Professional Documents

Culture Documents

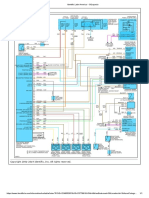

Esquema Hidraulico 777 F

Uploaded by

Gustavo Ramos ContrerasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esquema Hidraulico 777 F

Uploaded by

Gustavo Ramos ContrerasCopyright:

Available Formats

RENR8305-01

December 2008

Component Locations (Volume 1)

Item

Number

1

2A

2B

3

4A

4B

5

6

7

8

9

10

11A

11B

12

13

14

15

16

17

18

19

20

21

22

23

24

26

27

28

29

35

47

54

58

59

Part

Number

258-9852

255-5478

256-0561

255-5478

255-5478

256-0561

257-0273

289-0585

222-4744

205-0557

8X-7921

243-5545

8X-3810

243-5551

261-1316

249-5521

3E-7806

230-2637

3G-2887

228-7839

8X-4575

160-2609

220-5692

261-1317

245-1668

171-1232

8X-7224

7J-3723

6E-6640

141-4109

155-6061

230-2637

7J-0725

230-2637

185-4026

8J-6875

Description

TANK GP (HYD & TRANS)

PUMP GP (BRAKE CHARGING)

PUMP GP (BRAKE CHARGING)

PUMP GP (BRAKE COOLING)

PUMP GP (HOIST)

PUMP GP (HOIST)

VALVE GP- ACCUMULATOR CHARGING

VALVE GP-MTG & (PARKING BRAKE)

CONTROL GP-HYD (BRAKE RETRACT)

ADJUSTER GP- SLACK

ADJUSTER GP-SLACK

BRAKE GP-SERVICE & PARK

BRAKE GP-SERVICE (FRONT BRAKES)

BRAKE GP-SERVICE (FRONT BRAKES)

VALVE GP (CAB MANIFOLD)

VALVE GP-CHECK

SWITCH AS.- PRESSURE

PUMP GP-ELECTRIC (BRAKE RETRACT)

VALVE GP-DIVERTER

VALVE GP-RELIEF

FILTER (BREATHER)

SWITCH AS.-PRESSURE

ACCUMULATOR GP (BRAKE)

PEDAL GP-BRAKE VALVE

VALVE GP-CONTROL (HOIST)

CYLINDER GP-TELESCOPING (HOIST)

PLATE-ORIFICE (HOIST)

SCREEN AS.

SCREEN AS. (BRAKE COOLING)

CORE AS.-OIL COOLER

FILTER GP-OIL

PUMP GP-ELECTRIC (STEERING)

SCREEN AS.

PUMP GP-ELECTRIC (ENGINE OIL)

VALVE GP-CHECK

VALVE AS.-SHUTTLE

Schematic

Location

FLUID POWER SYMBOLS

BASIC COMPONENT SYMBOLS

A-4

MAIN AUX.

B-5

19 6

B-4

B-4

24 23 47 26 1

18

29

5 14 20

21

B-4

PUMP or MOTOR

11

16 17

B-4

LINE RESTRICTION

(FIXED)

RESTRICTION

PRESSURE

COMPENSATION

LINE RESTRICTION

(VARIABLE)

SPRING

(ADJUSTABLE)

VARIABILITY

CONTROL VALVES

SPRING

FLUID CONDITIONER

PUMP: VARIABLE and

PRESSURE COMPENSATED

2-SECTION PUMP

HYDRAULIC

PNEUMATIC

ENERGY TRIANGLES

ATTACHMENT

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

D-5

VALVES

F-6

VALVE ENVELOPES

D-7

VALVE PORTS

10

D-8

D-2

TWO POSITION

ONE POSITION

B-8, F-8

D-1, F-1

D-5

E-6

P T

SHIFTED POSITION

P T

NORMAL POSITION

CAB

E-4

INFINITE POSITION

SHUTTLE

SPRING

LOADED

BASIC

SYMBOL

MEASUREMENT

12 14

E-5

CHECK VALVES

AB

AB

F-4

FOUR-WAY

THREE-WAY

CONTROL VALVES

D-1, F-1

E-4

TWO-WAY

THREE POSITION

PILOT

CONTROLLED

ROTATING SHAFTS

A-6

PRESSURE

F-6

FLOW

TEMPERATURE

E-5

B-3, C-3, D-3

BIDIRECTIONAL

FLUID STORAGE RESERVOIRS

F-3

UNIDIRECTIONAL

777F and 777F OEM Off-Highway Truck

Hydraulic System

15 35 54

A-3

A-3

A-4

58

B-6, C-7

B-6, C-7

777F:

JRP1-UP

C-5

D-6

A-5

VENTED

RETURN ABOVE FLUID LEVEL

PRESSURIZED

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

777F OEM:

JXP1-UP

SOLENOID

SOLENOID

or MANUAL

D-5

SERVO

SOLENOID and

PILOT or MANUAL

SOLENOID

and PILOT

DETENT

THERMAL

MANUAL CONTROL SYMBOLS

E-5

E-3

MANUAL SHUTOFF

PUSH-PULL LEVER

GENERAL MANUAL

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

Tap Locations

Pressure, Sampling, and Sensor (Volume 1)

EXTERNAL RETURN

INTERNAL RETURN

SIMPLIFIED

INTERNAL

SUPPLY PRESSURE

COMPLETE

F-8

CROSSING AND JOINING LINES

ACCUMULATORS

B-8

HYDRAULIC AND PNEUMATIC CYLINDERS

D-8

F-4

SPRING LOADED

D-4

D-4

GAS CHARGED

LINES CROSSING

HYDRAULIC PUMPS

D-7

24 23

C-7

E-1

59

11

22

FIXED

DISPLACEMENT

LINES JOINING

SINGLE ACTING

INTERNAL PASSAGEWAYS

HYDRAULIC MOTORS

VARIABLE DISPLACEMENT

NON-COMPENSATED

FIXED

DISPLACEMENT

DOUBLE ACTING

VARIABLE DISPLACEMENT

NON-COMPENSATED

TWO

POSITION

THREE

POSITION

INFINITE

POSITIONING

E-1

A-3

UNIDIRECTIONAL

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

A-3

C-4

D-3

B-7

CROSS

FLOW

PARALLEL

FLOW

Printed in U.S.A.

2008 Caterpillar

All Rights Reserved

Electrical Symbols Table

4A 4B

4A 4B

2A 2B

Hydraulic Symbols (Electrical)

G

Transducer

(Fluid)

Transducer

(Gas / Air)

Pressure Switch

(Adjustable)

Pressure Switch

Generator

Electric Motor

Electrical Wire

Temperature Switch

29

Electrical Symbols (Electrical)

The brake system filter (29) is located on the left outer frame rear next to the left rear strut mount.

The brake system filter has a bypass switch.

Shown in the visual is the new location of the hoist pump (4A, 4B). The hoist pump is

a gear type pump and is attached to the brake cooling pump (3) and the brake charging pump (2A, 2B). The hoist pump is now driven by the gears at the back of the

engine.

Shown in the visual is the new location of the hoist pump (4A, 4B).

Pressure

Symbol

Temperature

Symbol

Flow

Symbol

Level

Symbol

Wire Number Identification Codes

Electrical Schematic Example

Hydraulic Schematic Example

Current Standard

Current Standard

Pressure Switch

Harness identification code

This example indicates

wire 135 in harness "AG".

Wire

Circuit Number

Identification

22

Wire Color

325-AG135 PK-14

325-PK

Circuit Identification

Number

The 777F has two slack adjusters. The top visual is of the rear slack adjuster (8). The rear slack adjuster is

located above the rear differential. The slack adjuster maintains a consistent feel and application of the brakes

as the brake discs wear.

20

Wire Color

Wire Gauge

Previous Standard

Shown in the visual are the three brake accumulators for the 777F. The accumulators

(20) are charged by the brake charging pump and supply the required oil flow to

disengage the front and rear brakes. The outer accumulators are for the rear service

brakes. The middle accumulator is for the parking brake and front service brakes.

Parking Brake Solenoid

The lower visual is of the front slack adjuster (9). The front slack adjuster is located on the left strut frame

support. The slack adjuster maintains a consistent feel and application of the brakes as the brake discs wear.

325-PK-14

Relief Valve

The accumulator charging valve (5) is located on the left side of the frame by the brake accumulators This valve

directs oil to the brake accumulators, brake cooling, and the tank. Once the accumulators are charged, the

excess oil flow is sent to cool the brakes before returning to the tank.

Wire Color

Wire

17

B

Circuit Number

Identification

16

Wire Gauge

(EXAMPLE VALVE)

Shown in the visual is the new location of the hoist control valve (22). The valve (22) is located behind the engine on

the right side of the frame. The valve (22) will function the same as the hoist control valve on the 777D.

The Brake ECM monitors the pressure in the service brake accumulators with pressure switch. If the pressure

in the service brake accumulators are low, the pressure switch will open and the Brake ECM will signal the

monitoring system to turn on the brake system-check indicator.

Pressure tap (B) is used to check the oil pressure in the service brake accumulators. Pressure tap (F) is used

to check the charge oil pressure from the pump.

Purge Solenoid

The accumulator charging valve contains a CUT-IN/CUT-OUT spool. Once the maximum brake system

pressure is reached, the spool will shift and send the excess flow to brake cooling. As the system pressure

continues to drop to the CUT-IN pressure setting, the spool will shift again and the system will charge to the

CUT-OUT pressure setting. This process will continue to repeat as often as needed to keep the brake system

fully charged. The CUT-IN/CUT-OUT pressure is checked at pressure tap (B).

The relief valve setting is set slightly higher than the CUT-OUT pressure setting. In the event that the

CUT-IN/CUT-OUT valve spool fails, the relief valve will protect the system from extreme pressure. Relief valve

can only be tested on a hydraulic test bench.

If the charge oil pressure is low at pressure tap (F), or the brake system never reaches the proper CUT-OUT

pressure, check relief valve. If relief valve is set properly and the brake system is not reaching the specified

CUT-OUT pressure, replace the accumulator charging valve. The CUT-IN/CUT-OUT spool is not adjustable.

Shown in this visual is the diverter (towing) valve (16) for the 777F. The diverter valve functions the

same however has changed locations. The diverter valve for the 777F is now located on the left

frame rail in front of the left front strut. The diverter valve must be manually shifted before towing.

Once the valve is shifted, oil flow from the electric secondary pump is directed to the parking brake

valve to release the parking brake. The relief valve (17) limits the maximum pressure when using

the towing pump.

This visual shows the parking brake valve (6) for the 777F which is located on the

inside left frame rail behind the middle cross member. The parking brake release

valve no longer works off pressurized air. This valve receives oil flow from the parking

brake accumulator. Contained within the valve is a parking brake solenoid valve (3)

and a purge solenoid valve (4).

Shown in the visual to the left are the pressure taps for the hoist control

valve. The pressure tap (N) checks the pilot pressure for the hoist lower

solenoid. The pressure tap (O) checks the pilot pressure of the raise

solenoid.

Shown in the visual to the right are the pressure taps for the hoist

cylinders. These pressure taps are located on the cross-tube between

the lower hoist cylinder mounts. The pressure tap (L) checks the

pressure of the cylinder lower circuit. The pressure tap (K) checks the

pressure of the cylinder raise circuit.

BRAKING

HOIST

(Dimensions: 39 inches x 28 inches)

A check valve in the circuit between the parking accumulator and the rear service

accumulators allows only the parking brake accumulator to be filled when using the

secondary electric pump.

FLOW ALLOWED IN

EITHER DIRECTION

Volume 1 of 2: Brakes and Hoist

COMPONENT LOCATIONS

B-3

FLOW IN ONE

DIRECTION

30 Page,

LEFT REAR SERVICE BRAKE

RIGHT REAR SERVICE BRAKE

REAR SLACK ADJUSTER INPUT

CAB MANIFOLD RESOLVER OUTPUT

ACCUMULATOR CHARGING OUTPUT

BRAKE CHARGING PUMP OUTPUT

LEFT PARK BRAKE

RIGHT PARK BRAKE

FRONT SLACK ADJUSTER INPUT

DRY FRONT BRAKE INPUT

CYLINDER HEAD END

CYLINDER ROD END

HOIST PUMP OUTPUT

HOIST VALVE RAISE PILOT

HOIST VALVE LOWER PILOT

BRAKE COOLING INPUT

27 28

10

Schematic

Location

Description

RENR8305-01 VOL 1 of 2

Tap

Number

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

REMOTE SUPPLY PRESSURE

14

10

21

12

DRY

WET

BLEEDDOWN

SOLENOID

A1

See Note A

PARK BRAKE

SOLENOID

LEFT REAR

19

LEFT

FRONT

3

P1

T1

11B

11A

LEFT

FRONT

ECM

16

17

P2

From Torque Converter

Lock-up Clutch Pilot

(Volume 2, F-3)

20

58

59

E

J

13

14

35

15

54

8

7

RAISE RELIEF

MAIN RELIEF

DUMP SPOOL

From Torque Converter

Lock-up Clutch.

(Volume 2, F-3)

9

5

DUAL STAGE

SIGNAL SPOOL

LOWER RELIEF

LOWER, FLOAT,

SNUB SOLENOID

ADJUSTER GP - SLACK

D

11A

RIGHT

FRONT

(Dimensions: 39 inches x 28 inches)

30 Page,

RENR8305-01 VOL 1 of 2

RIGHT

FRONT

11B

From Torque Converter

Lock-up Clutch. (Volume 2, E-2)

FRONT BRAKES

RAISE

From Torque Converter

(Volume 2, F-4)

29

HOLD

28

27

SNUB

FLOAT

28

LINE PATTERNS

BRAKE COOLING RELIEF

27

LOWER

2A

Pressure Line

4A

Pilot / Load Sensing Pressure

RIGHT REAR

See Note A

Drain / Return Lines

Component Group

2B

Attachment

4B

Air Line

10

See Note A

CALLOUTS

RAISE SOLENOID

18

YY

Taps (Pressure, Sampling,Sensor) by letter

52

Components by number

Note A: Dry brake configuration

22

K

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

ELECTRICAL CIRCUITS

BRAKE CHARGING CIRCUIT PUMP

HOIST CYLINDERS CIRCUIT

HOIST PUMP CIRCUIT

PUMP SUPPLY LINE

DRAIN / RETURN LINE

BRAKE COOLING

24 23

47

26

LOCK-UP CLUTCH VALVE PUMP CIRCUIT

BRAKE CIRCUIT (FRONT AND REAR)

THIS SCHEMATIC IS FOR THE 777F AND 777F OEM OFF-HIGHWAY TRUCK

PART #: 255-6188 CHG 04

Components are shown installed on a fully operable machine with the key and engine off and transmission

shifter in neutral.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

42

Component Locations (Volume 2)

Description

TANK GP (HYD & TRANS)

PUMP GP-ELECTRIC (BRAKE RETRACT)

FILTER (BREATHER)

FILTER GP-OIL

TANK GP-HYD (STEERING)

PUMP GP-PISTON (STEERING)

VALVE GP-CHECK (STEERING)

PUMP GP-METERING (STEERING)

CYLINDER GP-(STEERING)

PUMP GP-ELECTRIC (STEERING)

SWITCH AS.- PRESSURE

SWITCH AS.- PRESSURE

FILTER GP-OIL (STEERING)

FILTER GP-HYD (STEERING)

VALVE-BREAKER RELIEF

PUMP GP-GEAR (TORQUE CONV. SCAVENGE)

FILTER GP

VALVE GP-MODULATING

FILTER GP-OIL

FILTER GP-OIL

SWITCH AS.-LIQUID LEVEL

SCREEN AS.

CONVERTER GP-TORQUE

VALVE GP-RELIEF

PUMP GP-GEAR (TORQUE CONV. CHARGE)

PUMP GP-GEAR (LOCK-UP CLUTCH VALVE PILOT)

PUMP GP-GEAR (TRANSMISSION SCAVENGE)

PUMP GP-GEAR (TRANSMISSION CHARGING)

PUMP GP-ELECTRIC (ENGINE OIL)

VALVE GP-RELIEF

CORE GP- OIL COOLER

VALVE GP-CHECK

VALVE GP-RELIEF

VALVE GP-MTG &

Part

Number

258-9852

230-2637

8X-4575

249-2306

249-2925

261-5630

175-7050

195-6617

105-2440

230-2637

3E-6450

9X-4455

173-0159

249-2334

9T-0818

256-6123

4T-4760

244-3114

244-0121

270-5181

172-8660

7J-0725

249-5539

3P-0349

256-6123

256-6123

256-6123

256-6123

230-2637

3P-0348

4W-5056

268-3451

268-3998

277-8869

Schematic

Location

FLUID POWER SYMBOLS

BASIC COMPONENT SYMBOLS

C-4

MAIN AUX.

D-6

PUMP or MOTOR

CONTROL VALVES

SPRING

FLUID CONDITIONER

LINE RESTRICTION

(FIXED)

RESTRICTION

C-4

PUMP: VARIABLE and

PRESSURE COMPENSATED

2-SECTION PUMP

D-2

A-7

B-6

E-7

PRESSURE

COMPENSATION

LINE RESTRICTION

(VARIABLE)

SPRING

(ADJUSTABLE)

VARIABILITY

HYDRAULIC

PNEUMATIC

ENERGY TRIANGLES

ATTACHMENT

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

VALVES

E-7

VALVE ENVELOPES

F-7

VALVE PORTS

SOS

D-6

D-8

TWO POSITION

ONE POSITION

TWO-WAY

THREE POSITION

FOUR-WAY

THREE-WAY

E-6

Shown in this visual is the 777F torque converter charging filter (42). The charging filter is located on the

right frame rail, behind the right front tire. The SOS port is located on the torque converter filter. SOS Port

draws a sample from the outlet of the filter.

B-7

C-8

B-5

CONTROL VALVES

P T

SHIFTED POSITION

P T

NORMAL POSITION

D-3

D-3

CHECK VALVES

AB

AB

This view shows the torque converter lockup clutch filter. Port (X) is an SOS port. Port (T) is a pressure tap.

The pressure indicated at tap (T) is pump pressure for the lockup clutch pilot circuit.

E-3

INFINITE POSITION

SHUTTLE

SPRING

LOADED

BASIC

SYMBOL

MEASUREMENT

PILOT

CONTROLLED

ROTATING SHAFTS

F-3

F-3

B-2

PRESSURE

C-2

FLOW

TEMPERATURE

D-4

UNIDIRECTIONAL

BIDIRECTIONAL

FLUID STORAGE RESERVOIRS

F-4

D-3

777F and 777F OEM Off-Highway Truck

Hydraulic System

D-3

D-2

D-2

D-5

C-3

44

45

C-2

45

777F:

JRP1-UP

44

C-2

E-2

777F OEM:

JXP1-UP

VENTED

RETURN ABOVE FLUID LEVEL

PRESSURIZED

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

SOLENOID

SOLENOID

or MANUAL

C-8

SERVO

SOLENOID and

PILOT or MANUAL

SOLENOID

and PILOT

DETENT

THERMAL

MANUAL CONTROL SYMBOLS

Shown in the left visual is the 777F transmission charge filters. The 777F has two filters mounted on the

cross member on the right side of the machine. Port (U) is an SOS port. Port (Y) is a pressure tap. The

pressure indicated at tap (Y) is charge pressure for the transmission control valves. The rear filter housing

also has a bypass switch. The bypass switch provides an input signal to the Caterpillar Monitoring System,

which informs the operator if the filter is restricted.

MANUAL SHUTOFF

PUSH-PULL LEVER

GENERAL MANUAL

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

Shown in the this visual is pressure tap (S) for the lockup clutch valve and pressure tap (V) for the outlet

relief valve. The pressure indicated at tap (S) is the pressure in the lockup clutch. The pressure indicated

at tap (V) is the pressure inside the torque converter.

53

Tap Locations

Pressure, Sampling, and Sensor (Volume 2)

51

50

41

EXTERNAL RETURN

HMU INPUT

STEERING LOAD SENSE PILOT

LOCK-UP CLUTCH

LOCK-UP CLUTCH FILTER OUTPUT

TRANS CHARGE FILTER OUTPUT

TORQUE CONVERTER OUTLET RELIEF VALVE

SOS

SOS

TRANSMISSION CHARGE PRESSURE

SIMPLIFIED

CROSSING AND JOINING LINES

ACCUMULATORS

Schematic

Location

Description

INTERNAL RETURN

E-7

SPRING LOADED

GAS CHARGED

LINES CROSSING

INTERNAL

SUPPLY PRESSURE

COMPLETE

HYDRAULIC AND PNEUMATIC CYLINDERS

LINES JOINING

SINGLE ACTING

DOUBLE ACTING

D-8

E-3

HYDRAULIC PUMPS

D-3

F-3

FIXED

DISPLACEMENT

F-4

C-8

INTERNAL PASSAGEWAYS

HYDRAULIC MOTORS

VARIABLE DISPLACEMENT

NON-COMPENSATED

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

TWO

POSITION

THREE

POSITION

INFINITE

POSITIONING

D-2

E-2

FLOW IN ONE

DIRECTION

PARALLEL

FLOW

CROSS

FLOW

FLOW ALLOWED IN

EITHER DIRECTION

Volume 2 of 2: Steering and Power Train

55

Printed in U.S.A.

2008 Caterpillar

All Rights Reserved

49

43

NOTE: The taps shown in this visual

do not appear on the schematic.

Electrical Symbols Table

Hydraulic Symbols (Electrical)

Torque converter scavenge (41)

Torque converter charge (50)

Lockup clutch valve pilot circuit (51)

Transmission scavenge (52)

Transmission charge (53)

Shown in the lower visual are some of the torque converter system components for the 777F. The torque

converter systems are similar between the 777D and 777F. The torque converter inlet relief valve (55) and

the outlet relief valve (49) will function the same. The lockup clutch valve (43) on the 777F is now an ECPC

valve.

31

Shown in this visual is the 777F ECPC transmission. This new transmission has pressure taps located

on the outside of the transmission. This feature will aid in preventing contamination from entering the

transmission as well as saving time when checking the pressures on the 777F transmission.

Lube oil pressure can be checked at tap (3).

System pressure can be checked at tap (4).

Clutch 6 pressure can be checked at tap (5).

Clutch 5 pressure can be checked at tap (6).

Clutch 7 pressure can be checked at tap (7).

G

Transducer

(Fluid)

Clutch 4 pressure can be checked at tap (8).

Clutch 3 pressure can be checked at tap (9).

Clutch 2 pressure can be checked at tap (10).

Clutch 1 pressure can be checked at tap (11).

Transducer

(Gas / Air)

POWER TRAIN

Shown in this visual is the steering pump (31) for the 777F. The steering pump is now mounted on the back of the new C32

ACERT engine. The steering pump is still a load sensing, pressure compensated, piston-type pump

47 46 26 1

59

18

25

60

41 50 51 52 53 57

34

Generator

Pressure Switch

(Adjustable)

Pressure Switch

M

Electric Motor

Electrical Wire

Temperature Switch

Electrical Symbols (Electrical)

15 35 37 54

Pressure

Symbol

Steering Disable

Solenoid

Flow

Symbol

Level

Symbol

Temperature

Symbol

Relief Valve

Wire Number Identification Codes

33

Electrical Schematic Example

Hydraulic Schematic Example

Current Standard

Current Standard

55 49 48 43

Harness identification code

This example indicates

wire 135 in harness "AG".

61

CAB

56

Wire

Circuit Number

Identification

32

Wire Color

325-AG135 PK-14

325-PK

Circuit Identification

Number

34

Wire Color

Previous Standard

Wire Color

Wire

Shown in this visual is the steering valve (32) for the 777F. The 777F uses the same steering valve as the 777D. The steering

valve is located in the same place however the steering valve is mounted differently. The pressure tap (Q) checks the pressure

in the supply line to the HMU. If the supply oil pressure to the HMU is below specification, the relief valve

many need to be adjusted.

The steering disable valve (61) is located behind the shock on the right frame rail. When the steering disable solenoid valve is

energized, the flow from the steering to the steering valve is blocked by the steering disable valve (61). This allows servicing

behind the

Shown in the visual to the left is the electric

secondary steering pump (35) on the 777F. The

pump and motor are the same as the 777D

however the location has changed. The pump and

motor are now located on the front crossmember.

The secondary pressure switch (36) is also

mounted next to the secondary steering pump.

The pressure switch (36) detects if the wheels are

being turned via the steering wheel when secondary steering is applied. When the wheel is turned

in a secondary steering condition, the pressure

switch (36) will signal the Transmission/Chassis

ECM and the QuickEvac function will be disabled.

44

45

31

42

40 39 38 30

32 36

325-PK-14

B

Circuit Number

Identification

36

STEERING SYSTEM

Wire Gauge

Shown in the visual to the right is the 777F

steering system tank. The tank is located on the

right platform. The 777F steering tank functions

the same as the the 777D steering tank.

61

35

COMPONENT LOCATIONS

Wire Gauge

(EXAMPLE VALVE)

30

(Dimensions: 39 inches x 28 inches)

Shown in the top visual is the new five section gear pump. The gear pump is a different design then the

previous 777D. The gear pumps are for the following circuits:

30 Page,

Tap

Number

Q

R

S

T

U

V

W

X

Y

52

REMOTE SUPPLY PRESSURE

RENR8305-01 VOL 2 of 2

Item

Number

1

15

18

25

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

60

61

RENR8305-01

December 2008

TO BRAKE

COOLING

To Traction Control Valve

34

49

To Hoist Pilot

Signal Resolver

44 45

33

U

To Rockford Fan

Clutch Control

(Attachment)

37

43

LOCK UP

VALVE

32

15

60

T

TORQUE

CONVERTER

M

D

TO BRAKE

COOLING

LOCK-UP CLUTCH

PRESSURE

54

36

25

42

X

D

HYDRAULIC

CONTROLS

35

51

52

53

TRANSMISSION

48

(Dimensions: 39 inches x 28 inches)

30 Page,

RENR8305-01 VOL 2 of 2

ECM

18

55

41

C

C

56

50

57

1

W

61

31

26

POWERTRAIN:

TRANSMISSION AND TORQUE CONVERTER

40

39

46

47

38

30

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

ELECTRICAL CIRCUITS

TRANSMISSION AND TORQUE CONVERTER SCAVENGE PUMP CIRCUIT

LINE PATTERNS

PUMP SUPPLY LINE

DRAIN / RETURN LINE

BRAKE COOLING

Pressure Line

Pilot / Load Sensing Pressure

STEERING PUMP CIRCUIT

Drain / Return Lines

SECONDARY STEERING PUMP CIRCUIT

TRANSMISSION CHARGE PUMP CIRCUIT

LOCK-UP CLUTCH VALVE PUMP CIRCUIT

Component Group

Attachment

TORQUE CONVERTER CHARGE PUMP CIRCUIT

Air Line

CALLOUTS

LOAD SENSE STEERING SYSTEM

YY

52

Taps (Pressure, Sampling,Sensor) by letter

Components by number

THIS SCHEMATIC IS FOR THE 777F AND 777F OEM OFF-HIGHWAY TRUCK

PART #: 255-6188 CHG 04

Components are shown installed on a fully operable machine with the key and engine off and

transmission shifter in neutral.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Torqueflite A727 - A904Document79 pagesTorqueflite A727 - A904Jonny Eriksson83% (6)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Raptor 55 XP English Rev. 160606Document4 pagesRaptor 55 XP English Rev. 160606Fabio OliveiraNo ratings yet

- Lecture 11 Vector Control of Induction MotorDocument43 pagesLecture 11 Vector Control of Induction MotorNaveen Reddy100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Standard Equipment: Hydraulic ExcavatorsDocument8 pagesStandard Equipment: Hydraulic Excavatorsvitor santosNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Perbandingan Kecepatan Innova AT MT BensinDocument4 pagesPerbandingan Kecepatan Innova AT MT Bensindianto pwNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- MTech Autotronics SyllabusDocument1 pageMTech Autotronics SyllabusAnand Raj0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Aermacchi MB-339Document10 pagesAermacchi MB-339Marcelo José de SouzaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Mitsubishi Colt Electrical DiagramsDocument82 pagesMitsubishi Colt Electrical DiagramsVideoSurv Synology60% (5)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Diagrama 1 ABS 1 FUSEDocument1 pageDiagrama 1 ABS 1 FUSEaltechNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- P0770 Shift Solenoid E MalfunctionDocument2 pagesP0770 Shift Solenoid E MalfunctionwilfredoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hyundai Venue-N-Line-BrochureDocument10 pagesHyundai Venue-N-Line-BrochureRasakNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Troubleshooting (Musso & Korando)Document23 pagesTroubleshooting (Musso & Korando)francisca19100% (1)

- Activa 7gDocument4 pagesActiva 7gMegha MukherjeeNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Wheel Alignment JosamDocument4 pagesWheel Alignment JosamDeepak Kumar RautNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- SB66JRT English Hoogwerker Aerial Lift SnorkelDocument2 pagesSB66JRT English Hoogwerker Aerial Lift Snorkelhoogwerker0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- How To Repair A BicycleDocument1 pageHow To Repair A BicycleVictor J TorresNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- RIDE66 Manual Control Panel S866Document5 pagesRIDE66 Manual Control Panel S866jrcengeNo ratings yet

- Cat C15Document6 pagesCat C15Y.Ebadi100% (1)

- Corolla Cross 1.8 Hev (Auto) : Model Code: ZVG10Document4 pagesCorolla Cross 1.8 Hev (Auto) : Model Code: ZVG10ICTLAB SKLUNo ratings yet

- Hyundai Tucson Specifications SheetDocument5 pagesHyundai Tucson Specifications SheetMark MancqNo ratings yet

- PACCAR Medium Duty EnginesDocument2 pagesPACCAR Medium Duty EnginesGerardo Carmona80% (10)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 23 BulldozerDocument2 pages23 BulldozerRadhe shyam prasadNo ratings yet

- 3K 4K Troubleshooting Manual WTEC IIIDocument442 pages3K 4K Troubleshooting Manual WTEC IIIMuhammad Fahmi Mahmud80% (5)

- 5-12-04 Inspection Phase 4Document2 pages5-12-04 Inspection Phase 4Lady Laura Sierra RuizNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Faq On Law Enforcement and Traffic Adjudication System (Letas)Document16 pagesFaq On Law Enforcement and Traffic Adjudication System (Letas)glaiNo ratings yet

- Basic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseDocument121 pagesBasic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseMarian VasileNo ratings yet

- Concrete Mixer Truck, HDJ5380GJBHI (HINO 10m3)Document1 pageConcrete Mixer Truck, HDJ5380GJBHI (HINO 10m3)tachmidNo ratings yet

- Tuning Dyno Nfsu2 (De Um Tanto de Carro)Document5 pagesTuning Dyno Nfsu2 (De Um Tanto de Carro)kexada12100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Unit 1 For StudentsDocument6 pagesUnit 1 For StudentsІрина БлятникNo ratings yet

- PV776 TSP130751 1Document4 pagesPV776 TSP130751 1Benjamin Miranda FloresNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)