Professional Documents

Culture Documents

059579

Uploaded by

binhleduc36Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

059579

Uploaded by

binhleduc36Copyright:

Available Formats

GB

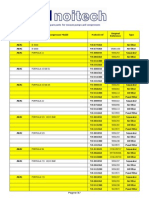

Technical Data Sheet

Page 1 of 3

Ultrapure 2000 Standard

Ultrapure 2000 Superplus

Midi (Type 0035 to 0100)

Complete purification package including adsorption dryer,

activated carbon adsorber, pre-, afterfilter and condensate drain

The Ultrapure 2000 breathing air systems are purification units based on

adsorption dryers Ultrapac 2000 to

supply breathing air in excess of all

relevant international standards and

medical prescriptions.

The purification consists of several

stages:

Compressed air is led through the

inlet of the unit (J) and across the pre

filter (2). At this stage, the air is

cleaned from particles and condensate. The condensate is removed via

a membrane condensate drain (5).

The following desiccant dryer

reduces the water vapour content of

the compressed air down to a pressure dew point of 40C (equivalent

to a remaining water content of 0.11

g/m3). In the following purification

stages (SP, AK, OX) (9) the content of

CO2 is adsorbed to a level far below

500 ppm the content of SO2 below 1

ppm and the content of NOX below 2

ppm. In the AK stage oil vapours,

hydrocarbons, taste and odours are

adsorbed to a level far below 0.003

mg/m3. In the OX stage a catalyst

converts CO to CO2 and thereby

reduces the carbon monoxide level

down below 5 ppm.

The final particle filter (3) removes all

particles which might be carried over

from the adsorption and /or catalyst

stages.

Ultrapure 2000

Superplus

Ultrapure

2000

Volume flow in

m3/h

(1 bar, 20C)*

Reg.air flow

average

m3/h

(1 bar, 20C)

Volume flow out

(min.)

m3/h

(1 bar, 20C)

0035

35

5.95

27.6

95

0050

50

8.5

39.4

120

0065

65

11.05

51.2

155

0080

80

13.6

63.0

280

0100

100

17

78.8

450

Pressure loss

initial

mbar

* Related to 1 bar (abs) and 20 C at intake of compressor and 7 bar (g) and 35 C inlet temperature

8

1

8

2

KO

RO

Technical alterations reserved (R03/ 2007/04/24)

Donaldson Filtration Deutschland GmbH Industrial Filtration Solutions Bssingstrae 1 D-42781 Haan Telefon +49/21 29/569-0 Telefax +49/21 29/569-100

Technical Data Sheet

GB

Page 2 of 3

Ultrapure 2000 Standard Midi / Superplus Midi

Features Ultrapure 2000:

Benefits:

Product description:

Purification package including

adsorption dryer, CO-, CO2-, NOX and SO2 removal, pre-, afterfilter

and automatic condensate drain

Turnkey system, no additional installation costs; all

components from one hand, therefore perfect technical match

Guaranteed and validated

separation effciency

Breathing air quality in excess of all relevant

international standards, as e.g. Pharmacope

Europenne; DIN EN 12021 (DIN 3188); EN

737-3; BS4275; ANSI/CGA G.7.1; Z180, 1

M85; AS2299-1979; NZL5813

Ultrapure 2000 Standard and

Superplus:

Complete purification package

including adsorption dryer, CO-,

CO2 -, NOX- and SO2 removal, pre-,

afterfilter and automatic condensate

drain

Medium:

Adsorbent in cartridges

Easy storage, transport and installation; optimum

fixation of desiccant; no risk of fluidizing of desiccant

Compact, space saving design

Installation in smallest spaces, possible also

as retrofit

min. 4 bar (g), max. 16 bar (g)

High operating safety, due to calculation of optimum

exchange point for filter elements and desiccant

cartridges

Medium temperature:

Compressed air

Operation pressure:

Component exchange display

Unique Multifunction Block

All moving parts and all electronic components

integrated in a function block, therefore easy and

efficient maintenance

min. 5 C, max. 50 C

Ambient temperature:

min. 4 C, max. 50 C

Features Ultrapure 2000 Superplus:

Benefits:

Intermittent operation standard

Link between dryer and compressor possible on

central applications, therefore saving of regeneration

air

Compressed air consumption:

Load dependent control

Adjustment of adsorption cycles to the actual inlet

water load, therefore saving of regeneration air and

reduction of operating cost

Power supply:

Self-Diagnosis-System

Sensor-controlled monitoring of regeneration air

flow, therefore without-gap-monitoring of dryer

functions and of system pressure

Text Display

Display of all operating status, of fault indication and

maintenance intervals in clear text messages

Info-Channel

Serial interface for transmission of alarm- and maintenance messages

Economizer-Function

Online calculation of optimum exchange point of filter elements by continuous evaluation of energy cost

versus cost of replacement filter element

Sizing:

f

4

5

6

7

8

9

10

11

12

13

14

15

16

bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g) bar(g)

17% of the rated flow, in average

230 V/50 -60 Hz AC;

110 V/50 -60 Hz AC

24 V DC; 24 V AC on request

Power consumption:

approx. 4 W

Air quality related to standard

inlet conditions:

Particles

< 1 m

Residual oil

content

< 0.01 mg/m3

Oil vapour and

hydrocarbons

< 0.003 mg/m3

Water vapour

PDP - 40C

(= 0.11 g/m3)

25C

0.69

0.82

0.96

1.10

1.24

1,38

1.50

1.50

1.50

1.50

1.50

1.50

1.50

30C

0.69

0.82

0.96

1.10

1.24

1,38

1.50

1.50

1.50

1.50

1.50

1.50

1.50

CO2

< 500 ppm

35C

0.63

0.75

0.88

1.00

1.13

1,26

1.38

1.50

1.50

1.50

1.50

1.50

1.50

CO

< 5 ppm

40C

0.48

0.58

0.68

0.77

0.87

0,96

1.06

1.16

1.25

1.35

1.45

1.50

1.50

0.38

0.45

0.53

0.60

0.68

0,75

0.83

0.90

0.98

1.05

1.13

1.20

1.28

SO2

< 1 ppm

45C

50C

0.30

0.36

0.42

0.48

0.54

0,60

0.66

0.72

0.78

0.84

0.90

0.96

1.02

NOX

< 2 ppm

Taste and odours

taste and odour

free

Vcorr =

.

Vnom

f

Example: Vnom = 50 m3/h, Inlet temperature = 30C, Operating pressure = 10 bar (g)

.

Vcorr =

50 m3/h

1.50

Declaration of conformity:

= 33,33 m3/h.

Calculated dryer size: Ultrapure 2000, type 0035

acc. to 73/23/EC

97/23/EC

Technical Data Sheet

GB

Page 3 of 3

Ultrapure 2000 Standard Midi

Ultrapure 2000 Superplus Midi

O

G

Ko

Ultrapure 2000 - Midi

Type

0035

0050

0065

0080

0100

G1

G1

G1

G1

G1

A

mm

532

532

532

532

532

B

mm

322

322

322

322

322

C

mm

665

920

1170

1420

1670

D

mm

230

355

485

605

730

E

mm

465

595

720

845

970

F

mm

165

165

165

165

165

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Scroll Oil-Free CompressorsDocument7 pagesScroll Oil-Free Compressorsbinhleduc36No ratings yet

- OMEGA AIR Alternative Filter Elements English PDFDocument56 pagesOMEGA AIR Alternative Filter Elements English PDFbinhleduc36100% (1)

- Cyclone 08.11 PDFDocument4 pagesCyclone 08.11 PDFPatricio TamayoNo ratings yet

- Каталог Remeza - 2015 Ганновер 2015 PDFDocument32 pagesКаталог Remeza - 2015 Ганновер 2015 PDFbinhleduc36No ratings yet

- 9820 3582 05 User Guide MKIV Ethernet-IP 03Document50 pages9820 3582 05 User Guide MKIV Ethernet-IP 03StevenNo ratings yet

- App Man Section5 Part7 Reduction Factors InfoDocument1 pageApp Man Section5 Part7 Reduction Factors Infobinhleduc36No ratings yet

- Compressors and Compressed Air SystemsDocument24 pagesCompressors and Compressed Air SystemsDipaloy DattaNo ratings yet

- Downloadedfile 0 2568 Van Xa Nuoc Tu Dong (Kieu Phao - Ben Ngoai Bo Loc) 0Document2 pagesDownloadedfile 0 2568 Van Xa Nuoc Tu Dong (Kieu Phao - Ben Ngoai Bo Loc) 0binhleduc36No ratings yet

- SKF - Ozyska Walcowe ENGDocument66 pagesSKF - Ozyska Walcowe ENGbinhleduc36100% (1)

- Osp 37vanDocument20 pagesOsp 37vanJuan ManuelNo ratings yet

- SKF Lock Nuts PDFDocument22 pagesSKF Lock Nuts PDFgrupa2904No ratings yet

- 049332Document3 pages049332binhleduc36No ratings yet

- Ultrapure ALG 20: Breathing Air Unit Including Microprocessor-Controlled Differential Pressure GaugeDocument1 pageUltrapure ALG 20: Breathing Air Unit Including Microprocessor-Controlled Differential Pressure Gaugebinhleduc36No ratings yet

- 032760Document3 pages032760binhleduc36No ratings yet

- LS-16 Sullair ManualDocument112 pagesLS-16 Sullair Manualbinhleduc36100% (2)

- NoitechDocument265 pagesNoitechbinhleduc36No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Surface Tension Article 1Document3 pagesSurface Tension Article 1Dr-Aqsa KhannNo ratings yet

- 12 Physics Notes Ch05 Magnetism and MatterDocument8 pages12 Physics Notes Ch05 Magnetism and MatterAmrit KumarNo ratings yet

- Astm f2129Document9 pagesAstm f2129edgmundarayNo ratings yet

- LPL 322Document2 pagesLPL 322Quality Control BiochemNo ratings yet

- Complete DissertationDocument240 pagesComplete DissertationAriSuandiNo ratings yet

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocument7 pagesASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNo ratings yet

- HVAC Cooling Load CalculationDocument98 pagesHVAC Cooling Load CalculationVishnupriya B.100% (3)

- Chitin and Chitosan: Structure, Properties and Applications in Biomedical EngineeringDocument14 pagesChitin and Chitosan: Structure, Properties and Applications in Biomedical EngineeringTrần QuangNo ratings yet

- Gas Laws Worksheet #2 Boyles Charles and CombinedDocument3 pagesGas Laws Worksheet #2 Boyles Charles and CombinedJeromeNo ratings yet

- Beta OxidationDocument41 pagesBeta Oxidationguna sundariNo ratings yet

- Furnace SoftwareDocument7 pagesFurnace SoftwareolaNo ratings yet

- Mil STD 650Document210 pagesMil STD 650Roberto Carlos Cabana Orellana100% (1)

- Pharmacognosy Lecture # 7+8 (Lipids) (By, Sir Tanveer Khan)Document40 pagesPharmacognosy Lecture # 7+8 (Lipids) (By, Sir Tanveer Khan)Arslan AbdullahNo ratings yet

- تقرير تأكل (Anodic Protection)Document10 pagesتقرير تأكل (Anodic Protection)ياسر نوفل ورد100% (1)

- Shrimp: In: Use of Sodium Metabisulfite, AlternativesDocument3 pagesShrimp: In: Use of Sodium Metabisulfite, Alternativesvalerie rosalind angkawidjajaNo ratings yet

- Operative Dentistry: Dental AdhesionDocument12 pagesOperative Dentistry: Dental AdhesionJohn CenaNo ratings yet

- Tutorial3 - C3 - CHE 244Document3 pagesTutorial3 - C3 - CHE 244Sheikh AdibNo ratings yet

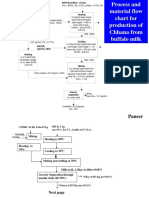

- Process Flow Chart Dairy ProductsDocument5 pagesProcess Flow Chart Dairy Productslokesh jainNo ratings yet

- yokAcikBilim 10185403Document71 pagesyokAcikBilim 10185403gozdebstnciNo ratings yet

- Carbon Enrichment in Mo SteelDocument50 pagesCarbon Enrichment in Mo SteelDhananjay ShimpiNo ratings yet

- Sadhu Forging Limite1 - 2Document4 pagesSadhu Forging Limite1 - 2Priya KaleNo ratings yet

- Plate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGDocument38 pagesPlate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGArnoldo OlivaNo ratings yet

- Wear Plate SpecsDocument4 pagesWear Plate SpecsJuan Carlos EspinozaNo ratings yet

- Exceed™ XP 8358 Series: Performance PolymerDocument2 pagesExceed™ XP 8358 Series: Performance PolymerMaram YasserNo ratings yet

- Basics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, CatalystsDocument5 pagesBasics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, Catalystsonizuka-t2263No ratings yet

- Stockmann 2016Document12 pagesStockmann 2016Barbara SilvaNo ratings yet

- Fundamentals of Automotive Electricity & ElectronicsDocument83 pagesFundamentals of Automotive Electricity & ElectronicsJohnny Ym100% (1)

- Numerical Analysis For Energy Performance Optimization of Hollow Bricks For Roofing. Case Study - Hot Climate of AlgeriaDocument10 pagesNumerical Analysis For Energy Performance Optimization of Hollow Bricks For Roofing. Case Study - Hot Climate of Algeriamah0809No ratings yet

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelNo ratings yet

- Duncan Sobre EsmaltesDocument9 pagesDuncan Sobre EsmaltesLeland StanfordNo ratings yet