Professional Documents

Culture Documents

Overhead Crane Girder Camber: Understanding Deflection and Strength

Uploaded by

Erc Nunez VOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhead Crane Girder Camber: Understanding Deflection and Strength

Uploaded by

Erc Nunez VCopyright:

Available Formats

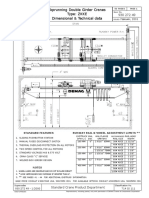

39 40 42_Layout 1 07/04/2014 16:47 Page 1

PRODUCT FOCUS

OVERHEAD CRANES

CRANE GIRDER CAMBER

An overview of overhead crane girder camber, deflection and bending strength. By Gary J. Davis

ABOUT THE AUTHOR

Gary J. Davis, P.E. is director

of consulting services,

Integrated Machinery

Solutions (IMS), Fort Worth,

Texas. He can be contacted at

GaryDavis@team-ims.com.

Fig. 1: "Free" camber

lant maintenance and

inspection personnel are

occasionally faced with

reports of "lost camber" or

"excessive deflection" of crane

girders. This article provides a

practical overview of crane

girder camber, deflection, and

bending strength to aid plant

personnel in evaluating these

conditions.

GIRDER CAMBER: WHY IS IT

REQUIRED?

Cambering effectively removes

the dead load deflection and

averages the live load deflection

relative to the level profile.

Cambering effectively cuts the

live load deflection in half. This

minimises the trolley rail slope

during live load deflection. The

reduced slope means less power

is required to drive the trolley

uphill toward the end of the

girder and less tendency to coast

downhill toward the center of

the span.

Fig. 1 shows the

recommended camber of 100%

of the dead load deflection plus

half of the live load deflection.

"Free" camber means the girder

is free to assume its unloaded

shape, for example, no dead

load or live load is present.

Camber is usually built into

the top profile of the girder. If

there is limited clearance over

obstructions near the bottom of

the girder, the bottom profile

may also require cambering. Fig.

1 shows a crane girder cambered

on the top and bottom,

unloaded, and laying on its side.

Girders are cambered by

building them with a convex

("crowned") profile, opposite to

the concave rsag produced by

deflection. The camber in Fig. 1

APRIL 2014

a small laser level and a ruler to

measure the elevations. The

trolley should be unloaded and

moved to the end of the bridge

before measuring. A string or a

wire cannot be used as a

reference line; regardless of the

amount of tension in the line, it

will sag too much to produce

meaningful results.

FIELD DATA ADJUSTMENT

If the laser and/or girder are not

level, adjust the field data as

shown in Fig. 2. Make a scale

layout of the data, as shown in

Fig. 2a, and connect the ends

with a straight line. The

adjusted elevations are

obtained relative to the line

connecting the ends of the

curve. Using the adjusted data,

the camber is the difference

between the maximum

elevation and the end point

(Fig. 2b). Typically, the middle

third of the span may appear to

be practically flat.

Fig. 2: Camber measurements

Fig. 3: Girder profiles

is equal to the deflection that

would be produced by the

girders own weight (DL) plus

half of the combined weight of

the trolley and the rated capacity

(LL).

CAMBER FIELD

MEASUREMENTS

The camber profile can be

obtained by measuring trolley

rail elevations at five-foot

intervals as shown in Fig. 2. Use

INTERPRETATION OF CAMBER

MEASUREMENTS

The camber requirement

should be obtained from the

crane manufacturer (or a

qualified person) and

compared to the field

measurements. Fig. 3 shows

ideal camber profiles for no

load, half rated capacity, and

full rated capacity. Fig. 3d

illustrates the difference

between a normal dead load

deflection profile and a

deformed profile from a severe

overload. After a severe

overload, cambered and uncambered girders may have a

slight "kink" near the center of

the span. When the measured

LIFT AND HOIST INTERNATIONAL LIFTANDHOIST.COM 39

39 40 42_Layout 1 07/04/2014 16:47 Page 2

PRODUCT FOCUS

camber is less than the required

amount, check the following:

1. Determine if the original

fabrication included the

required camber.

2. Check for buckled flanges

and webs.

3. Check the trolley rail for

local deformation between

the diaphragm support

points.

4. Check for local buckling at

the top edge of the

diaphragms that support

the trolley rail.

5. Check the welds for the

diaphragms supporting the

trolley rail.

6. A borescope is required for

inspecting internal

components.

7. Determine if the

diaphragm spacing for the

trolley rail support is

adequate. (Engineering

required).

8. Check the condition of the

bottom flange for fractures.

9. If the elevation profile

shows a negative camber

greater than what would be

produced by the dead load

deflection, and/or the

profile shows a "kink" (see

OVERHEAD CRANES

% RATED CAPACITY

Stress

Range

(ksi)

17

13

10

First Onset

of Yielding

First Measurable

Camber Loss

Ultimate Bending

Strength

185

185

305

200

255

330

310

390

510

3.

4.

Fig. 4: Estimated percentage overload for camber loss

Fig. 3d), it may indicate a

severe overload.

In addition to this list, the

entire structural and

mechanical load path should be

thoroughly inspected. Refer to

Reference 1: Guidelines for

Inspecting Overhead Crane

Structures for more information.

GIRDER DEFLECTION

Girder deflection is not directly

related to strength. No

conclusions can be made about

girder strength based on a

deflection measurement alone.

A crane may have a large

deflection and ample bending

strength, while a different crane

may be overstressed and show

very little deflection. Design

code deflection limits are based

GIRDER DEFLECTION IS NOT

DIRECTLY RELATED TO STRENGTH. NO

CONCLUSIONS CAN BE MADE ABOUT

GIRDER STRENGTH BASED ON A

DEFLECTION MEASUREMENT ALONE.

40 LIFT AND HOIST INTERNATIONAL LIFTANDHOIST.COM

on the live load only and

determined as a percentage of

the crane span.

MEASURING DEFLECTION

Some purchasing specifications

require deflection measurements

during load testing for design

verification. Deflection

measurements are only

meaningful if the magnitude of

the lifted load and trolley weight

are accurately known.

Deflection can be measured

relative to a point on the floor

using a laser distance meter and

a small level as follows:

1. Move the unloaded trolley

to the end of the bridge.

2. Mark a small target area at

the center of the crane

span, on the bottom flange

5.

6.

7.

8.

9.

of the girder, visible from

the floor.

Place the base of the laser

meter on the floor and use

the level to ensure that the

laser beam is plumb in all

directions while pointed on

the target.

Mark the spot on the floor

where the laser meter is

plumb and pointing on the

target.

After marking the laser

base location, the laser

should already be plumb

for later measurements and

the level should not be

needed.

Measure and record the

distance between the

marked spot on the floor

and the target spot on the

girder.

For this example, lift 50% of

the rated crane capacity

and move the load to the

center of the span.

Measure and record the

distance from the marked

spot on the floor and the

target spot on the girder.

The deflection is the

difference between the two

measurements.

40 ton single failure-proof trolley

built per U.S. Navy specifications.

APRIL 2014

39 40 42_Layout 1 07/04/2014 16:47 Page 3

PRODUCT FOCUS

25/25 ton Monorail Stoplog Hoist built

per U.S. Government Specifications.

If the required camber is

unknown, it can be determined

by measuring the deflection with

50% of the rated crane capacity.

The deflection measured in this

example should be

approximately equal to the

required camber as shown in Fig.

3a.

YIELD STRENGTH AND LOSS OF

CAMBER

If no other girder elements have

failed, loss of camber does not

indicate loss of bending strength.

Steel is elastic below the yield

strength and the girder will

spring back to its original shape

after the load is removed. Design

codes require the stress to be

below the yield strength at rated

capacity. If the load is large

enough to exceed the yield

strength by more than about

10%, the girder will not return to

its original shape and this will

appear as lost camber.

The next time the girders are

loaded (equal to or less than the

rated capacity), they will deflect

the normal incremental amount

and the stress will be at the

normal level. The only difference

is that the starting point for the

deflection increment will be at a

lower elevation due to the lost

camber. Additional camber will

be lost each time the girder is

loaded past the yield strength.

Some ductility will be lost, but

the bending strength of the

girder does not decrease.

INTERNAL RESIDUAL STRESS

Weld shrinkage from girder

fabrication creates zones of

longitudinal residual stress at

OVERHEAD CRANES

(or near) the yield point. This

locked-in stress will cause a

slight camber loss after load

testing. This type of camber

loss is a one-time event and is

too small to measure. Initial

loading with the test load

provides mechanical stressrelief for the welds by

removing most of the internal

stress in the working stress

range.

ULTIMATE GIRDER STRENGTH

At the first onset of yielding,

only the outermost surface of

the girder starts to yield and

the remainder of the section

remains elastic. The yielded

portion can only support the

load that caused the first

yielding, and nothing more. As

the load increases, more of the

section yields. When the entire

cross section has yielded, the

girder cannot support any

increase in load. If additional

load is applied, the girder will

not offer any resistance and

only more deformation will

occur. This is the ultimate

strength for bending of the

cross section. The girder can

fail by other limit states

(buckling, shear, welds, etc.)

before ever reaching the

ultimate strength.

OVERLOADING SCENARIOS

A computer model for bending

of a typical box girder was

used to estimate the

magnitude of overload

required to cause a measurable

camber loss. Three different

stress ranges are listed to

represent girders designed for

different utilization classes.

The results are shown in Fig. 4.

The threshold for a

measureable camber loss was

assumed as 1/8". At the first

onset of yielding, the girder

still returns to its original

shape when the load is

removed. The ultimate bending

strength is included as an

upper limit reference. The

results shown in Fig. 4 are

based on specific assumptions

and are only intended to

provide an "order of

magnitude" for the various

loadings required for camber

loss.

The analysis shows that

camber loss from an overload

is certainly possible, but the

likelihood depends on the

girder design classification. It

also depends on the type of

hoist drive. A.C. magnetic

wound rotor hoist drives can

deliver up to a 300% overload

based on the motor "pull-out

torque".

D.C. series magnetic hoist

drives can produce up to 600%

of the rated motor torque for

short periods. Present-day VFD

drives cannot produce an

overload large enough for

camber loss. Typical VFD

drives monitor the motor

current and shut down at

about 125% of the rated

capacity. When considering

overload multiples of two or

three times the rated capacity,

a "load snag" scenario would

be a more likely operator error

versus hoisting a freely

suspended load. The ultimate

bending strength for wide

flange girders is about 40%

less than box girders.

CONCLUSIONS AND

RECOMMENDATIONS

Loss of camber (for box

girders) due to an overcapacity

lift requires lifting 185 to 200%

the rated crane capacity. Other

failure modes can occur before

reaching the load that causes

camber loss. If overload is

suspected as the root cause for

camber loss, the entire

structural and mechanical

load path should be

thoroughly inspected. Consult

with an expert when making

this assessment and deciding

on a course of action. If inhouse expertise is not

available, consult with an

engineering firm that is

regularly engaged in structural

design and inspection of

overhead cranes and hoisting

equipment.

REFERENCES

1. Gary J. Davis, Guidelines for Inspecting Overhead Crane

Structures, Integrated Machinery Solutions, Fort Worth,

Texas, July 2011. Full text available at:

http://www.scribd.com/doc/83331227/Guidelines-forInspecting-Overhead-Crane-Structures-Full-version

2. Charles G. Salmon, John E. Johnson, Steel Structures,

Design and Behavior, Intext Educational Publishers, New

York, NY, 1971.

3. R. L. Brockenbrough, B. G. Johnston, Steel Design Manual,

United States Steel Corporation, Pittsburgh, PA, 1981.

IF IN-HOUSE EXPERTISE IS NOT AVAILABLE, CONSULT WITH AN ENGINEERING FIRM THAT IS REGULARLY

ENGAGED IN STRUCTURAL DESIGN AND INSPECTION OF OVERHEAD CRANES AND HOISTING EQUIPMENT.

42 LIFT AND HOIST INTERNATIONAL LIFTANDHOIST.COM

APRIL 2014

You might also like

- Crane Girder CamberDocument6 pagesCrane Girder CamberGary J. Davis, P. E.100% (1)

- Crane Girder Camber - Industrial Lift & Hoist Jan 2014Document4 pagesCrane Girder Camber - Industrial Lift & Hoist Jan 2014Gary J. Davis, P. E.No ratings yet

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraNo ratings yet

- 77-9 Design of CranesDocument10 pages77-9 Design of Cranesrip111176No ratings yet

- Gantry GirderDocument5 pagesGantry GirderDas TadankiNo ratings yet

- 5T X 25.5m DG CraneDocument10 pages5T X 25.5m DG CraneRv VaghasiaNo ratings yet

- Design Lifting Beam (80 MT)Document10 pagesDesign Lifting Beam (80 MT)hardeep SinghNo ratings yet

- Crane Wheel Load EccentricityDocument2 pagesCrane Wheel Load Eccentricitypranit_rai0% (1)

- Eot Crane DetailDocument2 pagesEot Crane DetailRakesh SharmaNo ratings yet

- 11 Crane Frame StructuresDocument6 pages11 Crane Frame StructuresYonas YGNo ratings yet

- Gantry Girders - Sections and Design - Construction - Civil Engineering PDFDocument12 pagesGantry Girders - Sections and Design - Construction - Civil Engineering PDFDinesh VermaNo ratings yet

- Beam Design Calculations and SelectionDocument24 pagesBeam Design Calculations and SelectionA.K.M Shafiq MondolNo ratings yet

- Crane Girder and Channel Design DetailsDocument1 pageCrane Girder and Channel Design DetailsAnonymous RXXdbl36ANo ratings yet

- Gantry Girder DesignDocument7 pagesGantry Girder DesignsatydevsinghnegiNo ratings yet

- Design and Static Analysis of I Section Boom For Rotary Jib Crane IJERTV3IS080816Document4 pagesDesign and Static Analysis of I Section Boom For Rotary Jib Crane IJERTV3IS080816Evodius RweyemamuNo ratings yet

- Crane Load CombinationsDocument12 pagesCrane Load CombinationsSusi UmarohNo ratings yet

- Ancient cranes lifted constructionDocument25 pagesAncient cranes lifted constructionIshaan00748850% (2)

- ABUS Jib Cranes Efficiency CentreDocument12 pagesABUS Jib Cranes Efficiency CentreGloria RomicNo ratings yet

- Report On Gantry Crane and Overhead CraneDocument23 pagesReport On Gantry Crane and Overhead CraneAbhay UpadhyayNo ratings yet

- Wheel Load Data PDFDocument54 pagesWheel Load Data PDFDinesh PatilNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- Design of 500kg Capacity Portable Lift CraneDocument57 pagesDesign of 500kg Capacity Portable Lift CraneJotham MorciloNo ratings yet

- MC Launching GantryDocument6 pagesMC Launching GantryNoelson CodizalNo ratings yet

- Electric and manual jib cranes up to 10,000kgDocument32 pagesElectric and manual jib cranes up to 10,000kgvuong100% (1)

- KBK Classic and KBK Ergo Crane Construction Kits GuideDocument12 pagesKBK Classic and KBK Ergo Crane Construction Kits GuideMahendran KuppusamyNo ratings yet

- EOT Crane Wheel Load CalculationDocument1 pageEOT Crane Wheel Load CalculationSantosh100% (2)

- Gantry Crane Design Calculations - Google SearchDocument2 pagesGantry Crane Design Calculations - Google SearchJebin Abraham100% (1)

- REGULAR TYPE Creep Hoist With Motor-Driven TrolleyDocument21 pagesREGULAR TYPE Creep Hoist With Motor-Driven TrolleyDo BuiNo ratings yet

- Crane Load D Mag PDFDocument50 pagesCrane Load D Mag PDFrahul ranjanNo ratings yet

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocument7 pages"Monorail" - Monorail Beam Analysis: Program DescriptionvenkieeNo ratings yet

- Sparta Spreader Bar CalculatorDocument1 pageSparta Spreader Bar CalculatorNalini MathuraNo ratings yet

- VERLINDE S.A.S. CRANE WHEEL LOAD DATADocument1 pageVERLINDE S.A.S. CRANE WHEEL LOAD DATAJoe NadakkalanNo ratings yet

- Emergency Braking System for EOT CranesDocument7 pagesEmergency Braking System for EOT CranesHarish Gupta (JSHL)No ratings yet

- Crane Rail Selection: Calculation of Required Rail Head WidthDocument1 pageCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISNo ratings yet

- Crane HookDocument55 pagesCrane HookEr Prabhakar100% (3)

- Crane Runway Beam Design Using CSA S16-14 CodeDocument3 pagesCrane Runway Beam Design Using CSA S16-14 CodesergiooiNo ratings yet

- TGN 08 Crane Rail Selection 2Document3 pagesTGN 08 Crane Rail Selection 2Prasad PatilNo ratings yet

- Crane Ga DrawingDocument1 pageCrane Ga DrawingJitendra Singh100% (1)

- Liebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFDocument8 pagesLiebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFJuan David Cabrera CardonaNo ratings yet

- Essential guide to EOT crane mechanicsDocument3 pagesEssential guide to EOT crane mechanicspjustino19700% (1)

- Design of Through Type Plate GirderDocument9 pagesDesign of Through Type Plate GirderAnju Kl0% (1)

- Calc For Portable Gantry CraneDocument4 pagesCalc For Portable Gantry Cranedandy imam fauziNo ratings yet

- Grooved Drum ArticleDocument2 pagesGrooved Drum ArticleLizardladNo ratings yet

- Verlinde Electric Wire Rope HoistDocument12 pagesVerlinde Electric Wire Rope HoistMahmoud AllamNo ratings yet

- ABUS 120.0t EOT Layout - 22.0m SpanDocument1 pageABUS 120.0t EOT Layout - 22.0m Spanfud3n100% (1)

- Cmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepDocument3 pagesCmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepmrnicusNo ratings yet

- Annex - E IS 3177 2020Document4 pagesAnnex - E IS 3177 2020dfdffNo ratings yet

- EOT Crane Load CalculationsDocument8 pagesEOT Crane Load Calculationstimothy ogbechieNo ratings yet

- Deflection CriteriaDocument4 pagesDeflection CriteriaaqhammamNo ratings yet

- Is 4137Document82 pagesIs 4137steelage80% (5)

- Demag Standard CranesDocument16 pagesDemag Standard CranesEldio KlenNo ratings yet

- API RP 9B 14TH ED Addendum 1 Sept. 2020Document6 pagesAPI RP 9B 14TH ED Addendum 1 Sept. 2020FrancoNo ratings yet

- Lessons From Crane RunwaysDocument5 pagesLessons From Crane Runwaysdicktracy11No ratings yet

- Lab ReportDocument20 pagesLab ReportJoshua Reynolds67% (3)

- 6 4uDocument7 pages6 4uElsayed Salah HamoudaNo ratings yet

- Laminated Elastomeric Rubber Bearings For BridgesDocument15 pagesLaminated Elastomeric Rubber Bearings For BridgesPatrick AugustinNo ratings yet

- Structural Steel Design GuideDocument26 pagesStructural Steel Design GuidePenelope MalilweNo ratings yet

- Excavator Stability Lift Capacity RatingDocument6 pagesExcavator Stability Lift Capacity Ratingrbachalli50% (2)

- RDSO Steel Bridges Technical PaperDocument314 pagesRDSO Steel Bridges Technical PaperTarun Kant Goyal100% (7)

- ESDEP LECTURE NOTE (WG14) CraneDocument22 pagesESDEP LECTURE NOTE (WG14) Cranefloi dNo ratings yet

- Cataloge Hoists 2009Document26 pagesCataloge Hoists 2009Erc Nunez VNo ratings yet

- RECEPTORDocument1 pageRECEPTORErc Nunez VNo ratings yet

- 97-20160113 DeHaan 1SheaveOverheadTravellingCraneDocument1 page97-20160113 DeHaan 1SheaveOverheadTravellingCraneErc Nunez VNo ratings yet

- 2000 - Maintenance Manual & Spare Parts CatalogueDocument61 pages2000 - Maintenance Manual & Spare Parts CatalogueErc Nunez VNo ratings yet

- 50373Document40 pages50373EricNo ratings yet

- Dechow 31511 Metallbearbeitung UKDocument38 pagesDechow 31511 Metallbearbeitung UKErc Nunez VNo ratings yet

- 97-20160113 DeHaan 1SheaveOverheadTravellingCraneDocument1 page97-20160113 DeHaan 1SheaveOverheadTravellingCraneErc Nunez VNo ratings yet

- A.Hak Annual Review 2014 (EN)Document23 pagesA.Hak Annual Review 2014 (EN)Erc Nunez VNo ratings yet

- Crane Components Catalogue ENG New 2017Document11 pagesCrane Components Catalogue ENG New 2017Erc Nunez VNo ratings yet

- 97-20160113 DeHaan 1SheaveOverheadTravellingCraneDocument1 page97-20160113 DeHaan 1SheaveOverheadTravellingCraneErc Nunez VNo ratings yet

- P 8361 SG A4Document28 pagesP 8361 SG A4Erc Nunez V100% (1)

- Receiver WiringDocument16 pagesReceiver WiringErc Nunez VNo ratings yet

- NorthAmericanIndustries CraneBrochureDocument28 pagesNorthAmericanIndustries CraneBrochureopreamihNo ratings yet

- Pa1002rev3 Setting Up Hoists and CranesDocument16 pagesPa1002rev3 Setting Up Hoists and CranesErc Nunez VNo ratings yet

- SPAMEL EN Kaseta Suwnicowa PKS 8 W03Document1 pageSPAMEL EN Kaseta Suwnicowa PKS 8 W03Erc Nunez VNo ratings yet

- Vigilohm IMD-IM9Document2 pagesVigilohm IMD-IM9Erc Nunez VNo ratings yet

- Fse 514Document18 pagesFse 514tsdcnNo ratings yet

- 1405 PI Quadrix En-Folleto PDFDocument2 pages1405 PI Quadrix En-Folleto PDFErc Nunez VNo ratings yet

- 800H3HZ4Document3 pages800H3HZ4Erc Nunez VNo ratings yet

- Technical Data 800T & 800HDocument44 pagesTechnical Data 800T & 800HarturoncNo ratings yet

- Gantrail Corporate Brochure PDFDocument7 pagesGantrail Corporate Brochure PDFErc Nunez VNo ratings yet

- E8A59BA8Document3 pagesE8A59BA8Erc Nunez VNo ratings yet

- Tesys D Lc1d128e7Document3 pagesTesys D Lc1d128e7Erc Nunez VNo ratings yet

- FCC FLEX ECO 8S&X ManualsDocument43 pagesFCC FLEX ECO 8S&X ManualsErc Nunez VNo ratings yet

- Gantrail Corporate Brochure PDFDocument7 pagesGantrail Corporate Brochure PDFErc Nunez VNo ratings yet

- Intermittent Rail Support Soleplates - GantrexDocument2 pagesIntermittent Rail Support Soleplates - GantrexErc Nunez VNo ratings yet

- Gantrail Corporate Brochure PDFDocument7 pagesGantrail Corporate Brochure PDFErc Nunez VNo ratings yet

- 04 VL PDFDocument2 pages04 VL PDFErc Nunez VNo ratings yet

- 7.7 Connection/circuit Diagrams: Motor For One Line Voltage or Dual Voltage MotorDocument31 pages7.7 Connection/circuit Diagrams: Motor For One Line Voltage or Dual Voltage MotorErc Nunez VNo ratings yet

- Uk JeiDocument14 pagesUk JeiErc Nunez VNo ratings yet

- Leonard Schiff Quantum MechanicsDocument563 pagesLeonard Schiff Quantum Mechanicssxydxt100% (5)

- x2.6. - Strouhal Instability - Von Karman Vortex StreetDocument4 pagesx2.6. - Strouhal Instability - Von Karman Vortex StreetcteranscribdNo ratings yet

- Scaffolding Design CalculationDocument8 pagesScaffolding Design Calculationbenchinoun100% (2)

- Applied ElectrochemistryDocument7 pagesApplied Electrochemistryshreeja mogiliNo ratings yet

- Technical TermodynamicsDocument8 pagesTechnical TermodynamicsPajooheshNo ratings yet

- Landau Levels and Inversion LayersDocument8 pagesLandau Levels and Inversion LayersahsbonNo ratings yet

- Ansi A92.2.1969Document18 pagesAnsi A92.2.1969HermanRomanNo ratings yet

- Introduction To The Stiffness (Displacement) MethodDocument12 pagesIntroduction To The Stiffness (Displacement) MethodZaher MoftyNo ratings yet

- Limit States Method (Cec402 Assignment of Group3a)Document50 pagesLimit States Method (Cec402 Assignment of Group3a)Kingshuk MukherjeeNo ratings yet

- 1 s2.0 S0925346717301192 MainDocument8 pages1 s2.0 S0925346717301192 MainlunarNo ratings yet

- Kitipornchai Et - Al (2005)Document11 pagesKitipornchai Et - Al (2005)JithinRajNo ratings yet

- CE6451-Fluid Mechanics and Machinery QBDocument10 pagesCE6451-Fluid Mechanics and Machinery QBVignesh DuraiNo ratings yet

- Crane Runway Beam DesignDocument7 pagesCrane Runway Beam Designvkumar_625189100% (1)

- Betini 2019Document13 pagesBetini 2019Jose G. Cueva CardeñaNo ratings yet

- Characterisation of Suction Effects On A Submarine Body Operating Near The Free SurfaceDocument4 pagesCharacterisation of Suction Effects On A Submarine Body Operating Near The Free Surfacejwpaprk1No ratings yet

- Grouting of Rock MassesDocument43 pagesGrouting of Rock MassesAnand YatriNo ratings yet

- STERA3D Technical Manual PDFDocument310 pagesSTERA3D Technical Manual PDFMacNo ratings yet

- 8fc63d2f f6Document18 pages8fc63d2f f6Chandra MohanNo ratings yet

- EXP1 - Relative Density-MinDocument16 pagesEXP1 - Relative Density-MingoblinsbrideNo ratings yet

- Light Gage Steel Design ManualDocument85 pagesLight Gage Steel Design ManualD SRINIVAS100% (1)

- Nusselt NumberDocument3 pagesNusselt NumberIzzat AshraffNo ratings yet

- Calculation sheet for supporting beam designDocument24 pagesCalculation sheet for supporting beam designKhairul JaggerNo ratings yet

- A335 P91 - P91 Material - SA335 P91 - ASTM A335 P91Document29 pagesA335 P91 - P91 Material - SA335 P91 - ASTM A335 P91Agniva Dutta100% (1)

- Epa Workshop Baer Smallparticlechemistry FinalDocument34 pagesEpa Workshop Baer Smallparticlechemistry FinalAdityaNo ratings yet

- Conductive "MC" Nylon/ ESD "MC" Nylon: Nippon PolypencoDocument1 pageConductive "MC" Nylon/ ESD "MC" Nylon: Nippon PolypencoVC KannanNo ratings yet

- Technical Data Sheet: Property Test Method Unit FrequencyDocument1 pageTechnical Data Sheet: Property Test Method Unit FrequencyJuli JulekNo ratings yet

- EXP5procedure PDFDocument2 pagesEXP5procedure PDFGeneva OrañoNo ratings yet

- 14 Draw Off Nozzle Hydraulics PDFDocument12 pages14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNo ratings yet

- Nylon 66 Technical Data SheetDocument1 pageNylon 66 Technical Data SheetRajeev BujjiNo ratings yet

- SS 40 Phy 14Document11 pagesSS 40 Phy 14Atul VermaNo ratings yet