Professional Documents

Culture Documents

Cement Fracture

Uploaded by

PedjaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Fracture

Uploaded by

PedjaCopyright:

Available Formats

Fracture Mechanics of Concrete

Fracture Mechanics of Concrete

Fracture Mechanics

Fracture mechanics for concrete can be a useful

tool for the designer because of the insight it

provides on size effects, that is, how the size of

a structural element will affect the ultimate load

capacity.

Fracture mechanics also provides powerful

criteria for the prediction of crack propagation.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fracture Mechanics

Linear elastic fracture mechanics theory was

developed in 1920, but not until 1961 was the

first experimental research in concrete performed.

Fracture mechanics was used successfully in

design for metallic and brittle materials early on;

however comparatively few applications were

found for concrete.

This trend continued up until the middle 70s

when finally major advances were made.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fracture Mechanics

In the 80s and 90s intensive research has been

performed and applications of fracture mechanics

in design of beams, anchorage and large dams

are becoming more common.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Linear Elastic Fracture Mechanics

Griffith is often regarded as the founder of

fracture mechanics.

He observed experimentally that small

imperfections have a much less damaging effect

on the material properties than the large

imperfections.

Griffith suggested an energy balance approach

based not only on the potential energy of the

external loads and on the stored elastic strain

energy but also on another energy term: the

surface energy.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Crack in a plate

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Crack in a plate

Griffith used a result obtained by Inglis that the

change in strain energy due to an elliptical crack

in an uniformly stressed plate is a 2 2 E and

therefore the change in potential energy of the

external load is twice as much .

The change of energy of the plate due to the

introduction of the crack is given by:

U cracked Uuncracked =

2 a2 2

E

a2 2

E

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

+ 4 a

Fracture Mechanics of Concrete

Crack in a plate

Minimizing the energy in relation to the crack

length,

a 2 2

+ 4 a = 0

a

E

gives the critical stress (for plane stress):

2 E

a

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Importance of the equation

This equation is significant because it relates the

size of the imperfection (2a) to the tensile

strength of the material.

It predicts that small imperfections are less

damaging than large imperfections, as observed

experimentally.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Critical energy release rate

Irwin proposed that instead of using the

thermodynamic surface energy, one should

measure the characteristic surface energy of a

material in a fracture test.

He introduced the quantity Gc as the work

required to produce a unit increase in crack area.

Gc is also referred to as the critical energy

release rate.

Gc is determined experimentally, normally using

simple specimen configuration.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Critical energy release rate

The energy release per unit increase crack area, G,

is computed; if the energy release rate is lower

than the critical energy release rate (G < Gc ) the

crack is stable.

Conversely, if G> Gc, the crack propagates.

In the case when the energy release rate is equal

to the critical energy release rate (G=Gc), a

metastable equilibrium is obtained.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Computation of G

Considering a plate with thickness B, the energy released by crack growth

GBa = Px U e

U e is the change in elastic energy due to crack growth

GB = P

dx dU e

da da

Ue

Introducing the compliance c = x/P

the strain energy is given by

U e =

cP 2

2

d (cP) d (cP 2 / 2)

GB = P

da

da

P 2 dc

G=

2 B da

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Example: Double cantilever beam with thickness B

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Computation of G

The deflection of each cantilever

Pa 3

=

2 3EI

I=

1 h 3

b( )

12 2

The compliance is given by

2a 3

c= =

P 3EI

Therefore the energy release rate is given by

P 2 dc P 2 a 2

G=

=

2 B da BEI

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Stability criteria

A crack is stable if the derivative of the strain

energy rate, with respect to crack length is

negative.

1 G

<0

G a

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

For load control (double cantiliver specimen)

G 2 P 2 a

=

a

BEI

(1/G )(G /a ) = 2a

is a positive number, therefore the crack will propagate in an unstable way.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

For displacement control

9 EI

G=

4

4a B

G

9 EI 2

= 5

a

a B

so

(1/G )(G /a ) = 4 /a

is a negative number, therefore, the crack will propagate in a stable manner.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Modes

Mode I: opening or tensile mode,

Mode II: sliding or in-plane shear mode

Mode III: tearing or antiplane shear mode.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Modes

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Stresses at the tip of the crack for mode I

3

y =

cos 1+sin sin

2 r

2

2

2

KI

x =

cos 1 sin sin

2 r

2

2

2

KI

3

xy =

sin cos cos

2 r

2

2

2

KI

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Stress-intensity factor

KI is called stress-intensity factor for Mode I.

Dimensional analysis of indicates that the stressintensity factor must be linearly related to stress

and to the square root of a characteristic length.

Assuming that this characteristic length is

associated with the crack length:

K I = a f (g )

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

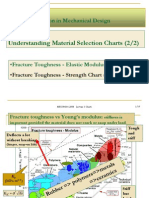

Fracture toughness

Suppose we measure the value of the stress at

fracture in a given test.

Using the previous equations, we determine the

critical stress intensity factor, Kc, or fracture

toughness as it is usually called in the literature.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Concrete Fracture Mechanics

The first experimental research on fracture

mechanics of concrete was performed by Kaplan

in 1961.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Importance of Size Effect

pc =

Kc

a f ( a /b )

pt = f t (1 ba )

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Brittleness number

Characterize the nature of the collapse; the lower

the brittleness number the more brittle the

behavior of the specimen.

Fracture occurs in specimens with a small

brittleness number, that is, for materials with a

comparatively low fracture toughness, a high

tensile strength, and in large specimens.

s = K c /f t b

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Mesh sensitivity

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Crack propagation in concrete

Courtesy from Prof. Nemati

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Crack propagation in concrete

Courtesy from Prof. Nemati

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Two simplifying assumptions for the strain in the fracture zone

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fictitious Crack Model

The fictitious crack model was created and

expanded upon by Hillerborg, Petersson, and coworkers.

One of the objectives of the model is to capture

the complex nature of concrete in tension.

The amount of microcracking in concrete, which is

in tension, is small before the peak stress is

reached, therefore, the deformation along the

specimen can be assumed to be uniform, and the

total elongation of the specimen can be

expressed in terms of the length of the specimen

l = l

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fictitious Crack Model

A localized fracture zone starts to develop just

after the peak load is reached.

In the model, this zone is assumed to form

simultaneously across an entire cross section.

As the total elongation increases, the stress

decreases and the region outside the fracture

zone experiences an unloading, while inside the

fracture zone, there is softening.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fictitious Crack Model

The fracture zone remains localized and does not

spread along the specimen, this is called strain

localization, somewhat akin to that seen in

plasticity. Beyond the peak stress, the total

elongation of the specimen is the sum of the

uniform deformation outside the fracture zone

and the additional localized deformation

l = l + w

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fictitious Crack Model

Two relationships are needed to characterize the

mechanical behavior of concrete in tension: (1) a

stress-strain relationship for the region outside

the fracture zone, and (2) a stress-elongation

relationship for the fracture zone.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Fracture energy

The fracture energy is equal to the area under the

stress-elongation curve.

G f = ( w)dw

0

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Experimental Results

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

CEB-FIP model code 1990

G f = f ( f cm /f cmo )

0.7

dmax

f (Nmm / mm2)

0.02

16

0.03

32

0.05

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Slopes

The stress-strain and stress-elongation curves are

related in the following manner: the slope of the

stress-strain diagram is E, and the slope of the

stress-deformation curve is proportional to

f t /(G f /f t )

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Characteristic length

The ratio between the two slopes has units of

length called the characteristic length of the

material:

lch =

EG f

ft

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Characteristic length

The characteristic length is often considered to be

a material property, and it gives a measure of the

brittleness of the material.

Cement paste has a characteristic length in the

range 5-15 mm, mortar in the range 100-200

mm, and concrete 200-400 mm.

Compared to normal-strength concrete, highstrength concretes and light-weight aggregate

concrete have lower characteristic lengths.

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

CEB-FIP model code 1990

ct = Ec ct

for ct 0.9 f ctm

0.1 f ctm

(0.00015 ct ) for 0.9 f ctm ct f ctm

ct = f ctm

0.00015 (0.9 f ctm /Ec )

For cracked section:

w

ct = f ctm (1 0.85 ) for 0.15 f ctm ct f ctm

w1

ct =

w1 =

0.15 f ctm

( wc w) for 0 ct 0.15 f ctm

wc w1

2G f

f ctm

0.15wc and wc = F

Gf

f ctm

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

Fracture Mechanics of Concrete

Stress-strain and stress-elongation for concrete in uniaxial tension

P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials

You might also like

- Microchip Drug Delivery - New Era of Drug Delivery SystemDocument8 pagesMicrochip Drug Delivery - New Era of Drug Delivery SystemDV65No ratings yet

- NRMC CIP 26pDocument2 pagesNRMC CIP 26pPedjaNo ratings yet

- Finishing Concrete Flatwork GuideDocument0 pagesFinishing Concrete Flatwork Guideتوان امتياس سامسدينNo ratings yet

- The Particle Nature of MatterDocument25 pagesThe Particle Nature of MatterMaria bonny aquinoNo ratings yet

- Exercises On Fracture MechanicsDocument33 pagesExercises On Fracture Mechanicsyaswanth199260% (5)

- Cold Weather Concreting TipsDocument2 pagesCold Weather Concreting TipsBoris DikovNo ratings yet

- PrEN 13043 - Aggregates For Bituminous Mixtures and SurfaceDocument45 pagesPrEN 13043 - Aggregates For Bituminous Mixtures and SurfacePedja100% (1)

- PrEN 12273 - Slurry Surfacing - Product StandardDocument25 pagesPrEN 12273 - Slurry Surfacing - Product StandardPedjaNo ratings yet

- Matematika Jedan Nikic Comic RP22Document152 pagesMatematika Jedan Nikic Comic RP22PedjaNo ratings yet

- M 004 ExercisesDocument33 pagesM 004 ExercisesKannan MuthusamyNo ratings yet

- Fracture MechanicsDocument31 pagesFracture MechanicsDhany SSat100% (2)

- Fracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsFrom EverandFracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms ProblemsJ. C. RadonNo ratings yet

- Filter Paper TestDocument14 pagesFilter Paper TestSallam MohammedNo ratings yet

- Fracture Mechanics ExercisesDocument33 pagesFracture Mechanics Exercises2luckystar100% (1)

- Cement Calculus 28Document2 pagesCement Calculus 28PedjaNo ratings yet

- Klinker Composition CalculationProt 231bDocument28 pagesKlinker Composition CalculationProt 231bPedjaNo ratings yet

- Non-Destructive Methods: P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and MaterialsDocument79 pagesNon-Destructive Methods: P.K. Mehta and P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materialsjuli_radNo ratings yet

- Seismic Fracture Analysis of Concrete Gravity Dams Based On Nonlinear Fracture MechanicsDocument21 pagesSeismic Fracture Analysis of Concrete Gravity Dams Based On Nonlinear Fracture MechanicsJulio Humberto Díaz RondánNo ratings yet

- A Numerical Simulation On The Perforation of Reinforced Concrete TargetsDocument15 pagesA Numerical Simulation On The Perforation of Reinforced Concrete TargetsVimal MohanNo ratings yet

- Fracture Mechanics: 1), The Max. Stress Equation Can Be Approximated byDocument20 pagesFracture Mechanics: 1), The Max. Stress Equation Can Be Approximated bykarrar333 ALIYAHIANo ratings yet

- Experimental Test and Numerical Simulation of The Initial Crack Reinforced Concrete Beam in BendingDocument6 pagesExperimental Test and Numerical Simulation of The Initial Crack Reinforced Concrete Beam in BendingErik Wahyu PradanaNo ratings yet

- Experimental Determination of Fracture Energy by RILEM MethodDocument10 pagesExperimental Determination of Fracture Energy by RILEM MethodtheijesNo ratings yet

- 1 s2.0 S0013794422000418 MainDocument17 pages1 s2.0 S0013794422000418 MainoumaymafstNo ratings yet

- Lecture Note 4Document4 pagesLecture Note 4Kannan MuthusamyNo ratings yet

- Fracture Mechanics Exercises for Linear-Elastic and Elastic-Plastic BehaviorDocument10 pagesFracture Mechanics Exercises for Linear-Elastic and Elastic-Plastic BehaviorChuoiEmNo ratings yet

- Concrete Rock InterfaceDocument7 pagesConcrete Rock Interfacedyc123No ratings yet

- A Variable Parameters Damage Model For Concrete QI LI LIU - 2020Document11 pagesA Variable Parameters Damage Model For Concrete QI LI LIU - 2020Ghina UtamiNo ratings yet

- Crack Formation and Fracture Energy of Normal andDocument12 pagesCrack Formation and Fracture Energy of Normal andIngénieurCivilNo ratings yet

- 1 s2.0 S0167844217301088 MainDocument9 pages1 s2.0 S0167844217301088 Main朱志清No ratings yet

- Experimental Determination of The Fracture Toughness Via PDFDocument10 pagesExperimental Determination of The Fracture Toughness Via PDFPacifier NothingfaceNo ratings yet

- SMiRT-23 Impact Paper-FinalDocument10 pagesSMiRT-23 Impact Paper-FinalMrigendra Nath RayNo ratings yet

- Infill RC FramesDocument14 pagesInfill RC FramesNILESH PATILNo ratings yet

- Analysis of Cracking-Moment Calculation Method of Pre-Stressed Sheet PileDocument11 pagesAnalysis of Cracking-Moment Calculation Method of Pre-Stressed Sheet PileMuhammad LutfhiNo ratings yet

- State-Of-The-Art Analysis For The Fracture Energy of Concrete: RevisitedDocument10 pagesState-Of-The-Art Analysis For The Fracture Energy of Concrete: RevisitedShivang JayswalNo ratings yet

- Az31 - NTCDocument17 pagesAz31 - NTCPabloNo ratings yet

- Kwak and SEODocument15 pagesKwak and SEOTony SiNo ratings yet

- Lecture 11Document39 pagesLecture 11B RAMUNo ratings yet

- Modified Crack Closure Integral (MCCI) For 3-d Problems Using 20-Noded Brick ElementsDocument1 pageModified Crack Closure Integral (MCCI) For 3-d Problems Using 20-Noded Brick ElementsDaniel C. RibuNo ratings yet

- Paper Authors CopyDocument8 pagesPaper Authors CopyShashankdutt BhyravajoshuluNo ratings yet

- Prestress SlabDocument31 pagesPrestress Slabrdey36886No ratings yet

- Ductility of Prefabricated Cage Reinforced Concrete Beams: Analytical StudyDocument9 pagesDuctility of Prefabricated Cage Reinforced Concrete Beams: Analytical StudymagdyamdbNo ratings yet

- Nonlinear RC Beam Analysis Using Moment-Curvature RelationsDocument14 pagesNonlinear RC Beam Analysis Using Moment-Curvature RelationsSamia ChowdhuryNo ratings yet

- AggregateDocument32 pagesAggregateAdnan JadoonNo ratings yet

- Elements of Fracture MechanicsDocument8 pagesElements of Fracture MechanicsMachine DesignNo ratings yet

- Composite Structures: S.A. Niaki, J.R. Mianroodi, M. Sadeghi, R. NaghdabadiDocument8 pagesComposite Structures: S.A. Niaki, J.R. Mianroodi, M. Sadeghi, R. NaghdabadiJohn VatistasNo ratings yet

- ch2 LEFMDocument30 pagesch2 LEFMntuten88No ratings yet

- Chapter 3 Utilization of High Density...Document9 pagesChapter 3 Utilization of High Density...chvi.plucena.auNo ratings yet

- Earthquake Risk Reduction and Seismic Safety Evaluation of Arch Dams Using Infinite ElementsDocument8 pagesEarthquake Risk Reduction and Seismic Safety Evaluation of Arch Dams Using Infinite ElementsGianfranco TacoNo ratings yet

- 3D Crack Specimen T-Stress Constraint ParametersDocument39 pages3D Crack Specimen T-Stress Constraint ParametersPragathees RamamoorthiNo ratings yet

- Kabir Shakya Anil C. Wijeyewickrema Tatsuo OhmachiDocument4 pagesKabir Shakya Anil C. Wijeyewickrema Tatsuo Ohmachinahan_khanehe_delNo ratings yet

- Correlation Study On Tensile Properties of Cu, CuCrZr and W by Small PunchDocument10 pagesCorrelation Study On Tensile Properties of Cu, CuCrZr and W by Small PunchFacundo PainetruNo ratings yet

- Application of Size Effect To Compressive Strength of Concrete MembersDocument18 pagesApplication of Size Effect To Compressive Strength of Concrete MembersBEN NARENDRANNo ratings yet

- Parametric Study On Structural Wall-Flat Slab Connection Under Seismic Type LoadingDocument11 pagesParametric Study On Structural Wall-Flat Slab Connection Under Seismic Type LoadingSurumi Rasia SalimNo ratings yet

- Wall Thickness Dependencies of Carbon Nanotube Reinforced NanocompositesDocument10 pagesWall Thickness Dependencies of Carbon Nanotube Reinforced NanocompositesSakil0104No ratings yet

- Barpi - Fuzzy Parameters Analysis of Time-Dependent Fracture of Concrete Dam ModelsDocument23 pagesBarpi - Fuzzy Parameters Analysis of Time-Dependent Fracture of Concrete Dam ModelsJoaquin RiccitelliNo ratings yet

- Bearing Capacity of Concrete Hinges Subjected To eDocument18 pagesBearing Capacity of Concrete Hinges Subjected To eMilchoNo ratings yet

- 29) Haridharan - 2017 - IOP - Conf. - Ser.: - Earth - Environ. - Sci. - 80 - 012014Document7 pages29) Haridharan - 2017 - IOP - Conf. - Ser.: - Earth - Environ. - Sci. - 80 - 012014HARINo ratings yet

- Finite Element Stress Analysis of Brick-Mortar Masonry Under CompressionDocument6 pagesFinite Element Stress Analysis of Brick-Mortar Masonry Under CompressionAnonymous P8Bt46mk5INo ratings yet

- Study On Fracture Characteristics of Reinforced Concrete Wedge Splitting TestsDocument18 pagesStudy On Fracture Characteristics of Reinforced Concrete Wedge Splitting TestsSai Asrith PylaNo ratings yet

- Determination of The Mohr-Coulomb Material Parameters For Concrete Under Indirect Tensile TestDocument8 pagesDetermination of The Mohr-Coulomb Material Parameters For Concrete Under Indirect Tensile Testshobhit mohtaNo ratings yet

- GEO Shrestha1Document8 pagesGEO Shrestha1sleshnepalNo ratings yet

- Numerical Study of RC Beam Blast LoadingDocument4 pagesNumerical Study of RC Beam Blast LoadingJangdiniNo ratings yet

- Seismic Performance of Confined Masonry Buildings Designed With The Mexico City Building CodeDocument13 pagesSeismic Performance of Confined Masonry Buildings Designed With The Mexico City Building CodeHector IncaNo ratings yet

- Caceres-L3 Understanding Materials Selection ChartsDocument23 pagesCaceres-L3 Understanding Materials Selection ChartsUngku Mohd RafiqNo ratings yet

- State-Of-The-Arts: Fracture Mechanics: March 2016Document9 pagesState-Of-The-Arts: Fracture Mechanics: March 2016MohamedElSakaNo ratings yet

- Mto Curvatura ManderDocument17 pagesMto Curvatura ManderSergio Echeverría RNo ratings yet

- Finally Published PaperDocument11 pagesFinally Published PaperPiyush BhattNo ratings yet

- Gdoutos CCC 2016Document9 pagesGdoutos CCC 2016PanosDanoglidisNo ratings yet

- Analysis The Effects of Lightweight Concrete in THDocument9 pagesAnalysis The Effects of Lightweight Concrete in TH429e10d421No ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- PrEN 12271-10 - Factory Production ControlDocument17 pagesPrEN 12271-10 - Factory Production ControlPedjaNo ratings yet

- Petar Subotic - Prirucnik Za Asfalt I DeoDocument308 pagesPetar Subotic - Prirucnik Za Asfalt I DeoPedjaNo ratings yet

- PrEN 12271 - Surface DressingDocument54 pagesPrEN 12271 - Surface DressingPedjaNo ratings yet

- PrEN 13020 - Road Surface Treatment MachinesDocument20 pagesPrEN 13020 - Road Surface Treatment MachinesPedjaNo ratings yet

- NRMC CIP 29pDocument2 pagesNRMC CIP 29pPedjaNo ratings yet

- Estimate Concrete Strength Using Maturity MethodsDocument2 pagesEstimate Concrete Strength Using Maturity MethodsRV Vimal100% (1)

- NRMC CIP 44prDocument2 pagesNRMC CIP 44prPedjaNo ratings yet

- NRMC CIP 32pDocument2 pagesNRMC CIP 32pPedjaNo ratings yet

- Aggregate Pop OutDocument0 pagesAggregate Pop Outتوان امتياس سامسدينNo ratings yet

- NRMC CIP 28pDocument2 pagesNRMC CIP 28pPedjaNo ratings yet

- CIP35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNo ratings yet

- NRMC CIP 43pDocument2 pagesNRMC CIP 43pPedjaNo ratings yet

- NRMC CIP 18pDocument2 pagesNRMC CIP 18pPedjaNo ratings yet

- High Strength ConcreteDocument0 pagesHigh Strength ConcreteAris Co AbergosNo ratings yet

- GuidelinesDocument2 pagesGuidelinesMike2322No ratings yet

- NRMC CIP 17pDocument2 pagesNRMC CIP 17pPedjaNo ratings yet

- NRMC CIP 23pDocument2 pagesNRMC CIP 23pPedjaNo ratings yet

- NRMC CIP 13pDocument2 pagesNRMC CIP 13pPedjaNo ratings yet

- STANDARD SPECIFICATIONS For HIGHWAY BRIDGESDocument0 pagesSTANDARD SPECIFICATIONS For HIGHWAY BRIDGESتوان امتياس سامسدينNo ratings yet

- NRMC CIP 20pDocument2 pagesNRMC CIP 20pPedjaNo ratings yet

- Hot Weather Concreting TipsDocument2 pagesHot Weather Concreting TipsTim_CNo ratings yet

- CIP 19 - Curling of Concrete SlabsDocument2 pagesCIP 19 - Curling of Concrete SlabsMaestroColicus100% (1)

- NONWOVEN - Vinay Kumar MidhaDocument11 pagesNONWOVEN - Vinay Kumar Midhaglobal-marketin8184No ratings yet

- Sai Water Tub AgreementDocument67 pagesSai Water Tub Agreementvinodhcivil9No ratings yet

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNo ratings yet

- Bronze Castings For Bridges and TurntablesDocument4 pagesBronze Castings For Bridges and TurntablesmatiullahNo ratings yet

- Rheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaDocument6 pagesRheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaNurfatini CheNo ratings yet

- VMC-Haj House - Final Estimate 09.01.19Document787 pagesVMC-Haj House - Final Estimate 09.01.19Patan Abdul Mehmood Khan100% (1)

- Analysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareDocument300 pagesAnalysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareChinmay TejaswiNo ratings yet

- About Welding Process 47Document1 pageAbout Welding Process 47XerexNo ratings yet

- HHD-S Cavity anchor installation guideDocument2 pagesHHD-S Cavity anchor installation guideIngeniero Miguel VillarroelNo ratings yet

- 2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions HyderabadDocument4 pages2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions Hyderabadnithish0% (1)

- MasterCast 141MDocument5 pagesMasterCast 141Mrobin rezkNo ratings yet

- Vertical Drains May Not Work Alone Due To Thick Uniform Soft ClayDocument77 pagesVertical Drains May Not Work Alone Due To Thick Uniform Soft ClayChitharanjan VishnukripalNo ratings yet

- Hazardous Waste Management TechniquesDocument12 pagesHazardous Waste Management TechniquesSyed YousufuddinNo ratings yet

- Afrox MIG/TIG 904L: Welding Consumables Stainless SteelDocument5 pagesAfrox MIG/TIG 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- TranslateDocument9 pagesTranslateWira AdjieNo ratings yet

- Angora Wool: Ultra-Soft Fiber From RabbitsDocument2 pagesAngora Wool: Ultra-Soft Fiber From RabbitsYogen Garbiyal100% (1)

- FME-2021-0403 Proof HiDocument41 pagesFME-2021-0403 Proof HiAsif EqubalNo ratings yet

- Duct Tape and Insulation Tape GuideDocument2 pagesDuct Tape and Insulation Tape GuideDhanish AhsenNo ratings yet

- ZOLLERN-Broschuere ZGF Legierungen ENGDocument16 pagesZOLLERN-Broschuere ZGF Legierungen ENGPablo PadillaNo ratings yet

- Liquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationDocument11 pagesLiquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationRajendrasinh PuvarNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Datasheet Potassium Formate KFORMSOLpdfDocument1 pageDatasheet Potassium Formate KFORMSOLpdfJuan MancipeNo ratings yet

- Honel A SeriesDocument6 pagesHonel A SeriesAustin WilsonNo ratings yet

- Bartle2002 PDFDocument11 pagesBartle2002 PDFMurilo PaixNo ratings yet

- Waukesha Worldpump - ArticleDocument4 pagesWaukesha Worldpump - Articlepaulo cesar hernandez mijangosNo ratings yet

- PQT First Aplication Banyu Urip Painting PrimerDocument19 pagesPQT First Aplication Banyu Urip Painting PrimerHeri FebriyantoNo ratings yet

- Corona Treater: Operation and MainenanceDocument34 pagesCorona Treater: Operation and MainenanceJUAN RODRIGUEZNo ratings yet