Professional Documents

Culture Documents

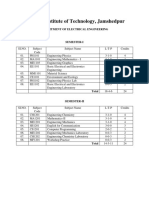

MTe C

Uploaded by

ryinejanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTe C

Uploaded by

ryinejanCopyright:

Available Formats

MTeC A4 zusgestellt Englisch

www.messko.de

10.02.2005

13:35 Uhr

Seite 1

MTeC - EPT202

Digital thermometer

Messko

MTeC A4 zusgestellt Englisch

10.02.2005

13:35 Uhr

Seite 2

MTeC-EPT202 the all-rounderMTO

ST160 und MTOSTF 160

The main functions such as Power, Alarm,

Trip, Error and the operating status of the

individual fan groups are quickly identifiable

by means of the LEDs in the control panel.

An examination of the ageing behaviour of the insulation system of transformers and

therefore the service life in particular shows that these are largely dependent on the

temperature in the winding. This temperature is primarily determined by the load of

the transformer, the parameterization of the cooling control and the overall design of

the cooling equipment.

The activation and deactivation of the radiator, controlled by the temperature of the

oil or winding, are particularly important in this respect.

A temperature monitoring system and fan control customized to the individual conditions posed by the respective transformer equipment firstly increases the expected

service life of the transformer and secondly reduces the total losses through fan

running times optimized for the load and temperature. The radiators are controlled

individually according to the type of cooling.

The new MTeC-EPT202 equipment generation (digital thermometer with loaddependent fan control) combines a number of functions for monitoring the temperature of transformers.

The basic device displays and monitors the temperature of the oil and winding.

The maximum and minimum values for the temperatures and load current are recorded

and can be called up later. Two analogue outputs and a RS485 interface are available

for remote indication of the temperature values.

The clear central display shows all of the

equipment information for operating and

programming the MTeC, according to the

menu item.

MTeC A4 zusgestellt Englisch

10.02.2005

13:35 Uhr

Seite 3

Navigation through the individual menu is

child's play thanks to the cursor keys on the

right-hand side next to the central display.

You can intuitively navigate your way

through the individual function areas.

The input can be freely parameterised

depending on which sensor you use to

measure the oil temperature

(4 mA ... 20 mA or Pt100).

We use safety screw terminals for communication and connecting the supply lines,

control wires and sensor lines. In addition,

these terminals simplify the assembly of the

device in its place of installation.

You can configure the individual main

switching contacts so that they are assigned

to either the oil temperature or winding

temperature. It is also possible to switch

each fan group manually.

MTeC A4 zusgestellt Englisch

10.02.2005

13:35 Uhr

Seite 4

In the "peak-value" menu item, you will find

handy variants of "mechanical drag hands".

Minimum/maximum values for the oil and

winding temperatures and the maximum

load current are recorded and displayed.

The input can be freely parameterised

depending on which sensor you use to

measure the oil temperature

(4 mA ... 20 mA or Pt100).

The main switching contacts can be checked

extremely easily as part of the regular

checks, using the Test function. All equipment functions continue to run in the

background.

You can configure the individual main

switching contacts so that they are assigned

to either the oil temperature or winding

temperature. It is also possible to switch

each fan group manually.

MTeC A4 zusgestellt Englisch

10.02.2005

13:35 Uhr

Seite 5

MTeC-EPT202 The functions at a glance

The lifetime of your transformer substantial

depends on the thermal aging of the

winding. The MTeC calculates the service

life already elapsed according to

international standards.

The new MTeC-EPT202 equipment generation (digital thermometer with loaddependent fan control) combines a number of functions for monitoring the

temperature of transformers:

+ Measurement/display of the temperature of the oil and 1 to 3 windings

+ Oil level display for on-load tap-changer and transformer oil conservator

+ Intelligent (cooling type- and load-dependent) fan control

+ Calculation of residual service life in line with international standards

+ Storage of data

+ Remote monitoring and parameterization via a SCADA system or on site via PC

+ Reduction of power loss (fan) and noise emissions

+ Targeted monitoring and reduction of thermal load of transformer

MTeC-EPT202 Modular structure

Top oil

temperature

CT phase

1

Parameter

CT phases

2 and 3

Oil level

PT 100

420 mA

The outputs of the MTeC can be set as

required. If you wish to connect another

device at a later date, simply redefine the

parameters of the output.

EPT 202

Analog

Digital

OL/CT

OL

CT

Analog

Extensionmodules

Oil temperature,

winding

temperature

SCADA

Oil level

MTeC A4 zusgestellt Englisch

10.02.2005

MTeC

Rail mounting:

19 sub-rack:

Flush panel mounting:

Installation in ED from MR:

Operation:

Storage:

Control elements:

Display:

Status LEDs:

Supply voltage:

Temperature sensor:

Current transformer input:

Analog outputs:

Interfaces:

Relais

Elektrical safety:

ECE conformity:

13:35 Uhr

Seite 6

Technical Data of EPT202

Protective housing

Aluminium housing, snaps on to mounting rail in line with DIN EN 60715 TH 35-7.5 and TH 35-15,

degree of protection IP 00 in line with IEC 60529, weight approx. 1.2 kg

19 plug-in housing in line with DIN 41494 part 5, 223 x 133 x 178 mm (W x H x D) for mounting

in 19 cabinet system, degree of protection IP 00 in line with IEC 60529, weight approx. 1.5 kg

Aluminium housing 270 x 200 x 133 mm (W x H x D) for panel cut-out 236 mm x 142 mm (W x H),

degree of protection IP 00 in line with IEC 60529, weight approx. 1.5 kg

19 plug-in housing in line with DIN 41494 part 5, 483 x 133 x 178 mm (W x H x D),

degree of protection IP 00 in line with IEC 60529, weight approx. 2.5 kg

Temperature range

-25 C+70 C

-30 C+85 C

Control elements, displays

5 x function keys with tangible pressure point

Monochrome display, White characters on blue illuminated background, 128 x 64 dot

1 x green LED for Power operating display

1 x yellow LED for Alarm contact

1 x red LED for TRIP contact

1 x red LED for ERROR contact

4 x yellow LEDs for S1, S2, S3 and S4 contacts

Inputs

100 V AC240 V AC, 50 Hz400 Hz or 100 V DC353 V DC, power consumption: max. 10 VA or W

Pt100-Signal in line with IEC 751 in 2- or 3-conductor technology or

420 mA signal (active or passive), standard measuring range:

-20C+140C (others available on request)

Instrument transformers can be provided for other input signals such as 01 mA or 010 V.

0,55 A rated CT current, durability: 10 A for 8 hours, short-time current: 500 A for 1 second

Outputs

1 x oil temperature (Oil Temp.), temperature range: -20 C+140 C,

1 x winding temperature (Winding), temperature range: 0 C160 C

Both analog outputs can be set as required within the following ranges: 010 V

01 mA

420 mA (errorsignal < 3,6 mA)

420 mA (errorsignal > 22 mA)

020 mA (errorsignal > 22 mA)

1 x RS 232 on 9-pole D-Sub connector for parametrization and data logging via PC

1 x RS 485 on screw terminals

1 x SPI-Bus on 15-pole D-Sub connector for connecting additional modules

4 x SPDT contacts for switching points S1S4,

make/break capability of contacts, AC: 250 V/12A, DC: 110 V/0.4 A

2 x SPDT contacts for ALARM and TRIP, make/break capability of contacts, AC: 250 V/5A, DC: 110 V/0.4 A

1 n/c contact for Error message, make/break capability of contact, AC: 250 V/5A, DC: 110 V/0.4 A

Tests

Class 1 protection as per IEC 60536

Pollution degree 2 as defined in IEC report 664-1

Overvoltage category III as defined in IEC report 664-1

EMC Directive 89/336 EEC

Low Voltage Directive 72/23 EEC

MTeC A4 zusgestellt Englisch

10.02.2005

13:35 Uhr

Seite 7

MTeC-EPT202 the all-rounder

MTOST160 und MTOSTF 160

(optional)

Transformer

CT

phase1

CT

phase 3

CT

phase 2

Oil temperature

(optional)

Oil level

Oil level

OLTCILTC

tank

MTOSTF160TT

Cooling control

Sensor

MT-ST160SK-TT

Pt100

TT-PWM60

Combi well

Analog input

Analog input

RS485

Control cabinet

Digital

output

RS232

Analog output

oil temperature,

winding temperature

Control room

Signal contacts

alarm, error,

trip

Analog output

oil levels

C

150

100

50

D1272

PQ 96

EI100

operations center

SCADA

system

Signalling lamp

D1272

EI100

MTeC A4 zusgestellt Englisch

www.messko.de

10.02.2005

Messko GmbH 2005

Gablonzer Strasse 2527

61440 Oberursel, Germany

13:35 Uhr

Seite 8

Phone +49 (0)61 71 63 98-0

Fax +49 (0)61 71 63 98-98

info@messko.de

Messko

Please note: Certain aspects of the equipment delivered may differ

from the information given in any of our publications. Subject to changes.

IN 2075/01en 0105/2000 2075/01/2000 Art. no. 990912

Printed in Germany Messko/Usa

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Meter - EIG Shark 50 - 100 - 100B - ManualDocument194 pagesMeter - EIG Shark 50 - 100 - 100B - ManualryinejanNo ratings yet

- The Types of ManagersDocument4 pagesThe Types of ManagersryinejanNo ratings yet

- Transistor Test Using An Analogue Multi MeterDocument3 pagesTransistor Test Using An Analogue Multi MeterryinejanNo ratings yet

- Transistor CasingDocument2 pagesTransistor CasingryinejanNo ratings yet

- Open Methods: by Lale Yurttas, Texas A&M University 1Document24 pagesOpen Methods: by Lale Yurttas, Texas A&M University 1ryinejanNo ratings yet

- Fixed Point IterationDocument19 pagesFixed Point IterationryinejanNo ratings yet

- Chap 06 of Numerical Methods For Engineers by Chapra and CanaleDocument53 pagesChap 06 of Numerical Methods For Engineers by Chapra and CanaleryinejanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 002.structured Cabling-Training DocumentsDocument18 pages002.structured Cabling-Training DocumentsSathiya Priya NatrajNo ratings yet

- LC8635 XX CDocument17 pagesLC8635 XX CFagh AbdoulNo ratings yet

- Galleon II: 1KVA/1.5KVA/2KVA/3KVADocument2 pagesGalleon II: 1KVA/1.5KVA/2KVA/3KVAWil LiamNo ratings yet

- Lecture 2 - Digital TelevisionDocument40 pagesLecture 2 - Digital TelevisionGerald Emmanuel100% (1)

- Electrical BtechDocument27 pagesElectrical BtechNikhil AnandNo ratings yet

- Mod 3Document69 pagesMod 3nishasaiyed2304No ratings yet

- Mi TV Tigo PDFDocument21 pagesMi TV Tigo PDFGiuseppe OspinaNo ratings yet

- Lecture05 Ee620 Charge PumpsDocument22 pagesLecture05 Ee620 Charge PumpsPeygamberinizi Sikiyim100% (1)

- Final Year Project - Viva PresentationDocument23 pagesFinal Year Project - Viva PresentationMalik SaifulNo ratings yet

- ECE 198 JL Worksheet 8: Storage Elements: Random Access MemoryDocument6 pagesECE 198 JL Worksheet 8: Storage Elements: Random Access MemoryShengyuan ZhongNo ratings yet

- Test 1 2021 Sem2Document7 pagesTest 1 2021 Sem2Zahid ElectronNo ratings yet

- ITU-T K.70, Series K, Protection Against Interference, Human Exposure To EMF, 2007Document56 pagesITU-T K.70, Series K, Protection Against Interference, Human Exposure To EMF, 2007locusstandi84No ratings yet

- Tesla CoilsDocument31 pagesTesla CoilsBhavish ParkalaNo ratings yet

- LG Flatron w1642c Chassis Lm73bDocument25 pagesLG Flatron w1642c Chassis Lm73bRonan NolascoNo ratings yet

- Service News: AudioDocument2 pagesService News: Audioprashantbabu7780No ratings yet

- KA7630/KA7631: Fixed Multi-Output RegulatorDocument6 pagesKA7630/KA7631: Fixed Multi-Output RegulatorTecnico GenioNo ratings yet

- GSLC Week 3 Tour de France PDFDocument5 pagesGSLC Week 3 Tour de France PDFDerian WijayaNo ratings yet

- Ltrarc 3500Document91 pagesLtrarc 3500Daniel VieceliNo ratings yet

- Rain AlarmDocument3 pagesRain AlarmSebastin AshokNo ratings yet

- The Mumbai Suburban Railway Smart CardDocument17 pagesThe Mumbai Suburban Railway Smart Cardrsmbgss575No ratings yet

- New Microsoft Word DocumentDocument22 pagesNew Microsoft Word Documentrishi_2009joshiNo ratings yet

- AV Receiver With Digital Amplifier Technology STR-DA5000ES, STR-DA3000ES, STR-DA2000ES Diagnostics and TDocument54 pagesAV Receiver With Digital Amplifier Technology STR-DA5000ES, STR-DA3000ES, STR-DA2000ES Diagnostics and TTeleramaNo ratings yet

- Crystal Units: AT-41 / AT-41CD2Document1 pageCrystal Units: AT-41 / AT-41CD2mohamedNo ratings yet

- Navigation InstrumentsDocument14 pagesNavigation InstrumentsJabez RichardsNo ratings yet

- Diodo 1 - 5ke100ca 3078726Document13 pagesDiodo 1 - 5ke100ca 3078726mario avila sanchezNo ratings yet

- Build your own Arduino oscilloscopeDocument4 pagesBuild your own Arduino oscilloscopeRodolfoPerezEscalonaNo ratings yet

- 21% Lebih Cepat Dari Ram 4GB: Bisa Upgrade Memory, Tersedia 1 Slot Bisa Upgrade Memory, Tersedia 1 SlotDocument12 pages21% Lebih Cepat Dari Ram 4GB: Bisa Upgrade Memory, Tersedia 1 Slot Bisa Upgrade Memory, Tersedia 1 SlotrendraNo ratings yet

- Profibus-Dp: Installation ManualDocument38 pagesProfibus-Dp: Installation ManualLeandroNo ratings yet

- AD-850 Cassette Deck/CD Player Owner's ManualDocument128 pagesAD-850 Cassette Deck/CD Player Owner's ManualJulio DinisNo ratings yet

- Data Center Isolated Parallel Ring Bus Differential Protection SchemeDocument6 pagesData Center Isolated Parallel Ring Bus Differential Protection Schemew.lin.gs.1888No ratings yet