Professional Documents

Culture Documents

Environmental Impact Assessment

Uploaded by

manil_5Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Impact Assessment

Uploaded by

manil_5Copyright:

Available Formats

ready-mix

concrete

environmental

declaration

R

O

D

N M

E N T A L

O

C T

A

D E C L

INDEX

Description of the organisation

and the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

the organisation

the product

- product specifications

impacts assessment

use of resources without energy content

use of resources with energy content

potential environmental impacts

waste generation

Other information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- resources with energy content

- resources without energy content

- potential environmental impacts I

- potential environmental impacts II

RCK 10

....................

RCK 15

....................

RCK 20

....................

RCK 25

....................

RCK 30

....................

Average

Ready-mix

concrete

Buzzi Unicem

Unicalcestruzzi

Santena [TO] plant

T

DU

A

CT DECLAR

system boundaries

parts of the Life Cicle included

ready-mix concrete environmental declaration

Ready-mix concrete type

Environmental performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

IO

ready-mix concrete production

IR

O NM NTAL

E

1_ DESCRIPTION OF THE ORGANISATION AND OF THE PRODUCT

R E A D Y-M I X C O N C R E T E E N V I R O N M E N T A L D E C L A R A T I O N

product specifications

Ready-mix concrete is a material formed by mixing cement, coarse and fine aggregate and water, with or without the

incorporation of additives and recycled materials like fly ashes.

Production and use of ready-mix concrete are in accordance with the international standard (EN 206/00).

D E S C R I P T I O N O F T H E O R G A N I S AT I O N A N D O F T H E P R O D U C T

All the impacts and environmental performance in this EPD are referred to 'average ready-mix concrete resulting from

the weighted average of the different concrete typologies produced at the plant.

The organisation

For every environmental performance, in chapt. 3, the difference between the average ready-mix concrete and each single

Buzzi Unicem S.p.A. is an industrial group with approximately 11 ,000 employees and plants located in Italy,

type of ready-mix concrete are specifiedand shown in the graphs.

Germany, Luxembourg, Poland, Czech Republic, Ukraine, Russia, United States, Mexico and Netherlands.

Its main activity is cement production and related activities including production of ready-mix concrete and

In accordance with EN 206-01, ready-mix concrete is classified by:

building products.

Compressive strength class;

Slump class;

In 2001, the Company started a project to implement an Environmental Management System for its activities

Environmental exposure class.

in the concrete sector.

Afterwards Orbassano (TO), Settimello (FI), Castelfiorentino (FI) and Monsummano (PT) plants have obtained

the certification for the same international standard

THE COMPRESSIVE

STRENGHT

C L A S S F O R E V E RY

................................................................................................

READY-MIX

CONCRETE TYPE

PRODUCTION

[m3]

COMPRESSIVE

STRENGTH CLASS [MPa]

SLUMP

CLASS

ENVIRONMENTAL

EXPOSURE CLASS

R E A DY- M I X

CONCRETE TYPE

The product

RCK 10

........................

2,739

10

S3 / S4 / S5

........................ ........................ ................... ......................

RCK 15

........................

7,296

15

S3 / S4 / S5

........................ ........................ ................... ......................

Functional unit:

production of 1 m3 of ready-mix concrete

RCK 20

........................

14,203

20

S3 / S4 / S5

X0

........................ ........................ ................... ......................

Estimated life cycle

of the product:

not important

(depends on the use to which the product is put)

RCK 25

........................

53,388

25

S3 / S4 / S5

X0

........................ ........................ ................... ......................

Year of study:

2006

Specificic data:

Production

data for year 2006

Energy

data for year 2006

Raw materials data for year 2006

Production site:

Santena [ TO ]

RCK 30

RE

AD

23,519

30

S3 / S4 / S5

X0 / XC1 / XC2 / XC3

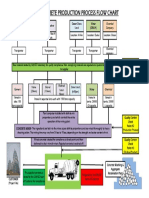

Ready-mix concrete production

Y-

IX

CO

The main phases of the ready-mix concrete cycle are as follows:

N

C

RE

Cement production

TE

PR

Extraction and production of inerts and production of additives

OD

UC

Transport of ready-mix concrete constituents

TIO

00

N 2

Constituents storage

Dosage into ready-mix concrete mixer

RCK 30 | 23.25%

RCK 25 | 52.78%

Distribution of ready-mix concrete

RCK 10 | 2.71%

RCK 15 | 7.21%

In the plant moreover a system of recovery of the ready-mix concrete, obtained from the washing of the

ready-mix concrete mixers is installed, to separate water and aggregates for the successive one re-use.

RCK 20 | 14.04%

R E A D Y- M I X C O N C R E T E E N V I R O N M E N T A L D E C L A R A T I O N

2_ ENVIRONMENTAL PERFORMANCE

Impacts assessment

Resources without energy content

Resources with energy content

Potential environmental impacts

E N V I R O N M E N TA L P E R F O R M A N C E

Waste generation

Parts of the Life Cycle included

To make sure a better data comparison, the values, relative to 1 m3 of "average ready-mix concrete"

production, are divided into:

Production/extraction of resources | Transport of resources | Ready-mix concrete process

From extraction of the raw materials to distribution of ready-mix concrete from the cradle to the gate.

System boundaries

The system boundaries analysed, in compilance with ready-mix concrete PCR, extend from the extraction of the raw materials

Use of resources without energy content

to the distribution of 1 m3 of ready-mix concrete.

The table shows the main natural resources consumed, excluding energy, for the activities of the extraction of raw materials to

the production of 1 m3 of ready-mix concrete.

PRODUCTION PHASE

1 m3 OF READY-MIX

CONCRETE

...

CEMENT

PRODUCTION

...

FLY

ASHES

...

END OF LIFE PHASE

...

CONSTITUENTS

STORAGE

DISTRIBUTION

USE

....

END

OF LIFE

DOSAGE

Non renowable resources

without energy content

............................

RESOURCES

PRODUCTION

RESOURCES

TRANSPORT

kg

2,315.66

0.47

..............

Renowable resources

without energy content

............................

..............

Water consumption

............... ..............

kg

0.00

0.00

2,316.13

..............

..............

0.00

0.00

..............

..............

180.78

589.47

0.00

............... ..............

397.04

READY-MIX

AVERAGE READY-MIX

CONCRETE PROCESS

CONCRETE

11.65

....

ADDITIVE

PRODUCTION

...

TRANSPORT

EXTRACTION AND

PRODUCTION OF INERT

MEASUREMENT

UNITS

WATER

USE PHASE

COMPOSITION OF 1m3

D I AV E R AG E R E A DY- M I X

CONCRETE

The use phase cannot be analysed in the LCA study, because ready-mix concrete is used as a raw material in many different

activities; it is therefore not possible to provide information on the environmental impacts caused during use.

The information on the use phase is contained in the Ready-mix oncrete safety data sheets (ref. Dir.1999/45/CE) which also

indicates the preventive measures to avoid negative environmental risks and impacts.

COMPONENTS

MEASUREMENT

UNITS

AVERAGE READY-MIX

CONCRETE

kg/m3

Cement 42.5 II ALL

............................. ..........................

263.6

..........................

kg/m3

Fly ashes

............................. ..........................

45.6

..........................

l/m3

Additives

............................. ..........................

1.5

..........................

l/m3

Water

............................. ..........................

175.0

..........................

Aggregates

kg/m3

1,871.7

1 m3 OF READY-MIX

CONCRETE

MEASUREMENT

UNITS

AVERAGE READY-MIX

CONCRETE

Cement

..................................

kg/m3

.......................

263.6

.......................

Fly ashes

..................................

kg/m3

45.6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

%

14.7

S UB S T I T U T I O N O F C E M E N T

WITH FLY ASHES

Secondary raw material used

Impacts assessment

Use of resources with energy content

The table shows the main resources with energy content, from the raw materials quarring to the production of 1 m3 of

ready-mix concrete.

1 m3 OF READY-MIX

CONCRETE

Renowable resources

with energy content [termic]

.............................

Non renowable resources

with energy content [termic]

.............................

Total resources

. . . . . . with

. . . . energy

. . . . . . .content

............

Electric energy [direct]

MEASUREMENT

UNITS

RESOURCES

PRODUCTION

RESOURCES

TRANSPORT

READY-MIX

AVERAGE READY-MIX

CONCRETE PROCESS

CONCRETE

MJ

..............

76.55

..............

0.11

..............

1.61

..............

78.27

..............

MJ

..............

1,547.01

..............

238.20

..............

15.50

..............

1,800.71

..............

MJ

..............

1,623.57

..............

238.31

..............

17.11

..............

1,878.98

..............

MWh

0.000

0.000

0.0013

0.0013

O T H E R I N F O R M AT I O N

R E A D Y- M I X C O N C RE TE E N V I R O N M E N T A L D E C L A R A T I O N

2_ ENVIRONMENTAL PERFORMANCE

The most important air emissions, due to the production of 1 m3 of "average ready-mix concrete",

are in the following table:

AIR EMISSION

g/m3 of average

ready-mix concrete

Potential environmental impacts

1 m3 OF READY-MIX

CONCRETE

MEASUREMENT

UNITS

Global warming - GWP

.............................

kg CO2 eq.

..............

212.45

..............

17.53

..............

1.06

..............

231.04

..............

Ozone depletion - ODP

.............................

kg CFC-11 eq.

..............

0.000003

..............

0.00000001

..............

0.0000000005

..............

0.000003

..............

Acidification - AP

.............................

kg SO2 eq.

..............

0.62

..............

0.15

..............

0.01

..............

0.78

..............

Eutrophication - NP

.............................

Photochemical oxidant

formation - POCP

kg PO43- eq.

..............

0.07

..............

0.02

..............

0.00

..............

0.09

..............

kg C2H4 eq.

0.04

0.01

0.00

0.06

RESOURCES

PRODUCTION

RESOURCES

TRANSPORT

READY-MIX

CONCRETE PROCESS

AVERAGE READY-MIX

CONCRETE

Dust

CO

TOC

3,592

623

7.1

.............................................................................................................

NOX

Methane

NH3

645

373

1.53

.............................................................................................................

CO2

HCI

Other Methals

222,414

1.73

0.001

.............................................................................................................

378

SOX

HF

0.04

N2O

0.00001

The following graph shows the variation of the impacts, for every ready-mix concrete type, from the

average ready-mix concrete:

Resources with energy content

Waste generation

Almost all generated waste can be ascribed to the raw materials extraction/production phase, while a small amount can be

attributed to the production process. Ready-mix concrete production does not generate waste which is instead produced during

maintenance.

Moreover the recycling plant allows recuperating aggregates and water and avoids waste generation from ready-mix concrete

mixers wash.

HAZARDOUS WASTE

IS SUCH DEFINED

BY UE DIRECTIVE

1 m3 OF READY-MIX

CONCRETE

. . . .. .....RCK

.. .. .. .10

. . . . .. .... .

. . . .. .....RCK

.. .. .. .15

. . . . .. .... .

. . . .. .....RCK

.. .. .. .20

. . . . .. .... .

. . . .. .....RCK

.. .. .. .25

. . . . .. .... .

. . . .. .....RCK

.. .. .. .30

. . . . .. .... .

20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

0.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-30.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

MEASUREMENT

UNITS

RESOURCES

PRODUCTION

RESOURCES

TRANSPORT

Waste production

.............................

kg

..............

35.05

..............

0.67

..............

2.72

..............

38.44

..............

-40.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

Hazardous waste production

.............................

kg

..............

0.410

..............

0.069

..............

0.002

..............

0.482

..............

-50.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

kg

34.64

0.60

2.72

37.95

Non hazardous waste production

READY-MIX

AVERAGE READY-MIX

CONCRETE PROCESS

CONCRETE

Total energy

Electric energy

3_ OTHER INFORMATION

Resources without energy content

%

RCK 10

RCK 15

RCK 20

RCK 25

RCK 30

20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

0,00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-30.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-40.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

Total resources

Concrete PCR was approved by Swedish Environmental Management

Council, on 09-13-2005, "PCR 2005:7 - Concrete".

PCR and EPD document are published on the Swedish Environmental

Management Council web site (www.environdec.com).

Contact for Buzzi Unicem

................................................................

Roberto Bogliolo

Buzzi Unicem S.p.A.

via Luigi Buzzi, 6

15033 Casale Monferrato [AL]

tel: +39 0142 416497

e-mail: rbogliolo@buzziunicem.it

Idric resources

Potential Environmental Impacts - I

%

RCK 10

RCK 15

RCK 20

RCK 25

RCK 30

20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

0.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

Requirements for an international Environmental Product Declaration scheme.

-10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

ISO 14025

-20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-30.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-40.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-50.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

Information from the certification body

................................................................

This EPD and relative LCA study have been approved by ICMQ S.p.A.

(www.icmq.org) in accordance with:

PCR 2005:7 - Concrete

Certification number: 05002EPD

First Emission:

22.06.2005

Current Emission:

19.11.2007

Expiry date:

19.11.2010

................................................................

Registration number: S-P-00108

................................................................

Acidification

........

EPD realised inside the "INTEND project" (www.intendproject.com)

. . . .. .....RCK

.. .. .. .20

. . . . .. .... .

. . . .. .....RCK

.. .. .. .25

. . . . .. .... .

. . . .. .....RCK

.. .. .. .30

. . . . .. .... .

20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

0.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-10.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-20.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-30.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

-40.00

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

. . . .. ....... .. .. . . . . . .. .... .

Eutrophication

8

Photochemical oxidant formation

Validity time: The EPD shall be renewed when the PCR is modified (usually every

three years). Whilst, when there is a variation higher than 5% in one or more

data reported in the EPD document, the EPD will be verified and the

verification will focus especially on parameters and data generating

the variation.

T

DU

A

CT DECLAR

. . . .. .....RCK

.. .. .. .15

. . . . .. .... .

. . . .. .....RCK

.. .. .. .10

. . . . .. .... .

Potential Environmental Impacts - II

IO

Global warming

IR

O NM NTAL

E

Buzzi Unicem S.p.A

via Luigi Buzzi, 6

15033 Casale Monferrato [AL]

Italia

tel +39 0142 416111

fax +39 0142 416464

info@buzziunicem.it

www.buzziunicem.it

Impianto di Santena

ss TorinoAsti, 50

10026 Santena [TO]

Italia

tel +39 011 9494285 / 9492597

fax +39 011 9498376

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Beginning Android DevelopmentDocument721 pagesBeginning Android DevelopmentNikola Johnny Popadic67% (3)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Audit Report-2 SignedDocument12 pagesAudit Report-2 Signedmanil_5100% (2)

- Diamond DA 42 Systems - V12 - 5clases 19 de JunioDocument402 pagesDiamond DA 42 Systems - V12 - 5clases 19 de JunioLiu Antonio Tang100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Tutorial On Geometric CalculusDocument16 pagesTutorial On Geometric Calculusschlemihl69No ratings yet

- Audit Report 2 - ClientDocument10 pagesAudit Report 2 - Clientmanil_5No ratings yet

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Lecture 04 Critical Path Method (CPM) PDFDocument25 pagesLecture 04 Critical Path Method (CPM) PDFAmira HachemNo ratings yet

- C88 2013Document5 pagesC88 2013manil_5No ratings yet

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5No ratings yet

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5No ratings yet

- Corrosion Types and Prevention Methods in 40 CharactersDocument75 pagesCorrosion Types and Prevention Methods in 40 CharactersCipri Croitor0% (1)

- Giignl Custody Transfer Handbook 6.0 - May 21 0Document195 pagesGiignl Custody Transfer Handbook 6.0 - May 21 0Александр КарташовNo ratings yet

- Impact of Gadgets on Learning in Senior High StudentsDocument16 pagesImpact of Gadgets on Learning in Senior High StudentsBlessing Joy Capiz83% (36)

- (Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFDocument534 pages(Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Beacon Explorer B Press KitDocument36 pagesBeacon Explorer B Press KitBob AndrepontNo ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- 4E Roadmap for Energy Efficient Electric Motors and Motor SystemsDocument30 pages4E Roadmap for Energy Efficient Electric Motors and Motor SystemsCarlos LopezNo ratings yet

- Norma ASTM C117.1589619-1Document3 pagesNorma ASTM C117.1589619-1Mónica ZúñigaNo ratings yet

- C87C87M 2010Document4 pagesC87C87M 2010manil_5No ratings yet

- C115C115M. 2010Document8 pagesC115C115M. 2010manil_5No ratings yet

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument5 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method Formanil_5No ratings yet

- C70. 2013Document3 pagesC70. 2013manil_5No ratings yet

- Admix ComparisonDocument1 pageAdmix Comparisonmanil_5No ratings yet

- WP Message From DM.Document1 pageWP Message From DM.manil_5No ratings yet

- Excel Stats Nicar2013Document6 pagesExcel Stats Nicar2013yaktamerNo ratings yet

- CBGMDocument16 pagesCBGMmanil_5No ratings yet

- Waste AuditDocument47 pagesWaste Auditmanil_5No ratings yet

- Alkali Aggregate ReactionDocument26 pagesAlkali Aggregate Reactionmanil_5No ratings yet

- Light Weight DesignDocument12 pagesLight Weight Designmanil_5No ratings yet

- Admix ComparisonDocument1 pageAdmix Comparisonmanil_5No ratings yet

- Load Cell KAUDocument4 pagesLoad Cell KAUmanil_5No ratings yet

- Process Flow ChartDocument1 pageProcess Flow Chartmanil_5No ratings yet

- Waste AuditDocument47 pagesWaste Auditmanil_5No ratings yet

- 1Document8 pages1manil_5No ratings yet

- Basic Concrete Technology (BCT) : Examination Questions - January, 2016 (Total Marks 50, Max Time 2 Hours)Document9 pagesBasic Concrete Technology (BCT) : Examination Questions - January, 2016 (Total Marks 50, Max Time 2 Hours)manil_5No ratings yet

- NDT 1Document126 pagesNDT 1manil_5No ratings yet

- Load Cell 46-23Document2 pagesLoad Cell 46-23manil_5No ratings yet

- 277 SpecDocument86 pages277 Specmanil_5No ratings yet

- Environmental Impact AssessmentDocument7 pagesEnvironmental Impact Assessmentmanil_5No ratings yet

- Accelerated C TankDocument1 pageAccelerated C Tankmanil_5No ratings yet

- Ktu Laca Solved Question PaperDocument22 pagesKtu Laca Solved Question PaperSofiyaNo ratings yet

- Heat Exchangers: T T T TDocument11 pagesHeat Exchangers: T T T Tcjc0706No ratings yet

- PNG382 FT en 11Document2 pagesPNG382 FT en 11Misu1983No ratings yet

- Environmental Engineering - Civil Engineering - McGill UniversityDocument4 pagesEnvironmental Engineering - Civil Engineering - McGill Universityamrin jannatNo ratings yet

- Michlaski Light Ultraviolet and InfraredDocument21 pagesMichlaski Light Ultraviolet and Infraredm_bohnNo ratings yet

- Nylatron GSM Technical Data SheetDocument1 pageNylatron GSM Technical Data SheetgovindsrNo ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- White Paper c11 737101Document13 pagesWhite Paper c11 737101Aleksandar PopovicNo ratings yet

- Electrical Machine DesignDocument2 pagesElectrical Machine DesignAnonymous 1abQZINo ratings yet

- Fertilizer Granulating Machine TypesDocument4 pagesFertilizer Granulating Machine TypesMichael MedinaNo ratings yet

- Drum Unloading SystemDocument2 pagesDrum Unloading SystemJas SumNo ratings yet

- Pneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingDocument4 pagesPneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingYi WUNo ratings yet

- Kurd Live - PastebinDocument2 pagesKurd Live - PastebinMmmmohNo ratings yet

- HOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsDocument12 pagesHOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsJo PatrickNo ratings yet

- Activate &sap - Edit in Se16n (Sap Ecc 6Document4 pagesActivate &sap - Edit in Se16n (Sap Ecc 6raovijay1976No ratings yet

- Balancing Redox ReactionsDocument2 pagesBalancing Redox ReactionsblobmarleyNo ratings yet

- SeminarDocument4 pagesSeminarmukulNo ratings yet

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Document20 pagesSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarNo ratings yet