Professional Documents

Culture Documents

Homework #1 Due: Beginning of Class Tuesday, January 13

Uploaded by

Kevin BriceOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Homework #1 Due: Beginning of Class Tuesday, January 13

Uploaded by

Kevin BriceCopyright:

Available Formats

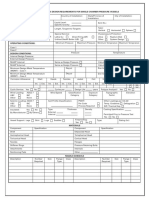

IME 450 Manufacturing Process and Tool Engineering Winter 2015

Homework #1

Due: Beginning of class Tuesday, January 13.

Refer to notes and Chapters 3, 4, 6, 13, and 26 in Groover 5th ed. to answer the following

questions using a separate sheet of paper.

1.

2.

3.

4.

5.

6.

7.

8.

9.

See Section 26.2 (and internet sources) and read about ferrite, cementite,

austenite, bainite, pearlite, and martensite:

a) What is the composition and microstructure of ferrite?

b) Which form is unstable at room temperature (i.e., exists only at high

temps)?

c) Which form of steel is the hardest?

d) Which is not really steel but a ceramic carbide compound?

e) Which form has a Body Centered Tetragonal (BCT) structure?

f) Which is a form of steel produced with the slowest cooling rate?

g) What cooling strategy produces a needle or feather-like mixture of ferrite

and Fe3C?

See section 6.2 (or internet sources) and explain the primary compositional

difference between type 440 and type 430 stainless steel, and state how it

affects the general processing and properties of these two.

Use the density of tin at room temperature (20oC) given in Table 4.1 in the text

to estimate its density at 230oC, just prior to melting. Note that the coefficient

for thermal expansion is defined for linear dimensions only.

Use Table 4.2 to determine the amount of energy (J) needed to raise the

temperature of a plate of tin as in the previous problem. Assume the plate is

inch thick and measures 6 x 10 inches.

Use the internet to find the heat of fusion for tin and give the total energy (J)

required to melt (from room temperature) the tin plate in the previous

problem. Also determine how long it would take with a 90% efficient, 10

kilowatt furnace.

List at least five elemental metals that could be cast in an iron (steel) die

casting mold. See Chapter 4 and/or 6.

Consider 7075-T4 aluminum in Section 6.3.

a) What is the major alloying element in this type of aluminum?

b) What kind of strengthening (tempering) treatment has been applied?

c) How does its strength compare to typical aluminums (e.g. 6061-T6)? Note

that our mold blocks will be made of this alloy.

Degree of Polymerization of a polymer is the average number of monomer

chains in each molecule (see 8.1). How does the Degree of Polymerization

affect the strength properties and processing characteristics for the polymer?

Consider the discussion of linear, branched, or cross-linked polymers in

sections 8.1.2 and 8.1.3.

a) Which general types of polymers form a cross-linked structure?

b) Which type of structure tends to form crystals: linear, branched, or crosslinked?

c) Which type of stereoregularity (i.e., tactic arrangements) tends to form the

most crystalline structure?

(continued on reverse)

IME 450 Manufacturing Process and Tool Engineering Winter 2015

10.

11.

12.

13.

14.

15.

Two different polypropylene blends have been used in the lab for molding.

One is described as highly crystalline (96%), while the other has a low crystal

structure (45%). How would you expect these two polymers to behave

differently

a) during molding (i.e. considering melting temperature, viscosity)?

b) as functional parts (i.e., considering density, strength, stiffness, thermal

resistance, opacity)?

Consider thermoplastic polystyrene as described in Chapter 8 Section 8.2:

a) What is its chemical formulation?

b) What engineering components or applications is it used for?

c) What is its density and stiffness? Is it clear?

d) What are its glass transition and melting temperatures?

e) Compare its strength to HDPE and polypropylene.

From Section 13.1, explain what makes a fluid a Newtonian fluid and describe

how typical polymer melts differ from Newtonian fluids.

Problem 3.30 on page 81 in Groover 5th ed.

Problems 6.5 on page 158 in Groover 5th ed.

Problem 6.6 on page 158 in Groover 5th ed.

(continued on reverse)

You might also like

- 4 Me MQ EMMDocument2 pages4 Me MQ EMMBIBIN CHIDAMBARANATHANNo ratings yet

- Unit 1: 13 Marks Questions: Anna University QuestionsDocument4 pagesUnit 1: 13 Marks Questions: Anna University Questions10BShalini.B IgmmNo ratings yet

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsFrom EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNo ratings yet

- Me6403 Engineering Materials and Metallurgy: Unit 1.alloys and Phase Diagram Part ADocument6 pagesMe6403 Engineering Materials and Metallurgy: Unit 1.alloys and Phase Diagram Part Ajamunaa83No ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- ME6403-Engineering Materials and Metallurgy PDFDocument10 pagesME6403-Engineering Materials and Metallurgy PDFRaviggg0% (1)

- ME6403-Engineering Materials and MetallurgyDocument10 pagesME6403-Engineering Materials and Metallurgykannan100% (1)

- CM7202-Applied Materials EngineeringDocument6 pagesCM7202-Applied Materials EngineeringJayaraman TamilvendhanNo ratings yet

- Previous Question Papers of Metallurgy and Material SciencesDocument10 pagesPrevious Question Papers of Metallurgy and Material SciencesRajeev SaiNo ratings yet

- ACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlDocument2 pagesACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlShine KunnathNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)P MithunNo ratings yet

- L-4/T-l/MME - Date: 17/02/2018Document12 pagesL-4/T-l/MME - Date: 17/02/2018Utsho DasNo ratings yet

- 18bem0046 Materials Da 2Document20 pages18bem0046 Materials Da 2QUANTUM SOLEOSNo ratings yet

- BF1113 Assignment 2Document2 pagesBF1113 Assignment 2sanasieNo ratings yet

- Sample Questions For Phase DiagramDocument5 pagesSample Questions For Phase DiagramMohaiminul Islam TalhaNo ratings yet

- MMS Nov08Document7 pagesMMS Nov08Kiran KancharlaNo ratings yet

- Mechanical Behaviour and Testing of MaterialsDocument5 pagesMechanical Behaviour and Testing of MaterialsSachi DhanandamNo ratings yet

- MF9211 Jan 2012Document3 pagesMF9211 Jan 2012pravi2010No ratings yet

- Tugas 01: Classification and Characteristics of SteelsDocument8 pagesTugas 01: Classification and Characteristics of SteelsAprian HidayatNo ratings yet

- Metallurgy Question Bank - Questions OnlyDocument6 pagesMetallurgy Question Bank - Questions OnlyMANYAM. HARI KRISHNA MECHANICAL ENGINEERINGNo ratings yet

- G. H. Raisoni College of Engineering, Nagpur: Mechanical Engineering Department Question BankDocument12 pagesG. H. Raisoni College of Engineering, Nagpur: Mechanical Engineering Department Question BankRaj PatelNo ratings yet

- 2Document2 pages2faizrummanNo ratings yet

- Engineering Materials and MetallurgyDocument11 pagesEngineering Materials and Metallurgyabdulhere4uNo ratings yet

- Question Papers - Heat TreatmentDocument9 pagesQuestion Papers - Heat TreatmentSrilakshmi Shunmugaraj100% (3)

- ENS167 Sample FinalDocument1 pageENS167 Sample FinalFatima Zaynab AbdulzamadNo ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: 2012 Material Science and TechnologyDocument7 pagesHT TP: //qpa Pe R.W But .Ac .In: 2012 Material Science and TechnologyPuspendu Roy ChowdhuryNo ratings yet

- ME6403-Engineering Materials and MetallurgyDocument12 pagesME6403-Engineering Materials and Metallurgysanthanam102No ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: 2013 Materials Science and TechnologyDocument7 pagesHT TP: //qpa Pe R.W But .Ac .In: 2013 Materials Science and TechnologyPuspendu Roy ChowdhuryNo ratings yet

- Tugas 01 (Soal)Document2 pagesTugas 01 (Soal)Andika Aldi IINo ratings yet

- UNIT-I (Constitution of Alloys and Phase Diagrams) Part-ADocument7 pagesUNIT-I (Constitution of Alloys and Phase Diagrams) Part-AkarthisanNo ratings yet

- 2-1 MMS (Nov 2009 Regular)Document4 pages2-1 MMS (Nov 2009 Regular)micmechNo ratings yet

- TA9 Heat Treatment 2-Rev31Document5 pagesTA9 Heat Treatment 2-Rev31Carlene ToaNo ratings yet

- Name: - MSE464/564: Metals and Alloys Spring 2021 Closed Books, Closed Notes, No Cell Phone UseDocument12 pagesName: - MSE464/564: Metals and Alloys Spring 2021 Closed Books, Closed Notes, No Cell Phone Useharlow6winfield6adamNo ratings yet

- K.S.Rangasamy College of Technology, Tiruchengode - 637 215: (Autonomous)Document4 pagesK.S.Rangasamy College of Technology, Tiruchengode - 637 215: (Autonomous)balakaleesNo ratings yet

- Principles of Material Selection Question BankDocument7 pagesPrinciples of Material Selection Question BankGurpreet SinghNo ratings yet

- Material Engineering QUESTION BANKDocument13 pagesMaterial Engineering QUESTION BANKFUNTUBENo ratings yet

- Time: 3 Hours Maximum Marks: 70 Answer Any Seven Questions. All Questions CarryDocument3 pagesTime: 3 Hours Maximum Marks: 70 Answer Any Seven Questions. All Questions Carrymurugan_collegemanNo ratings yet

- TUGAS 01-Teknik Las LanjutDocument2 pagesTUGAS 01-Teknik Las Lanjutapri melianes febriNo ratings yet

- Question Papers Metallurgy and Material Science Jntu Previous YearsDocument9 pagesQuestion Papers Metallurgy and Material Science Jntu Previous YearsAtul GaurNo ratings yet

- Model Question PaperDocument3 pagesModel Question PaperMohanraj KulandasamyNo ratings yet

- A109210306-Metallurgyandmaterialsscience - November 2010Document6 pagesA109210306-Metallurgyandmaterialsscience - November 2010venkateshyadav2116No ratings yet

- AE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BDocument3 pagesAE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BRahul100% (1)

- MTC 336 Study Guide 1228594655Document3 pagesMTC 336 Study Guide 1228594655Aaron SotoNo ratings yet

- Assignment On Material EngineeringDocument1 pageAssignment On Material EngineeringPnpnNo ratings yet

- Me 2253 - Engineering Materials and Metallurgy April - May 2011Document3 pagesMe 2253 - Engineering Materials and Metallurgy April - May 2011imamuddeenNo ratings yet

- Mechanical Properties and Its Testing MethodDocument9 pagesMechanical Properties and Its Testing MethodMohammad Khairul Azmi Mohd KassimNo ratings yet

- Questions From Last YearDocument5 pagesQuestions From Last YearwizlanNo ratings yet

- 123 DwqdweDocument2 pages123 Dwqdwepravi2010No ratings yet

- Emm Lab QuestionsDocument9 pagesEmm Lab QuestionsVijai KaladadNo ratings yet

- NR 311803 Heat Treatment TechnologyDocument4 pagesNR 311803 Heat Treatment TechnologySrinivasa Rao GNo ratings yet

- ESG 332 Exam 2 Covering Modules 8-12Document1 pageESG 332 Exam 2 Covering Modules 8-12blehalaNo ratings yet

- CA02 ParchamentoJVMDocument6 pagesCA02 ParchamentoJVMJohnrey ParchamentoNo ratings yet

- QdweDocument9 pagesQdwepravi2010No ratings yet

- Ph8251 Ms Rejinpaul Iq Am19Document1 pagePh8251 Ms Rejinpaul Iq Am19JairusNo ratings yet

- Question Bank (Material Sciences) SastraDocument11 pagesQuestion Bank (Material Sciences) SastraMohamed SohaibNo ratings yet

- 07a81803 SuperalloysDocument4 pages07a81803 SuperalloysSharanya ThirichinapalliNo ratings yet

- Btech Metta Mme 4 Sem Phase Transformation and Heat Treatment Pmt4i101 2019Document2 pagesBtech Metta Mme 4 Sem Phase Transformation and Heat Treatment Pmt4i101 2019Isolated MelodyNo ratings yet

- Eng-Material FINALDocument7 pagesEng-Material FINALjordan th1No ratings yet

- Udr 1Document2 pagesUdr 1shazanNo ratings yet

- Q200680 - Ledeen Technical DescriptionDocument7 pagesQ200680 - Ledeen Technical Descriptioncoyana9652No ratings yet

- 03 Port and Harbour HaTelit May 2021Document40 pages03 Port and Harbour HaTelit May 2021Mobile LegendsNo ratings yet

- HDPEDocument14 pagesHDPESandy YansikuNo ratings yet

- Machines: Inclined PlaneDocument4 pagesMachines: Inclined PlaneManik BholaNo ratings yet

- Cooling Water CircuitDocument3 pagesCooling Water CircuitJamil AhmedNo ratings yet

- Problem 6: Heat Exchange in A Series of TanksDocument5 pagesProblem 6: Heat Exchange in A Series of TanksAbu Bakr Abdul MajeedNo ratings yet

- Materials For Engineering 4 PDFDocument2 pagesMaterials For Engineering 4 PDFHimanshu MishraNo ratings yet

- Polarography: Pharmaceutical Chemistry IIIB 516-T Course Incharge: Dr. Somia GulDocument17 pagesPolarography: Pharmaceutical Chemistry IIIB 516-T Course Incharge: Dr. Somia GulTayyab Siddiqui100% (1)

- CZ P 10 en Es Cs de FR 04 2022Document82 pagesCZ P 10 en Es Cs de FR 04 2022MichaelNo ratings yet

- Name: Date: Class: Life Science Class Period: Microscope Lab: The LetterDocument3 pagesName: Date: Class: Life Science Class Period: Microscope Lab: The LetterAiven LapitanNo ratings yet

- Class B Lubricant For Voith Retarders.: VR Fluid SDocument2 pagesClass B Lubricant For Voith Retarders.: VR Fluid SMarco AchinaNo ratings yet

- DataLog Drilling Fluids ManualDocument57 pagesDataLog Drilling Fluids ManualJohnSmithNo ratings yet

- D0 350 Nikkiso Non Seal Pumps enDocument24 pagesD0 350 Nikkiso Non Seal Pumps enEdwin Mercado0% (1)

- HT Lecture 13 ConvectionSolvedProblemsDocument17 pagesHT Lecture 13 ConvectionSolvedProblemsJulio Cesar Castañeda MancipeNo ratings yet

- Installation Operation MaintenanceDocument64 pagesInstallation Operation MaintenanceMoriyasu NguyenNo ratings yet

- Lecture 6Document26 pagesLecture 6rookeeNo ratings yet

- QP Am Ii SemDocument6 pagesQP Am Ii SemnishNo ratings yet

- CENG 197 - CE Competency Appraisal II Problem Set 3b Fluid Statics 2 - Hydrostatic Forces On Plane and Curved SurfacesDocument13 pagesCENG 197 - CE Competency Appraisal II Problem Set 3b Fluid Statics 2 - Hydrostatic Forces On Plane and Curved SurfacesApple AterradoNo ratings yet

- Questions On ISE Choose The Correct AnswerDocument3 pagesQuestions On ISE Choose The Correct Answerنيرمين احمدNo ratings yet

- Electronic Distance Measurement (EDM)Document29 pagesElectronic Distance Measurement (EDM)Kavi MaranNo ratings yet

- MCQ Ucmp Unit Iii Chemical and Electro Chemical Energy Based ProcessesDocument38 pagesMCQ Ucmp Unit Iii Chemical and Electro Chemical Energy Based ProcessesBollu SatyanarayanaNo ratings yet

- Analysis of Yield Stress Ratio and OverconsolidatiDocument10 pagesAnalysis of Yield Stress Ratio and OverconsolidatiZakwan GusnadiNo ratings yet

- Workshop Mass TransferDocument2 pagesWorkshop Mass TransferYessica Viviana Solano PradoNo ratings yet

- Olivetti Copia 9910 SMDocument159 pagesOlivetti Copia 9910 SMvenci_kamenovNo ratings yet

- Torsion in Beams and How To Eliminate Torsion in EtabsDocument2 pagesTorsion in Beams and How To Eliminate Torsion in Etabsabdul khaderNo ratings yet

- Chapter 9B: Natural Convection: BTEN 3320 Dr. Mariatul Fadzillah MansorDocument18 pagesChapter 9B: Natural Convection: BTEN 3320 Dr. Mariatul Fadzillah MansorAireen NajihahNo ratings yet

- EXP 1 Lab Rep For PrintDocument6 pagesEXP 1 Lab Rep For PrintJohn leo-mar PadillaNo ratings yet

- Ebara Multistage Brochure 2021Document24 pagesEbara Multistage Brochure 2021Nitin SeenauthNo ratings yet

- Din 2215 2Document7 pagesDin 2215 2Dule JovanovicNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesFrom EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraRating: 4.5 out of 5 stars4.5/5 (4)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)