Professional Documents

Culture Documents

M E Senior Design Poster

Uploaded by

Kelzie BenenskyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M E Senior Design Poster

Uploaded by

Kelzie BenenskyCopyright:

Available Formats

Design of a Supercritical Carbon Dioxide

Power Generation Cycle for Small Modular Reactors

Kelsa Benensky, Karen Bobkowski, Hardik Jasani, John Merlino

The Pennsylvania State University

Department of Nuclear and Mechanical Engineering

Background

Problem Statement

The mission of small modular reactors (SMRs) is to provide

safe and reliable small scale power to developing areas by

maximizing the efficiency, transportability, and

manufacturability of power plant design.

Current SMRs use steam in the secondary loop to rotate the

turbine blades and produce power. This working fluid

requires a high flow volume through large, multi-stage

turbines to achieve required power output.

System Components

The proposed design incorporates a supercritical carbon dioxide (SCO2) secondary loop to decrease size and increase

efficiency.

The entire system is made up of:

Primary Pressurized Water Loop

Intermediate Steam Loop

Secondary SCO2 Loop

o Steam-SCO2 Heat Exchanger

o Turbine

o Circulating Water-SCO2 Loop

o Compressor

Circulating Water Loop

Proposed Design

Heat Exchanger Selection

Working Fluid

A plate heat exchanger was chosen because of its

compatibility with SCO2 and large surface area that

maximizes heat transfer efficiency

SCO2 has the potential for 20x smaller turbine size and

less stages compared to steam for given power output

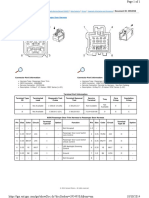

Heat Balance

The heat balance of the system was determined by Thermoflow software using

component inputs. The results produced the temperature, pressure, mass flow

rate, and enthalpy for each of the following state points:

State Enthalpy Temperature Pressure Mass Flow

Point (BTU/lb)

(F)

(psi) Rate (lb/s)

1

-27.2

82

1000

4922

2 -4.141

268.9

3060

4922

3

77.75

520

3000

4922

4

42.25

328.2

1000

4922

1.

2.

3.

4.

Inlet of Compressor

Inlet of Steam-SCO2 HxR

Inlet of Turbine

Inlet of Circulating Water-SCO2 HxR

These state points follow the Brayton cycle

model, depicted to the right

Results are shown in the table to the left

Conclusions

The proposed system design with a SCO2 working

fluid provides a net power output of 65 MWe and can

be improved to 73 MWe by adding a recuperation

cycle. This analysis proves that a SCO2 working fluid

has greater electrical power output potential than a

steam power conversion cycle of similar size.

Future Considerations

The secondary SCO2 loop is capable of being modelled with a

recuperator to provide additional power from the turbine. A low and

high temperature recuperator provides additional heat to the cycle

and results in an 18% increase in net power output.

In order for the proposed design to be competitive with steam

cycles, heat exchanger design must allow for high efficiencies.

Heat exchanger sizing also limits the viability of the system.

Turbo machinery materials research and sizing must be proven for

a system on the scale of MWe power output.

Thank you to: Bechtel Corporation Stephen Routh, James Haldeman, John Glen, Steven Kline, Desmond Chan

Penn State Mechanical and Nuclear Engineering Department

ME Senior Design Director, Dr. Frecker and Section Professor, Mr. Rose

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AET Assignment C Kate ThomsonDocument12 pagesAET Assignment C Kate ThomsonaymenmoatazNo ratings yet

- Bid Evaluation Report Sample TemplateDocument2 pagesBid Evaluation Report Sample Templatemarie100% (8)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- COMMUNICATIONS Formulas and ConceptsDocument24 pagesCOMMUNICATIONS Formulas and ConceptsAllan Paul Lorenzo Abando76% (17)

- F9 Smart Study NotesDocument97 pagesF9 Smart Study NotesSteven Lino100% (5)

- NRX-A5 Final ReportDocument97 pagesNRX-A5 Final ReportKelzie BenenskyNo ratings yet

- Paul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Document817 pagesPaul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Andreea Dobrita67% (3)

- Innovative Nuclear Space Power and Propulsion InstituteDocument2 pagesInnovative Nuclear Space Power and Propulsion InstituteKelzie BenenskyNo ratings yet

- PSU Interview TipsDocument7 pagesPSU Interview TipsKelzie BenenskyNo ratings yet

- Little Windy Team 2D ME 340 Final ReportDocument48 pagesLittle Windy Team 2D ME 340 Final ReportKelzie BenenskyNo ratings yet

- NRX/EST Reactor Test Analysis ReportDocument579 pagesNRX/EST Reactor Test Analysis ReportKelzie Benensky100% (1)

- NRX-A6 Final ReportDocument178 pagesNRX-A6 Final ReportKelzie BenenskyNo ratings yet

- ME 370 MDOF and Special Concepts NotesDocument51 pagesME 370 MDOF and Special Concepts NotesKelzie BenenskyNo ratings yet

- f11 SCH 200Document8 pagesf11 SCH 200Kelzie BenenskyNo ratings yet

- XDocument2 pagesXKelzie BenenskyNo ratings yet

- Group Exercises IDocument16 pagesGroup Exercises IKelzie BenenskyNo ratings yet

- 2023 Reso-01Document3 pages2023 Reso-01John Mark Mercado JubelagNo ratings yet

- 04.CNOOC Engages With Canadian Stakeholders PDFDocument14 pages04.CNOOC Engages With Canadian Stakeholders PDFAdilNo ratings yet

- Problems of Spun Concrete Piles Constructed in Soft Soil in HCMC and Mekong Delta - VietnamDocument6 pagesProblems of Spun Concrete Piles Constructed in Soft Soil in HCMC and Mekong Delta - VietnamThaoNo ratings yet

- Imp121 1isDocument6 pagesImp121 1isErnesto AyzenbergNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- Capitol Medical Center, Inc. v. NLRCDocument14 pagesCapitol Medical Center, Inc. v. NLRCFidel Rico NiniNo ratings yet

- Aircraft MaintenanceDocument32 pagesAircraft MaintenanceTateNo ratings yet

- Alfa Laval Plate Heat Exchangers: A Product Catalogue For Comfort Heating and CoolingDocument8 pagesAlfa Laval Plate Heat Exchangers: A Product Catalogue For Comfort Heating and CoolingvictoryanezNo ratings yet

- Vacuum Dehydrator & Oil Purification System: A Filter Focus Technical Publication D1-14Document1 pageVacuum Dehydrator & Oil Purification System: A Filter Focus Technical Publication D1-14Drew LeibbrandtNo ratings yet

- Siemens C321 Smart LockDocument2 pagesSiemens C321 Smart LockBapharosNo ratings yet

- Future Generation Computer SystemsDocument18 pagesFuture Generation Computer SystemsEkoNo ratings yet

- God Save The Queen Score PDFDocument3 pagesGod Save The Queen Score PDFDarion0% (2)

- MIami Beach City Attorney's DenialDocument7 pagesMIami Beach City Attorney's DenialDavid Arthur WaltersNo ratings yet

- Price Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)Document22 pagesPrice Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)kalpesh kathar100% (1)

- X606 PDFDocument1 pageX606 PDFDany OrioliNo ratings yet

- General Electric/ Massachusetts State Records Request Response Part 3Document673 pagesGeneral Electric/ Massachusetts State Records Request Response Part 3Gintautas DumciusNo ratings yet

- Eudemon8000E XDocument2 pagesEudemon8000E XGladys Medina100% (1)

- Web Server ProjectDocument16 pagesWeb Server Projectمعتز العجيليNo ratings yet

- Quiz1 2, PrelimDocument14 pagesQuiz1 2, PrelimKyla Mae MurphyNo ratings yet

- Pa 28 151 161 - mmv1995 PDFDocument585 pagesPa 28 151 161 - mmv1995 PDFJonatan JonatanBernalNo ratings yet

- Charts & Publications: Recommended Retail Prices (UK RRP)Document3 pagesCharts & Publications: Recommended Retail Prices (UK RRP)KishanKashyapNo ratings yet

- Oil Refinery OpsDocument3 pagesOil Refinery OpsPhiPhiNo ratings yet

- Group Tour Operators in Pune - Best Tours and Travels in PuneDocument10 pagesGroup Tour Operators in Pune - Best Tours and Travels in PuneGargi ToursNo ratings yet

- Lozada V Bracewell DigestDocument3 pagesLozada V Bracewell DigestMickey OrtegaNo ratings yet

- Basics Stats Ti NspireDocument7 pagesBasics Stats Ti NspirePanagiotis SotiropoulosNo ratings yet