Professional Documents

Culture Documents

Control of Colum Cell

Uploaded by

krlossnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control of Colum Cell

Uploaded by

krlossnCopyright:

Available Formats

Preprints of the 19th World Congress

The International Federation of Automatic Control

Cape Town, South Africa. August 24-29, 2014

ENGINEERS TRAINING IN AUTOMATION OF FLOTATION

PROCESSES

Luis G. Bergh and Juan B. Yianatos

CASIM, Centre for Automation and Supervision of Mineral Industry,

Chemical Engineering Department, Santa Maria University

Valparaiso, Chile, luis.bergh@usm.cl

Abstract: The wide plant control integration of mining, mineral and metal processes poses many

challenges. Testing process monitoring, diagnosis and control strategies for flotation processes is

expensive, and usually requires either complex pilot plant facilities or to deal with the hard constraints

posed by experimentation in real plants.

One critical aspect to take advantage of the present technological developments is the training of

engineers to understand and master when and how some technique may be appropriate to solve a

particular problem and to identify the challenges implicitly underlying in its implementation. In this sense

the use of hybrid laboratories is presented, where fully instrumented pilot plants are operated under PLC

and DCS coupled on-line with phenomenological models, to recreate an environment as close as possible

to industry.

Copyright 2014 IFAC

Keywords: training, flotation, modeling, automation, process control

with the required quality. In summary, data collected

following a designed experiment to make good decisions is

more difficult and costly to be obtained.

1. INTRODUCTION

How to improve the operation of different processes by

using several techniques have been proposed in the last

decade. Hodouin et al. (2001) and Hodouin (2011), for

example, recently discussed the state of art and challenges in

the mining, minerals and metal processing area. These

discussions included data reconciliation, soft sensor and

pattern recognition, process modeling, process monitoring,

fault detection and isolation, control loop monitoring,

control algorithms and supervisory control.

Simulations of the application of novel methods by using a

plant model present some known advantages and

drawbacks. If a model of a plant were available, the new

methodology can be tested under a number of different

conditions, at low cost. However, the high cost of producing

reliable models for complex process must be considered.

Usually, highly non-linear phenomenological models could

be built, with the aid of experiments to estimate model

parameters. However, in order to reduce the mathematical

complexity and thus find a solution, some simplifying

assumptions are usually made. Consequently, the value of

comparisons of different methods by simulation can be

significant degraded, and often cannot replace

experimentation in the real world.

Theoretical advantages of any novel method have to be

finally confronted and tested in real plants. However,

experimentation on real plants may present several

difficulties and usually is of high cost. To avoid risky

operating conditions or high losses in products, the input

variables can only be changed inside a narrow band. Some

confusing results may be obtained when important

disturbances cannot always be managed, interrupting and

degrading the experiments. On the other hand, to reproduce

experimentally a given disturbance may be extremely

difficult, as, for example, a change in particle size

distribution. In the mineral processing industry, the

measurements of important variables, such as a stream grade

or particle size, demands large efforts on instrumentation

maintenance plans in order to obtain these measurements

Copyright 2014 IFAC

On the other hand, pilot plants can reproduce most of the

experimental advantages of a real plant. The small plant

scale provides a better chance to a wide experimentation, by

relaxing at the same time some constraints. However,

installations, with large storing facilities and expensive on

stream analyzers, are demanded because of the presence of

solids in flotation, or expensive organic solvents for copper

extraction. The lack of instrumentation and computer

11488

19th IFAC World Congress

Cape Town, South Africa. August 24-29, 2014

Distributed control of local objectives can be administrated

by supervisory control strategies based on estimation of the

crucial variables. Process monitoring, diagnosis and fault

detection, isolation and remediation studies can also be

developed under low cost. Figure 1 shows how real and

virtual input variables (feed characterization) can be

combined with real output variables to feed a plant

simulator. The plant simulator produces on-line virtual

output variables.

platforms may represent a problem difficult to overcome,

even when the pilot plant were located nearby a plant.

Environmental issues are strongly dependent on plant

location and facilities. The flexibility gained for working in

a smaller scale is lost when environmental regulations put

hard constraints and when the instrumentation investment

and maintenance cannot be paid by the generation of

products in small scale.

2. A HYBRID APPROACH

Real input

variables

Some processes can be represented by differentiating the

phenomena in different classes: the hydrodynamics and the

change in concentration of one or more species. The

hydrodynamics refer to how the different streams are mixed

and separated in a process unit. In most cases, the physical

properties of each phase, such as viscosity or density, are

usually invariant or experiment moderate changes as a

function of the concentration of one solute. This can occur

due to a chemical reaction, where some species partially

disappear to form other species, or due to a selective

difusion of some species from one phase to another. In

flotation some species are selectively attached to gas

bubbles and form a froth phase separated from a pulp phase.

In the pulp phase some solid particles remain in the liquid

phase and are reported to the tailings. Sometimes, changes

in solute concentration may also change transport properties,

and this artificial decoupling is not effectively occurring.

More generally speaking, the process behaviour can be

separately represented when the process hydrodynamics is

not significantly influenced by changes in solute

concentration. The experimentation approach in pilot plants

can be simplified when this hypothesis is accepted, in

twofolds:

Pilot plant

Real output

variables

Plant simulator

Virtual output

variables

Virtual input

variables

Fig.1 Hybrid system: combining real plant with simulators.

The Process Automation and Supervision Laboratory at

Santa Maria University, consists of four pilot plants fully

instrumented and controlled: a solvent extraction unit, a

continuous stirred tank reactor, a flotation pneumatic cell

circuit and a flotation column. In this paper both flotation

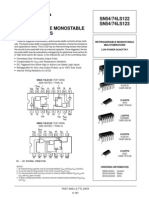

plants are described. The communication and control

platforms are shown in Figure 2.

ProMV

MVOnL

(i) Experimentally each fluid (liquid, pulp and gas) may be

substituted by low cost and easy manageable fluids, such as

water in a liquid phase reaction, water and organic solvent in

solvent extraction process or water and air in flotation. The

process hydrodynamics will be well characterized by such

fluid mixing and separation in a process unit. In this way,

experimental work can be carried on under safety and low

cost condition.

MatLab

Excel,..

PC

Network

PLC

Pilot plant

Sensors,

actuators

PI server

Fig. 2. Communication and control platforms.

Sensors and actuators are communicated to a PLC (Fanuc

90/30 from General Electric (2013)) where calibrations and

local control are implemented, and the data is sent to a PC

network, that it is used as a DCS platform, running the

software Wonderware InTouch , from Invensys (2013).

Process model predictions are obtained by running software

in Matlab or Excel Macros . All data is displayed at PC

stations and historical data files are built in a PI server, from

OsiSoft (2013) for further analysis. Operating variables (real

and virtual) can also be analyzed off-line by using ProMV

software or on-line VOnLine from Prosensus (2013).

Supervisory control running on PC network writes DCS set

points on PLC.

(ii) The solute concentration changes can be obtained from

detailed models relating measured operating conditions,

such as flow rates, temperatures, pressures and levels, and

initial concentration state of the feed. These virtual variables

will replace the real variables, overcoming the difficulties

found in a real case to use low cost and reliable

instrumentation. This kind of models usually is difficult to

obtain and remain a problem to be solved.

Therefore, when the pilot plant is operated by using these

low cost fluids and a model is available, a hybrid system can

be developed. The main hydrodynamic characteristics are

still well represented even when the real plant behaviour has

been simplified. The target variables of the process

operation can now be predicted (not measured), under a

wide operating region, by using this kind of models.

At the Control Laboratory in Santa Maria University, two

flotation pilot plants were built, instrumented and controlled

11489

19th IFAC World Congress

Cape Town, South Africa. August 24-29, 2014

air flow rates (in forced air cells) are measured on line, and

tailings and air flow rates are manipulated. pH control and

chemical reagent addition control are also included in some

circuits.

in the mineral processing area: a column and a three

mechanical cells circuit. A brief description of both plants

and their instrumentation and control systems is as follows.

3. FLOTATION COLUMN PILOT PLANT

Flotation columns (Finch and Dobby, 1990) have been used

world-wide as efficient cleaning stages in a large number of

sulfide mineral concentrators. Large variations in

metallurgical performance have been observed due to more

degrees of freedom in their operating variables, leading to

much scope for improving their control than mechanical

cells (Bergh and Yianatos, 1993, 2003).

The primary objectives are the concentrate grade and the

column recovery, as indices of product quality and process

productivity. These variables can be obtained if the grade of

each stream is measured with good accuracy and high

availability (Bergh and Yianatos, 2003). However, the online estimation from on-stream analyzers requires significant

amount of work in maintenance and calibration. Therefore,

most of the time secondary objectives, such as, feed pH,

froth depth, gas flow rate and wash water flow rate are

controlled (Bergh and Yianatos, 1993).

Consistent metallurgical benefits can be obtained if basic

distributed control systems are implemented to ensure a

stable operation of flotation columns. In general, at least

froth depth, air flow and wash water rates are measured on

line, and tailings, air and wash water flow rates are

manipulated. Chemical reagent addition and pH controls are

also included in some circuits. A P&ID of the pilot column

is shown in Figure 3. The virtual variables are shown in grey

boxes.

Fig. 3 P&ID of flotation column pilot plant

Design parameters:

Hight, diameter,

geometry

A hydrodynamics supervisory control coordinates the

control of these secondary objectives. The approach of

substituting the feed by water and frother represents quite

well the column hydrodynamics and avoid working with

solids and collectors. The output grades are predicted from

operating variables by using a phenomenological model

reported in Bergh et al. (1998) and it is schematically shown

in Figure 4.

Feed characteristics: flow

rate, particle size, grades,

species, density, solid

percentage, kinetic

constants

4. MECHANICAL CELLS CIRCUIT

Concentrate

grade

Recovery

Process

Metallurgic

Simulator

air flow rate

froth depth

water flow rate

Mechanical cells have been used for a long time as efficient

rougher and scavenger circuits. Similarly to flotation

columns, the primary objectives are the concentrate grade

and the column recovery, as indices of product quality and

process productivity. However, the quality of these on-line

estimations usually requires significant amount of work in

maintenance and calibration of on-stream analyzers

(Thwaites, 2007). Therefore, most of the time secondary

objectives, such as, feed pH, chemical reagent addition,

solids percentage, froth depth profile and gas flow rate

profile in forced air cells are controlled (Bergh and Yianatos

2011). Consistent metallurgical benefits can be obtained if

basic distributed control systems are implemented to ensure

a stable operation. In general, at least froth depth profile and

Fig. 4 Metallurgical model of a flotation column.

A P&ID of the pilot cell circuit is shown in Figure 5. The

virtual variables are shown in grey boxes. A hydrodynamics

supervisory control coordinates the control of these

secondary objectives. The approach is similar as the one

used in the pilot flotation column. To predict output grades

from operating variables a phenomenological model,

reported in Bergh and Yianatos (2013), was used. Figure 6

shows the necessary information to build this kind of model.

11490

19th IFAC World Congress

Cape Town, South Africa. August 24-29, 2014

Concentratee

SC

104

FIC

C

10

04

Cu,Fegrades

%solids

Particlesize

FIC

101

Cu,Fegrades

%solids

Particlesize

LIC

LIC

101

LIC

1

103

102

Feed

Air

FIC

10

02

FIC

103

Cu,Fegrades

%solids

Particlesize

Tailings

F 5 P&ID off three cells flotation circuit.

Fig.

PSE

high

h or recoveryy is low and cconcentrate grade

g

is too high,

then

n an abnormall operation haas been detecteed.

8

6

4

2

0

0

200

400

Samplle number

600

200

400

Samplle number

600

Figg. 6 Experimeental data needded to fit moddel parameterss for

eacch cell.

20

10

0

E

NTAL RESU

ULTS

5. EXPERIMEN

5.11 Process Monnitoring and Diagnosis

D

Conc. grade

33

18000 sets of dataa correspondiing to a normaal condition of

o 16

varriables were used

u

to build a PCA (Prinncipal Component

Annalysis) modell (Kourti and MacGregor, 1995; MacGregor

et al.,

a 2007). Thhe variables inncluded were: the measuredd gas

holld up (E), frooth depth (Z)), low and hiigh pressure (PL,

PH

H), mA signalss to tailings (P

PT) and air (PA

A) control vallves,

biaas (Jb), air (Jgg), wash waterr (Jw) and feeed (Jf) flow raates,

thee defined virtuual variables: feed particlee size d80 (D), Cu

graade (FCG) annd solid perccentage (S), and

a the prediicted

varriables: Cu concentrate gradde (CCG) andd process recovvery

(R)). At least 92 % of the variaance in the ceentered and sccaled

preetreated data was explaineed by a moddel with 6 laatent

varriables. For monitoring

m

thee process the Hotelling

H

T2 limit

l

waas found to be

b 12.6, whille the PSE (pprediction sqquare

errrors) limit wass 3.81 (Bergh and Yianatos,, 2011).

31

29

27

C

Concentrate

grrade

25

0

Recov

very

200

400

Samplle number

90

85

80

75

70

65

60

R

Recovery

%

Hotelling

30

600

Fiig. 7 Operatingg condition teest.

Figu

ure 8 shows the contribuution to the T2 residuals for

sam

mple 512, in order to identiffy which variables are caussing

thiss problem. Frroth depth annd the high and

a low dp/ccells

pressented the maain contributioons, showing that the problem

is due

d to a low froth

f

depth, ccausing high recovery

r

and low

con

ncentrate gradee.

Expperiments weere carried onn to detect when

w

an abnorrmal

opeerating condittion is met., One

O can see frrom Figure 7 that

moost of the tim

me the PSE test is satisfiedd, while T2 test is

failled at intervalls 130-200, 300-430 and 480-560.

4

On thhese

perriods, the conccentrate gradee is too low annd recovery is

Ano

other interestiing case is w

when only the PSE test faails,

indiicating that a measuring ddevice must be

b recalibratedd or

repllaced. The sensibility

s

off this test was

w measuredd in

11491

19th IFAC World Congress

Cape Town, South Africa. August 24-29, 2014

5.4 Soft Sensors

% residual Ti

percentage of error necessary to detect the failure. Errors

less than 7% on Dp/cells, 15% on flow meters, 5% on

pressure to control valves and 10% on virtual measurements

of concentrate grade were detected for different operating

conditions. The virtual measurement error of copper

concentrate grade is shown in Figure 9.

30

Using the hybrid systems, the available real and virtual

variables were collected in the pilot plant for a set of steady

state operations. PLS models (MacGregor et al. 2007) have

been built to predict on-line Cu concentrate and tailings

grades (Nakagawa and Bergh, 2008).

20

5.5 On-line Steady State Test

10

0

Since supervisory control often is running when a steady

state condition is met and in practice a plant is never in

steady state, algorithm proposed by Cao and Rinehardt

(1995) has been implemented on-line. This application is

very useful to collect the proper data to build models.

E P L P H P A P T Jb Jf Jg Jt Jw R CCG D FCG S

Fig. 8 Contributions to abnormal operation.

15

5.6 Formal Programs

SPE

10

In the Chemical Engineering Program students learn the

control fundamentals and use the Lab to master

conventional modeling techniques and PID control. Some

students can follow a Research Lab in advanced process

control topics and learn in a Process Control Seminar how to

configure a PLC, a DCS software and in general how to use

the complete hybrid systems to experiment with the kind of

applications discussed before. Students following the Master

Program learn identification and discrete control techniques

in Application of Computer Control. This activity is both

theoretical and practical, using the Lab facilities. In the

course Advanced Statistics they learn the theory and

practice of multivariate statistics methods, such as PCA

models for diagnosis and fault detection and PLS modeling

for soft sensors. Finally, a thesis that has been developed

either in the Lab or in industry completes the training

program.

5

0

-15

-10

-5

10

15

Error %

Fig. 9 Failure detection on concentrate grade.

5.2 Modeling and Distributed Control

Laboratory, pilot and industrial scale experiments have

been done over many years to better understand the flotation

phenomena and to build phenomenological models.

Dynamic models were discussed in Bergh and Yianatos

(1994), hierarchical control aspects in Bergh et al. (1995),

and contributions to mixing characterization in Yianatos et

al. (2005), estimation of kinetics parameters in Yianatos et

al. (2010a), Yianatos (2007), froth modeling in Yianatos et

al. (2010b and 2012), Yianatos and Contreras (2010), Leiva

et al. (2010, 2012), Vinnett et al. (2012), Contreras et al.

(2013), Liu and MacGregor (2008).

CONCLUSIONS

Low cost, as well as safe and wide range experimentation in

pilot plants is possible when on-line process measurements

are combined with variables predicted by models. When the

phenomena of changing the concentration of some species

can be decoupled from process hydrodynamics, considerable

simplification for experimentation can be achieved.

Experiments describing the real process hydrodynamics can

be performed using low cost materials, such as water and

air. Reliable information on key unmeasured variables can

be obtained from these simpler phenomenological models.

5.3 Supervisory Control

Expert-fuzzy systems to keep concentrate grade in a narrow

band and copper recovery over a minimum value were the

control objectives in a flotation column. The available

resources were the froth depth, air flow rate and wash water

flow rate set points. When column capacity was reached

feed flow rate set point was decreased (Bergh and Yianatos,

1999). Fuzzy system was based on actual and past Cu grade

errors, by using triangular membership functions (Soto,

2013). Similarly in the cells circuit, the control objectives

were to maximize the Cu recovery while keeping the

concentrate grade in an acceptable band (to be determined

by the cleaning circuit actual capacity). These are classical

objectives for rougher and scavenger circuits. In this case

froth depth and air flow rate profiles are adjusted (Bergh and

Yianatos, 2013; Duran, 2014) to keep the process on targets.

These hybrid units can be used to train engineers in testing

the advantages and drawbacks of novel approaches related

to process monitoring, diagnosis, fault detection and

isolation, virtual sensors and supervisory control of complex

processes as flotation, in a quasi industrial environment.

In a near future, more tests on novel strategies can be

performed giving considerable insight on process

performances under real experimentation.

11492

19th IFAC World Congress

Cape Town, South Africa. August 24-29, 2014

Kourti T. and J.F. MacGregor (1995). Process Analysis

Monitoring and Diagnosis using Multivariate Projection

Methods A Tutorial, Chemometrics and Intelligent

Laboratory Systems 28, pp. 3-21.

Leiva J., L. Vinnett, F. Contreras, J. Yianatos (2010).

Estimation of the actual bubble surface area flux in

flotation, Minerals Engineering, 23, pp. 888-894.

Leiva J., L. Vinnett, J. Yianatos (2012). Estimation of air

recovery by measuring froth transport over the lip in a

bi-dimensional flotation cell, Minerals Engineering, 36

38, pp. 303-308.

Liu J. and J.F. MacGregor (2008). Froth-based modeling

and control of flotation processes, Minerals Engineering

21, pp. 642651.

MacGregor J.F., T. Kourti, J. Liu, J. Bradley, K. Dunn, H.

Yu, (2007). Multivariate methods for the analysis of data

bases process monitoring, and control in the material

processing industries, in: Proceedings 12th IFAC

Symposium MMM 07, Quebec City, pp. 193-198.

Nakagawa V., L.G. Bergh (2008). Soft sensor based on PLS

in a flotation circuit, Internal Research Report (in

Spanish), Chem. Eng. Dept., Santa Maria University,

Chile.

Osisoft (2013). The PI System: Empowering Business in

Real

Time,

retrieved

10/2013

from

http://www.osisoft.com/

Prosensus (2013). Multivariate Analysis for Manufacturing,

retrieved 10/2013 from www.prosensus.ca/

Soto D. (2013). Expert-fuzzy control of a pilot flotation

column, MSc Thesis, Chem. Eng. Dept., Santa Maria

University, Chile (in Spanish).

Thwaites P. (2007) Process control in metallurgical plants from an Xstrata perspective, Annual Reviews in Control,

31 pp. 221-239.

Vinnett L., F. Contreras, J. Yianatos (2012). Gas dispersion

pattern in mechanical flotation cells, Minerals

Engineering, 26, pp. 80-85.

Yianatos J.B., L.G. Bergh, F. Daz, J. Rodrguez (2005).

Mixing characteristics of industrial flotation equipments,

Chemical Engineering Science, 60, pp. 2273-2282.

Yianatos J.B. (2007). Fluid flow and kinetic modelling in

flotation related processes: columns and mechanically

agitated cells, Chemical Engineering Research and

Design 85 (A12) pp. 1-13.

Yianatos J., F. Contreras (2010). Particle entrainment model

for industrial flotation cells, Powder Technology, 197,

pp. 260-267.

Yianatos J.B., Bergh L.G., Vinnett L., Contreras F., and F.

Daz (2010a). Flotation rate distribution in the collection

zone of industrial cells, Minerals Engineering, 23, pp.

Yianatos J., F. Contreras, F. Daz (2010b). Gas holdup and

RTD measurement in an industrial flotation cell,

Minerals Engineering, 23, pp. 125-130.

Yianatos J., L. Bergh, C. Pino, L. Vinnett, C. Muoz, A.

Yaez (2012). Industrial evaluation of a new flotation

mechanism for large flotation cells, Minerals

Engineering, 3638, pp. 262-271.

ACKNOWLEDGEMENTS

The authors would like to thanks Santa Maria University

(Project 271351) and Fondecyt (Project 11300568) for their

financial support.

REFERENCES

Bergh L.G. and J.B. Yianatos, (1993). Control Alternatives

for Flotation Columns. Minerals Engineering, 6, pp.

631-642.

Bergh L.G. and J.B. Yianatos (1994). Experimental Studies

on Flotation Column Dynamics, Minerals Engineering,

7, pp. 345-355.

Bergh L.G., Yianatos J.B., Acua C. (1995). Hierarchical

Control Strategy for Flotation Columns, Minerals

Engineering, 8, pp. 1583-1591.

Bergh L.G., Yianatos J.B., Leiva C., (1998). Fuzzy

Supervisory Control of Flotation Columns., Minerals

Engineering , 11, pp. 739-748.

Bergh L.G., J.B. Yianatos, C. Acua, H. Prez and F. Lpez

(1999). Supervisory Control at Salvador Flotation

Columns, Minerals Engineering, 12, pp. 733-744.

Bergh L.G. and J.B. Yianatos, (2003), State of the art:

automation on flotation columns, Control Engineering

Practice, 11, N1, p 67-72.

Bergh L.G., J.B. Yianatos and A. Len (2005). Multivariate

projection methods applied to flotation columns,

Minerals Engineering, 18, pp. 721-723.

Bergh L.G. and J.B. Yianatos (2011). The Long Way

Towards Multivariate Predictive Control of Flotation

Processes, Journal of Process Control, 21, pp. 226-234.

Bergh L.G. and J.B. Yianatos (2013). Control of Rougher

Flotation Circuits Aided by Industrial Simulator, Journal

of Process Control, 23, 2, pp. 140-147.

Cao S. and R.R. Rhinehart (1995), An efficient method for

on-line identification of steady state, Journal of Process

Control, 5, 6, pp. 363-374.

Contreras F., J. Yianatos, L. Vinnet (2013). On the froth

transport modelling in industrial flotation cells,

Minerals Engineering, 41, pp. 17-24.

Duran J.P. (2013) Supervisory control of a pilot flotation

circuit, MSc Thesis, Chem. Eng. Dept., Santa Maria

University, Chile (in Spanish).

Finch, J.A. and G.S. Dobby (1990). Column Flotation.

Pergamon Press. General Electric (2013). Intelligent

Platforms, retrieved 10/2013 from http://www.geip.com/products/programmable-logic-controller/c552

General Electric (2013) Intelligent Platforms, retrieved

10/2013

from

http://www.geip.com/products/programmable-logic-controller/c552

Hodouin D., S-L Jamsa-Jounela, M.T. Carvalho, L.G. Bergh

(2001). State of art and challenges in mineral processing

control, Control Engineering Practice; 9, pp 1007-1012.

Hodouin D. (2011). Methods for automatic control,

observation, and optimization in mineral processing

plants, Journal of Process Control, 21, pp. 211-225.

Invensys (2013). Wonderware InTouch retrieved 10/2013

from http://global.wonderware.com/

11493

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- To Sir With LoveDocument2 pagesTo Sir With LoveRamita Udayashankar100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 50 Cool Stories 3000 Hot Words (Master Vocabulary in 50 Days) For GRE Mba Sat Banking SSC DefDocument263 pages50 Cool Stories 3000 Hot Words (Master Vocabulary in 50 Days) For GRE Mba Sat Banking SSC DefaravindNo ratings yet

- Literature - Part I: Group InterventionsDocument14 pagesLiterature - Part I: Group InterventionsDanielNo ratings yet

- Fusion Tech ActDocument74 pagesFusion Tech ActrahulrsinghNo ratings yet

- 600 2 Sub-Zero Built-In Series Refrigerator Service ManualDocument188 pages600 2 Sub-Zero Built-In Series Refrigerator Service Manual911servicetechNo ratings yet

- U309 Ta10zg1b Dop eDocument6 pagesU309 Ta10zg1b Dop ekrlossnNo ratings yet

- U231 U10a D eDocument1 pageU231 U10a D ekrlossnNo ratings yet

- DVP - Communication ProtocolDocument15 pagesDVP - Communication ProtocolKashif KhanNo ratings yet

- DVP - Communication ProtocolDocument15 pagesDVP - Communication ProtocolKashif KhanNo ratings yet

- Atx12v PSDG2.01Document44 pagesAtx12v PSDG2.01Abdul Basit AminNo ratings yet

- Eeb 500 UgDocument110 pagesEeb 500 Ughamedmalas67131No ratings yet

- Atx12v PSDG2.01Document44 pagesAtx12v PSDG2.01Abdul Basit AminNo ratings yet

- SFNDocument15 pagesSFNTrya Agung PahleviNo ratings yet

- 74 Ls 121Document10 pages74 Ls 121krlossnNo ratings yet

- lm741 PDFDocument9 pageslm741 PDFtry_nguyenNo ratings yet

- People vs. Abad SantosDocument2 pagesPeople vs. Abad SantosTrixie PeraltaNo ratings yet

- Chapter 1. Introduction To TCPIP NetworkingDocument15 pagesChapter 1. Introduction To TCPIP NetworkingPoojitha NagarajaNo ratings yet

- The Art of Woodworking Shaker FurnitureDocument147 pagesThe Art of Woodworking Shaker Furnituremalefikus100% (2)

- The Story of Babri MasjidDocument54 pagesThe Story of Babri MasjidKiran Penumala100% (1)

- Lecture Notes 1-8Document39 pagesLecture Notes 1-8Mehdi MohmoodNo ratings yet

- Perkin Elmer Singapore Distribution CaseDocument3 pagesPerkin Elmer Singapore Distribution CaseJackie Canlas100% (1)

- Forms and Types of Business OrganizationDocument2 pagesForms and Types of Business Organizationjune hetreNo ratings yet

- Narasimha EngDocument33 pagesNarasimha EngSachin SinghNo ratings yet

- The Forty Nine StepsDocument312 pagesThe Forty Nine Stepsoldnic67% (3)

- Foundation of Special and Inclusive EducationDocument25 pagesFoundation of Special and Inclusive Educationmarjory empredoNo ratings yet

- Primer To Using Stampplot® Pro Standard User LicensedDocument21 pagesPrimer To Using Stampplot® Pro Standard User LicensedSandy Rachman AdrianNo ratings yet

- A Study On Inventory Management Towards Organizational Performance of Manufacturing Company in MelakaDocument12 pagesA Study On Inventory Management Towards Organizational Performance of Manufacturing Company in MelakaOsama MazharNo ratings yet

- Mock Exam 2Document33 pagesMock Exam 2Althea Karmylle M. BonitaNo ratings yet

- Testing Your Understanding: The Dash, Slash, Ellipses & BracketsDocument2 pagesTesting Your Understanding: The Dash, Slash, Ellipses & BracketsBatsaikhan DashdondogNo ratings yet

- June 2016 - QuestionsDocument8 pagesJune 2016 - Questionsnasir_m68No ratings yet

- Bombardier CityfloDocument14 pagesBombardier CityfloBiju KmNo ratings yet

- IFRS 17 Risk Adjustment For Non-Financial Risk For Life and Health Insurance ContractsDocument34 pagesIFRS 17 Risk Adjustment For Non-Financial Risk For Life and Health Insurance ContractsaljdummyNo ratings yet

- Answer Here:: FAMILY NAME - FIRST NAME - CLASSCODEDocument4 pagesAnswer Here:: FAMILY NAME - FIRST NAME - CLASSCODEUchayyaNo ratings yet

- ViscosityDocument7 pagesViscositykiran2381No ratings yet

- Readingdev 7Document2 pagesReadingdev 7api-190328610No ratings yet

- Islamic Finance in the UKDocument27 pagesIslamic Finance in the UKAli Can ERTÜRK (alicanerturk)No ratings yet

- Javier Couso, Alexandra Huneeus, Rachel Sieder Cultures of Legality Judicialization and Political Activism in Latin America Cambridge Studies in Law and SocietyDocument290 pagesJavier Couso, Alexandra Huneeus, Rachel Sieder Cultures of Legality Judicialization and Political Activism in Latin America Cambridge Studies in Law and SocietyLívia de SouzaNo ratings yet

- Book Review Reclaim Your HeartDocument7 pagesBook Review Reclaim Your HeartShaheer KhanNo ratings yet

- Formula Sheet For Astronomy 1 - Paper 1 and Stars & PlanetsDocument2 pagesFormula Sheet For Astronomy 1 - Paper 1 and Stars & PlanetsprashinNo ratings yet

- Research Online Research OnlineDocument11 pagesResearch Online Research OnlineMunib HussainNo ratings yet