Professional Documents

Culture Documents

Polymer Aluminum Electrolytic Capacitors

Uploaded by

RanaJafaryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polymer Aluminum Electrolytic Capacitors

Uploaded by

RanaJafaryCopyright:

Available Formats

Polymer Aluminum

Electrolytic Capacitors

!Note Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

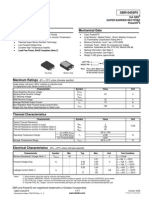

Description

Murata Manufacturing Co., Ltd.'s ECAS series of polymer aluminum electrolytic capacitors realize low ESR, low

impedence and high capacitance by means of multilayered aluminum foil for anode, solid conductive polymer for

cathode. With no bias characteristics and stable temperature characteristics, ECAS series have excellent

performance in ripple absorption, smoothing and transient response suitable for numerous applications.

Therefore, it is suitable for smoothing of input-output current of various power supply circuits, and the backup use

over the load change of the CPU circumference.

This contributes to reduction of the number of parts, or reduction of substrate area.

Appearance

External Dimensions

L

Polarity Indicator Bar (+)

Capacitance Code

Rated Voltage Code

W1

(in mm)

Case Size EIA Metric

Ex.) 220F/2V

Example of Structure

Etched Aluminum Foil

D4

7343

7.30.3 4.30.2 1.90.1 2.40.2 1.30.2

7343

7.30.3 4.30.2 2.80.3 2.40.2 1.30.2

D9

7343

7.30.3 4.30.3 4.20.3 2.40.2 1.30.2

Dielectric

Al Oxidized Film

Epoxy Resin

External Electrodes

Carbon Paste

Silver Paste

External Electrodes

Anode

Etched Aluminum foil

Cathode

Conductive Polymer

Specifications

Capacitor Map (Cap & ESR)

Capacitance Range

100

Ta Capacitor

(MnO2)

: 6.8 to 560F

Operating Temperature: -40C to +105C

Rated Voltage

Al Capacitor

(Can Type / Electrolyte)

10

Ta Capacitor

(Polymer)

ESR

: 2 to 16Vdc

: 4.5 to 70m

Features

High capacitance and Low ESR

Stable capacitance with applied

0.1

Al Capacitor

(Can Type/Polymer)

ECAS

Series

0.01

DC voltage/temperature/high frequencies

Excellent Ripple absorption, Smoothing,

Transient response

No voltage derating required

MLCC

Polarity bar (positive) noted on product

Surface mount construction

0.001

1

10

100

Capacitance (F) at 120Hz

1000

10000

RoHS compliant

Halogen free

MSL 3 packaging

W1

D6

Conductive Polymer

Capacitor Model

Al Oxidized Film

ESR (ohm) at 100kHz

!Note Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Product Lineup

Capacitance Value (F)

10

Rated Voltage (Vdc)

6.8

15

22

33

47

56

68

100

150

220

330

470

560

D4

9

D4

16

D6

10

D9

10

D4

9

D6

10

D6

10

D4 D6

9

7

D9

8

D9

9

D6

6

D9

4.5

D4

20

D4

15

D6

15

D4

16

D4

16

D4

15

D9

10

D9

12

2

4

D4

55

D4

55

D4

55

D4

60

6.3

10

12.5

D4

70

16

D4

55

D4

45

D4

28

D4

30

D6

30

D4

45

D4

40

D4

25

D4

25

D6

20

D4

25

D4

25

D4

25

D6

20

Case Size Code

ESR (m)

Characteristics

Low ESR & Z

Z

ESR or Z ()

0.1

0.01

0.001

40

Representative Data

20

0

-20

-40

-60

10

100

1,000

Frequency (kHz)

10,000

Temperature Characteristics of Capacitance

Representative Data

ESR

1

DC Bias Characteristics

40

Capacitance Change (%)

ECASD60D477M006K00

ECASD60J157M010K00

ECASD61C226M030K00

Capacitance Change (%)

10

100,000

25

50

75

Bias Voltage/Rated Voltage (%)

100

20

0

-20

-40

No Bias

50% of Rated Voltage

-60

-50

-25

25

50

75

Temperature (C)

100

125

Design Support Tool - SimSurfing

http://www.murata.com/simsurfing/

- Frequency responses (Z, ESR, ESL) of ECAS Series are available.

- Netlist and S-parameter can be downloaded.

- The software "SimSurfing" is also available for your simulation on the go where no internet connection

is available.

Applications

Market

Set/Application

Notebook/Netbook

Overall Power Management

Ex.1) Power Supply line around IC etc...

CPU

ASIC

FPGA

etc

Power

Supply

Server

Target

Computer

Motherboard/Graphics Card

IC on

ESLsESR

Multi Function Peripheral (Copier/Printer)

V

V

Digital TV (LCD/Plasma)

Digital AV

Game Console

Cap

c Stabilizes

c Eliminates Ripple

Voltage Source

c Smoothes Voltage Source

c Eliminates High Frequency

Noise from IC

Ex.2) USB bus power line

Set Top Box

Network/Switch/Router

Telecom

c Peak Power Assistance

USB2.0

USB3.0

IC

5V

USB

Port

Power supply

from ECAS

Target

Base Station

t

Power supply

from Battery

!Note Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Part Numbering

rCapacitance

(Part Number)

ECAS D4 0D 227 M 009

q

00

Expressed by three-digit numeric code. The unit is pico-farad (pF).

The first and second figures are significant digits, and the third figure

expresses the number of zeros which follow the two numbers.

Ex.)

u i

Code

Capacitance

476

47F

107

100F

227

220F

477

470F

qSeries

Product ID

ECAS

Polymer AI Electrolytic Capacitor

tCapacitance Tolerance

Code

Capacitance Tolerance

20%

+10%, -35%

wDimension (LxWxT) (mm)

Code

D4

7.30.3

4.30.2

1.90.1

D6

7.30.3

4.30.2

2.80.3

D9

7.30.3

4.30.3

4.20.3

yESR

Expressed by three-digit alphanumerics. The unit is milli-ohm (m).

If there is a decimal point, it is expressed by the capital letter "R".

Ex.)

eRated Voltage

Code

Code

ESR

4R5

4.5m

Rated Voltage

0D

DC 2V

009

9m

0E

DC 2.5V

010

10m

0G

DC 4V

0J

DC 6.3V

0K

DC 8V

Code

Packaging

1A

DC 10V

330mm Embossed Taping

1B

DC 12.5V

1C

DC 16V

uPackaging

iIndividual Specification Code

Expressed by two figures.

Specifications and Test Methods

No.

1

Item

Operating Temperature Range

Test Conditions

Characteristics

-40C to +105C

Series resistor : 1000 ohm

Applied voltage: Rated Voltage

Measuring after 2 minutes of application

Please conduct pre-conditioning below, if you have a doubt.

Pre-conditioning: Apply rated DC voltage for 1 hour at 105C

through 1000 ohm series resistor.

Then discharge and keep in the room temperature for

4 to 24 hours.

Leakage Current

BThe value of "Part Number Listing"

Capacitance Tolerance

Please refer to "Part Number Listing"

Dissipation Factor

B0.06

ESR

BThe value of "Part Number Listing"

Measuring frequency : 100kHz 10%

Measuring voltage

: no more than +1Vr.m.s.

Measuring temperature: 25C

Allowable Ripple Current

Please refer to "Part Number Listing"

Measuring frequency: 100kHz 10%

Solderability

More than 75% of each terminal face is

covered by new solder

Lead Free Solder : Sn/3.0Ag/0.5Cu

Flux

: Rosin 25%, IPA 75%

Solder temperature: 245 5C

Immersing time

: 3 0.5s

Measuring frequency : 120Hz 10%

Measuring circuit

: Equivalent series circuit

Measuring voltage

: +1Vr.m.s.

Measuring temperature: 25C

B750% of initial specified value

8

Moisture

Resistance

Under No

Bias

Leakage Current

for 2V to 10V products

B300% of initial specified value

for 12.5V to 16V products

Capacitance Change -20% and +50% of initial measured value

Dissipation Factor

B0.12

Appearance

No defects or abnormalities

Test temperature: 602C

Relative humidity: 90 to 95%RH

Test time

: 500+24, -0h

!Note Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

No.

Item

Moisture

Resistance

Under

Load

10

Shelf Life

11

Endurance

Characteristics

Test Conditions

BThe value of "Part Number Listing"

Leakage Current

Capacitance Change -20% and +50% of initial measured value

Dissipation Factor

B0.12

Appearance

No defects or abnormalities

Leakage Current

BThe value of "Part Number Listing"

Capacitance Change 10% of initial measured value

Test temperature: 1052C

Test time

: 1000+48, -0h

Dissipation Factor

B0.06

Appearance

No defects or abnormalities

Leakage Current

BThe value of "Part Number Listing"

Capacitance Change 10% of initial measured value

Dissipation Factor

B0.06

Appearance

No defects or abnormalities

Leakage Current

BThe value of "Part Number Listing"

Capacitance Change 10% of initial measured value

12

Dissipation Factor

B0.06

Appearance

No defects or abnormalities

Test temperature: 602C

Relative humidity: 90 to 95%RH

Test time

: 1000+48, -0h

500+24, -0h (ECASD40D337Y009KA0)

Applied voltage : Rated Voltage

Surge

Test temperature: 1052C

Test time

: 1000+48, -0h

Applied voltage : Rated Voltage

Temperature:

+85C for 2V to 10V products

Room temp. for 12.5V to 16V products

Applied voltage:

Rated voltage x1.25 for 2V to 10V products

Rated voltage x1.15 for 12.5V to 16V products

Current limiting resistance:

33 ohm (in series) for 2V to 10V products

1k ohm (in series) for 12.5V to 16V products

Discharge resistance:

33 ohm (in series) for 2V to 10V products

1k ohm (in series) for 12.5V to 16V products

Charge on/off:

30 sec. each, 1000 times

(The measurement condition in No.2 to 4 applies to No.8 to 12.)

Recommended Reflow Profile

Land Pattern Design

10sec. max.

(Peak Temp.: 245C max.)

250

Temperature (C)

Capacitor

2.8

200

60sec. max.

(225C and over)

150

160sec. max.

(150C to 195C)

100

115sec. max.

(195C and over)

4.0

50

Max temperature 245C, two times.

If peak temperature is over 245C, please contact Murata for more details.

8.8

(in mm)

Time (sec.)

4.00.1

1.5 +0.1

0

2.00.1

Polarity

D

12.00.3

5.50.1

2.00.5

(-)

130.2

1.5+0.25

0

210.8

(+)

C

8.00.1

(in mm)

Case

Size

Cavity Size (mm)

A 0.2

B0.2

C0.2

1.750.1

Packaging

Minimum Qty.

(pcs.)

D4

4.5

7.6

2.2

0.4max.

3,000

D6

4.5

7.6

3.2

0.4max.

2,500

D9

4.5

7.6

4.6

0.4max.

2,000

(in mm)

W1

Reel Size Tape Width

330

12

330.02.0 100.01.0

W1

17.51.5

13.51.5

!Note Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Part Number Listing

Ripple

Current

(Arms)

100kHz

Min.

Packaging

Quantity

(pcs.)

8.0

2.0

3,000

12.0

3.0

3,000

1.9

17.6

3.0

3,000

7343

1.9

66.0

3.0

3,000

D6

7343

2.8

26.4

3.5

2,500

20

D6

7343

2.8

37.6

3.5

2,500

560

20

D9

7343

4.2

4.5

44.8

4.0

2,000

68

20

D4

7343

1.9

20

10.9

1.9

3,000

ECASD40G107M016K00

100

20

D4

7343

1.9

16

16.0

2.1

3,000

ECASD40G157M016K00

150

20

D4

7343

1.9

16

24.0

2.1

3,000

ECASD60G227M010K00

220

20

D6

7343

2.8

10

35.2

3.0

2,500

ECASD90G337M008K00

330

20

D9

7343

4.2

52.8

3.3

2,000

ECASD40J106M055K00

6.3

10

20

D4

7343

1.9

55

2.6

1.0

3,000

ECASD40J226M045K00

6.3

22

20

D4

7343

1.9

45

5.6

1.0

3,000

ECASD40J336M025K00

6.3

33

20

D4

7343

1.9

25

8.4

1.8

3,000

ECASD40J476M025K00

6.3

47

20

D4

7343

1.9

25

11.9

1.8

3,000

ECASD40J686M015K00

6.3

68

20

D4

7343

1.9

15

17.2

2.0

3,000

ECASD40J107M015K00

6.3

100

20

D4

7343

1.9

15

25.2

2.0

3,000

ECASD60J157M010K00

6.3

150

20

D6

7343

2.8

10

37.8

3.0

2,500

ECASD60J227M010K00

6.3

220

20

D6

7343

2.8

10

55.5

3.0

2,500

ECASD90J337M009K00

6.3

330

20

D9

7343

4.2

83.2

3.4

2,000

ECASD41A106M055K00

10

10

20

D4

7343

1.9

55

4.0

1.0

3,000

ECASD41A226M028K00

10

22

20

D4

7343

1.9

28

8.8

1.6

3,000

ECASD41A336M025K00

10

33

20

D4

7343

1.9

25

13.2

1.8

3,000

ECASD41A476M025K00

10

47

20

D4

7343

1.9

25

18.8

1.8

3,000

ECASD61A686M015K00

10

68

20

D6

7343

2.8

15

27.2

2.0

2,500

ECASD91A107M010K00

10

100

20

D9

7343

4.2

10

40.0

3.0

2,000

ECASD91A157M010K00

10

150

20

D9

7343

4.2

10

60.0

3.0

2,000

ECASD41B106M055K00

12.5

10

20

D4

7343

1.9

55

12.5

1.0

3,000

ECASD41B156M045K00

12.5

15

20

D4

7343

1.9

45

18.8

1.0

3,000

ECASD41B226M030K00

12.5

22

20

D4

7343

1.9

30

27.5

1.6

3,000

ECASD41B336M025K00

12.5

33

20

D4

7343

1.9

25

41.3

1.8

3,000

ECASD61B476M020K00

12.5

47

20

D6

7343

2.8

20

58.8

2.0

2,500

ECASD61B566M020K00

12.5

56

20

D6

7343

2.8

20

70.0

2.0

2,500

ECASD91B107M012K00

12.5

100

20

D9

7343

4.2

12

125.0

2.5

2,000

ECASD41C685M070K00

16

6.8

20

D4

7343

1.9

70

10.9

1.0

3,000

ECASD41C106M060K00

16

10

20

D4

7343

1.9

60

16.0

1.0

3,000

ECASD41C156M040K00

16

15

20

D4

7343

1.9

40

24.0

1.0

3,000

ECASD61C226M030K00

16

22

20

D6

7343

2.8

30

35.2

1.6

2,500

Case Size

ESR Max.

Leakage

(m)

Current

100kHz

(A)

/+25C

Part Number (Murata)

Rated

Voltage

(V.DC)

Cap.

(F)

Cap.

Tolerance

(%)

Code

LxW

(mm)

T

(mm)

ECASD40D107M016K00

100

20

D4

7343

1.9

16

ECASD40D157M009K00

150

20

D4

7343

1.9

ECASD40D227M009K00

220

20

D4

7343

ECASD40D337Y009KA0

330

+10, -35

D4

ECASD60D337M007K00

330

20

ECASD60D477M006K00

470

ECASD90D567M4R5K00

ECASD40G686M020K00

!Note Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Cautions for Use

Cautions

<1>Prohibited Circuits For Use

Do not use the capacitor with the following circuits.

qTime-constant circuit

wCoupling circuits

e2 or more capacitors connected serially

rCircuit which are greatly affected by leakage current

<2>Polarity

Polymer aluminum electrolytic capacitor is polarized. Please not to reverse the polarity when using.

If reverse voltage is applied even momentary, it may damage the oxide film and the capacitor itself.

<3>Operating Voltage

When DC-rated capacitors are to be used in AC or ripple current circuits, be sure to maintain the Vp-p value of the applied voltage or the

Vo-p which contains DC bias within the rated voltage range.

When the voltage is applied to the circuit, starting or stopping may generate irregular voltage for a transit period because of resonance or

switching. Be sure to use a capacitor with a rated voltage range that includes these irregular voltages.

<4>Inrush Current

Extreme inrush current may cause short circuit or leakage current increase. If the inrush current exceeds 20A, adding protection circuit is

recommended.

<5>Allowable Ripple Current

Please not to apply ripple current exceeding the allowable value specified in this document. If excessive current is applied, it may

generate heat and the heat may damage the capacitor.

The sum of DC voltage and the peak AC voltage shall not exceed the rated voltage. The sum of the DC voltage and the peak AC voltage

shall not allow a voltage reversal.

<6>Operating Temperature

The operating temperature limit depends on the capacitor.

qDo not apply temperature exceeding the upper operating temperature. It is necessary to select a capacitor with a suitable rated

temperature that will cover the operating temperature range. Also it is necessary to consider the temperature distribution in equipment

and the seasonal temperature variable factor.

wConsider the self-heating of the capacitor. The surface temperature of the capacitor shall be the upper operating temperature or less

when including the self-heating factors.

<7>Reflow Soldering

Please not to apply excessive force to the capacitor during insertion as well as after soldering. The excessive force may result in damage

to electrode terminals and/or degradation of electrical performance.

<8>Operating Environment

Confirm the environment in which the equipment will operate is under the specified conditions. Do not use the equipment under the

following environments.

qBeing spattered with water or oil.

wBeing exposed to direct sunlight.

eBeing exposed to Ozone, ultraviolet rays or radiation.

rBeing exposed to toxic gas (e.g., hydrogen sulfide, sulfur dioxide, chlorine, ammonia gas, etc.)

tBeing exposed to excessive vibrations or mechanical shocks.

yBeing exposed to condensable environments.

Storage Conditions

<1>Term of warranty for this product is two years after packaging in a moisture-proof bag, under the conditions below with sealed packaging.

Recommended storage environment: Room temperature: 5-30C

Humidity

: no more than 60%RH

<2>Polymer aluminum electrolytic capacitors should not be stored in an atmosphere consisting of corrosive gas (e.g., hydrogen sulfide, sulfur

dioxide, chlorine, ammonia gas, etc.).

<3>Polymer aluminum electrolytic capacitors should be stored in a dry atmosphere, avoiding direct sunlight and condensation. If capacitors

are kept at a higher humidity, the following problems may occur:

qLeakage current will increase at the beginning of use and damage the circuit.

wMoisture absorbed in a resin will evaporate and expand with heat of mounting and damage the mold resin.

<4>Please confirm a dry state with a humidity indicator card after open immediately. If 20% indication was in a pink state after opened, it is

recommended to bake under the conditions below.

<5>The capacitors should be kept dry using desiccators or any other methods after unsealing the moisture-proof packaging. If more than one

week has passed under the recommended storage environment specified above after unsealing the packaging, it is recommended to

bake under the conditions below.

Recommended baking conditions: Temperature: 60 (+0, -5) C

Time

: 168 hours

<6>This product meets MSL-3.

EU RoHS Compliant

s�All

the products in this catalog comply with EU RoHS.

RoHS is "the European Directive 2011/65/EU on the Restriction of the Use of Certain Hazardous Substances in Electrical and

Electronic Equipment."

s�For more details, please refer to our website 'Murata's Approach for EU RoHS' (http://www.murata.com/info/rohs.html).

s�EU

Cat. No. C90E-2

Global Locations

For details please visit www.murata.com

Note

1 Export Control

For customers outside Japan:

No Murata products should be used or

sold, through any channels, for use in the

design, development, production, utilization,

maintenance or operation of, or otherwise

contribution to (1) any weapons (Weapons of

Mass Destruction [nuclear, chemical or biological

weapons or missiles] or conventional weapons)

or (2) goods or systems specially designed or

intended for military end-use or utilization by

military end-users.

For customers in Japan:

For products which are controlled items subject

to the Foreign Exchange and Foreign Trade Law

of Japan, the export license specied by the law

is required for export.

2 Please contact our sales representatives or

product engineers before using the products in

this catalog for the applications listed below,

which require especially high reliability for the

prevention of defects which might directly

damage a third partys life, body or property, or

when one of our products is intended for use

in applications other than those specified in

this catalog.

1

Aircraft equipment

Aerospace equipment

Undersea equipment

Power plant equipment

Medical equipment

Transportation equipment (vehicles, trains,

ships, etc.)

Traffic signal equipment

Disaster prevention / crime prevention

equipment

Data-processing equipment

10

Application of similar complexity and/or

reliability requirements to the applications

listed above

Murata Manufacturing Co., Ltd.

www.murata.com

3 Product specications in this catalog are as of

September 2014. They are subject to change or

our products in it may be discontinued without

advance notice. Please check with our sales

representatives or product engineers before

ordering. If there are any questions, please contact

our sales representatives or product engineers.

4 Please read rating and CAUTION (for storage,

operating, rating, soldering, mounting and

handling) in this catalog to prevent smoking

and/or burning, etc.

5 This catalog has only typical specications.

Therefore, please approve our product

specications or transact the approval sheet

for product specications before ordering.

6 Please note that unless otherwise specied, we

shall assume no responsibility whatsoever for any

conict or dispute that may occur in connection

with the effect of our and/or a third partys

intellectual property rights and other related

rights in consideration of your use of our products

and/or information described or contained in our

catalogs. In this connection, no representation

shall be made to the effect that any third parties

are authorized to use the rights mentioned above

under licenses without our consent.

7 No ozone depleting substances (ODS) under the

Montreal Protocol are used in our manufacturing

process.

You might also like

- 104 K5C CapacitorDocument54 pages104 K5C CapacitorsotaquitoNo ratings yet

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaNo ratings yet

- Datasheet - HK 1206ca681kat1a 4362363 PDFDocument2 pagesDatasheet - HK 1206ca681kat1a 4362363 PDFShopfaraonTiendaNo ratings yet

- PTC Thermistors POSISTOR For Circuit ProtectionDocument103 pagesPTC Thermistors POSISTOR For Circuit Protectionkn65238859No ratings yet

- Murata High Performance Electrical Double Layer CapacitorDocument8 pagesMurata High Performance Electrical Double Layer Capacitorkn65238859No ratings yet

- Murata Ceramic Capacitor Data BookDocument83 pagesMurata Ceramic Capacitor Data Bookvemuri_sriNo ratings yet

- C85e AshxDocument84 pagesC85e AshxRanaJafaryNo ratings yet

- Murata PTC-NTC For Surface Mounting ApplicationDocument12 pagesMurata PTC-NTC For Surface Mounting Applicationkn65238859No ratings yet

- Radial Lead Type Monolithic Ceramic Capacitors: Cat - No.C49E-21Document54 pagesRadial Lead Type Monolithic Ceramic Capacitors: Cat - No.C49E-21davidninrioNo ratings yet

- Codificare Rezistente SMD 60A Are 412 Ohmi CF TabelDocument6 pagesCodificare Rezistente SMD 60A Are 412 Ohmi CF Tabelromeo1966No ratings yet

- Varistor 222k.6kvDocument5 pagesVaristor 222k.6kvJess AJNo ratings yet

- Vishay Bccomponents: FeaturesDocument16 pagesVishay Bccomponents: FeaturesPetrutStefanVartolomeiNo ratings yet

- Kem A4003 ExvDocument16 pagesKem A4003 ExvAndrzej GomulaNo ratings yet

- Id Almiec CPH Tech eDocument60 pagesId Almiec CPH Tech ealltheloveintheworldNo ratings yet

- Murata Products Safety Certified Capacitors 85eDocument70 pagesMurata Products Safety Certified Capacitors 85ealltheloveintheworldNo ratings yet

- ACPL312TDocument18 pagesACPL312Tcms_saNo ratings yet

- High Performance Electrical Double Layer Capacitor DMT SeriesDocument8 pagesHigh Performance Electrical Double Layer Capacitor DMT SeriesRanaJafaryNo ratings yet

- High Voltage MLC Chips: For 600V To 5000V ApplicationsDocument2 pagesHigh Voltage MLC Chips: For 600V To 5000V ApplicationsJoseph Abou El OulaNo ratings yet

- 3 NTCDocument48 pages3 NTCMuhammad Yunus AndrianNo ratings yet

- Kem F3050 C44P Radial-1103058Document9 pagesKem F3050 C44P Radial-1103058Alexander MedinaNo ratings yet

- Multilayer Ceramic CapacitorsDocument12 pagesMultilayer Ceramic CapacitorscostpopNo ratings yet

- ICL8069 - Low Voltage Reference - Intersil CorporationDocument6 pagesICL8069 - Low Voltage Reference - Intersil Corporationwlen2012No ratings yet

- Pyu-Pa e 51 RohsDocument11 pagesPyu-Pa e 51 Rohssales6No ratings yet

- C02e AshxDocument186 pagesC02e AshxRanaJafaryNo ratings yet

- MCH 18Document15 pagesMCH 18Tim SmithNo ratings yet

- SMT Current Sense Transformers: A Í Püééí A Í PüééíDocument9 pagesSMT Current Sense Transformers: A Í Püééí A Í PüééíAENo ratings yet

- Metal Film Resistors MRS16S/25: Philips Components Product SpecificationDocument12 pagesMetal Film Resistors MRS16S/25: Philips Components Product SpecificationnrsaranNo ratings yet

- NTC ThermistorsDocument44 pagesNTC Thermistorskn65238859No ratings yet

- c106m PDFDocument6 pagesc106m PDFDaniel Tenezaca BejaranoNo ratings yet

- C106MGDocument6 pagesC106MGCesar VeraNo ratings yet

- Surface Mount Multilayer Ceramic Chip Capacitors: Commerical GradeDocument19 pagesSurface Mount Multilayer Ceramic Chip Capacitors: Commerical Gradedovesnest_inNo ratings yet

- Fixed Carbon Composition Resistors: CharacteristicsDocument3 pagesFixed Carbon Composition Resistors: CharacteristicsHiru SegwayNo ratings yet

- Hoja de Datos de Los TermistoresDocument6 pagesHoja de Datos de Los TermistoresIan GaribayNo ratings yet

- Codigos de SMD CapasitoresDocument26 pagesCodigos de SMD CapasitoresHugo Roberto RibeiroNo ratings yet

- Series 800 1000 TubularDocument6 pagesSeries 800 1000 TubularRatnesh GaurNo ratings yet

- Data Sheet: General Purpose Chip ResistorsDocument9 pagesData Sheet: General Purpose Chip ResistorsJamesSmith2014No ratings yet

- Rmi 4 NDocument3 pagesRmi 4 NSami SaadNo ratings yet

- C106BOS Datasheetz PDFDocument6 pagesC106BOS Datasheetz PDFAnonymous na7OSZaNo ratings yet

- Avr3311ci SM PDFDocument216 pagesAvr3311ci SM PDFSimona IonascuNo ratings yet

- Large Capacitance Aluminum Electrolytic Capacitors: S I EsDocument2 pagesLarge Capacitance Aluminum Electrolytic Capacitors: S I EsbehzadNo ratings yet

- MCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument7 pagesMCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsErnestoGarciaMontanoNo ratings yet

- 200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CDocument9 pages200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CselocaNo ratings yet

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliNo ratings yet

- Type RN73 Series: Key FeaturesDocument5 pagesType RN73 Series: Key FeaturesdannnirNo ratings yet

- G5Q PCB Relay: Ordering InformationDocument4 pagesG5Q PCB Relay: Ordering InformationLAU_CBrNo ratings yet

- Relay 5vDocument2 pagesRelay 5vNgoc Loi Nguyen HoNo ratings yet

- Chemi-Con KZG Series Electrolytic Capacitors DatasheetDocument2 pagesChemi-Con KZG Series Electrolytic Capacitors DatasheetJBHignNo ratings yet

- MH 182Document11 pagesMH 182harshalvikasNo ratings yet

- Data SheetDocument3 pagesData Sheetfadel_destroNo ratings yet

- Samsung TantalumDocument34 pagesSamsung TantalumSanthosh SanthuNo ratings yet

- Tak Cheong: 1 Watt DO-41 Hermetically Sealed Glass Zener Voltage RegulatorsDocument4 pagesTak Cheong: 1 Watt DO-41 Hermetically Sealed Glass Zener Voltage RegulatorsPantallazo AzulNo ratings yet

- Semipont 2: Power Bridge RectifiersDocument3 pagesSemipont 2: Power Bridge Rectifiersfabiano_amcNo ratings yet

- LM12CLKDocument14 pagesLM12CLKGheorghe DanielNo ratings yet

- SCR c106Document4 pagesSCR c106Francisco PedrozaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- 16Document98 pages16RanaJafaryNo ratings yet

- Interv Mini: Smaller Profile, Wider Options, Less TraumaDocument4 pagesInterv Mini: Smaller Profile, Wider Options, Less TraumaRanaJafaryNo ratings yet

- Fabia MY15 Brochure WebDocument32 pagesFabia MY15 Brochure WebRanaJafaryNo ratings yet

- Abb 2013-2014Document516 pagesAbb 2013-2014Jennifer JonesNo ratings yet

- 7 NDocument24 pages7 NRanaJafaryNo ratings yet

- Nuclear InstrumentsDocument6 pagesNuclear InstrumentsRanaJafaryNo ratings yet

- 6 yDocument10 pages6 yRanaJafaryNo ratings yet

- C02e AshxDocument186 pagesC02e AshxRanaJafaryNo ratings yet

- Unitek Temporary Anchorage Device Tad SystemDocument4 pagesUnitek Temporary Anchorage Device Tad SystemRanaJafaryNo ratings yet

- High Performance Electrical Double Layer Capacitor DMT SeriesDocument8 pagesHigh Performance Electrical Double Layer Capacitor DMT SeriesRanaJafaryNo ratings yet

- C85e AshxDocument84 pagesC85e AshxRanaJafaryNo ratings yet

- StabiliT Brochure PML3443 AEDocument8 pagesStabiliT Brochure PML3443 AERanaJafaryNo ratings yet

- SYNOPSIS Make in IndiaDocument7 pagesSYNOPSIS Make in IndiaMathew George KNo ratings yet

- Case GalanzDocument7 pagesCase GalanzLeonard LiNo ratings yet

- The Great EU Sugar Scam: How Europe's Sugar Regime Is Devastating Livelihoods in The Developing WorldDocument39 pagesThe Great EU Sugar Scam: How Europe's Sugar Regime Is Devastating Livelihoods in The Developing WorldOxfamNo ratings yet

- Nishat Textile - Strategic Management FrameworkDocument39 pagesNishat Textile - Strategic Management FrameworkZara Imran50% (2)

- ECGC PolicyDocument48 pagesECGC Policynikhiljain19743100% (1)

- Pdf24 Merged RemovedDocument277 pagesPdf24 Merged RemovedAnonymousNo ratings yet

- Essay On The Problem of Rising PricesDocument2 pagesEssay On The Problem of Rising PricesTaibur Rahaman100% (1)

- 8 Shyam KhemaniDocument16 pages8 Shyam KhemaniAkhmad Fikri YahmaniNo ratings yet

- Association of Philippine Coconut Desiccators Vs PcaDocument13 pagesAssociation of Philippine Coconut Desiccators Vs PcaryuseiNo ratings yet

- IB AssignmentDocument15 pagesIB Assignmentayush jindalNo ratings yet

- Apar 2004 2005Document51 pagesApar 2004 2005RamaNo ratings yet

- International Trade Theory and Development StrategyDocument48 pagesInternational Trade Theory and Development StrategyIrish Dela FuenteNo ratings yet

- Pestle Analysis (Oyo)Document5 pagesPestle Analysis (Oyo)SUNABHA DASNo ratings yet

- Duty Entitlement Passbook SchemeDocument12 pagesDuty Entitlement Passbook SchemeKalyani VuyyuruNo ratings yet

- MCQ Economics Ind Devt Ch1Document43 pagesMCQ Economics Ind Devt Ch1Jain AayushNo ratings yet

- CONCORDocument32 pagesCONCORIsha Varma100% (2)

- Cash Incentive ACNABINDocument68 pagesCash Incentive ACNABINWasik Abdullah Momit100% (1)

- Marketing Airpork Case StudyDocument13 pagesMarketing Airpork Case StudykartickapurNo ratings yet

- Jagatpur PC CollegeDocument10 pagesJagatpur PC CollegeAtul RanjanNo ratings yet

- Ecuadorian Cocoa Export AnalysisDocument31 pagesEcuadorian Cocoa Export AnalysisKarla MataNo ratings yet

- Macroeconomics 10th Edition Colander Test Bank Full Chapter PDFDocument66 pagesMacroeconomics 10th Edition Colander Test Bank Full Chapter PDFcarlarodriquezajbns100% (12)

- Extract SixDocument50 pagesExtract Sixsimbiro100% (1)

- Export Credit Insurance Policy PDFDocument2 pagesExport Credit Insurance Policy PDFBrianNo ratings yet

- Beximco PharmaDocument13 pagesBeximco Pharmandc6105058100% (3)

- Notice: Customhouse Broker License Cancellation, Suspension, Etc.Document6 pagesNotice: Customhouse Broker License Cancellation, Suspension, Etc.Justia.comNo ratings yet

- Furniture Complete Report TDAPDocument22 pagesFurniture Complete Report TDAPMohammad SiddiquiNo ratings yet

- GD Topic - Coronavirus - 'Black Swan' of Global Economy How It Impacts India - PDFDocument10 pagesGD Topic - Coronavirus - 'Black Swan' of Global Economy How It Impacts India - PDFAshutosh Sharma100% (1)

- Foreign Direct Investment On Export of Leather and Leather Products in India PDFDocument5 pagesForeign Direct Investment On Export of Leather and Leather Products in India PDFMohammed AlqahtanyNo ratings yet

- The Political Economy of Deregulation in IndonesiaDocument18 pagesThe Political Economy of Deregulation in Indonesiacat dogNo ratings yet

- Notes On Currency ConvertibilityDocument2 pagesNotes On Currency ConvertibilityBitan Banerjee100% (1)