Professional Documents

Culture Documents

1 s2.0 S095965261400002X Main PDF

Uploaded by

Gabriela BalintOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S095965261400002X Main PDF

Uploaded by

Gabriela BalintCopyright:

Available Formats

Journal of Cleaner Production 73 (2014) 269e274

Contents lists available at ScienceDirect

Journal of Cleaner Production

journal homepage: www.elsevier.com/locate/jclepro

The environmental effects of seasonal food purchase: a raspberry case

study

Chris Foster a, *, Catarina Guben a, Mark Holmes b, Jeremy Wiltshire b, Sarah Wynn b

a

b

EuGeos Limited, UK

ADAS, UK

a r t i c l e i n f o

a b s t r a c t

Article history:

Received 28 March 2013

Received in revised form

6 December 2013

Accepted 19 December 2013

Available online 17 January 2014

The environmental effects of seasonal food supply have been explored through a Life Cycle Assessment

(LCA) study of raspberries supplied to UK consumers at different times of year. Supply of raspberries at

different times of the year draws on different production systems and locations. Despite that, the results

of this LCA, based on data from individual producers, reveal relatively small differences in impacts for

different times of supply, except in the case of the water footprint measures. LCIA results are very

sensitive to fruit yield. So in this case, yield and agricultural practice appear stronger drivers of the

environmental burden of food production than is time of supply. In such situations a strong focus on

seasonality in sustainable food provisioning is unlikely to deliver large environmental benets. Using

LCA to establish what benets might be available from a more general shift to seasonal food consumption, often advocated as more sustainable, will require a multi-product approach. Such an

approach could take current food consumption patterns or environmental targets as its starting point.

2014 Elsevier Ltd. All rights reserved.

Keywords:

Seasonal

Fruit

Seasonal food

Raspberry

LCA

1. Introduction

1.1. Seasonal food

As urbanisation progressed in the second half of the 20th Century and the agricultural workforce shrank, so Western European

citizens disengaged from food production, losing their connection

with its seasonal patterns. From the 1960s onwards, seasonal

variation in the availability of certain foods reduced, leading to the

commonly-described position of all-year-round availability for

many foods. Recently, interest in seasonal foods has been resurgent; Dibb et al. (2006) state that two-thirds of people in the UK are

now taking steps to buy seasonally. This trend has various drivers

but e as Dibb et al.s title suggests e some see implications for the

environment in it. In line with this, advice on sustainable diet

often advocates consumption of seasonal food. Seeking additional

evidence relevant to such recommendations, the UKs Department

of the Environment, Food and Rural Affairs commissioned a

research project exploring the environmental implications of seasonal food purchasing (DEFRA research project FO0412). This paper

reports some ndings of the project, focussing on environmental

implications of seasonal food supply explored through a raspberry

LCA case study.

A review of literature and consumer research demonstrated that

clearly identifying seasonal food is in fact quite difcult. Few

commentators take the trouble to dene the term seasonal, while

consumer research found that UK consumers have only a vague

denition of seasonal food. In essence very different denitions

and perceptions of what is seasonal are applied by different parties

(Brooks and Foster, 2011). To inform the project noted above, two

working denitions of seasonal food were used e one derived from

discussions with industry and policy makers and one informed by

consumer research reported in ADAS et al. (2012). The rst was a

production-oriented or global denition: food that is outdoor

grown or produced during the natural growing/production period

for the country or region where it is produced. It need not necessarily be consumed locally to where it is grown.1 The second was a

consumer-oriented, more local denition: food that is produced

and consumed in the same climatic zone, e.g. UK, without high

energy use for climate modication such as heated glasshouses or

high energy use cold storage. Inevitably, these denitions are

themselves open to interpretation. The LCA research on which this

article draws covered a number of food items meeting one or the

other (or both) of these denitions.

* Corresponding author.

E-mail addresses: chrisf@eugeos.co.uk, c.foster@manchester.ac.uk, chris.foster@

mbs.ac.uk (C. Foster).

0959-6526/$ e see front matter 2014 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.jclepro.2013.12.077

This was originally suggested in Defras project specication.

270

C. Foster et al. / Journal of Cleaner Production 73 (2014) 269e274

1.2. Food, seasonality and the environment

The timing of agricultural activities in any one place can change

the effects of those activities on the wider environment, even if the

activities remain the same. Thus changing the timing of pesticide

applications can result in increased or reduced effects on non-pest

susceptible species, simply because these will be present in

different numbers, variety and development stage; moving nitrogen fertiliser applications to times of higher rainfall will likely lead

to higher leaching rates; the presence of crop canopy in times of

higher rainfall might mitigate soil erosion. So if a crops planting-toharvest cycle is moved earlier or later in the year and fertiliser and/

or pesticide applications moved in step, then the total effects on the

environment can change.

As food production for supply in a certain place is shifted further

away in time from the natural, or normal time of production

there, so one or both of two additional changes occurs: either the

nature of the producing activity changes (e.g. through the use of

protected growing environments) or the place of production

changes (change can include division, as in the case reported

below). Furthermore, preservation and storage allow the time of

production and the time of supply to be separated, introducing

further exibility into the supply system. Finally of course, consumers also have access to preservation and storage, so can separate the time of supply from the moment of consumption.

Each of these adjustments changes the interaction between the

food system and the natural environment surrounding it: different

production systems for the same basic foodstuff have different

yields and require different inputs, almost all preservation techniques require energy inputs, as does cold storage. The fact that

these adjustments can be made at different points in a generic food

production-consumption system is a strong indicator that life cycle

assessment will be an effective tool to explore their environmental

implications.

1.3. LCA and seasonality

While the need to consider the whole food productionconsumption system favours the application of LCA in this context,

care is needed because of the way temporality is handled within LCA.

For agricultural products the product system is normally dened as a

full annual (sometimes multi-annual) cycle and the life cycle inventory (LCI) integrates emissions occurring throughout that cycle,

dividing them equally among the total harvest. Thus few life cycle

analyses of food products or systems explicitly explore seasonality.

When LCA studies refer to seasonality, the term is associated e

implicitly or explicitly e with a crops natural growing season and

its cropping period, thus with its availability for fresh consumption.

Some LCAs examine seasonal variation in impacts more explicitly,

for example Williams et al. (2009). This and other studies (Blanke

2007; Blanke and Burdick, 2005, 2007, Hospido et al., 2009; Jones,

2006; Mil i Canals et al., 2007; Saunders et al., 2006) consider

seasonality in the context of the supply of fresh produce to consumers in Northern Europe all year round e and thus closely connected to the local vs. global or food miles debate.

Examination of this literature highlights some issues that

require attention if seasonal effects on the environmental impacts

of food supply are to be separated from other factors that may differ

between supply systems but are not directly linked to seasonality.

For example, a review by Evans (2014) found the range of specic

energy use (energy use per volume) in cold stores in the UK alone to

be very wide for each temperature regime studied e with an eightfold difference between the most and least efcient. Blanke and

Burdick (2005), Mil i Canals et al. (2007), Saunders et al. (2006),

Sim et al. (2007) and Williams et al. (2009) all report LCAs of

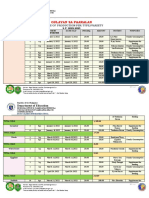

Fig. 1. UK raspberry supply 2007.

Sources: Defra horticultural statistics, UK Trade statistics.

apples; it is clear from these that the impacts associated with the

different stages of the apple life cycle are of similar order of

magnitude, a situation that may then reasonably be anticipated for

other top-fruit. Differences in post-harvest technology, arising

coincidentally, may therefore outweigh differences driven by the

season of production. In cases where supply at a particular time of

year requires storage, the scale of product loss or degradation

during storage must be accounted for. The degree of geographical

resolution embedded in impact assessment (LCIA) methods (few of

which exist in regionalised form) may also limit the extent to which

LCA can inform about the environmental effects of seasonal variation in food supply when that variation involves production in

different places.

2. Methods

2.1. Scope

The aim of the research was to explore the environmental implications of upstream changes that arise as supply of particular

foodstuffs progresses through the year. Therefore a selection of

individual foods was studied, rather than a sequence of baskets.

Here the raspberry case study is reported to illustrate how environmental impacts vary across the year for one food consumed in

the UK. Clearly at a certain time of year raspberries are in-season

in the UK, at other times they are not. The project considered only

the effect of changing the times of production and supply in the

system as far as delivery to the food retailer. In effect, we equate

(reecting mainstream economics and consumer data) consumption with purchase, and purchase with supply to the retailer. This

embodies a simplication: it is possible that consumers store foods

for extended periods after purchasing them. The environmental

implications of this, if it occurs, were not considered in the LCA; it

would make food consumption less seasonal than statistics

would lead us to believe it is. Some of the volume captured by this

data is supplied to commercial buyers (the foodservice sector or

institutions) rather than nal consumers, of course. This is still

purchase, however, and there seems to be no reason to exclude it.

Fig. 1 shows how UK supply of raspberries changes through the

year in volume and by source (data compiled from UK production2

and import3 statistics with quantity, in tonnes, as the y-axis which

2

Department of Environment, Food and Rural Affairs Horticultural Statistics:

www.defra.gov.uk/statistics/foodfarm/landuselivestock/bhs/.

3

HM Revenue & Customs Trade Statistics: https://www.uktradeinfo.com/Pages/

Home.aspx.

C. Foster et al. / Journal of Cleaner Production 73 (2014) 269e274

is not shown) There is scarcely competition between local production e certainly seasonal according to the consumer-oriented

denition above e and imports, which are seasonal only according to the global denition; rather imports complement local

produce in an overall supply pattern. To gain some insight into the

environmental implications of this supply pattern an LCA of raspberries was conducted. This covered 3 functional units:

A. 1 kg raspberries delivered fresh to a supermarkets retail distribution centre (RDC) in May

B. 1 kg raspberries delivered fresh to a RDC in July

C. 1 kg raspberries delivered frozen to a RDC in November

271

2.2. Boundaries

The product systems incorporated production of fertilisers,

canes, packaging, fuels and all other inputs. Production of material

for polytunnels was included, but other capital equipment was

excluded so that the calculations of global warming potential were

compliant with PAS 2050:2008, which was the most recent version

of that standard at the time the work was carried out. For the

production system in B & C, an additional year of operation without

any crop production was included as an allowance for cane production, for which direct data were unavailable.

2.3. Data

Given the data underlying Fig. 1, an appropriate product system

for A involves production in Southern Spain. In a production system common there, raspberries are grown on an annual basis in

elds that are covered for the whole season with Spanish tunnels. The ground is prepared each year and beds then formed. The

planting material (canes) is produced in the UK or Netherlands

and transported to the producing site in chilled lorries. The canes

are kept for 3e4 weeks in a cold store prior to planting, then

planted directly through plastic into the pre-prepared beds. Fertilisers are applied through drip irrigation: nitrogen as ammonium

nitrate or potassium nitrate. Water for irrigation is abstracted from

an aquifer. Harvesting occurs by hand with the fruit then transported directly to the packhouse; average yield is 8 tonnes

marketable fruit per ha. (FAOSTAT 2009) In the packhouse the fruit

is graded and cleaned, before being placed into punnets with a

plastic lm lid. Punnets are cooled in a cold store prior to export in

refrigerated trucks which travel 2,500 km from Spain to the UK.

For B and C production in the UK is clearly appropriate. a typical

production system is located in the east of England, on canes

grown for seven years in elds covered with polytunnels during

fruiting. In this case in the rst year the ground is prepared, beds

formed and soil sterilised (e.g. with chloropicrin). The canes are

produced on a separate farm, cold stored prior to planting, then

planted directly through plastic into the pre-prepared beds. On an

annual basis (for seven croppings) fertilisers are applied through

drip irrigation including nitrogen fertiliser as ammonium nitrate

or potassium nitrate. Irrigation uses water from an aquifer. Fruit is

hand-harvested then transported directly to the packhouse. Yield

averages 12t marketable fruit per hectare per year for the seven

cropping years. In the packhouse the fruit is graded and cleaned,

before being placed into punnets with a plastic lm lid. Punnets

are cooled in a cold store prior to distribution in refrigerated

trucks. At the end of the season the soil between the beds is

pulverised to reduce compaction. At the end of the seven years the

crop is grubbed out, the ground sub-soiled and the plastic rolled

up and recycled.

These are commonly-encountered production techniques producing for the UK supply pattern, and individual producers

employing them provided complete or partial operating data for

use in the project (see next section).

In the case of C, Fig. 1 indicates that there is little e although not

zero e supply from primary producers in November. Supply of

frozen raspberries originally produced in the UK production system

described for B was included to investigate the signicance of

adding storage alone to one of the production systems already

studies. An alternative mechanism for supply of raspberries to the

UK market in November would involve import by air of fresh fruit

produced overseas, probably North America on the basis of Fig. 1.

We had no access to data characterising raspberry production in

North America and so this possible fourth case was not included.

Frozen and fresh raspberries may indeed not be considered as

substitutable products by purchasers.

Primary data from individual operating locations were used to

characterise agricultural operations, with expert consultation used

to ll data gaps. Background data to represent production of inputs

such as fertilisers, fuel and polyethylene lm were taken from the

ecoinvent database v2 (www.ecoinvent.ch). Data characterising

outdoor production of raspberry canes in the UK were developed by

the research team, based on the data provided for raspberry fruit

production outdoors in the UK and advice from a horticultural

expert on likely per ha yields. Methane and nitrous oxide emissions, where they arose, were calculated using the method set out

in the IPCCs (2006) Guidelines for National Greenhouse Gas Inventories. This aligned the method with PAS 2050:2008. The water

footprint of a primary crop is calculated as the ratio of volume of

water consumed for crop production to the crop yield. The Food and

Agriculture Organization of the United Nations CROPWAT tool (FAO,

2010a) was used to estimate volumes of rain and irrigation water

evaporated in the eld during production: the green and blue water

footprint. As input into this model, climate data was taken from the

CLIMWAT database (FAO, 2010b), rened with local data wherever

possible. To calculate grey water footprint and to enable calculation

of eutrophication potentials, nitrate leached to water was estimated

using the ADAS Nitcat (Lord, 1992 and subsequent revisions) eldscale nitrate leaching model, with data specic for each location.

Where the model was deemed inappropriate for the growing

conditions or crops, estimates of leached nitrate were obtained

from the literature.

A single set of data, from one of the operating locations, was

used to characterise all packhouse operations and packaging; a loss

rate of 1% in the packhouse was assumed.

A dataset for chilling and short-term cold storage of soft fruit

was developed to characterise packhouse operations and storage

prior to transhipment either to the RDC or to a long-term coldstorage location. This was based on data for annual operation

provided by one business participating in the study. To create an

appropriate dataset for an equivalent operation in Spain, the source

of electricity used was changed from the UK grid to the Spanish

one; energy consumption was assumed to be the same in both

locations e i.e. any additional cooling energy required in the

warmer climate of Spain was ignored. A dataset characterising

frozen storage was also developed, encompassing energy use and

refrigerant loss and accounting for the burdens of providing a unit

volume of cold storage capacity for a unit time; energy use in cold

stores was taken from a review of UK facilities (Evans, n.d.); a

mixture of gases (the constituents of R404A in the appropriate

proportions and NH3) was used to represent emissions to air,

reecting the most widely-used refrigerants, while actual data for

refrigerant use (assumed equal to losses over a full year) were

supplied by the raspberry packer. In the survey of energy use in cold

stores, Evans (2014) found the range of specic energy use within

each temperature regime to be much greater than differences between the different temperature regimes (i.e. frozen and

272

C. Foster et al. / Journal of Cleaner Production 73 (2014) 269e274

chilled). Because most LCA results for food products relate to a

unit mass of product rather than volume (the factor to which cold

store energy consumption is typically normalised for reporting

purposes), gures for mass of product per unit of storage volume

were taken from Brunel University (2009) to calculate the cold

storage volume needed for 1 kg raspberries. Finally, a dataset for

the unit operation of road transport in refrigerated trucks was

developed using values for fuel consumption, vehicle utilisation

and refrigerant loss given by Brunel University (2009); emissions

per unit of fuel used were taken from ecoinvent v2.1 (Spielmann

et al., 2007).

2.4. Impact assessment

Impact assessment was conducted for environmental categories

deemed relevant to the project. Category and impact assessment

method selection were also guided by a requirement for compatibility with results from previous LCAs of UK agricultural commodities, particularly those produced by Williams et al. (2009).

Therefore, CML midpoint methods (Guine, 2002) were used for

the categories global warming, eutrophication, acidication and

photochemical oxidation. In addition agricultural land occupancy

was reported in units of m2 yr. (the result obtained by simply

adding all land occupation of all classes in the inventory), as were

the unweighted water footprint (to the method described by

Hoekstra and Chapagain, 2008); weighted water footprint (using a

method very similar to that outlined by Ridoutt and Pster (2010)

whereby a water stress characterisation factor for producing locations was introduced through the use of a water stress index (WSI,

Pster et al., 2009) to weight the water use according to the degree of water stress at the place of use) and environmental impact

quotient (EIQ, Kovach et al., 1992) of pesticides used. This last

method is based on average effects, and is neither geographicallynor temporally-sensitive. Regionalised LCIA methods are available

for eutrophication and acidication, but were not used here

because other factors, noted above, drove LCIA method selection.

3. Results

The impact assessment results are shown in Table 1.

Sensitivity analysis was undertaken to assess the effect on the

LCIA results of raspberry cane yield (no. Per ha) for case A and of

cold-store operating parameters for case C. Selected results are

shown in Table 2 (below). Results for impact categories driven

strongly by horticultural process parameters (for example, land

occupation, global warming) are, as expected, highly sensitive to

product yield. Categories to which transport process emissions

contribute more (notably acidication) are of course less sensitive

to this factor. Sensitivity to other parameters, such as cold-store

efciency, was found to be weaker than to those included in

Table 2. For cold storage, small variations in energy consumption

per unit volume are less signicant inuences on overall LCA results than the nature of the refrigerant used and assumed loss rates

for the more environmentally-signicant refrigerants.

4. Discussion

The results in Table 1 represent the progression of the environmental impacts associated with supply of raspberries through

the year. Because food at one time of the year is not, for many

consumers, substitutable for food at another, while it is reasonable

to reect on the changes in LCIA results between one case and

another, the three cases cannot really be compared as alternatives.

The differences between the LCIA results obtained for these

particular cases of raspberry supply at three points in the year are

relatively small, except for the water footprint measures. The fact

that both canes and fruit are subject to long-distance refrigerated

transport is a signicant factor behind the higher acidication and

abiotic depletion values obtained for raspberries delivered fresh in

May (A); for example product transport accounts for 35% of the

acidication potential for A but 18% of the acidication potential for

B. The close similarity between the EIQ values obtained partly results from the use of expert consultation to ll data gaps; results

obtained for strawberries within the same project (for which the

pesticide use data was of higher quality) suggest that differences in

soil sterilant application rates and frequencies can have a signicant inuence on this indicator. It is notable that the weighted

water footprint measure is the one LCIA method applied here

which is sensitive to location and is the one for which the differences between the three cases is largest.

For impact categories other than water, likely (e.g. year-to-year)

variations in fruit yield and cane yield could give rise to variations

in the results obtained for one particular case greater than the

differences between the different cases shown in Table 1.

N2O emissions from horticulture contribute a large proportion

of the GWP: 75% for A and more than 90% for B and C. However, in

this project the calculation of N2O emissions from soil following the

incorporation of crop residues both in the UK or overseas was

highly problematic. The IPCC 2006 method using the tier 1

approach is complex and uses many default values for specic crops

or crop groups. A large number of crops are not represented in the

IPCC method, therefore default data relevant to several of the

products considered in this project e including raspberries e were

not available. Data for another crop product were used as a proxy,

but this introduces a further element of uncertainty.

The production of polyethylene contributes some 25% of the

abiotic depletion potential in A. Tunnels account for the majority of

the polyethylene in this case. While there is some uncertainty about

Table 1

LCIA results, raspberries in the UK at different times of year.

Impact category

GWP100 (kg CO2 eq)

Water footprint (WF) (m3 Virtual water)

Weighted WF (m3 Virtual water)

Agricultural fruit-growing land occupation (m2 yr)

Pesticide hazard indicator E.I.Q.

Abiotic depletion (kg antimony eq.)

Photochemical oxidation e high NOx (kg ethylene eq.)

Acidication e (kg SO2 eq.)

Eutrophication (kg PO4 eq.)

Product system

A. Raspberries, fresh

at UK RDC in May

B. Raspberries fresh at

UK RDC in July

C. Raspberries frozen at

UK RDC in November

7.3

2.7

2.7

1.1

0.3

0.01

0.0004

0.01

0.005

7.4

1.3

0.09

1.2

0.3

0.004

0.0001

0.003

0.004

7.7

1.3

0.09

1.2

0.3

0.006

0.0002

0.004

0.004

C. Foster et al. / Journal of Cleaner Production 73 (2014) 269e274

273

Table 2

Sensitivity analysis results.

Impact category

GWP100 (kg CO2 eq)

Water footprint (WF)

(m3 Virtual water)

Weighted WF

(m3 Virtual water)

Agricultural fruitgrowing land

occupation (m2 .yr)

Pesticide hazard

indicator E.I.Q.

Abiotic depletion

(kg antimony eq)

Photochemical

oxidation e high

NOx (kg ethylene eq.)

Acidication e

(kg SO2 eq.)

Eutrophication

(kg PO4 eq.)

Product system

A. Raspberries,

fresh at UK

RDC in May

(base)

A1. Raspberries,

fresh at UK

RDC in May,

fruit yield 10%

A2. Raspberries

fresh at UK RDC

in May, planting

material (canes)

yield 30%

B. Raspberries

fresh at UK

RDC in July

B1. Raspberries fresh

at UK RDC in July,

fruit yield 10%

C. Raspberries

frozen at UK

RDC in November

C1. Raspberries frozen

at UK RDC in

November, maximal

cold-store occupancy

7.3

2.7

5.7

Not calculated

6.0

Not calculated

7.4

1.3

6.7

Not calculated

7.7

1.3

7.5

Not calculated

2.7

Not calculated

Not calculated

0.09

Not calculated

0.09

Not calculated

1.1

1.0

1.0

1.2

1.1

1.2

1.2

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.01

0.01

0.01

0.004

0.004

0.006

0.005

0.0004

0.0004

0.0004

0.0001

0.0001

0.0002

0.0002

0.01

0.008

0.009

0.003

0.003

0.004

0.003

0.005

0.004

0.005

0.004

0.003

0.004

0.003

the fate and longevity of the material used for these tunnels in

practice, extending the materials life and recycling it when it is no

longer useable are clearly desirable.

In case C (frozen raspberries supplied in November) no allowance was made for loss or spoilage during cold storage. Such losses

increase the impacts associated with supplied product but no

relevant data for loss rates were available when the work was

conducted. Recent work by WRAP (Terry et al., 2011) provides an

estimate of 2e3% losses of fresh raspberries in packing and in retail

stores, but provides no estimate for losses of packed fruit consigned

to frozen storage. The loss rates found for packing are similar to

those used in this study.

5. Conclusions

An LCA has been completed of a soft fruit supplied in the UK at

three different times of the year. Here we draw some tentative

conclusions based on the results of this LCA.

The impact assessment results obtained show relatively small

shifts as the time of supply progresses through the year, perhaps

surprising in light of the operational differences between the

supply systems. The inuence on environmental impact of the

place of production shows through strongly in the weighted water

footprint. This impact assessment method has, of course, locationsensitivity built into it; it may be that if regionalised methods had

been used for other categories (notably eutrophication), the inuence of place would have shown in those too.

Comparing the results obtained for the different cases with the

results of the sensitivity analysis suggests that, for raspberries at

least, yield and agricultural practice are stronger drivers of the

environmental burden of food production than is time of supply. In

such situations, it seems that a strong focus on seasonality in

sustainable food provisioning is unlikely e by itself e to deliver

large environmental benets.

That conclusion must be recognised as provisional because of the

nature of the LCAs undertaken here e based on particular examples

of production rather than statistically-representative datasets for

production at certain times of the year, employing modelled data for

emissions and LCIA methods without regional sensitivity to explore

the effects of emissions which arise in different places at different

times of the year. Such reservations about LCA method aside, the

literature review and study design highlighted challenges facing any

assessment of the environmental effects of a shift towards seasonal

food consumption. If such a shift occurred at any signicant scale, it

would presumably involve a complex adjustment of food purchasing

and consumption patterns. The method used in this work precluded

consideration of the environmental consequences of seasonallychanging consumption patterns. Understanding the environmental implications of such patterns remains a desirable aim. Future

work should look beyond single food items. An important rst step

in such work would be to draw on food purchasing statistics to

establish how consumers food purchases actually vary through the

year; month-by-month results from the UKs National Food Survey

represent such a source (Ofce of National Statistics). In setting up

scenarios that might be used as realistic alternatives to existing

patterns that might be revealed in such statistics, account must be

taken of differences in understandings of seasonal food, modern

health norms (e.g. 5-a-day) and 21st-century consumer expectations.4 Established or desirable environmental goals should also be

considered in any such scenario-based LCA study; such a study

might then try to build year-long consumption patterns that meet

both modern health norms and environmental targets while

incorporating seasonal variation.

References

ADAS, Serio, EuGeos Limited, CFI Shefeld Hallam University 2012. Final Report of

DEFRA project FO0412. http://sciencesearch.defra.gov.uk/Document.aspx?

Document10257_FO0412SID5draftv2005_Aug_12. (accessed 02.12.13.).

Blanke, M.M., 2007. Life cycle assessment (LCA) and food miles: an energy balance for

fruit imports versus home-grown apples. In: Proceedings of the 5th International

Conference LCA in Foods (25e26 April 2007, Gothenburg, Sweden), pp. 111e116.

Blanke, M.M., Burdick, B., 2005. Food (miles) for thought e energy balance for locallygrown versus imported apple fruit. ESPR e Environ. Sci. Pollut. Res.12 (3),125e127.

Blanke, M.M., Burdick, B., 2007. Imported versus home-grown apples: LCA, food

miles and energy balance. In: Proceedings of the 5th International Conference

LCA in Foods (25e26 April 2007, Gothenburg, Sweden), pp. 117e120.

4

For a discussion of the co-evolution of consumer expectations and food products, see Foster et al. (2012) or Freidberg (2009).

274

C. Foster et al. / Journal of Cleaner Production 73 (2014) 269e274

Brooks, M., Foster, C., Holme, s M., Wiltshire, J., 2011. Does consuming seasonal

foods benet the environment? Br. Nutrit. Bull. 36, 449e453.

Brunel University, 2009. Greenhouse Gas Impacts of Food Retailing. Defra, London.

Report of project FO 0405.

Dibb, S., Collins, J., Mayo, E., 2006. Seasons Promise: an Enjoyable Way to Tackle

Climate Change. National Consumer Council.

Evans, J., n.d. Cold Storage of Food. Review of Available Information on Energy

Consumption and Energy Savings Options. FRPERC, University of Bristol.

FAO, 2010a. CROPWAT Tool. Available at: http://www.fao.org/nr/water/infores_

databases_cropwat.html (last visited 28/03/2013).

FAO, 2010b. CLIMWAT Tool. Available at: http://www.fao.org/nr/water/infores_

databases_climwat.html (last visited 28/03/2013).

Foster, C., McMeekin, A., Mylan, J., 2012. The entanglement of consumer expectations and (eco) innovation sequences. Technol. Anal. Strat. Manag. 24, 391e405.

Freidberg, S., 2009. Fresh, a Perishable History. Harvard University Press, Cambridge, Mass.

Guine, J.B., 2002. In: Gorre, M., Heijungs, R., Huppes, G., Kleijn, R., de Koning, A.,

Van Oers, L., Wegener Sleeswijk, A., Suh, S., Udo de Haes, H.A., De Bruijn, J.A.,

Van Duin, R., Huijbregts, M.A.J. (Eds.), Handbook on Life Cycle Assessment:

Operational Guide to the ISO Standards, Series: Eco-efciency in industry and

science. Kluwer Academic Publishers, Dordrecht.

Hoekstra, A.Y., Chapagain, A.K., 2008. Globalization of Water: Sharing the Planets

Freshwater Resources. Blackwell Publishing, Oxford, UK.

Hospido, A., Mil i Canals, L., McLaren, S., Truninger, M., Edwards-Jones, G., 2009.

The role of seasonality in lettuce consumption: a case study of environmental

and social aspects. Int. J. Life Cycle Assess. 14 (5), 381e391.

IPCC Guidelines for National Greenhouse Gas Inventories, 2006. In: Eggleston, H.S.,

Buendia, L., Miwa, K., Ngara, T., Tanabe, K. (Eds.), Intergovernmental Panel on

Climate Change (IPCC), IPCC/OECD/IEA/IGES, Hayama, Japan.

Jones, A., October 2006. A Life Cycle Analysis of UK Supermarket-imported Green

Beans from Kenya. International Institute for Environment and Development

(IIED). Fresh Insights No. 4.

Kovach, J., Petzoldt, C., Degnil, J., 1992. A method to measure the environmental

impact of pesticides. New. Yorks Food Life Sci. Bull. 139, 1e8.

Lord, E.I., 1992. Modelling of nitrate leaching: nitrate sensitive areas. Aspects Appl.

Biol. 30, 19e28.

Mil i Canals, L., Cowell, S.J., Sim, S., Basson, L., 2007. Comparing domestic versus

imported apples: a focus on energy use. Env. Sci. Pollut. Res. 14 (5), 338e344.

Pster, S., Koehler, A., Hellweg, S., 2009. Assessing the environmental impacts of

freshwater consumption in LCA. Environ. Sci. Technol. 43, 4098e4104.

Ridoutt, B.G., Pster, S., 2010. A revised approach to water footprinting to make

transparent the impacts of consumption and production on global freshwater

scarcity. Global Environ. Change e Hum. Policy Dimen. 20 (1), 113e120.

Saunders, C., Barber, A., Taylor, G., July 2006. Food Miles e Comparative Energy/

Emissions: Performance of New Zealands Agriculture Industry. Agribusiness &

Economics Research Unit, Lincoln University, New Zealand, ISBN 0-909042-713. Research Report 285.

Sim, S., Barry, M., Clift, R., Cowell, S.J., 2007. The relative importance of transport in

determining an appropriate sustainability strategy for food sourcing. Int. J. Life

Cycle Assess. 12 (6), 422e431.

Spielmann, M., Bauer, C., Dones, R., Tuchscmid, M., 2007. Transport Services.

Ecoinvent report no. 14, Villigen and Uster.

Terry, L.A., Mena, C., Williams, A., Jenney, N., Whitehead, P., 2011. Fruit and Vegetable Resource Maps. WRAP, Banbury. Final report of project RSC008.

Williams, A.G., Pell, E., Webb, J., Tribe, E., Evans, D., Moorhouse, E., Watkiss, P., 2009.

Comparative Life Cycle Assessment of Food Commodities Procured for UK

Consumption through a Diversity of Supply Chains. Defra, London. Final Report

for Defra Project FO0103.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Adel A. Abul-Soad, Jameel M. Al-Khayri - Cultivation For Climate Change Resilience - Volume 1 - Tropical Fruit Trees-CRC Press - Science Publishers (2023)Document297 pagesAdel A. Abul-Soad, Jameel M. Al-Khayri - Cultivation For Climate Change Resilience - Volume 1 - Tropical Fruit Trees-CRC Press - Science Publishers (2023)Armando HernandezNo ratings yet

- Roundup Advance Liquid Concentrate 280ml-LabelDocument2 pagesRoundup Advance Liquid Concentrate 280ml-LabelPaul LesterNo ratings yet

- Gulayan Sa Paaralan: Department of EducationDocument4 pagesGulayan Sa Paaralan: Department of EducationLot-Lot VillamonteNo ratings yet

- The Effect of Culture On TravelDocument21 pagesThe Effect of Culture On TravelFobe NudaloNo ratings yet

- British Food Journal: Article InformationDocument18 pagesBritish Food Journal: Article Informationyana maulanaNo ratings yet

- Farm Power 2010Document8 pagesFarm Power 2010Mayseee06No ratings yet

- Position Qualifications and Composition Disqualifications Duties Appointing AuthorityDocument9 pagesPosition Qualifications and Composition Disqualifications Duties Appointing AuthorityonlineonrandomdaysNo ratings yet

- Thesis Statement About PotatoesDocument6 pagesThesis Statement About PotatoesAmy Isleb100% (2)

- AI in AgricultureDocument12 pagesAI in AgricultureRass SeyoumNo ratings yet

- LO 4: Clean Up On Completion of Cropping Work According To Company Standard ProceduresDocument37 pagesLO 4: Clean Up On Completion of Cropping Work According To Company Standard ProceduresRizaLeighFiguesNo ratings yet

- Creating Shared Value Sustainability Report 2022 en PDFDocument63 pagesCreating Shared Value Sustainability Report 2022 en PDFDal TaylorNo ratings yet

- Functions of Labour LawDocument36 pagesFunctions of Labour LawAkanksha AgrahariNo ratings yet

- Syllabus For Science Technology and SocietyDocument13 pagesSyllabus For Science Technology and SocietyAnthony AlagonNo ratings yet

- The Great RobberyDocument164 pagesThe Great RobberyAbdullah Rahim RomanNo ratings yet

- Integrated Agricultural Production SystemDocument76 pagesIntegrated Agricultural Production SystemAziz Khan KakarNo ratings yet

- Consevation of Water ResourcesDocument2 pagesConsevation of Water ResourcesCatherine AlmarioNo ratings yet

- List of Major and Minor HeadsDocument453 pagesList of Major and Minor HeadsanandNo ratings yet

- Food ProductionDocument40 pagesFood ProductionDashampreet KaurNo ratings yet

- Biogas Construction ProposalDocument18 pagesBiogas Construction ProposalMosisa Dugasa100% (1)

- Introduction To WaterDocument2 pagesIntroduction To WaterKenneth John Anthony TabagNo ratings yet

- Ielts Reading 1Document4 pagesIelts Reading 1sarahhesham992021No ratings yet

- GEC 007 - Science, Technology and SocietyDocument19 pagesGEC 007 - Science, Technology and SocietyRosita MercadoNo ratings yet

- Undeveloped CountriesDocument2 pagesUndeveloped Countriespdalingay100% (1)

- Programme Development Cooperation Cz-Bosnia and Herzegovina-2011-2017 enDocument16 pagesProgramme Development Cooperation Cz-Bosnia and Herzegovina-2011-2017 enpunxterNo ratings yet

- Review of Related Literature and StudiesDocument4 pagesReview of Related Literature and StudiesRalph CelesteNo ratings yet

- The Influence of Fulvic Acid (AGT-50) On Spring Cereals and Sugar Beets Seed Germination and Plant ProductivityDocument7 pagesThe Influence of Fulvic Acid (AGT-50) On Spring Cereals and Sugar Beets Seed Germination and Plant Productivitydr.titaniumNo ratings yet

- Agrochemicals and Seeds - Sector Report - Apr 09Document126 pagesAgrochemicals and Seeds - Sector Report - Apr 09eknathNo ratings yet

- Opportunities and Challenges of Rural Livelihoods in Dandi Woreda, EthiopiaDocument136 pagesOpportunities and Challenges of Rural Livelihoods in Dandi Woreda, Ethiopiatem100% (1)

- Questionnaire For The Dairy Baseline Survey in MalawiDocument26 pagesQuestionnaire For The Dairy Baseline Survey in MalawiAdnan AzamNo ratings yet

- ArticleText 57221 1 10 20210626Document8 pagesArticleText 57221 1 10 20210626Alley WaysNo ratings yet