Professional Documents

Culture Documents

Design of Machine Elements

Uploaded by

Ashok DaraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Machine Elements

Uploaded by

Ashok DaraCopyright:

Available Formats

Sub Code: ME53

UNIT V

DESIGN OF BEARINGS AND MISCELLANEOUS ELEMENTS

Sliding contact and rolling contact bearings -- Design of hydrodynamic journal bearings,

McKee's Eqn., Sommerfield Number, Raimondi & Boyd graphs, -- Selection of Rolling

Contact bearings -- Design of Seals and Gaskets -- Design of Connecting Rod.

A bearing is a machine element which supports another moving machine element. It

permits a relative motion between the contact surfaces of the members while carrying the load.

Due to the relative motion between the surfaces a certain amount of power is wasted in

overcoming frictional resistance and if the rubbing surfaces are indirect contact there will be

rapid wear. In order to reduce frictional resistance and wear resistance in some cases to cases

carry away the heat generated a layer of fluid may be provided.

Depend upon the nature of contact

(i) Sliding contact bearing

The sliding takes place along the surfaces of contact between the moving element and

fixed element

(ii) Rolling contact bearing

The steel balls or rollers are interposed between the moving and fixed element. The

balls offer rolling friction at the two points for each ball or roller.

JOURNAL BEARING

A sliding contact bearing that supports a load in a radial direction is known as journal

bearing. It consists of two main parts, a shaft and a hollow cylinder. The portion of the shaft

inside the hollow cylinder also known as bearing is called as journal. In most applications the

journal rotates while the bearing is stationary. However there are some applications where the

journal is stationary and the bearing rotates and even somewhere both the journal and bearing

Page 47 of 53

Einstein College of Engineering

Sub Code: ME53

rotates. This journal bearing may be classified as full journal bearing and partial journal bearing

depending upon whether the journal is fully or partially covered by bearing.

TERMS USED IN HYDRODYNAMIC JOURNAL BEARING

1. Diameter clearance: It the different between the diameter of journal and the bearing.

c= D-d

2. Radial clearance: it is the different between the radial of the bearing and the journal.

c1=R-r=D-d/2

3. Diameteral clearance ratio: It is the ratio of the diameteral clearance to the diameter of the

journal.

=c/d=(D-d)/d

4. Eccentricity: It is the radial distance between the center of the bearing and the displaced center

of the bearing under load.

5. Minimum oil film thickness: It is the minimum distance between the bearing and the journal

under complete lubrication condition. It is denoted by ho and occurs at the line of centers.

COEFFICENT OF FRICTION FOR JOURNAL BEARINGS

To determine the coefficient of friction for well lubricated full journal bearings, the

following empirical relation established by McKee based on the experimental data

m=

33

10 8

ZN d

+ k

p c

- Coefficient of friction

Z- Absolute viscosity of oil

N- Speed of journal in r.p.m

p- bearing pressure on the projected bearing area

Page 48 of 53

Einstein College of Engineering

Sub Code: ME53

d- diameter of journal

l-length of bearing

c- diameter clearance

k- factor to correct for end leakage.

CRITICAL PRESSURE OF THE JOURNAL BEARING

The pressure at which the oil film breaks down so the metal to metal contact begins, is

known as critical pressure or the minimum operating pressure of the bearing. It may be obtained

by the following relation.

2

p=

ZN

d l

6

4.75 10 c d + l

SOMMERFELD NUMBER

The sommerfeld number is also a dimensionless parameter used extensively in the design

of journal bearings.

sommerfeld number=

ZN d

p c

HEAT GENERATED IN A JOURNAL BEARING

The heat generated in a bearing due to the fluid friction and friction of the parts having

relative motion.

Qg=WV

After the thermal equilibrium is reached heat will be dissipated at the outer surface of the

bearing at the same rate at which it is generated in the oil film. The amount of heat will depend

upon the temperature difference size and mass of the radiating surface and on the amount of air

flowing around the bearing. However for the convenience in bearing design the actual heat

dissipating area may be expressed in terms of the projected area of the journal.

Page 49 of 53

Einstein College of Engineering

Sub Code: ME53

Heat dissipated by the bearing Qd = CA(t b - t a )

C- heat dissipation coefficient

A- projected area of the bearing

tb-temperature of the bearing surface

ta- temperature of the surrounding air

DESIGN PROCEDURE FOR JOURNAL BEARING

1. Determine the length of bearing.

2. Calculate the bearing pressure.

3. Select the type of oil used.

4.Determine the amount of heat generated.

5. Determine the amount of heat rejected.

ROLLING CONTACT BEARING

The advent of automobiles and many high speed machineries make very much use

another type of bearings known as rolling contact bearings. The friction produced in these

bearing is very low. These bearings also called as antifriction bearings. They differ from sliding

contact bearings in their structure and usage.

COMPONENTS OF ROLLING CONTACT BEARINGS

The rolling bearing consists of four main components (1) the inner ring, (2) outer ring,

(3) the balls or rollers, (4) the retainers or separators. The inner ring is forced to fitted with

machine shaft and outer ring is fitted with machine housing. The shaft rotates because of relative

rotations of balls or rollers. The retainers is used to prevent the balls or rollers from ejecting out

during operation.

Page 50 of 53

Einstein College of Engineering

Sub Code: ME53

CLASSIFICATION OF ROLLING CONTACT BEARINGS

The rolling contact bearings are classified into two major groups with respect to their

structure

(1) Ball bearings

(2) Roller bearings

Basically the structure of ball bearings are similar expect that whether the rolling element

between the inner ring and outer ring are balls or rollers. Also these ball bearings are many types

such as deep grove ball bearings, angular contact bal bearings and so on. Both type of bearing

can carry radial loads and axial loads acted individually or in combined form. Generally the ball

bearings are used for light loads and the roller bearings are usually used for heavier loads. Also

in the case of ball bearings the nature of contact is the point contact hence the friction produced

is very less compared to roller bearings where the nature of contact is the line contact which

produce more friction.

Figure 5.1 Types of radial ball bearing

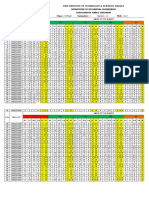

SELECTION OF BEARINGS FOR STEADY LOADING

The size of bearing required is judged by the magnitude and nature of applied load, life

and reliability. The bearing load is composed of weights involved forces derived from power

transmitted and additional force based on method of operation.

1

k

L

P

C =

L

10

Page 51 of 53

Einstein College of Engineering

Sub Code: ME53

C- basic dynamic load rating

L- life of bearing in million revolutions

L10- life of bearing for 90% survival at 1 million revolutions

P- Equivalent load

k- exponent (3 for ball bearing, 10/3 for roller bearings)

P=(XFr+YFa)S

Fr- radial load

Fa- axial load

X- radial load factor

Y- axial load factor

S- service factor

SELECTION OF BEARING FOR VARIABLE LOADING

The rolling contact bearing are frequently operate under variable load and speed

conditions. This is due to many causes like power fluctuation in electrical machineries or

requirement of different cutting forces for different kinds of machining tools, or running with

loading and unloading condition as in automobiles. Such as variable loaded bearings are

designed by considering all these different loaded conditions of work cycle and not solely upon

most sever operating conditions. The work cycle may be divided into a number of portions in

each of which operation condition may be taken as constant.

For variable speed

P 3 n + P2 3 n 2 + P3 3 n3 + .... + Pn 3 n n

Pm = 1 1

For variable time

Page 52 of 53

Einstein College of Engineering

Sub Code: ME53

P1 3 t1 + P2 3 t 2 + P3 3 t 3 + .... + Pn 3 t n

Pm =

P1- constant load during n1 revolution (or) during the period of time t 1

P2- constant load during n2 revolution (or) during the period of time t 2

n=n1+n2+n3++nn

t=t1+t2+t3++tn

Page 53 of 53

Einstein College of Engineering

You might also like

- BearingsDocument52 pagesBearingsrahul singhNo ratings yet

- Proposed 2-Storey Residential BLDGDocument34 pagesProposed 2-Storey Residential BLDGclarkgagui100% (1)

- 17-4 PHDocument48 pages17-4 PHsunsirNo ratings yet

- HCM001 Hollow-Core Design Manual - Complete - 03.23.15Document38 pagesHCM001 Hollow-Core Design Manual - Complete - 03.23.15lbhnsw5930100% (1)

- Improve Machine Tool SpindlesDocument23 pagesImprove Machine Tool SpindlesOkan ÖzelNo ratings yet

- Design and Optimization of Idler for Belt ConveyorDocument6 pagesDesign and Optimization of Idler for Belt ConveyorVaibhav GuptaNo ratings yet

- BearingDocument18 pagesBearingBudhaditya Goswami89% (45)

- 03-Bearing Life PDFDocument34 pages03-Bearing Life PDFchanayireNo ratings yet

- How Unbalance Affects Bearing LifeDocument8 pagesHow Unbalance Affects Bearing Lifeagrocel_bhv5591No ratings yet

- Design of Bearings in 40 CharactersDocument35 pagesDesign of Bearings in 40 Charactersdressfeet100% (1)

- Flyer Rolling Bearing AnalysisDocument4 pagesFlyer Rolling Bearing AnalysisBikash Ranjan SahooNo ratings yet

- Rolling Contact BearingDocument31 pagesRolling Contact Bearingpotnuru JaivanthNo ratings yet

- TDBFP ManulDocument266 pagesTDBFP ManulJackSparrow8678% (9)

- Dte - Rolling Contact BearingsDocument32 pagesDte - Rolling Contact Bearingspotnuru Jaivanth100% (1)

- Absorption Refrigeration SystemsDocument33 pagesAbsorption Refrigeration SystemsAdedire FisayoNo ratings yet

- Engine BearingsDocument22 pagesEngine Bearingsandrew munyivaNo ratings yet

- NYB Fan Handbook - 2007Document112 pagesNYB Fan Handbook - 2007José Pedro Casagrande Trentín100% (1)

- Unit III Sliding Contact BearingDocument26 pagesUnit III Sliding Contact BearingSHUBHAM GOVILNo ratings yet

- Rolling Contact Bearings NBC JaipurDocument23 pagesRolling Contact Bearings NBC JaipurlavishNo ratings yet

- Filipino House Architecture: Bahay Na BatoDocument13 pagesFilipino House Architecture: Bahay Na BatoJazmine PinedaNo ratings yet

- Chapter One .. Preview: Fig.1.1. Semi-Elliptic Leaf SpringsDocument13 pagesChapter One .. Preview: Fig.1.1. Semi-Elliptic Leaf SpringsMustafa Al Aobidi100% (1)

- Build A Log CabinDocument7 pagesBuild A Log CabinaeonsofloveNo ratings yet

- 1 3 Rolling Contact Bearings RNR 25012021Document31 pages1 3 Rolling Contact Bearings RNR 25012021potnuru Jaivanth100% (1)

- Bearing Shaft Fits and Tolerances 1Document9 pagesBearing Shaft Fits and Tolerances 1Arun KumarNo ratings yet

- Modern Pulley Design Techniques And Failure AnalysisDocument17 pagesModern Pulley Design Techniques And Failure AnalysisSiva SubramaniNo ratings yet

- Comparing shaft designs for conveyor pulleys and idler rollsDocument3 pagesComparing shaft designs for conveyor pulleys and idler rollssouvonik100% (1)

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- Target Issuance 30 May 2023Document4 pagesTarget Issuance 30 May 2023Achmad OktafionoNo ratings yet

- Pipe Coat & LiningDocument22 pagesPipe Coat & Liningjadav parixeet100% (3)

- Cojinetes de Generador Renk Manual de AplicacionesDocument39 pagesCojinetes de Generador Renk Manual de AplicacionesMiguel Angel PonceNo ratings yet

- PD 6691-2022Document74 pagesPD 6691-2022sghrkorkzan43100% (1)

- Design of Bearings & Miscellaneous ElementsDocument14 pagesDesign of Bearings & Miscellaneous ElementsjvanandhNo ratings yet

- Catalogue of Spherical Roller and Special BearingsDocument67 pagesCatalogue of Spherical Roller and Special BearingsVolodymyrNo ratings yet

- Bearing HandoutsDocument15 pagesBearing HandoutsSudhananda Mallick0% (1)

- 15.rolling Bearings in Bulk ConveyorsDocument17 pages15.rolling Bearings in Bulk ConveyorsPrashant DinkarNo ratings yet

- Dte OneDocument39 pagesDte OneBashu Dev SanjelNo ratings yet

- Dme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Document13 pagesDme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Anonymous tZfJJPRKsNo ratings yet

- LO 4 Handout SLO1,2,3, and 4 All Suboutcome CompleteDocument38 pagesLO 4 Handout SLO1,2,3, and 4 All Suboutcome Completesushil.vgiNo ratings yet

- Fdocuments - in BearingDocument18 pagesFdocuments - in BearingAd Man GeTigNo ratings yet

- Spring 1Document48 pagesSpring 1Owais Ahmad KhanNo ratings yet

- Machine Design II (MCE325)Document39 pagesMachine Design II (MCE325)Jeffrey EtimNo ratings yet

- ZKL Brno Katalog 2007 enDocument74 pagesZKL Brno Katalog 2007 enPhanHathamNo ratings yet

- How retaining forces impact spindle bearing preloadDocument6 pagesHow retaining forces impact spindle bearing preloadmurali036No ratings yet

- Unit 6 - Design of Antifriction BearingsDocument19 pagesUnit 6 - Design of Antifriction BearingsKunal Ahiwale100% (1)

- DK1915 CH12Document70 pagesDK1915 CH12gao379100% (1)

- Finite Element Simulation of Non LinearDocument11 pagesFinite Element Simulation of Non LinearmostafaNo ratings yet

- PDFenDocument31 pagesPDFenLurking RogueNo ratings yet

- Shaft Diameter PDFDocument8 pagesShaft Diameter PDFrusruleti100% (1)

- NSK Cat E728g 13 (1) LDocument0 pagesNSK Cat E728g 13 (1) LIvana StevanićNo ratings yet

- Dme Unit 5 NotesDocument22 pagesDme Unit 5 NotessithananthansithuNo ratings yet

- Cross Split Roller ENGDocument16 pagesCross Split Roller ENGMaria De Jesus GuzmanNo ratings yet

- Bearing FitsDocument9 pagesBearing FitsPPMNo ratings yet

- Design of connecting rod for petrol engineDocument26 pagesDesign of connecting rod for petrol enginesajal agarwalNo ratings yet

- Rolling Contact Bearings - DMEDocument28 pagesRolling Contact Bearings - DMESumitNo ratings yet

- Rudder Force and Design RequirementsDocument37 pagesRudder Force and Design Requirementsmohammed attiaNo ratings yet

- RoughDocument119 pagesRoughDeepak KumarNo ratings yet

- TOPIC 4 BearingDocument44 pagesTOPIC 4 BearingHafiy Qursyeini100% (1)

- Surface Durability of Spur and Helical Gears - KHK GearsDocument12 pagesSurface Durability of Spur and Helical Gears - KHK GearsKalipse FerreiraNo ratings yet

- Design Factors When Using Small Bearings: Part 2: Mounting and FittingDocument11 pagesDesign Factors When Using Small Bearings: Part 2: Mounting and FittingankitsarvaiyaNo ratings yet

- Bearing Selection GuideDocument12 pagesBearing Selection GuideKunal ShindeNo ratings yet

- Design and analysis of hydrodynamic journal bearingsDocument8 pagesDesign and analysis of hydrodynamic journal bearingsjhpandiNo ratings yet

- ClutchDocument39 pagesClutchJawed ShaikhNo ratings yet

- Part 2 Design AssignmentsDocument3 pagesPart 2 Design AssignmentsPatrick NdlovuNo ratings yet

- Rudder Force and Rudder TorqueDocument41 pagesRudder Force and Rudder TorqueGiannis PanagiotopoulosNo ratings yet

- 508MAD24 27 KK ScrewDrivesDocument2 pages508MAD24 27 KK ScrewDrivesLuis DemyanenkoNo ratings yet

- DTS Unit 5Document20 pagesDTS Unit 5Muthuvel MNo ratings yet

- Rolling Contact BearingDocument44 pagesRolling Contact BearingMuhammad Waleed Khan 940-FET/BSME/F20No ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- PHD Positions in The Area of Mechanical MetamaterialsDocument1 pagePHD Positions in The Area of Mechanical MetamaterialsAshok DaraNo ratings yet

- JPME 21 0615 Proof HiDocument9 pagesJPME 21 0615 Proof HiAshok DaraNo ratings yet

- An Intelligent ANFIS Approach for Autonomous Mobile Robot Path PlanningDocument11 pagesAn Intelligent ANFIS Approach for Autonomous Mobile Robot Path PlanningAshok DaraNo ratings yet

- Genetic Fuzzy Based Scalable System of Distributed Robots For A Collaborative TaskDocument13 pagesGenetic Fuzzy Based Scalable System of Distributed Robots For A Collaborative TaskAshok DaraNo ratings yet

- 2 DDocument4 pages2 DAshok DaraNo ratings yet

- Pace Iqac API FormDocument5 pagesPace Iqac API FormAshok DaraNo ratings yet

- 1 Types of Lines DoneDocument12 pages1 Types of Lines DoneAshok DaraNo ratings yet

- DMM IiDocument44 pagesDMM IiAshok DaraNo ratings yet

- Sar Ug T II Final Ver 06Document3 pagesSar Ug T II Final Ver 06Ashok DaraNo ratings yet

- Applications of Fuzzy Graph Theory Portrayed in Various FieldsDocument8 pagesApplications of Fuzzy Graph Theory Portrayed in Various FieldsAshok DaraNo ratings yet

- Co's & Pso's Mapping-dmm-II & FemDocument6 pagesCo's & Pso's Mapping-dmm-II & FemAshok DaraNo ratings yet

- Unit V Belt Drive PullyDocument25 pagesUnit V Belt Drive PullyAshok DaraNo ratings yet

- Program Curriculum and Teaching-Learning ProcessesDocument5 pagesProgram Curriculum and Teaching-Learning ProcessesAshok DaraNo ratings yet

- Development of NC Code For Face Milling OperationDocument10 pagesDevelopment of NC Code For Face Milling OperationAshok DaraNo ratings yet

- I-I Mid 1 and Mid 2 Consolidate SEC-ADocument4 pagesI-I Mid 1 and Mid 2 Consolidate SEC-AAshok DaraNo ratings yet

- Pace Institute of Technology & Sciences::Ongole: Department of Mechanical EngineeringDocument3 pagesPace Institute of Technology & Sciences::Ongole: Department of Mechanical EngineeringAshok DaraNo ratings yet

- FEM-Question Paper PDFDocument4 pagesFEM-Question Paper PDFAshok DaraNo ratings yet

- Pace Institute of Technology & Sciences:: Ongole Remedial Classes-Time Table - (2017-18) Department of Mechanical EngineeringDocument2 pagesPace Institute of Technology & Sciences:: Ongole Remedial Classes-Time Table - (2017-18) Department of Mechanical EngineeringAshok DaraNo ratings yet

- Thermodynamics Exam Questions and AnswersDocument8 pagesThermodynamics Exam Questions and AnswersAshok DaraNo ratings yet

- RecordDocument31 pagesRecordAshok DaraNo ratings yet

- First Year Orientation Program 2013Document2 pagesFirst Year Orientation Program 2013Ashok DaraNo ratings yet

- Agma 927Document10 pagesAgma 927Άπολος Απόλλων Μακεδών100% (1)

- Simulationlab DO's &DON'TDocument6 pagesSimulationlab DO's &DON'TAshok DaraNo ratings yet

- Department of Mechanical EngineeringDocument4 pagesDepartment of Mechanical EngineeringAshok DaraNo ratings yet

- Introduction: Basic Concepts: System, Control Volume, SurroundingDocument7 pagesIntroduction: Basic Concepts: System, Control Volume, SurroundingAshok DaraNo ratings yet

- Zheng 2016Document24 pagesZheng 2016Ashok DaraNo ratings yet

- Li 2016Document10 pagesLi 2016Ashok DaraNo ratings yet

- Lecture 2 MpeDocument25 pagesLecture 2 MpeAshok DaraNo ratings yet

- Explain A Simple Vapour Compression Cycle Giving Clearly Its Flow Diagram?Document5 pagesExplain A Simple Vapour Compression Cycle Giving Clearly Its Flow Diagram?Ashok DaraNo ratings yet

- JNTUK Mech Engg Simulation Lab Course OverviewDocument1 pageJNTUK Mech Engg Simulation Lab Course OverviewAshok DaraNo ratings yet

- Fresh & Healthy Home VentilationDocument2 pagesFresh & Healthy Home VentilationdetailsNo ratings yet

- Reinforced Concrete Column Design: B 250mm H 250mmDocument7 pagesReinforced Concrete Column Design: B 250mm H 250mmAli Al-BashaNo ratings yet

- Tang2015 PDFDocument19 pagesTang2015 PDFLuky HandokoNo ratings yet

- Korado Connection Fittings HMDocument4 pagesKorado Connection Fittings HMlovac1No ratings yet

- PistonDocument16 pagesPistonhilmy yusuf maulanaNo ratings yet

- 1new PenstockDocument23 pages1new PenstockEr Harsh Mahato100% (1)

- Ventilation schematic consultant repliesDocument4 pagesVentilation schematic consultant repliesAfsal JhNo ratings yet

- KEUMDUK KDW PumpDocument17 pagesKEUMDUK KDW PumpThairanil AbduljaleelNo ratings yet

- Fire Rated DoorDocument43 pagesFire Rated Doorshwetha shweNo ratings yet

- Smart MaterialDocument12 pagesSmart MaterialPower RiderNo ratings yet

- Ressure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsDocument1 pageRessure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsrajeshNo ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document161 pagesOf The Nuclear Safety Standards Commission (KTA)pradeepajadhavNo ratings yet

- Ladish CatalogDocument9 pagesLadish CatalogCamilo VarelaNo ratings yet

- Non Metallic MaterialsDocument16 pagesNon Metallic MaterialsthisisjineshNo ratings yet

- Conservation of Architectural Ironwork - Decay Mechanisms and Hazards by David MitchellDocument13 pagesConservation of Architectural Ironwork - Decay Mechanisms and Hazards by David MitchellDebashrita KunduNo ratings yet

- Thermo Poly RockDocument15 pagesThermo Poly RockParvathy Uv100% (1)

- HVAC JointsDocument2 pagesHVAC JointsEmre DalgicNo ratings yet

- Design Guidelines For The Use of HM Strips - Strengthening of Steel Concrete Composite Bridge With High Modulus Carbon Fibrer Reinforced Polymer (CFRP) StripsDocument40 pagesDesign Guidelines For The Use of HM Strips - Strengthening of Steel Concrete Composite Bridge With High Modulus Carbon Fibrer Reinforced Polymer (CFRP) Stripsvlad lupasteanuNo ratings yet

- MC-Color T 21 DE DE EN TDSDocument2 pagesMC-Color T 21 DE DE EN TDSY TingNo ratings yet

- Installation Procedure T5MaxDocument2 pagesInstallation Procedure T5MaxCarlos Alberto RuedaNo ratings yet