Professional Documents

Culture Documents

Uni Lift Instructions

Uploaded by

MarcosPauloGrillo0 ratings0% found this document useful (0 votes)

455 views2 pagesinstruçoes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstruçoes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

455 views2 pagesUni Lift Instructions

Uploaded by

MarcosPauloGrilloinstruçoes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

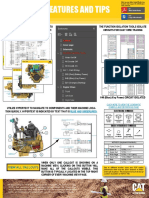

UNI LIFT Instructions

NOTE: Your router must be turned off and unplugged during

installation and adjustment of the UNILIFT.

ATTACHING YOUR ROUTER

Step 1

Step 1 With the exception of

Step 5

Step 5 Set router into recess

machined into plate.

the DeWalt 621, 625 or the FEIN

RT1800, remove the plastic subbase from the router. Store subbase and screws for future use.

Step 2

Step 2 With the UNILIFT face

Step 5

Step 6 Using a 5/8" socket

down and the Router Mounting

wrench, rotate lift screws counter-

Plate raised 2 4 inches, remove

clockwise to lower bearing blocks

six screws holding mounting plate

against plate. Stop when blocks

to bearing blocks.

just touch plate. Do not over

tighten.

Step 3

Step 3 With the counter-bored

Step 7

Step 7 Loosely install all six

side of the Router Mounting Plate

screws removed in step 2. Once

face up, use the Router Mounting

all screws are in, fully tighten.

Hole Map to locate your routers

bolt hole pattern. Mark each hole

with pencil or masking tape.

Step 4

Step 4 Locate hardware pack

for your router model. Mount

plate to router using appropriate

number of screws.

NOTES: 1. Certain router model types require alternate orientations.

If the handles of your router cannot go through the router

table opening, try rotating router and remounting.

2. The D-Handle on the Milwaukee 5612 router must be

removed to be used with the UNILIFT.

rev. 1.03

UNI LIFT Instructions

INSTALLING THE UNILIFT

Starting Pin

STARTING PIN A starting

pin is included to help start edge

OPENING SIZE The UNILIFT is designed to fit an opening

routing cuts during free hand

9.265 x 11.765 x .400 deep. A 1/2" ledge around the full perimeter

routing operations. The starting

is required.

pin can be installed in either of

Orientation

FENCE

BEARINGS

two available holes. Simply

ORIENTATION The UNILIFT

thread into place until tight.

has a spring loaded ball bearing

on one long and one short edge.

The long edge bearing should

face the fence.

The Brake

THE BRAKE The UNILIFT

features a positive break. It can

be operated by rotating the brake

Leveling

screw. The brake should always

LEVELING To level the

be engaged when routing and

UNILIFT, begin by adjusting the

must be disengaged when adjust-

two leveling screws on each

ing. Rotate brake screw clockwise

short end of the plate. Adjust

to lock, counter-clockwise to unlock.

the leveling screws so that the

plate is slightly above the router

table surface. The UNILIFT should

Height Adj.

HEIGHT ADJ. Before mak-

be above the router table approxi-

ing height adjustments, be sure

mately the thickness of a piece

to unlock brake by turning brake

of paper. This will ensure free movement of stock through the router

screw counter-clockwise. Next,

bit in both directions.

insert the hex crank tool into

either hex drive socket. Rotate

Once the first four screws are set, adjust the remaining screws for

clockwise to raise the router bit,

support. The four leveling screws near the long edges merely pro-

counter clockwise to lower it.

vide support. The short edge screws are used for leveling.

Rings

RINGS Each UNILIFT

comes with (3) aluminum rings.

Maintenance

MAINTENANCE Use light

machine oil for all maintenance.

Rings are removed by engaging

spanner wrench and rotating

CHAIN Keep chain clear of

CLOCKWISE, then lifting ring

large chips. Oil occasionally.

up out of plate. Rings are

installed by setting ring into

POSTS Oil occasionally.

opening and rotating

LIFT SCREWS Clean with

COUNTER-CLOCKWISE.

brush or compressed air and

oil occasionally.

PLATE SURFACE Wax and

polish to reduce friction.

P.O. Box 29510 Parma, Ohio 44129 phone: 440.230.2442 fax: 440.230.2552 www.woodpeck.com

Woodpeckers Inc. 2003

You might also like

- How To Fine Tune Your 3D Printer ENDER 3Document87 pagesHow To Fine Tune Your 3D Printer ENDER 3Michaël Memeteau100% (5)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocument30 pagesThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanNo ratings yet

- China Patcher Users Manual71719 PDFDocument13 pagesChina Patcher Users Manual71719 PDFeric pacha60% (5)

- Center Mount Bicycle Motor Kit PlansDocument47 pagesCenter Mount Bicycle Motor Kit PlansLiveFastMotors100% (2)

- Dutch Iris Eng 9734 HappyPattyCrochetDocument68 pagesDutch Iris Eng 9734 HappyPattyCrochetFrancisca Rico100% (6)

- Rear Mount Chain Drive Bicycle Motor Kit PlansDocument39 pagesRear Mount Chain Drive Bicycle Motor Kit PlansLiveFastMotors50% (2)

- 27 1405 Saturn Vue Installation Instructions CaridDocument2 pages27 1405 Saturn Vue Installation Instructions CaridenthonytopmakNo ratings yet

- Singer AdvancedDocument8 pagesSinger AdvancedMatthew Cole80% (5)

- Envisionlabs Wood ClocksDocument22 pagesEnvisionlabs Wood ClocksAlfonso100% (1)

- Schwinn Stingray OCC Chopper Bicycle Motor Kit PlansDocument38 pagesSchwinn Stingray OCC Chopper Bicycle Motor Kit PlansLiveFastMotors81% (16)

- Home Built CNCDocument110 pagesHome Built CNCBobby Chipping100% (4)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 4 Stroke Shift Kit Installation InstructionsDocument15 pages4 Stroke Shift Kit Installation InstructionsJ. RussellNo ratings yet

- View All Callouts: Function Isolation ToolsDocument29 pagesView All Callouts: Function Isolation Toolsمهدي شقرونNo ratings yet

- BM DF 3000 Complete ManualDocument21 pagesBM DF 3000 Complete ManualEduardo DelgadoNo ratings yet

- MD Profiler Instruction ManualDocument11 pagesMD Profiler Instruction ManualTatiana Trenogina100% (1)

- Shimano Alfine 11 SG-S700 Overhaul InstructionsDocument20 pagesShimano Alfine 11 SG-S700 Overhaul InstructionsFreyr Gunnar100% (1)

- Test 2-Module 1 12-10-2017: VocabularyDocument2 pagesTest 2-Module 1 12-10-2017: VocabularySzabolcs Kelemen100% (1)

- Craftsman Dovetail TemplateDocument16 pagesCraftsman Dovetail TemplateEvan MosemanNo ratings yet

- Claim of FactDocument11 pagesClaim of FactXeb UlritzNo ratings yet

- Concept 2 Rower Model C UsersManualDocument38 pagesConcept 2 Rower Model C UsersManualCrashNo ratings yet

- GV500 Series Winch Manual PDFDocument41 pagesGV500 Series Winch Manual PDFĐại Hùng100% (2)

- Woodpecker Plungelift™ Installation Instructions: Step 1Document2 pagesWoodpecker Plungelift™ Installation Instructions: Step 1MarcosPauloGrilloNo ratings yet

- DART Sensor Install 1 15Document6 pagesDART Sensor Install 1 15eldi_yeNo ratings yet

- Slr250 RidgidDocument80 pagesSlr250 RidgidAlex HammilionNo ratings yet

- Tevo Tornado: Assembly ManualDocument24 pagesTevo Tornado: Assembly Manualwalternia1No ratings yet

- 601 Car Frame Installations R1Document16 pages601 Car Frame Installations R1bhupiisterNo ratings yet

- EN Pilot-XPDocument6 pagesEN Pilot-XProssandcoNo ratings yet

- TornadoDocument24 pagesTornadoAbdel AdimNo ratings yet

- Monoprice CNC Manual 44220 - Manual - 230310Document24 pagesMonoprice CNC Manual 44220 - Manual - 230310looie daquickNo ratings yet

- TevoDocument9 pagesTevoJean-m DuguayNo ratings yet

- Useful Hints and Tips For All NAXO BindingsDocument24 pagesUseful Hints and Tips For All NAXO BindingsTomnaticNo ratings yet

- 512 User's ManualDocument17 pages512 User's ManualSam CozaNo ratings yet

- NSS8 Manual08212014Document13 pagesNSS8 Manual08212014CTS-incNo ratings yet

- Runner Dismantling InstallationDocument7 pagesRunner Dismantling InstallationReynaldo PesqueraNo ratings yet

- Lada Niva GEARBOX AssemblyDocument17 pagesLada Niva GEARBOX Assemblyektoras49No ratings yet

- Reflector Assembly and Installation: Parts List Tools NeededDocument2 pagesReflector Assembly and Installation: Parts List Tools NeededJeff Ben FabregasNo ratings yet

- Brake Shoes Removal and Installation PDFDocument6 pagesBrake Shoes Removal and Installation PDFMichael HernandezNo ratings yet

- Pulley Puller InstructionsDocument4 pagesPulley Puller InstructionsMark SchaubNo ratings yet

- Heidts Superide IRSDocument8 pagesHeidts Superide IRSNovita EmRoseNo ratings yet

- ShopsmithDocument12 pagesShopsmithJhon Torr LueNo ratings yet

- Agri-Fab, Craftsman Front Mount DethatcherDocument12 pagesAgri-Fab, Craftsman Front Mount DethatcherKevins Small Engine and Tractor ServiceNo ratings yet

- TUG T1X2 95373 DDocument25 pagesTUG T1X2 95373 DTiagoNo ratings yet

- Vemco 612 User's ManualDocument25 pagesVemco 612 User's ManualRobert Cannavino100% (1)

- Sequential Shifter Fitting Instructions v2 A4Document17 pagesSequential Shifter Fitting Instructions v2 A4Ufix FabricationNo ratings yet

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellNo ratings yet

- Bicycle Motor Plans Instructions Tire Roller Rear Friction DriveDocument3 pagesBicycle Motor Plans Instructions Tire Roller Rear Friction DriveLiveFastMotorsNo ratings yet

- Drive Unit Removal and Re-InstallationDocument10 pagesDrive Unit Removal and Re-InstallationSuhas JadhavNo ratings yet

- Simba User Manual Ed2 021214 PDFDocument20 pagesSimba User Manual Ed2 021214 PDFChengodan KandaswamyNo ratings yet

- Eagle Eyes Antenna Pan/Tilt Assembly InstructionsDocument12 pagesEagle Eyes Antenna Pan/Tilt Assembly InstructionsdanielNo ratings yet

- Inst AllureDocument30 pagesInst AllurePravin K PatelNo ratings yet

- The Useless Machine: Instructions GuideDocument20 pagesThe Useless Machine: Instructions GuideDDNo ratings yet

- Operation and Maintenance Instructions: 334 SERIES THREE-PIECE BALL VALVES - 1/4" To 2-1/2"Document5 pagesOperation and Maintenance Instructions: 334 SERIES THREE-PIECE BALL VALVES - 1/4" To 2-1/2"MASOUDNo ratings yet

- Valve Lash Adjustment 8L 22L4 PDFDocument12 pagesValve Lash Adjustment 8L 22L4 PDFMindo.silitongaNo ratings yet

- Abd 350 - 360 - 375Document64 pagesAbd 350 - 360 - 375Jose Rodriguez CorporanNo ratings yet

- David White l6-20 ManualDocument20 pagesDavid White l6-20 ManualGuillermo Agustín Yáñez QuezadaNo ratings yet

- Manual Inglês Esteira Reebok I-Wal... I-Run RE-11306Document8 pagesManual Inglês Esteira Reebok I-Wal... I-Run RE-11306xatozo50% (2)

- DART Ratio Change 1 15Document5 pagesDART Ratio Change 1 15eldi_yeNo ratings yet

- Adjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsDocument22 pagesAdjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsWilliam BarriosNo ratings yet

- BORS Installation Instructions Leupold PDFDocument3 pagesBORS Installation Instructions Leupold PDFblazerman3No ratings yet

- Reciprocator Compact Single and MultiheadDocument14 pagesReciprocator Compact Single and MultiheadjoecentroneNo ratings yet

- Beltway Scale Manual 2009Document56 pagesBeltway Scale Manual 2009morris_timNo ratings yet

- SM-330 - SM430 - SM-936 - 1136 Semi-Automatic Divider Rounder SeriesDocument20 pagesSM-330 - SM430 - SM-936 - 1136 Semi-Automatic Divider Rounder Serieshugo_1990No ratings yet

- SkidSteer Track Installation InstructionsDocument16 pagesSkidSteer Track Installation InstructionsMichael KhushfNo ratings yet

- IR2153 Parte6Document1 pageIR2153 Parte6FRANK NIELE DE OLIVEIRANo ratings yet

- Ultracold Atoms SlidesDocument49 pagesUltracold Atoms SlideslaubbaumNo ratings yet

- Very Narrow Aisle MTC Turret TruckDocument6 pagesVery Narrow Aisle MTC Turret Truckfirdaushalam96No ratings yet

- Genuine Fakes: How Phony Things Teach Us About Real StuffDocument2 pagesGenuine Fakes: How Phony Things Teach Us About Real StuffGail LeondarWrightNo ratings yet

- Pediatrics: The Journal ofDocument11 pagesPediatrics: The Journal ofRohini TondaNo ratings yet

- Traditional Perceptions and Treatment of Mental Illness in EthiopiaDocument7 pagesTraditional Perceptions and Treatment of Mental Illness in EthiopiaifriqiyahNo ratings yet

- Module 5 What Is Matter PDFDocument28 pagesModule 5 What Is Matter PDFFLORA MAY VILLANUEVANo ratings yet

- Yetta Company ProfileDocument6 pagesYetta Company ProfileAfizi GhazaliNo ratings yet

- A Comparative Study of Public Private Life Insurance Companies in IndiaDocument5 pagesA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalNo ratings yet

- Data MiningDocument28 pagesData MiningGURUPADA PATINo ratings yet

- DirectionDocument1 pageDirectionJessica BacaniNo ratings yet

- Assessment of Embodied Carbon Emissions For Building Construc - 2016 - Energy AnDocument11 pagesAssessment of Embodied Carbon Emissions For Building Construc - 2016 - Energy Any4smaniNo ratings yet

- I. Learning Objectives / Learning Outcomes: Esson LANDocument3 pagesI. Learning Objectives / Learning Outcomes: Esson LANWilliams M. Gamarra ArateaNo ratings yet

- 10 1108 - TQM 03 2020 0066 PDFDocument23 pages10 1108 - TQM 03 2020 0066 PDFLejandra MNo ratings yet

- Nutridiet-Enteral and Parenteral FeedingDocument3 pagesNutridiet-Enteral and Parenteral FeedingBSN 1-N CASTRO, RicciNo ratings yet

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalNo ratings yet

- Ej. 1 Fin CorpDocument3 pagesEj. 1 Fin CorpChantal AvilesNo ratings yet

- Lodge at The Ancient City Information Kit / Great ZimbabweDocument37 pagesLodge at The Ancient City Information Kit / Great ZimbabwecitysolutionsNo ratings yet

- CATaclysm Preview ReleaseDocument52 pagesCATaclysm Preview ReleaseGhaderalNo ratings yet

- D25KS Sanvick PDFDocument4 pagesD25KS Sanvick PDFJiménez Manuel100% (1)

- 11.3.1 Some Special CasesDocument10 pages11.3.1 Some Special CasesSiddharth KishanNo ratings yet

- 444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16Document1 page444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16whatisNo ratings yet

- China Training WCDMA 06-06Document128 pagesChina Training WCDMA 06-06ryanz2009No ratings yet

- Multinational MarketingDocument11 pagesMultinational MarketingraghavelluruNo ratings yet

- AE Notification 2015 NPDCLDocument24 pagesAE Notification 2015 NPDCLSuresh DoosaNo ratings yet