Figure 43 Load-displacement diagram for simulations 61, 63, 68 and 70 ......................................... 38

Figure 44 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 67 for a horizontal displacement equal to 0.3 mm.............................................................. 39

Figure 45 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 69 for a horizontal displacement equal to 0.3 mm.............................................................. 39

Figure 46 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 67 for a horizontal displacement equal to 0.6 mm.............................................................. 40

Figure 47 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 69 for a horizontal displacement equal to 0.6 mm.............................................................. 40

Figure 48 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 67 for a horizontal displacement equal to 1.0 mm.............................................................. 41

Figure 49 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 69 for a horizontal displacement equal to 1.0 mm.............................................................. 41

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

xvii

Computational Modeling of Irregular Masonry Failure

Figure 50 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 68 for a horizontal displacement equal to 0.5 mm .............................................................. 42

Figure 51 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 70 for a horizontal displacement equal to 0.5 mm .............................................................. 42

Figure 52 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 68 for a horizontal displacement equal to 1.0 mm .............................................................. 43

Figure 53 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 70 for a horizontal displacement equal to 1.0 mm .............................................................. 43

Figure 54 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 68 for a horizontal displacement equal to 1.5 mm .............................................................. 44

Figure 55 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 70 for a horizontal displacement equal to 1.5 mm .............................................................. 44

Figure 56 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 68 for a horizontal displacement equal to 2.8 mm .............................................................. 45

Figure 57 Principal compressive stresses (N/mm2) depicted on the deformed mesh of simulation

model 70 for a horizontal displacement equal to 2.8 mm .............................................................. 45

Erasmus Mundus Programme

xviii

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

1.

INTRODUCTION

"I need to discuss science vs. engineering. Put glibly: In science if you know what you are doing you

should not be doing it. In engineering if you do not know what you are doing you should not be doing

it. Of course, you seldom, if ever, see either pure state." (Richard W. Hamming, 1915-1998)

Numerical models of mechanical systems may be described as mathematical idealizations of their

physical characteristics. They assume geometry, loads and material properties as well as the

governing equations that link these variables with the response variables of the system

(displacements, strains, stresses). The finite element method provides a powerful tool of numerical

solutions to such boundary value problems. Coupled with advanced formulations of constitutive laws,

approximations can be achieved with high level of accuracy for engineering purposes.

The three main approaches to the modeling of masonry as an anisotropic material are detailed micromodeling, simplified micro-modeling and macro-modeling. In the first approach, units and mortar joints

are represented by continuum elements whereas the unit-mortar interface is represented by a

discontinuum element. In the second approach, the mortar joints and the unit-mortar interface are

lumped in discontinuum elements and the units are represented by continuum elements and

expanded to keep the geometry unchanged. In the third approach, units, mortar and unit-mortar

interface are smeared out in a homogenous continuum. The approaches differ in implemented

assumptions and in complexity, which is linked to the cost of the numerical computation, the accuracy

and the validity range, all of which should be adequately considered and prioritized when choosing a

modeling strategy, depending on the desired performance scale. For most practice oriented

applications, macro-modeling is considered efficient whereas micro-modeling is considered more

suitable for smaller scale applications, where individual units and joints and their interaction are of

interest. (Loureno 2002).

Figure 1 Modeling strategies for masonry structures: (a) detailed micro-modeling; (b) simplified

micro-modeling; and (c) macro-modeling, Loureno (2002).

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

One of the remaining challenges lies in the inherent randomness of material properties in the

structural components. The significance of both natural material randomness and manmade

geometrical arrangement has been subject to comprehensive research during the past few decades.

In the case of masonry structures in particular, many related studies focus on formulating descriptive

and optimal computational solutions to these 'built-in' yet statistically foreseeable imperfections, mostly

within the framework of homogenization approaches to the definition of equivalent material properties

(Zucchini & Loureno 2004) and equivalent periodic representations of irregular masonry (Spence,

Gioffr & Grigoriu 2008).

In this study, these uncertainties are factored back into the models by means of stochastic or

probabilistic mechanics, with the objective of assessing the effects of randomness, as well as the

accuracy of the averaged deterministic approaches commonly used in civil engineering. Specifically,

displacement controlled simulations of compression and shear tests are performed on masonry wall

specimens. An initial geometry is taken from an existing wall and a representative finite element model

is compiled as a 2D mesh, consisting of blocks and interfaces (simplified micro-modeling). Once the

model is validated by comparing simulation results with documented laboratory experiments, three

types of assumptions are made in subsequent simulations: (i) deterministic material properties, (ii)

stochastic material properties expressed as discretized random fields and (iii) probabilistic distribution

of material properties expressed as random input variables per masonry block. A fourth type of

simulation is performed assuming deterministic material properties and randomly generated geometry,

true to the reference model in terms of statistical distributions of the geometrical parameters.

Simulations are repeated with a variety of isolated or coupled modified fields and variables in order to

estimate the sensitivity of the structural behavior to each parameter.

Erasmus Mundus Programme

2

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Figure 2 Masonry wall defined as reference geometry, Cavalagli, Cluni and Gusella (2013).

Figure 3 Blocks and interfaces representation of reference geometry.

Figure 4 Representative 1mX1m specimens from reference geometry.

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

4

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

2.

ADOPTED MESO MODELING

The FEM simulations are modeled in ATENA nonlinear finite element software. The general

mathematical formulation of the problem follows a classical energetic approach. The principle of virtual

work is applied in its virtual displacement variation. Equilibrium and boundary condition equations are

expressed in an incremental form, where the structural response up to time t is assumed known and a

load is applied at t+Dt. Linearization is performed by neglecting 2

nd

order terms of the nonlinear strain

increment, arriving at the general governing equations balancing virtual internal work with work done

by external forces. The domain is decomposed by applying the Finite Element Method. The

discretized displacement field is approximated for each element at each load increment and the nodal

displacements are determined from a system of nonlinear algebraic equations solved by an iterative

Newton-Raphson Method solver. Detailed numerical assumptions and formulations of the process and

of the incorporated nonlinear material models and elements are found in ATENA Program

Documentation.

2.1 Finite element mesh

The modeled finite element mesh consists of CCIsoQuad plane stress quadrilateral isoparametric

elements and CCIsoGap 2D interface elements, representing masonry blocks and joints, respectively.

Figure 5 Geometry of CCIsoQuad quadrilateral element, adapted from ervenka, Jendele and

ervenka (2013).

The CCIsoQuad plane stress isoparametric element is bilinearly interpolated over its area and the

integrals arising in the finite element method are approximated using four Gauss integration points.

The interpolation functions at each point are expressed in the local coordinate system r,s:

Node i

Function hi

1

(1+r)(1+s)

4

1

(1-r)(1+s)

4

1

(1-r)(1-s)

4

1

(1+r)(1-s)

4

(1)

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

The CCIsoGap 2D interface element is a linear approximation derived from the isoparametric element.

It is defined by a pair of gapped lines, each located on opposing side of the interface. The degrees of

freedom defined for the element are the relative displacements Du, Dv, expressed in the local

coordinate system, which is aligned with the gap direction.

Figure 6 Geometry of CCIsoGap 2D interface element, ervenka, Jendele and ervenka (2013).

The initial state of the gap is closed, allowing full contact interaction. In addition, friction sliding is

possible within the gap. In open state, there is no contact between the lines. This behavior is modeled

by employing a penalty method. A constitutive matrix of the interface is defined:

F K

F = = tt

F 0

0 u

= Du

K nn v

(2)

where Du, Dv are the relative displacements of the interface sides (sliding and opening), Ktt, Knn are

the shear and normal stiffness, respectively and

F , F are the tractions at the interface. All values are

defined in the local coordinate system r, s.

The relative displacements Du, Dv are derived:

1

1

(1 + r ), h2 = (1 r )

2

2

u h2 u1,4 + h1u2,3

u = =

v h2 v1,4 + h1v2,3

h1 =

h

u = 1

0

h2

h2

h1

h2

0

h2

(3)

h1

0

u1

v

1

u 2

0 v2

= Bu

h1 u3

v3

u

4

v4

A numerical integration in two Gauss points is used to integrate the interface element stiffness matrix.

The stiffness coefficients depend on the gap state. The interface is considered open if the normal

Erasmus Mundus Programme

6

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

stress exceeds the interface tensile strength, in which case a stress free constitutive law is considered

(Fi=0) and the stiffness is set to a small, but nonzero value. The local stiffness matrix and internal

tractions vector are transformed into the global coordinate system and then assembled in the general

problem governing equations.

2.2 Constitutive material models

The damage-based SBETA constitutive model, in which cracks are computed using a smeared

approach, is assigned to the block elements. The properties defined for a material point are valid

within a certain material volume, associated with a Gauss integration point. The mathematical

formulation is considered in the plane stress state. The principal directions of the computed stresses

and strains may be identical or different, depending on the state of the material (un-cracked or

cracked). The input parameters used to construct the constitutive model are given in Table 1.

Table 1 Input parameter of SBETA material

Parameter

E

Definition

Elastic modulus

Poisson's ratio

Tensile strength

Compressive strength

Specific fracture energy

Compressive strain at uniaxial compressive strength

Compressive strength reduction factor due to cracks

Critical compressive displacement

Specific material weight

ft

fc

Gf

c

c

wd

In the simulations described in Chapter 3, these input variables are defined as either deterministic or

random and assigned values accordingly. The following effects of the material behavior are accounted

for by the listed input variables and relations formulations of the constitutive model:

nonlinear behavior in compression including softening

tensile fracturing based on nonlinear fracture mechanics

biaxial strength failure criterion

reduction of compressive strength after cracking

tensile softening effect

rotated crack direction model

The material stiffness matrix is defined by the elastic constants derived from a stress-strain function

representing an equivalent uniaxial law, where different laws are used for loading and unloading,

allowing energy dissipation. The nonlinear behavior in the biaxial stress state is described by means of

ef

eq

a so-called effective stress and the equivalent uniaxial strain .

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

eq =

(4)

Ei

The effective stress is in most cases a principal stress. The equivalent uniaxial strain is introduced in

order to eliminate the Poissons effect in the plane stress state and may be considered as the strain

that would be produced by the stress i in a uniaxial test with modulus Ei associated with the direction

i. Peak compressive and tensile stresses reflect biaxial stress state.

Figure 7 Uniaxial stress-stain law, adapted from ervenka, Jendele and ervenka (2013)

t

The tangent modulus E is used in the material stiffness matrix D to construct an element stiffness

matrix for the iterative solution. For numerical reasons, E is set to a minimum positive value near the

compressive peak and tensile softening ranges of the stress-strain curve.

Tensile behavior prior to cracking is assumed linear elastic. Post cracking tensile behavior is based on

an exponential crack opening law and fracture energy, derived experimentally by Hordijk (1991) and

defined per unit area of a crack.

Figure 8 Exponential crack opening law, ervenka, Jendele and ervenka (2013)

The particular form of the crack opening law reads:

w 3

w

w

=

1

+

3

exp

6.93

28 exp(6.93),

' ef

ft

wc

wc

wc

G

wc = 5.14 ' eff

ft

(5)

Erasmus Mundus Programme

8

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

where w is the crack opening, wc is the crack opening at the complete release of stress, is the

'ef

normal stress in the crack, ft is the effective tensile strength and Gf is the fracture energy . The crack

opening displacement w is calculated as total strains normal to the crack direction multiplied by band

size, which is associated with the finite element mesh size and skew.

Compressive behavior prior to peak stress is expressed as:

ef = f c ' ef

E

kx x 2

, x = ,k = 0

c

1 + (k 2) x

Ec

ef

(6)

'ef

where is the compressive stress, fc is the effective compressive strength, and c are the strain

and strain at peak stress respectively, E0 is the initial elastic modulus and Ec is the secant elastic

modulus at peak stress.

Post peak compressive behavior is defined by a linearly descending softening law. In an analogy to

the tensile cracking theory, the shape of the crack opening law is associated with a plastic

displacement and fracture energy defined and considered material properties. Both tensile and

compression failure bands are introduced in the formulation with the purpose of eliminating finite

element size and orientation effects and are defined as projections of the finite element dimensions on

the failure planes, assumed normal to the principal stresses. For skewed meshes, band size is

increased with respect to the element orientation angle.

A biaxial stress failure criterion according to Kupfer et al. (1969) is used.

Figure 9 Biaxial failure function, adapted from ervenka, Jendele and ervenka (2013)

Cracks are formed in the material when the principal stress exceeds the tensile strength. They are

assumed uniformly distributed within the material volume. A rotated crack model is defined, in which

the directions of the principal stress and principal strain are identical. Therefore, no shear strain occurs

on the crack plane and only two normal stress components are defined.

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Decreased compressive strength due to cracks is expressed by normal strain and reduction factor c

parallel to the cracks:

f c ' ef = rc f c' , rc = c + (1 c)e (128 )

(7)

The material stiffness matrix prior to cracking is defined as elastic isotropic and written in the global x,

y coordinate system:

1

0

E

D=

0

1

2

1

1

0 0

(8)

where E is the elastic modulus derived from the equivalent uniaxial law and is the Poisson's ratio

regarded constant. In the cracked material, the stiffness matrix takes the form of an elastic orthotropic

solid. It is defined in a coordinate system coinciding with crack direction. Local direction 1 is defined

normal to the crack and local direction 2 parallel to it. The matrix is derived as an inverse of a

manipulated plane stress state flexibility matrix, in which 21= is assumed and symmetry relation

12E2= 21E1 is used to obtain 12 =

E1

.

E2

The stiffness matrix DL found accordingly in the local coordinate system:

E

E1

1

E

E2

2

E

E

DL = E1 (1 1 2 ) 1

1

E2

E2

0

0

(9)

and is transformed to the global coordinate system and assembled into the global matrix.

Erasmus Mundus Programme

10

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

The joints are assigned with an Interface material model which simulates the contact between the

blocks and is based on Mohr-Coulomb criterion with tension cut off. The constitutive relation is given in

terms of tractions on the interface plane and relative sliding and opening displacements (2).

The initial failure surface corresponds to Mohr-Coulomb condition (10). Once stresses violate this

condition, the surface collapses to a residual dry friction surface.

| | c , 0

= 0

( c )2

1

, 0 =

( ft c )2

c2

1

( ft c )2

f t 2

, c =

, 0 < < ft

c 2 f t

(10)

= 0, = f t

The tensile failure criterion is represented by an ellipsoid intersecting the normal stress axis at ft with a

vertical tangent and the shear axis at c (i.e. cohesion) with a tangent equivalent to .

Figure 10 Interface element failure surface, adapted from ervenka, Jendele and ervenka (2013)

Knn and Ktt denote the initial elastic normal and shear stiffness respectively. Theoretically, post failure

stiffness is zero, however, for numerical reasons both are set to a positive value of ~1 0 00 of the initial

stiffness. The input parameters of the interface material model are listed in Table 2. These parameters

are defined as either deterministic or random in the FEM simulations and assigned with values

accordingly.

Table 2 Input parameter of Interface material

Parameter

Knn

Ktt

ft

C

F

MIN

Knn

MIN

Ktt

Definition

Normal stiffness

Shear stiffness

Tensile strength

Initial cohesion

Friction coefficient

Minimal normal stiffness for numerical purposes

Minimal shear stiffness for numerical purposes

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

11

Computational Modeling of Irregular Masonry Failure

2.3 Modeling of uncertainties

The random fluctuations in the mechanical properties of the materials are captured by introducing

randomized input variables in the FEM models. An initial set of deterministic variables is defined,

assigned with values representing average physical properties of natural building stones and mortar

joints (reduced to 2D interfaces in the models). These values and their probability density functions

(PDF) are estimated based on experimental and numerical studies by Oliveira (2003), ejnoha,

ejnoha, Zeman, Skora and Vorel (2008) and Naghoj, Youssef and Maaitah (2010). Randomized

input values are generated using the Latin Hypercube Sampling (LHS) technique. Utilizing this

sampling strategy, the need for a large number of samples is avoided, as the range of the probability

density functions of the random variables is divided into N equivalent intervals, where N is the number

of simulations. The centroids of the intervals are then used in the simulation process; therefore, the

range of the PDF for each variable is divided into N intervals of equal probability 1/N. The cumulative

probability density function (CPDF) is used directly for the random sampling:

k 0.5

xi ,k = i1

(11)

-1

where xi,k is the k-th sample of the i-th variable Xi and Fi is the inverse of the CPDF of Xi.

Figure 11 Division of the variable domain into intervals, Novk, Tepl, Kerner and Voechovsk

(2002)

Every interval of each variable is used once in the sampling, resulting in an N by n table, where n is

the number of variables. Two types of samples are collected implementing this method: (i) randomized

input variables associated with material properties of the blocks, generated per block and (ii) random

fields of both block and interface material properties, generated per integration point associated with a

finite element. Each generated sample of random material properties replaces deterministic input in a

FEM simulation.

Erasmus Mundus Programme

12

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

The geometrical characteristics of the reference wall are statistically analyzed and artificially

reproduced using a set of random parameters, derived from their respective PDF, accounting for the

height and width distribution of the blocks. The length distribution of the bed joints is used as control

criteria to prevent vertical overlap of head joints. If a sample fails the control criteria it is rejected and a

new sample is generated. The samples are converted into coordinate input for FEM models, as well

as the two samples taken directly from the actual wall. Compression and shear test simulations are

performed, considering deterministic material properties, thus isolating the effects of the geometrical

arrangement. The performed simulations are reported and discussed in Chapter 3.

(a)

(b)

(c)

Figure 12 Estimation of probability density function for the reference wall shown in Figure 2:

(a) stones width, (b) stones height, (c) bed joints' length, Cavalagli, Cluni and Gusella (2013).

Figure 13 Randomly generated geometries

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

13

Computational Modeling of Irregular Masonry Failure

Erasmus Mundus Programme

14

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

3.

FEM SIMULATIONS AND RESULTS

3.1 Deterministic validation model

For the purpose of procedure validation, an initial FEM model is developed, representing a 1m X 1m

specimen from the reference geometry. The model is numerically analyzed with deterministic input

variables calculated using the same considerations and basic configuration implementation to match

experimental and simulation studies by Loureno and Ramos (2004) and Loureno, Oliveira, Roca

and Ordua (2005). The compared specimens differ in geometrical arrangement and parameters,

which can be characterized as periodic in the experimental study case and quasi-periodic in the

reference geometry.

Figure 14 Geometry and schematic loading arrangement, Loureno, Oliveira, Roca and Ordua

(2005)

Figure 15 Geometry and finite element mesh of the validation model

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

15

Computational Modeling of Irregular Masonry Failure

The input variables for the material models are shown in Table 3.

Table 3 Input material parameters of the validation model

Material

Block

Interface

Property

Value

Unit

Definition

15500

MPa

Young's modulus

0.2

Poisson's ratio

ft

3.7

MPa

Tensile strength

fc

MPa

Compressive strength

Gf

c

- 80.3

110

N/m

-3.277E-03

Specific fracture energy

Compressive strain at uniaxial compressive strength

0.8

Compressive strength reduction factor due to cracks

wd

-0.5

mm

Critical compressive displacement

Specific material weight

2.500E-02

MN/m

Knn

155000

MN/m

Normal stiffness

Shear stiffness

Ktt

64580

MN/m

ft

0.015

MPa

Tensile strength

0.019

MPa

Initial cohesion

0.62

100

3

MN/m

Friction coefficient

MIN

Knn

MIN

Ktt

60

MN/m

Minimal normal stiffness for numerical purposes

Minimal shear stiffness for numerical purposes

While both present similar global structural responses in terms of triggered failure mechanisms and

load-displacement behaviors, each specimen exhibits a different stress path and a different post peak

behavior, most likely linked with their respective geometries, which dominate the location of the

diagonal cracks propagating through the head and bed joints and the formation of struts.

Figure 16 Load-displacement diagrams, Loureno, Oliveira, Roca and Ordua (2005) on the left,

validation model on the right

Erasmus Mundus Programme

16

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Figure 17 Principal compressive stresses (N/mm ) depicted on the incremental deformed mesh for a

horizontal displacement equal to (mm): (a) 1.0; (b) 2.0; (c) 3.0; and (d) 15.0, Loureno, Oliveira, Roca

and Ordua (2005).

Figure 18 Principal compressive stresses (N/mm ) depicted on the deformed mesh of the validation

model for a horizontal displacement equal to (mm): (a) 1.0; (b) 2.0; (c) 3.0; and (d) 15.0

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

17

Computational Modeling of Irregular Masonry Failure

The comparison between the results leads to the development of two random modeling strategies.

The first is achieved by performing repetitive simulations, altering material properties input to capture

their natural physical randomness, whereas the second is realized by performing repetitive simulations

altering the geometrical arrangement which captures manmade irregularity of the masonry.

3.2 Random input models

The model described in the previous article is used in subsequent random input modeling. For the

purpose of this study, the material properties are redefined according to average values for limestone

masonry. The input variables of the block and interface material models are shown in Table 4. The

statistical distribution around some of these mean values is assumed normal, with a coefficient of

variation equal to 0.25, while the remaining values are assumed deterministic in the simulations, for a

MIN

number of reasons. For example, a numerical input parameter such as Knn

has no physical meaning

and therefore is not randomized. On the other hand, the specific material weight which certainly is a

physical characteristic is not randomized to avoid changing the self weight load, since randomized

loads are not investigated within the scope of this study.

Table 4 - Elastic and inelastic properties of the material models

Material

Block

Property

E

ft

fc

Gf

Interface

c

wd

Knn

Ktt

ft

C

F

MIN

Knn

MIN

Ktt

Value

35610

Unit

MPa

Definition

Young's modulus

0.178

4

- 40

80

-2.257E-03

0.8

-0.5

2.300E-02

350000

150000

0.225

0.35

MPa

MPa

N/m

mm

3

MN/m

3

MN/m

3

MN/m

MPa

MPa

0.75

350

150

3

MN/m

3

MN/m

Poisson's ratio

Tensile strength

Compressive strength

Specific fracture energy

Compressive strain at uniaxial compressive strength

Compressive strength reduction factor due to cracks

Critical compressive displacement

Specific material weight

Normal stiffness

Shear stiffness

Tensile strength

Initial cohesion

Friction coefficient

Minimal normal stiffness for numerical purposes

Minimal shear stiffness for numerical purposes

In the initial simulation, deterministic values are defined according to Table 4. The self weight load is

applied to the blocks and a compressive distributed vertical load of -80 kN/m is applied on the top of

the wall. A master slave condition is defined on the top nodes in the vertical direction and a prescribed

horizontal displacement is incrementaly applied. Simulations 2 through 30 are performed with identical

geometrical and loading configurations, while the input variables are randomized in isolated and

coupled variations as reported in Table 6. An illustration of randomized fields is shown in Figure 19.

Erasmus Mundus Programme

18

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

ft

fc

Figure 19 Random fields of material sample DG2RB1

Table 5 Mean and standard deviation of random fields in material sample DG2RB1

Field

ft

fc

Mean

36800 MPa

3.8043 MPa

-38.974 MPa

Standard deviation

8436.7 MPa

1.0241 MPa

-10.744 MPa

All samples are defined to mimic natural randomness of mechanical properties, with the exception of

those generated for simulations 21 through 23, in which the variables are defined to represent a

probabilistic scatter of properties among the stones, but not within them. In each randomized sample,

the mean value of any particular input variable is slightly shifted from the mean of the population, while

the coefficient of variation may differ significantly, as described in Chapter 2. Nevertheless, the

responses obtained in all simulations are remarkably similar, practically identical before failure. This

phenomenon is due to the global nature of the mechanical behavior, in which localized material

failures have lesser influence on the response than the overall geometrical arrangement that

determines the triggered mechanisms. However, it has been well established that the vertical load

applied to a wall plays a significant role in its shear capacity and failure modes (rocking vs. crushing).

As the investigated wall exhibits minimal cracks, simulations 31 through 41 are performed with an

increased vertical load equal to -100 kN. The samples used in these simulations are reported in Table

7. As expected, the responses computed with the increased vertical load configuration exhibit an

elevated horizontal force peak. The peak loads in the latter simulations appear at exactly the same

horizontal displacement as in the former. The responses suggest that the failure modes triggered are

identical for both the lower and the higher stress capacities, which complies with experimental

evidence of correlation between the equivalent stiffness and the applied vertical load.

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

19

Computational Modeling of Irregular Masonry Failure

Table 6 Input variables of material properties in simulations 1-30

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Simulation

Sample ID

DG1D

DG1RE1

DG1RE2

DG1RE3

DG1RE4

DG1RE5

DG1RK1

DG1RK2

DG1RK3

DG1RK4

DG1RK5

DG1RB1

DG1RB2

DG1RB3

DG1RB4

DG1RB5

DG1RJ1

DG1RJ2

DG1RJ3

DG1RJ4

DG1RBB1

DG1RBB2

DG1RBB3

DG1RFC1

DG1RFC2

DG1RFC3

DG1RFC4

DG1RFC5

DG1RFC6

DG1RFC7

Input variables of material properties

Blocks

Joints

Deterministic

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random Knn, Ktt, ft fields

Deterministic

Random Knn, Ktt, ft fields

Deterministic

Random Knn, Ktt, ft fields

Deterministic

Random Knn, Ktt, ft fields

Deterministic

Random E, ft, fc input per unit

Deterministic

Random E, ft, fc input per unit

Deterministic

Random E, ft, fc input per unit

Deterministic

Random C,F, ft fields

Deterministic

Random C,F, ft fields

Deterministic

Random C,F, ft fields

Deterministic

Random C,F, ft fields

Deterministic

Random C,F, ft fields

Deterministic

Random C,F, ft fields

Deterministic

Random C,F, ft fields

Deterministic

Table 7 Input variables of material properties in simulations 31-41

No.

31

32

33

34

35

36

37

38

39

40

41

Simulation

Sample ID

DG1D

DG1RE1

DG1RE2

DG1RE3

DG1RE4

DG1RE5

DG1RK1

DG1RK2

DG1RK3

DG1RK4

DG1RK5

Input variables of material properties

Blocks

Joints

Deterministic

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random E field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Random Knn field

Deterministic

Erasmus Mundus Programme

20

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Figure 20 Load-displacement diagram for simulations 1-30

Figure 21 Load-displacement diagram for simulations 31-41

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

21

Computational Modeling of Irregular Masonry Failure

For the first loading configuration, a peak response with a median value of 46.88 kN is obtained when

the prescribed displacement reaches 0.79 mm (median value). At this point, the head joints along the

propagated diagonal crack have all reached failure. Stresses redistribute, as the bed joints along the

diagonal crack are partially in contact. The second peak marks the triggering of the second failure

mode. As the bed joints along the diagonal crack fail, the boundary conditions associated with the

partial confinement of the specimen allow the corner bed joints of the crack to establish partial contact,

which results in high stress concentrations and eventual crushing. As the secondary failure mode is a

localized one, dominated by the stress concentrations, the scatter in the responses of the different

specimens is directly linked to the randomness of their mechanical material properties. The weaker the

specimen is at the crucial remaining contact areas, the sooner a crushing mechanism appears, i.e. at

lower values of displacement and force. Once the crushing mechanism is activated and the residual

available stress paths are exhausted, the structure yields. The yielding mechanism may be

characterized as a combined failure mode of rocking and crushing, as the scattered responses appear

to converge back into a global rather than local failure mode. A similar behavior is exhibited by the

responses computed for the second loading configuration. Once the primary failure mode is activated,

the structure reaches a peak response with a median value of 56.56 kN, at a displacement of 0.8 mm.

The secondary failure mode of the specimens is scattered on the load-displacement curve, while

triggered at slightly lower displacement values with respect to the first configuration, due to the higher

stresses. It is noted that for both loading configurations, the responses of the deterministic sample

marked DG1D are of intermediate values in comparison to those of the randomized samples.

Moreover, as the localized crushing mechanism is governed primarily by the material properties of the

stone and since the random samples used in the second set of simulations are the same as those

used in the first set, the order in which the crushing mechanism is triggered in these samples is

identical for both loading configurations.

Figure 22 Load-displacement diagram for simulations 1 and 31

Erasmus Mundus Programme

22

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

In the mechanical sense, these results suggest that the random fluctuations of material properties

have negligible effects on the global response of the structure and are only significant when a weakest

link type of localized failure is dominant, in which case, the performance of a structure with a narrower

scatter of material properties is not necessarily superior, but is more predictable.

The last set of samples with randomized input variables is generated and used in simulations 43

through 47, as reported in Table 8. A FEM model is compiled using geometrical input derived from a

second specimen of the reference wall, in which the number of blocks (and their mean height) is

identical to the first specimen, while their width (and consequential area) has a higher variation. The

simulations are performed with a loading configuration identical to the one used in simulations 1

through 30. As the expected scatter of the responses is dominated by the material properties of the

blocks, the interface material properties are not randomized in these simulations. All six specimens

exhibit similar behavior, almost identical before the peak response, after which a low scatter is

observed. The responses of deterministic material model marked DG2D are of intermediate values

within said scatter. The peak response has a median value of 50.02 kN, at a median displacement

value of 1.38 mm.

Table 8 Input variables of material properties in simulations 42-47

No.

42

43

44

45

46

47

Simulation

Sample ID

DG2D

DG2RB1

DG2RB2

DG2RB3

DG2RB4

DG2RB5

Input variables of material properties

Blocks

Joints

Deterministic

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Random E, ft, fc fields

Deterministic

Figure 23 Load-displacement diagram for simulations 42-47

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

23

Computational Modeling of Irregular Masonry Failure

Comparing the structural behaviors of the two geometrical specimens, taken from the same reference

wall and applied with the same loading, several differences are noted, suggesting that the geometrical

arrangement within the wall plays a significant role in the response, while the fluctuations in material

properties play a minor one. In the initial linear phase, no noticeable differences are present, but

throughout the nonlinear phase, each specimen presents a different response, associated with the

different failure mechanisms. The first cracks appear in the specimen marked DG1D before the peak

load is reached, resulting in a semi brittle behavior, local softening, stress redistribution and combined

failure modes of rocking and crushing. In the specimen marked DG2D, the first cracks appear after the

peak load is reached, resulting in a more ductile behavior.

Figure 24 Load-displacement diagram for simulations 1 and 42

Erasmus Mundus Programme

24

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

-1.576E+00

-1.395E+00

-1.215E+00

-1.035E+00

-8.550E-01

-6.600E-01

-4.800E-01

-3.000E-01

-1.200E-01

4.751E-02

Figure 25 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 1 for a horizontal displacement equal to 0.2 mm

-1.339E+00

-1.185E+00

-1.005E+00

-8.250E-01

-6.600E-01

-4.800E-01

-3.000E-01

-1.350E-01

4.500E-02

2.013E-01

Figure 26 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 42 for a horizontal displacement equal to 0.2 mm

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

25

Computational Modeling of Irregular Masonry Failure

-3.528E+00

-3.150E+00

-2.730E+00

-2.310E+00

-1.890E+00

-1.470E+00

-1.050E+00

-6.300E-01

-2.100E-01

1.556E-01

Figure 27 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 1 for a horizontal displacement equal to 0.4 mm

-2.718E+00

-2.430E+00

-2.100E+00

-1.770E+00

-1.440E+00

-1.140E+00

-8.100E-01

-4.800E-01

-1.500E-01

1.523E-01

Figure 28 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 42 for a horizontal displacement equal to 0.4 mm

Erasmus Mundus Programme

26

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

-8.423E+00

-7.470E+00

-6.480E+00

-5.490E+00

-4.500E+00

-3.510E+00

-2.520E+00

-1.530E+00

-5.400E-01

2.846E-01

Figure 29 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 1 for a horizontal displacement equal to 0.8 mm

-3.987E+00

-3.560E+00

-3.080E+00

-2.600E+00

-2.120E+00

-1.680E+00

-1.200E+00

-7.200E-01

-2.400E-01

1.715E-01

Figure 30 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 42 for a horizontal displacement equal to 0.8 mm

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

27

Computational Modeling of Irregular Masonry Failure

3.3 Random geometry models

Considering the results obtained in simulations 1 through 47, simulations 48 through 60 are performed

by generating random geometries as described in Chapter 2 and keeping the material properties fixed

to the values listed in Table 4. As the former simulations demonstrate the effect of the random material

properties on the structural behavior, the latter are meant to demonstrate the significance of the

geometrical arrangement of the masonry. It is understood that given a fixed set of building stones, a

finite number of possible arrangements exists and determining between them is up to the mason. The

geometries are randomly generated taking into account the statistical distribution of stone dimensions

from the reference geometry, as well as incorporating the mason's discretion by applying a control

criteria derived from the statistical distribution of the bed joint dimensions. The generated 1m X 1m

specimens are applied with the same loading configuration described in the previous article. The

scatter found in the responses of the random geometries is significantly higher than the scatter

associated with the randomness of the material properties and is apparent throughout the loaddisplacement curve. It is noted that the responses of the samples marked DG1D and DG2D taken

from the reference geometry are of intermediate values in comparison to those obtained in the random

geometry simulations.

Figure 31 Load-displacement diagram for simulations 1, 42 and 48-60

Erasmus Mundus Programme

28

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Table 9 Results summary for simulations performed with a vertical load equal to -80 kN

Geometry

Reference

wall

specimen

#1

Reference

wall

specimen

#2

Random

Random

Random

Random

Random

Random

Random

Random

Random

Random

Random

Random

Random

Simulation

No. Sample ID

1

DG1D

2

DG1RE1

3

DG1RE2

4

DG1RE3

5

DG1RE4

6

DG1RE5

7

DG1RK1

8

DG1RK2

9

DG1RK3

10

DG1RK4

11

DG1RK5

12

DG1RB1

13

DG1RB2

14

DG1RB3

15

DG1RB4

16

DG1RB5

17

DG1RJ1

18

DG1RJ2

19

DG1RJ3

20

DG1RJ4

21 DG1RBB1

22 DG1RBB2

23 DG1RBB3

24 DG1RFC1

25 DG1RFC2

26 DG1RFC3

27 DG1RFC4

28 DG1RFC5

29 DG1RFC6

30 DG1RFC7

42

DG2D

43

DG2RB1

44

DG2RB2

45

DG2RB3

46

DG2RB4

47

DG2RB5

48

RG1

49

RG2

50

RG3

51

RG4

52

RG5

53

RG6

54

RG7

55

RG8

56

RG9

57

RG10

58

RG11

59

RG12

60

RG13

Responses for vertical load=-80 kN

Horizontal disp. at peak load [mm]

Peak horizontal load [kN]

0.80

46.88

0.80

46.85

0.80

46.88

0.80

46.82

0.80

46.87

0.75

46.69

0.80

46.89

0.80

46.88

0.80

46.88

0.80

46.88

0.80

46.88

0.80

46.81

0.75

46.82

0.80

46.84

0.70

47.05

0.70

46.75

0.80

46.88

0.80

46.87

0.80

46.87

0.80

46.88

0.80

46.87

0.80

46.88

0.80

46.87

0.80

46.91

0.80

46.91

0.80

46.91

0.80

46.91

0.80

46.91

0.80

46.91

0.80

46.91

1.35

50.00

1.35

49.81

1.35

49.88

1.40

50.03

1.40

50.17

1.40

50.44

1.13

46.98

0.80

52.90

0.85

44.41

0.70

43.45

0.70

44.64

1.49

57.20

1.01

51.00

1.45

45.63

1.09

46.52

0.65

42.17

1.05

47.72

0.80

46.82

0.80

47.56

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

29

Computational Modeling of Irregular Masonry Failure

Samples RG6 and RG8 (simulations 53 and 55, respectively) both exhibit high values in terms of the

displacement corresponding to the peak response (1.49 mm and 1.45 mm respectively), but while the

peak response obtained by sample RG6 has the highest value (57.20 kN), the peak response value of

sample RG8 (45.63 kN) is lower than the median value (46.82 kN). In comparison with the other

samples, the geometrical assemblies of both these samples sufficiently allow diagonal struts to form

through partial contact in the joints. However, in sample RG6 there are larger stones located in the

diagonal path compared to those in sample RG8 and therefore these paths are exhausted at a much

later stage in comparison, postponing the formation of cracks in the stones. These occurrences lead to

the high deformability of both samples as well as to the high equivalent stiffness and load capacity of

sample RG6 and the corresponding lower values of sample RG8.

Figure 32 Load-displacement diagram for simulations 53 and 55

Erasmus Mundus Programme

30

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

-3.852E+00

-3.440E+00

-3.000E+00

-2.520E+00

-2.080E+00

-1.600E+00

-1.160E+00

-6.800E-01

-2.400E-01

2.009E-01

Figure 33 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 53 for a horizontal displacement equal to 0.5 mm

-3.234E+00

-2.905E+00

-2.520E+00

-2.135E+00

-1.785E+00

-1.400E+00

-1.015E+00

-6.650E-01

-2.800E-01

6.724E-02

Figure 34 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 55 for a horizontal displacement equal to 0.5 mm

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

31

Computational Modeling of Irregular Masonry Failure

-5.046E+00

-4.510E+00

-3.905E+00

-3.300E+00

-2.695E+00

-2.090E+00

-1.485E+00

-8.800E-01

-2.750E-01

2.723E-01

Figure 35 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 53 for a horizontal displacement equal to 1.0 mm

-6.200E+00

-5.525E+00

-4.810E+00

-4.030E+00

-3.315E+00

-2.600E+00

-1.820E+00

-1.105E+00

-3.900E-01

2.867E-01

Figure 36 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 55 for a horizontal displacement equal to 1.0 mm

Erasmus Mundus Programme

32

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

-5.564E+00

-4.920E+00

-4.260E+00

-3.600E+00

-2.940E+00

-2.280E+00

-1.620E+00

-9.600E-01

-3.000E-01

3.018E-01

Figure 37 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 53 for a horizontal displacement equal to 1.45 mm

-7.706E+00

-6.880E+00

-6.000E+00

-5.040E+00

-4.160E+00

-3.280E+00

-2.320E+00

-1.440E+00

-5.600E-01

2.559E-01

Figure 38 Principal compressive stresses (N/mm ) depicted on the deformed mesh of simulation

model 55 for a horizontal displacement equal to 1.45 mm

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

33

Computational Modeling of Irregular Masonry Failure

The next set of simulations (61-66) is performed using samples RG1 through RG6 with an increased

compressive load equal to -200 kN. As the influence of the geometrical arrangement is under

investigation, it is important to establish whether the scatter in the responses is somehow linked to the

loads and to what extent. It is noted that the increase in the peak horizontal response and the

corresponding displacement was more or less predictable, meaning that each sample performed as

was expected, with the exception of sample RG6, which while obtained the expected peak response,

had no significant increase in the displacement corresponding to it. Although the limited number of

simulations renders these results inconclusive, it is decided to proceed to the final modeling approach

for further validation.

Figure 39 Load-displacement diagram for simulations 61-66

Erasmus Mundus Programme

34

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

Computational Modeling of Irregular Masonry Failure

Table 10 Results summary for simulations 61-66

No.

61

62

63

64

65

66

Simulation

Sample ID

RG1

RG2

RG3

RG4

RG5

RG6

Responses for vertical load=-200 kN

Horizontal disp. at peak load [mm]

Peak horizontal load [kN]

2.60

103.70

1.65

112.10

1.30

94.92

1.30

99.61

1.93

102.00

1.75

124.10

Figure 40 Peak response versus applied vertical load for samples RG1-RG6

Erasmus Mundus Programme

ADVANCED MASTERS IN STRUCTURAL ANALYSIS OF MONUMENTS AND HISTORICAL CONSTRUCTIONS

35

Computational Modeling of Irregular Masonry Failure

3.4 Periodic geometry models

To demonstrate the significance of the geometrical arrangement, the final set of simulations is

performed by placing a set of averaged sized blocks in what is considered a poor arrangement,

meaning that the head joints are aligned throughout the height of the masonry wall (stack bond). This

overlapping is expected to reduce the capacity of the wall and bring to an early onset of failure, even

compared to the lowest results obtained in former simulations. Then, the blocks are rearranged in the