Professional Documents

Culture Documents

Installation and Use Manual Oil Transformer

Uploaded by

freddysh4330Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and Use Manual Oil Transformer

Uploaded by

freddysh4330Copyright:

Available Formats

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Installation and use

Manual

OIL TRANSFORMER

Emiss. 10/12

Rev.00 - Pag. 1/19

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 2/19

TABLE OF CONTENTS

1 INTRODUCTION........................................................................................................................................ 3

1.1 Reference standard .................................................................................................................................. 3

1.2 Electromagnetic compatibility ................................................................................................................ 3

1.3 Marking CE ............................................................................................................................................. 3

2 GENERAL ................................................................................................................................................... 3

3 OUTLINE OF THE TRANSFORMER AND THE ACCESSORIES ......................................................... 4

4 RECEPTION, HANDLING, STORAGE .................................................................................................... 8

4.1 Reception ................................................................................................................................................. 8

4.2 Handling .................................................................................................................................................. 9

4.3 Storage ................................................................................................................................................... 11

5 INSTALLATION ....................................................................................................................................... 11

5.1 Standard installation conditions ............................................................................................................ 11

5.2 Ventilation ............................................................................................................................................. 11

5.3 Insulating distances ............................................................................................................................... 13

5.4 Earthing connections ............................................................................................................................. 13

5.5 LV and HV connections ........................................................................................................................ 13

5.6 Regulation of transformation ratio ........................................................................................................ 14

5.7 Parallel connection of transformers ....................................................................................................... 14

6 TRANSFORMER PROTECTIONS .......................................................................................................... 15

6.1 Over temperature protection .................................................................................................................. 15

6.2 Overloading and short circuit protection ............................................................................................... 15

6.3 Protection against over voltages ............................................................................................................ 15

7 COMMISSIONING ................................................................................................................................... 16

7.1 Mechanical checks before the commissioning ...................................................................................... 16

7.2 Electrical checks before the commissioning ......................................................................................... 17

7.3 Insulating fluid level.............................................................................................................................. 17

7.4 Arcing horns .......................................................................................................................................... 18

7.5 Air dryer ................................................................................................................................................ 18

7.6 Buchholz Relay ..................................................................................................................................... 18

7.7 Thermometer ......................................................................................................................................... 18

7.8 Integrated safety device ......................................................................................................................... 18

7.9 Operations for commissioning .............................................................................................................. 19

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 3/19

1 INTRODUCTION

1.1

Reference standard

The oil transformer referred to the attached test report, has been designed and manufactured by TESAR

in order to meet to Italian CEI and international IEC Standards requirements in force at the moment of

its manufacturing (unless different agreement).

1.2

CEI Standards (Italian)

-

CEI EN 60076-1

CEI EN 60076-2

CEI EN 60076-3

CEI EN 60076-4

CEI EN 60076-5

CEI EN 60076-10

CEI 14-7

CEI 14-15

- Power transformer part 1 : General

- Power transformer part 2 : Temperature Rise

- Power transformer part 3 : Insulation levels, dielectric tests and

external clearances in air

- Power transformer part 4 : Guide to the lightning impulse and

switching impulse testing - Power transformers and reactors

- Power transformer part 4 : Ability to withstand short circuit

- Power transformer- part 10 determination of sound levels

- Marcatura dei terminali dei trasformatori di potenza

- Guida di carico per trasformatori immersi in olio

IEC Standards (International)

-

IEC 60076-1

IEC 60076-2

IEC 60076-3

IEC 60076-4

IEC 60076-5

IEC 60076-10

- Power transformer part 1 : General

- Power transformer part 2 : Temperature Rise

- Power transformer part 3 : Insulation levels, dielectric tests and

external clearances in air

- Power transformer part 4 : Guide to the lightning impulse and

switching impulse testing - Power transformers and reactors

- Power transformer part 4 : Ability to withstand short circuit

- Power transformer- part 10 determination of sound levels

IEC 60616

-Terminal and tapping markings for power transformers

IEC 60076-7

- Loading guide for oil-immersed power transformers

Electromagnetic compatibility

The intensity of low frequency magnetic field emitted by the windings is of a limited value and,

however, it is equal or lower than those of the field emitted by the connections and the low voltage

bars. Its value quickly decreases by increasing of the distance from the transformer.

1.3 Marking CE

TESAR does not affix the marking CE on its transformers as foreseen at paragraph 5.4.2 of the Guide

to the application of the Directive 89/336/EEC which excludes from the Directive application field:

High voltage inductor

High voltage transformer

2 GENERAL

This publication aims to guide users on the properties of power and distribution transformers insulated

with mineral, silicone or vegetable oil. Two types of transformers are considered:

- Hermetically sealed total filled (Fig. 1)

- Breathing with conservator (Fig. 2)

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 4/19

3 OUTLINE OF THE TRANSFORMER AND THE ACCESSORIES

Fig. 1

Fig. 2

Hermetically sealed total filled transformer

Breathing with conservator transformer

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 5/19

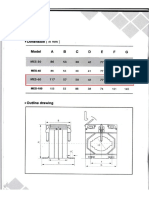

Standard components and accessories:

a. Rating plate (Fig. 3 and Fig. 4)

b. HV porcelain bushing (Fig. 4)

c. LV porcelain bushing (Fig. 4)

d. Off-load tap-changer (Fig. 4)

e. N2 earthing terminals (Fig. 4)

f. Tow attachment (Fig. 4)

g. Lifting eyes (Fig. 4)

h. Truck with rollers for lengthways or sideway travel (Fig. 4)

i. Thermometer pocket (Fig. 4)

j. Drain valve(Fig. 4)

k. Arcing horns on HV porcelain bushing, for transformer without HV cable box (Fig. 4)

l. Air dehydrating breathers, for breathing transformer (Fig. 4)

m. Oil level indicator, for breathing transformer (Fig. 4)

Optional components and accessories:

I. Plug-in HV terminals (Fig. 5)

II. Thermometer, to install on the thermometer pocket (Fig. 5)

III. RIS or equivalent for hermetically sealed transformer (Fig. 5)

IV. Buchholz Relay for breathing transformer (Fig. 5)

V. Safety valve (Fig. 5)

VI. PT100 thermo-resistance (to install in the thermometer pocket) (Fig. 5)

VII. HV and/or LV cable boxes (Fig. 5)

Fig. 3

Rating plate

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 6/19

k

g

i

f

b

c

d

a

j

e

Fig. 4

Standard components and accessories

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

I Plug-in for HV terminals

II Thermometer

IV - Buchholz Relay

(for breathing transformer)

Rev.00 - Pag. 7/19

III RIS or equivalent

(for hermetically sealed transformer)

V - Safety valve

VII - HV and/or LV cable boxes

Fig. 5

Emiss. 10/12

Optional components and accessories

VI - PT100 thermo-resistance

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 8/19

4 RECEPTION, HANDLING, STORAGE

4.1 Reception

The transformer is generally supplied totally assembled and ready to be connected to the medium and

low voltage line.

According to the specification, the transformer is shipped with a polythene protection, or packed into

wooden cage, for protection against dust and little shocks, or finally packed into a wooden case for

over-sea shipments.

On receipt of the transformer, both at the client's plants or at site, it is necessary to carry out the

following checks:

Check there are no signs of damage on the packing or on the transformer occurred during the

transport.

The characteristics of the transformer detailed on the rating plate must correspond to those of the

shipping documents and with those of the test report, which is attached to the transformer.

Check each transformer is complete with the accessories foreseen in the contract (wheels, bushing,

etc.).

IMPORTANT: In case any anomalies are found, please contact immediately the manufacturer.

If within 5 days there will be no notification of anomalies or defects, it can be considered that the

transformer has been delivered in perfect conditions. The manufacturer, therefore, cannot be

considered responsible neither for what could happen to the transformer during service nor for

the eventual consequences.

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 9/19

4.2 Handling

During the transport or the handling, it is recommended to use only the special lifting eyes and tow

attachments (see g and f letter in the Fig. 4).

IMPORTANT: The transformer cannot be moved pushing the cooling fins or radiators or tank.

Ropes must be arranged so as not to interfere with the radiators or cooling fins.

Lifting can be made using the appropriate hooks remembering to use ropes long enough so that H is

never less than L (Fig. 6). Always use all the existing hooks and not only one of them.

Fig. 6

Lifting transformer

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Example of handling

Fig. 7

Handling by means of bridge crane and forklift truck

Fig. 8

Manual handling

Fig. 9

Wrong handling

Emiss. 10/12

Rev.00 - Pag. 10/19

OIL TRANSFORMER HV/LV

Emiss. 10/12

INSTALLATION AND USE MANUAL

Rev.00 - Pag. 11/19

4.3 Storage

4.3.1 Transformer for indoor installation

The transformer must be stored in a sheltered, clean and dry ambient maintaining the packing up to the

installation.

4.3.2 Transformer for outdoor installation

The transformer may be stored outdoor until the installation time.

IMPORTANT: The storage temperature must not be lower than -25C.

5 INSTALLATION

5.1 Standard installation conditions

The maximum height of installation must not exceed 1000 m above sea level.

When the transformer is in service, the ambient temperature of the room must be within the following

limits:

Minimum temperature:

-25C

Yearly average temperature:

+20C

Monthly average temperature:

+30C

Maximum temperature:

+ 40C

In case the height of the place of installation and/or the ambient temperature values are higher

than the ones specified above, it is necessary to specify it at the ordering stage since a particular

dimensioning of the transformer depends upon these values.

5.2 Ventilation

The electric current passing through the windings, and the effect of the core magnetising current

produce electrical losses resulting in localised heating of the windings and core.

The transformer is designed in such a way that natural cooling maintains the transformer temperature

under the maximum values foreseen by the standards.

In order to avoid temperature accumulation in the room where the transformer is installed, it is

necessary to provide suitable ventilation.

Each TESAR transformer is equipped with a thermometer pocket where a thermometer with contacts

may be installed (optional accessory).

The suggested values for setting the contacts are following (oil temperature):

Description

Alarm C

Trip C

Oil

90C

100C

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 12/19

Dimensioning of air louvers

Natural cooling

In the room where the transformer is installed, it is necessary to install air louvers sufficient to

dissipate the heat generated by transformer during service, in order to guarantee the standard

service conditions and to prevent exceed the over temperature limits of the transformer.

Therefore the room must be provided with a louver on the lower part S, in order to guarantee an

appropriate fresh air flow; and a louver S on the upper part of the opposite wall, in order to extract

the hot air (see Fig. 10).

To calculate the surface of the louvers for air incoming and outgoing, for a nominal annual ambient

temperature of 20C, the following formula may be used:

S 0.188

P

H

S ' 1.10 S

where:

P = Sum of the transformer no-load losses and the load losses at 120C [kW]

(if the losses are at 75C, they must be multiply for 1.15)

S = Surface of the incoming louver [m2]

S = Surface of the outgoing louver [m2]

H = Height between the two louvers [m]

Fig. 10 Natural cooling

In order not to obstruct cooling is necessary that the transformer is installed at a distance not less

than 30 cm from the walls and not less than 60 cm from other transformers.

Forced cooling

Forced cooling is necessary in the following cases:

Frequent overloading

Low-dimensioned room

Room scarcely ventilated

Medium daily temperature higher than 30C.

The forced cooling can be realized by means of installation of air extractor located in the upper

part of the room controlled by a suitable thermostat or directly by a transformer thermal protection

relay, with a suggested flow of approx. 3,54 m3/min for each kW of total losses at 120 C (if the

losses are at 75C, they must be multiplied by 1.15).

ATTENTION: an insufficient air circulation, besides reducing the nominal life of the

transformer, causes over heating which, in the worst cases, can determine the intervention of the

thermal protection relay.

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 13/19

5.3 Insulating distances

The transformer supplied for service without HV/LV cable-box (IP00) must be installed in the room

respecting the insulating distances specified in the national standard (in Italy, CEI 11-1).

The transformer, also with plug-in bushing, must be protected against direct contacts.

5.4 Earthing connections

Tesar is not responsible for the transformer installation.

The installation must be carried out according to the standards in force, to the applicable laws and to

the present instructions.

The following points must be taken into consideration when the installation is carried out:

connect the earthing conductors to the relative earth points on the metallic parts of the transformer

and cable boxes.

connect the low voltage neutral to earth when required or when required by the protection system

to earth.

5.5 LV and HV connections

Execution without cable boxes (IP00)

The cables and the bus bars which are connected to the transformer must be duly fixed to avoid any

mechanical stress on the LV and HV transformer terminals.

Both upper and bottom cable connections can be performed, being sure, however, to respect the

configuration showed in the drawings. In case the connections arrive from the bottom please ensure

that there is sufficient depth for the bending of the cables.

Execution with cable boxes

The cables and/or the bus bars which are connected to the transformer must enter in the cable boxes

only through suitable flanges specified at the ordering stage.

In any case the cables and/or the bus bars must be duly fixed outside the cable boxes to avoid any

mechanical stress on the LV and HV terminals of the transformer and also on the cable boxes. After

the installation please check the correct degree of protection is maintained near the passageway of the

cables and/or the bus bars.

HV cable box: cables coming only from the bottom

LV cable box: cables coming from the bottom or from the top

Fig. 11 Cables coming from the bottom (left) and from the top (right)

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 14/19

5.6 Regulation of transformation ratio

The variation of the primary voltage is obtained by changing the position of the voltage off-load tapchanger located on the cover of the tank. Ensure always that the position of the tap-changer is properly

inserted and not in an intermediate position.

In case the primary voltage of the system does not correspond exactly to the voltage of the central tap,

it is necessary to modify the position of the tap duly positioning it on one of the other taps in order that

the secondary obtained is the no-load voltage shown on the rating plate.

Note: At the time of shipping, the position of the voltage off-load tap-changer are located on the

central tap.

In case of transformers with double ratio, please be sure that the position corresponding to the voltage

of the system feeding the transformer is properly connected.

Note: At the time of shipping, the position of the voltage off-load tap-changer are connected on

the position of the higher primary voltage.

Important

A) In case of transformers with double ratio, please be sure the tap corresponding to

voltage of the system feeding the transformer it-self, is duly connected.

B) In case the position of the tap-changer has to be changed after the transformer has

been put into service the first time, it is recommended to put the transformer out of

service and to connect to ground the LV and HV circuits before approaching the

transformer.

5.7 Parallel connection of transformers

If the transformer must be connected in parallel with other transformers, please verify the total

compatibility of the voltage ratio and of the conditions stated by the IEC 60076-1 standards, and

particularly:

Identical voltage ratio

Identical frequency of functioning

Identical vector group

Identical short circuit voltage (Tolerance 10%)

The rated power (kVA) of the biggest transformer should not be larger than twice the smallest

transformer

The LV connections must be the same length from the LV terminals (of two different units) to the

switch junction.

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 15/19

6 TRANSFORMER PROTECTIONS

6.1 Over temperature protection

The protection can be realized with:

- thermometer (optional accessories)

- RIS or equivalent equipment (optional accessories for hermetically sealed transformer)

The thermometer is generally installed in the thermometric pocket on the cover of the tank.

The thermometer may be equipped with two settable contacts, one for alarm, the other for trip.

The suggested values are written at paragraph 5.2.

The integrated safety device for hermetically sealed transformer (RIS or equivalent) provides:

- two settable contacts for temperature, one for alarm and the other for trip. The suggested values

are written at paragraph 5.2.

- one settable trip contact for pressure (The suggested value is 0.3 bar)

- one trip contact for oil level

6.2 Overloading and short circuit protection

According to the parameters of the standards shown at point 1.1, the transformer is designed and

manufactured in such a way to withstand limited abnormal situation of over-voltages, overloading and

short circuit. Therefore, the transformer must be protected against thermal and dynamic effects caused

by continuous overloading and secondary short circuits by means of an automatic switch or suitable

fuses, able to disconnect the transformer in case of current flow higher than the one fixed by the

protection.

The protections setting and/or the choice of fuses HV and LV side, must be carried out taking into

consideration the primary and secondary rated currents stated in the transformer rating plate, taking

also into consideration that when we feed the transformer, a very high magnetizing current is

established on the primary, by means of variable starting from a minimum of 10 times the rated

current (in the worst conditions of insertion depending from the instant when the feeding circuit is

closed, from the electric characteristics of the feeding network, from the reactance and resistance

values of the circuit network-transformer, the insertion current can reach also 20 times the rated

current), even if the automatic switch located on the secondary is open and therefore without loading.

Therefore, it is necessary to duly set the relay of maximum current HV side, in current and time value,

by introducing a little delay (approx. some tens of ms), in such a way that the protection relay will not

operate. Furthermore, we suggest limiting the number of connections and disconnection of the

transformer on the network.

6.3 Protection against over voltages

In order to protect the transformers against over-voltages at industrial frequencies or the ones due to

atmospheric origin, it is recommended that voltage surge arrester with variable resistance are used.

The characteristics of the surge arresters depend on the transformer insulation level and from the

characteristics of the distribution system line.

It is recommended to install the surge arresters when the transformer is connected, directly or through

a short cable, to the main networks.

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 16/19

7 COMMISSIONING

7.1 Mechanical checks before the commissioning

Check the earth connections

Check of the insulating distance of the parts under voltage towards ground as shown at paragraph

5.3

Check the tightening of HV and LV terminals applying the following values of the tightening

torque.

Bushing

On the central conductor LV/HV in copper or brass

Bolts

Torque N*m

M8 M12 M20 M30x2 M42x3 M48x3 M55x3 M75x3

10

13

30

70

110

180

250

250

On the fixing stud screw HV insulators

Bolts

Torque N*m

M10 M12 M16

15

25

40

On the pinch bolts connecting flags

Bolts

Torque N*m

M10 M12 M16

25

40

90

Mechanical parts

Bolts

M8

M10

M12

M14

M16

M18

M20

M22

Torque N*m

20

45

75

125

190

275

385

530

With torque wrench set in kgm, divide the values by 10

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 17/19

7.2 Electrical checks before the commissioning

Verify that the position of the tap-changer is inserted correctly. In case of double primary

voltages, please check the feed to the transformer correspond to the correct position.

Check the correct functioning of the switches located as protection of the transformer on

HV and LV side.

Check the correct setting and functioning of the overloading and short-circuit protection

relay.

Check the correct setting and functioning of the over-temperature protection relay and of

the thermometer.

Check the functioning of the fans.

Check the general conditions of the transformer and proceed with the measurement of the

insulating resistance by means of a Megger at 2500 V.

This measurement must be carried out with HV and LV terminals disconnected from

the equipment, it means before connecting the cables and/or the bus bars.

The values of the measured resistances must be approx. the following:

HV terminals / LV terminals grounded

20 M

LV terminals / HV terminals grounded

10 M

HV terminals - LV terminals / ground terminal

10 M

In case the measured values are lower, please contact our after sale service.

ATTENTION: In case a transformer is put into service after a long storage period, or

after a long de-energised period, it will be necessary:

1) clean the HV/LV bushings from eventual dust and condensation by means of dry

compressed air jets and dry cloth.

2) if the transformer has been held in stock far more than six months in normal climates

or far more than a month in damp climates, check the dielectric strength of the

insulating oil. Using the procedure established by the IEC standard to check the

dielectric strength of the insulating oil, if the test is negative proceed to dry the

dielectric oil of the transformer, otherwise contact Tesar.

It is recommended, finally, to carry out always a visual check of the transformer in order

to verify any unlikely presence on the surface the cooling ducts

7.3 Insulating fluid level

Check that the reading on the level indicator approximately correspond to ambient temperature

(transformer with conservator or RIS for hermetically sealed). If the insulating fluid needs to be

topped up, only fluid with the same characteristic and not containing PCBs must be used and with the

required dielectric strength.

The oil transformer must be topped up according to the manufactersinstruction.

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 18/19

7.4 Arcing horns

If the transformer is equipped with arcing horns, check that the position of the spark gap rods mounted

on HV porcelain bushings corresponds to the insulation class, as shown in the following chart.

Insulation Class

[kV]

A

[mm]

B

[mm]

12

15

70

17.5

15

90

24

15

100

36

15

200

Fig. 12

Arcing horns

7.5 Air dryer

If the transformer is equipped with air dryer (transformer with conservator), check that the salts of

silicagel are orange. If they are neutral colour, they have already picked up moisture and do not fulfil

their function as dehydrating air. It is necessary to remove the salts and regenerate the dryer by placing

them in an oven at 150C until they are come back to orange colour.

7.6 Buchholz Relay

If the transformer is equipped with Buchholz relay (transformer with conservator) to avoid

unnecessary activation, proceed carefully with the leaking operation of the relay, acting on the taps

(see instruction relay). If during commissioning or in the first hours of the energization the Buchholz

relay should signal the formation of gas, in small quantities, first to believe that there is a fault in the

transformer and repeat the leaking operation.

7.7 Thermometer

If the transformer is equipped with the thermometer check the threshold of the alarm and trip are set at

the operating conditions. The setting temperature are provided to the manufacturers in according to

transformer type and the insulation class.

7.8 Integrated safety device

If the transformer is equipped with the integrated safety device (RIS or equivalent) check the setting

of the alarm and trip of the thermometer and the values of pressure shown are matched to operating

conditions. For more additional information, consult the operating manual supplied with the integrated

security device, you must be careful not to change the orientation fixing RIS or equivalent (the exact

position should be required before delivery).

OIL TRANSFORMER HV/LV

INSTALLATION AND USE MANUAL

Emiss. 10/12

Rev.00 - Pag. 19/19

7.9 Operations for commissioning

Closing of HV switch

When the switch is closed the transformer gives out a sharp noise, which decreases in few ms

until it stabilises.

Check of secondary voltages

Before closing the low voltage switch or make additional checks for parallel operation with

other transformers, it is necessary:

Check by means of a voltmeter the proper value between each two phases and of the three

wye-connected voltage.

Check the proper phases displacement and the correct vector group.

In case the values correspond to those stated in the rating plate, it is possible to proceed and

complete the commissioning or to carry out the checks for the parallel service.

Run in parallel service with other transformer

In case the transformer has to run in parallel with another, it is also necessary:

Check the compatibility of the rating plates of both transformers

Verify the concordance of the phases by measuring the voltage between the phase "one" of

the transformer already in service and the phase "one" of the transformer to be connected

in parallel by means of a voltmeter. The value of this result must be zero. Continue in

the same way for phase 2 and phase 3

Closing of LV switch

Complete the commissioning of the transformer closing the LV switch.

IMPORTANT

We remind you that qualified technical personnel must carry out the operation,

commissioning and energization. Furthermore, during the voltage measurements and the

phase displacement checks on the upper terminals of the LV switches, you are

recommended to use suitable instruments and suitable insulating gauntlets.

For more accurate and complete checks, please contact our Assistance Service

Phone

Fax

E-Mail

(+39)-0575.317.1

(+39)-0575.317.201

info@tesar.eu

You might also like

- Transformer Installation ManualDocument38 pagesTransformer Installation ManualbhsujanNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Substation InstallationDocument12 pagesSubstation InstallationasawinrajaNo ratings yet

- Intern Ship Report of 132Kv Grid StationDocument81 pagesIntern Ship Report of 132Kv Grid Stationdarkroom92% (25)

- Erection Procedure For Power TransformerDocument3 pagesErection Procedure For Power Transformerparuchurivenkat5272No ratings yet

- Maintenance of Power TransformerDocument18 pagesMaintenance of Power TransformerMohammed Jaffar Adnan100% (1)

- Substation Design WorkshopDocument34 pagesSubstation Design WorkshopasawinrajaNo ratings yet

- System Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejDocument34 pagesSystem Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejBrijesh BhadauriaNo ratings yet

- Transformer Protections: by Alok RaiDocument8 pagesTransformer Protections: by Alok RaiAlok RaiNo ratings yet

- 69kV and Above Oil Immersed Transformer Instruction ManualDocument30 pages69kV and Above Oil Immersed Transformer Instruction ManualYaser MajeedNo ratings yet

- Voltage Transformer CommissioningDocument12 pagesVoltage Transformer CommissioningjamilNo ratings yet

- SwitchgearDocument35 pagesSwitchgearkailasamvv100% (1)

- Root Cause Analysis TransformerDocument81 pagesRoot Cause Analysis TransformerarsalanhamidNo ratings yet

- ABB Transformer Installation ManualDocument18 pagesABB Transformer Installation Manualjt4fds100% (3)

- University of Turkish Aeronautical Association Faculty of Engineering EEE DepartmentDocument57 pagesUniversity of Turkish Aeronautical Association Faculty of Engineering EEE DepartmentratheeshkumardNo ratings yet

- Testing and Commissioning Procedure: 2007 EDITION (Incorporating Corrigendum No. Gsee01)Document98 pagesTesting and Commissioning Procedure: 2007 EDITION (Incorporating Corrigendum No. Gsee01)Khairil ZainudinNo ratings yet

- Testing of TransformerDocument24 pagesTesting of TransformerObakoma JosiahNo ratings yet

- Safety Operations On Medium Voltage Switch GearDocument3 pagesSafety Operations On Medium Voltage Switch GearpecampbeNo ratings yet

- Substation Work SpecifiationDocument98 pagesSubstation Work SpecifiationnknfiveNo ratings yet

- Commissioning of Power TransformerDocument35 pagesCommissioning of Power TransformerzenrajaNo ratings yet

- 5 11kV XLPE CABLEDocument32 pages5 11kV XLPE CABLEalgiorgeNo ratings yet

- Electrical Switchboard Test and Commissioning ProcedureDocument4 pagesElectrical Switchboard Test and Commissioning ProcedureAodman4u100% (2)

- Module 4 - Transformer TestingDocument22 pagesModule 4 - Transformer Testingleantonato75% (4)

- 198kv Lightning ArrestersDocument13 pages198kv Lightning ArrestersgovindarulNo ratings yet

- Chapter 11 Power CablesDocument46 pagesChapter 11 Power CablesAhmed Magdy100% (1)

- Testing and Commissioning Report of Olakha SubstationDocument130 pagesTesting and Commissioning Report of Olakha SubstationCheten Tshering100% (1)

- 132kv SwitchyardDocument72 pages132kv Switchyardjogiyajee0% (1)

- Siemens Transformer - O & I ManualDocument34 pagesSiemens Transformer - O & I ManualHassan RazaNo ratings yet

- Power Transformer PDFDocument43 pagesPower Transformer PDFsnadeem0750% (2)

- Instruction Manual For 500kV Shunt ReactorDocument43 pagesInstruction Manual For 500kV Shunt ReactorTerefe Tadesse100% (2)

- Protection of SubstationDocument21 pagesProtection of SubstationARVIND100% (2)

- Power Transformer Basic DesignDocument31 pagesPower Transformer Basic DesigntajakaNo ratings yet

- Section - 25: Erection, Testing and CommissioningDocument26 pagesSection - 25: Erection, Testing and CommissioningM Usman RiazNo ratings yet

- Distribution Transformer Main HandbookDocument84 pagesDistribution Transformer Main HandbookmellymoyoNo ratings yet

- ABB Cast Resin Dry Type Transformer CATDocument16 pagesABB Cast Resin Dry Type Transformer CATTruong Minh Rang50% (2)

- The Role of Medium Voltage Switchgear in Power SystemDocument3 pagesThe Role of Medium Voltage Switchgear in Power SystemkienNo ratings yet

- Bus Bar SchemesDocument26 pagesBus Bar SchemesSoorya Priya GopalakrishnaNo ratings yet

- Site Training Manual For Power TransformerDocument99 pagesSite Training Manual For Power TransformerYadav GaneshNo ratings yet

- Testing of CTDocument17 pagesTesting of CTsasikumarNo ratings yet

- Erection Testing and CommissioningDocument30 pagesErection Testing and CommissioningEngr Muhammad Abu BakrNo ratings yet

- Test ManualDocument66 pagesTest ManualAakoji Devikumar100% (3)

- Dewa Testing ProcedureDocument27 pagesDewa Testing ProcedureramNo ratings yet

- OHL Manual Vol.2 Drawings & Reference Info v3 July 2006Document190 pagesOHL Manual Vol.2 Drawings & Reference Info v3 July 2006somchak2000100% (2)

- Transformer and Transformer Feeder ProtectionDocument42 pagesTransformer and Transformer Feeder Protectionjuljan sinani100% (3)

- 132kV Power TransformerDocument7 pages132kV Power TransformerblaagicaNo ratings yet

- Power Transformer Testing ProcessDocument19 pagesPower Transformer Testing ProcessRajj PruthiviNo ratings yet

- Method of Statement For Transformers: Owner/Client Owner'S Engineer ContractorDocument12 pagesMethod of Statement For Transformers: Owner/Client Owner'S Engineer ContractorPandrayar Maruthu100% (3)

- Install, Operate and Maintain Low Voltage PanelDocument72 pagesInstall, Operate and Maintain Low Voltage Panelgiau richkyNo ratings yet

- ABB TransformersDocument20 pagesABB TransformersjasonlaiymNo ratings yet

- Sagana Kutus 132kv Transmission Line and SubstationDocument324 pagesSagana Kutus 132kv Transmission Line and Substationshivvaram-1100% (1)

- Control and Relay Panel - Technical SpecificationDocument57 pagesControl and Relay Panel - Technical SpecificationLourdhu Sagaya Jayakumar JNo ratings yet

- Power Transformers: Our Journey Towards ExcellenceDocument14 pagesPower Transformers: Our Journey Towards ExcellenceshasailuNo ratings yet

- Maintenance Guide For Liquid Filled Distribution TransformersDocument28 pagesMaintenance Guide For Liquid Filled Distribution TransformersshivaNo ratings yet

- P-46-08 - Power TransformerDocument81 pagesP-46-08 - Power TransformerNasrullahNo ratings yet

- Installation and operating instructions for Movitec V 2, 4, 6 & 90 High-Pressure In-Line pumpsDocument28 pagesInstallation and operating instructions for Movitec V 2, 4, 6 & 90 High-Pressure In-Line pumpsRenderf AlipioNo ratings yet

- Operating ManualDocument132 pagesOperating ManualMuhammad RasyidiNo ratings yet

- Technical Specification for Auto TransformerDocument53 pagesTechnical Specification for Auto TransformerPremBhushanNo ratings yet

- Le 15Document48 pagesLe 15JsgNo ratings yet

- TESAR Installation Use and Maintenance EngDocument20 pagesTESAR Installation Use and Maintenance EngceragonNo ratings yet

- ABTED103157ENDocument8 pagesABTED103157ENfreddysh4330No ratings yet

- 505xNL A, E505xNL E: Neo Wall SwitchDocument12 pages505xNL A, E505xNL E: Neo Wall Switchfreddysh4330No ratings yet

- MK6E BrochureDocument2 pagesMK6E Brochurefreddysh4330No ratings yet

- Essential LEC ENDocument24 pagesEssential LEC ENfreddysh4330No ratings yet

- Installation DHD QIG Series-ENDocument2 pagesInstallation DHD QIG Series-ENfreddysh4330No ratings yet

- BLOKSET Technical GuideDocument189 pagesBLOKSET Technical GuideHANIF AKBAR100% (2)

- 8BT2 - Installation and Operating InstructionsDocument96 pages8BT2 - Installation and Operating Instructionsalanetn100% (1)

- Schneider Electric - Modicon-X80-I-Os - BMXDDO1602Document6 pagesSchneider Electric - Modicon-X80-I-Os - BMXDDO1602freddysh4330No ratings yet

- Schneider Electric - Altivar-Easy-610 - ATV610D45N4Document5 pagesSchneider Electric - Altivar-Easy-610 - ATV610D45N4freddysh4330No ratings yet

- Acudc 240: DC Power & Energy Meter DatasheetDocument6 pagesAcudc 240: DC Power & Energy Meter DatasheetDuy ChuNo ratings yet

- ABB Photo Voltaic PlantsDocument116 pagesABB Photo Voltaic PlantsfiestastefNo ratings yet

- Afp Afd-29eb4-2768 2421Document2 pagesAfp Afd-29eb4-2768 2421freddysh4330No ratings yet

- Wing 4 OPzS 200 EN201711 1Document1 pageWing 4 OPzS 200 EN201711 1freddysh4330No ratings yet

- Essential LEC ENDocument24 pagesEssential LEC ENfreddysh4330No ratings yet

- Switch datasheet specs IP20 dark greyDocument2 pagesSwitch datasheet specs IP20 dark greybarryNo ratings yet

- TeSys Deca Contactors - LC1D25M7Document6 pagesTeSys Deca Contactors - LC1D25M7freddysh4330No ratings yet

- HVAC-Sensors-TC900 SeriesDocument2 pagesHVAC-Sensors-TC900 Seriesfreddysh4330No ratings yet

- Wing 4 OPzS 200 EN201711 1Document1 pageWing 4 OPzS 200 EN201711 1freddysh4330No ratings yet

- 6ED10521FB080BA1 Datasheet enDocument2 pages6ED10521FB080BA1 Datasheet enTorcatori PloiestiNo ratings yet

- ComPact NS 630bNDocument2 pagesComPact NS 630bNfreddysh4330No ratings yet

- PyrOptic BrochureDocument5 pagesPyrOptic Brochurefreddysh4330No ratings yet

- ComPact NS 630bNDocument2 pagesComPact NS 630bNfreddysh4330No ratings yet

- 20121130133052209Document5 pages20121130133052209freddysh4330No ratings yet

- Dimensi CT AxleDocument1 pageDimensi CT Axlefreddysh4330No ratings yet

- GenosV2Pack DataListDocument5 pagesGenosV2Pack DataListfreddysh4330No ratings yet

- WS PowerSystem Engineering 24-26 April 07Document3 pagesWS PowerSystem Engineering 24-26 April 07freddysh4330No ratings yet

- Soléfuse Fuse Characteristics and DimensionsDocument2 pagesSoléfuse Fuse Characteristics and Dimensionsfreddysh4330No ratings yet

- Velleman Dimmer SelectionDocument1 pageVelleman Dimmer Selectionfreddysh4330No ratings yet

- Access Control in Total ControlDocument12 pagesAccess Control in Total Controlfreddysh4330No ratings yet

- Technical Specification: LOW FrequencyDocument1 pageTechnical Specification: LOW Frequencyfreddysh4330No ratings yet

- B-65395en 01Document387 pagesB-65395en 01Salvador Deyvi RojasNo ratings yet

- PSP Lab-1 Nahid PDFDocument6 pagesPSP Lab-1 Nahid PDFWasim RiadNo ratings yet

- DOCUMENTSINAMICS DCM as three-phase AC power controller for heating applicationsDocument27 pagesDOCUMENTSINAMICS DCM as three-phase AC power controller for heating applicationsMr.K chNo ratings yet

- Kg-545 Automatic Mains Failure UnitDocument35 pagesKg-545 Automatic Mains Failure UnitJack GehlotNo ratings yet

- Prestige Aps596eDocument16 pagesPrestige Aps596eErwin HernandezNo ratings yet

- Power Supply 1 Schematic DiagramDocument1 pagePower Supply 1 Schematic Diagrammongas9001yahoo.com.mx100% (1)

- Lorentz PP2000 Ac Powerpack Manual enDocument2 pagesLorentz PP2000 Ac Powerpack Manual enejboerioNo ratings yet

- 22kv Simosec EngDocument44 pages22kv Simosec Engmimran18No ratings yet

- SR489 Setting FileDocument9 pagesSR489 Setting FileVarun SharmaNo ratings yet

- 2006 Toyota Rav4 39Document10 pages2006 Toyota Rav4 39Pușcă MartinNo ratings yet

- 442464L PDFDocument170 pages442464L PDFmichael jossef prada burgosNo ratings yet

- The CircuitCalculator - Com Blog PCB Trace Width CalculatorDocument36 pagesThe CircuitCalculator - Com Blog PCB Trace Width CalculatorRolando LopezNo ratings yet

- ANNEXURE 2 (Electrical Data Sheets) PDFDocument113 pagesANNEXURE 2 (Electrical Data Sheets) PDFGuha ArnabNo ratings yet

- X Series InterconnectGuide Non-IR CompressorsDocument48 pagesX Series InterconnectGuide Non-IR CompressorsDipak SatavNo ratings yet

- "Grid-Tie" FX and VFX Inverter/Charger: Outback Power SystemsDocument55 pages"Grid-Tie" FX and VFX Inverter/Charger: Outback Power SystemsalfredohdnNo ratings yet

- Cassette Air Conditioner Installation ManualDocument288 pagesCassette Air Conditioner Installation ManualRm MohNo ratings yet

- CMU200 Quickstart 06 V5-20Document83 pagesCMU200 Quickstart 06 V5-20vinnyNo ratings yet

- Bicotest-T625 ManualDocument57 pagesBicotest-T625 Manualhino_kaguNo ratings yet

- Power System RestructuringDocument54 pagesPower System RestructuringsachinNo ratings yet

- MC-767W Microwave Oven Service ManualDocument38 pagesMC-767W Microwave Oven Service ManualEfrain Magaña Ponce50% (2)

- Aseptico DTC Motor l6cfm45 en 1402Document20 pagesAseptico DTC Motor l6cfm45 en 1402ilietisbitulNo ratings yet

- Speed Queen Dryer Service Manual 512261-Alliance-Homestyle-DryersDocument82 pagesSpeed Queen Dryer Service Manual 512261-Alliance-Homestyle-Dryers80sDweeb100% (1)

- Electrical Risk AssessmentDocument4 pagesElectrical Risk AssessmentanisaanNo ratings yet

- 657 Gb1064acDocument2 pages657 Gb1064acCarmen IoanaNo ratings yet

- LAB 12 To Investigate Double Bus-Bar Basic System: ObjectivesDocument5 pagesLAB 12 To Investigate Double Bus-Bar Basic System: ObjectivesFARYYAD RANANo ratings yet

- Aislador Epoxi Catalogo 2011 ENGDocument56 pagesAislador Epoxi Catalogo 2011 ENGmk116dNo ratings yet

- BTPC (CPG) 09 PDFDocument8 pagesBTPC (CPG) 09 PDFGIGINo ratings yet

- Kaeser T Series Compressor Service GuideDocument75 pagesKaeser T Series Compressor Service Guided3vil_yoNo ratings yet

- Nissan-Versa 2015 EN US Manual de Taller Bateria Fusible Principal Manojo de Cable Etc 91df20fe6dDocument72 pagesNissan-Versa 2015 EN US Manual de Taller Bateria Fusible Principal Manojo de Cable Etc 91df20fe6dvictor borjaNo ratings yet

- 1079 3Document5 pages1079 3Marco OlivettoNo ratings yet

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)