Professional Documents

Culture Documents

STAMANT SysBeschrbg GB 01okt09

Uploaded by

Alhgasjsghjagjsdajlsd AsdalsdlkaksdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STAMANT SysBeschrbg GB 01okt09

Uploaded by

Alhgasjsghjagjsdajlsd AsdalsdlkaksdCopyright:

Available Formats

BRUGG-STAMANT Safety Pipe

Systems description

pproval

a

e

p

y

t

l

Genera

07

Z-38.4-2

BRUGG-STAMANT Safety Pipe

Contents

5.0

Contents

5.1

5.101

Systems description

BRUGG-STAMANT Safety Piping

5.102

5.103

5.104

General type approval

Technical project description leak detector

Technical project description materials specification

5.201

BRUGG-STAMANT construction elements

5.4

5.400

5.410

5.450

5.470

Leak detection

Leak detection BRUGG-STAMANT Safety Piping

Leak detection on the vacuum principle

Leak detection on the positive pressure principle

Leak detection on the positive pressure principle

5.601

Selection of construction elements from our standard range

5.801

Details for underground works

01.10.2009

Subject to technical changes

SMR 5.0

BRUGG-STAMANT Safety Pipe

SMR 5.101

Systems description

Monitorable BRUGG-STAMANT Safety Piping

BRUGG-STAMANT Safety Piping is a prefabricated double-walled piping system delivered

in construction elements, in the dimensions DN 15/32 to DN 800/900, which is particularly

suitable for the transport of flammable and non-flammable water hazardous substances.

The installation and laying of the construction elements is done by specialist firms certified acc.

to 19 l WHG, TRbF 50 who can prove their qualifications in process and welding techniques.

1

2

The annular gap between the inner and secondary containment pipes is used as a surveillance

space for a leak detector, which carries out permanent and complete leak monitoring. In the

event of a spillage an optical and acoustic alarm is given and, where required, further transport

of the medium is interrupted.

The leak detector regulates the monitoring pressure in the surveillance space of the safety

piping and registers any changes in pressure, even in the case of minimal spillages, both in the

inner and secondary containment pipes.

Additional functions when an alarm is given, such as passing on the alarm signal, switching off

pumps or closing down magnetic valves, bring additional operational safety.

There are two monitoring systems:

Leak monitoring on the

1. Vacuum principle

2. Positive pressure principle

Besides increasing operating safety, the use of a leak detector brings considerable economic

advantages:

1. The entire system can be checked simply at any time without interrupting operations.

2. Requirements such as pressure-/volume measurements, pressure tests or inspections

of the piping route become unnecessary.

The construction elements, which are assembled at our works, include all necessary fittings for

the project (such as elbow, T-piece, wall through-connection etc.), including the complete outer

corrosion proofing for underground piping according to the requirements of DIN 30672.

The type of material used for the outer pipe and for the inner medium pipe depends on the expected mechanical, thermal, and chemical stress levels as well as on the currently valid building

regulations. Conventional project planning for double-walled piping systems, especially with

large pipe dimensions for the transport of flammable, environmentally hazardous media makes

stringent demands on the technical standards of a design, as well as on the manufacturers

know-how in fire and explosion prevention and the protection of bodies of water.

Years of experience in planning and implementing projects using steel-cased piping in the field

of district heating systems and FLEXWELL safety piping in industrial plants, the petrochemical sector and fuel depot construction mean that we are perfectly capable of meeting these

requirements

01.10.2009

Subject to technical changes

3

4

Structure of the

BRUGG-STAMANT

safety pipe

1 Inner pipe

2 Surveillance space

3 Secondary

containment pipe

4 Corrosion proofing

BRUGG-STAMANT Safety Pipe

General type approval Z-38.4-207

The construction design of BRUGG-STAMANT Safety Piping with leak monitoring is manufactured and used in projects

according to the description in the general type approval and according to the pressure device regulations 97/23/EG, as

well as according to the construction regulations of the TRbF 50. The system is subject to the requirements of 11.GSGV,

19 g WHG , 7 BetrSichV (Operating Safety Ordinance) and the requirements of the various German federal states

under the VAwS.

Principles of testing and evaluation used in the leak detector

(Definition of the surveillance space, the leak detector with connecting cables and the leak detection medium acc. to

TRbF 503)

BetrSichV

Technical rules for flammable liquids - TRbF

TRbF 50 Part 1 Piping on the factory premises

TRbF 502, EN 13160 Guideline/Construction and testing principles for leak detectors for double-walled piping

Water conservation law - WHG

Regulations concerning installations handling water hazardous substances - VAwS

and their appropriate regulations - VVAwS

Tests

According to the general type approval, the pressure device regulations 97/23/EG, as well as according to the construction and testing regulations of the TRbF 50.

Material, construction and pressure tests

We carry out the necessary material, construction, and pressure tests together with the competent official experts during

manufacturing in our factory. The final tests of the piping connections on site are also done by the official expert supported by the internal expert from the specialist firm.

Acceptance test

The function test and operational start-up of the leak monitoring system is carried out according to the description in the

approval documents of the specific leak detector used.

Proof of qualifications

Besides our experience, the following proof of qualifications guarantees that your orders will be carried out professionally

and to high quality standards:

Specialist firm acc. to 19 WHG

Specialist firm acc. to TRbF 180 Nr. 1.7

Specialist firm acc. to TRbF 503

Procedures test acc. to AD - Data sheet HP 2/1

Welder test acc. to AD - Data sheet HP 3

Specialist firm for the manufacture and installation of piping

Acceptance is monitored according to the pressure device regulations 97/23/EG

01.10.2009

Subject to technical changes

SMR 5.102

BRUGG-STAMANT Safety Pipe

Technical project description leak detector

Leak detector

(Safety piping and leak monitoring)

approved for the transport of water-hazardous (flammable and non-flammable) media

acc. to VbF i.Vm. of the 11. GSGV, WHG, VAwS

Safety piping

as a double-walled steel piping construction with surveillance space as part of a leak detection system.

Type: BRUGG-STAMANT safety piping

Leak monitoring (acc. to TRbF 502)

Positive pressure leak detector

Vacuum leak detector

Manufacturer

BRUGG Rohrsysteme GmbH

Installation / laying

by authorized specialist firms certified acc. to 19 l WHG and TRbF 50

Applications

Underground or above-ground piping

Transport medium

Water-hazardous [flammable and non-flammable] media

Dimensions

Outer pipe DN 32 to DN 900

Inner pipe DN 15 to DN 800

Operating conditions:

Operating pressure in inner pipe:

up to max. 16 bar positive pressure leak monitoring

up to max. 20 bar vacuum leak monitoring

Calculated pressure, monitoring pressure: according to the description in the approval documents

Testing pressure TRbF 50

Inner pipe: 1.3 times the monitoring pressure in the inner pipe

Surveillance space: 1.3 times the monitoring pressure or acc. to pressure device regulations (DGRL)

A testable static strength calculation acc. to BAZ is made for every BRUGG-STAMANT pipe system.

01.10.2009

Subject to technical changes

SMR 5.103

BRUGG-STAMANT Safety Pipe

SMR 5.104

Technical project description materials specification

Inner pipe

Dimensions seamless and welded pipes acc. to EN 10220

Technical conditions of delivery acc. to TRbF 50 or EN 10216-2, 10217-1, 10217-2, 10208-2

Acceptance test certificate acc. to DIN EN 10204 3.1.

Outer pipe

Dimensions seamless and welded pipes acc. to EN 10220

Technical conditions of delivery acc. to TRbF 50 or EN 10216-2, 10217-1, 10217-2, 10208-2

With external PE corrosion-proofing jacket acc. to DIN 30670 or DIN 30671.

Acceptance test certificate acc. to DIN EN 10204 3.1.

IP elbow

Pipe elbow DIN 2605

Works certificate acc. to DIN EN 10204 3.1.

as per description in the approval documents (see also Worksheet SMR 5.03.01/02)

OP elbow

Pipe elbow, radius according to the inner pipe curvature with appropriate material specification outer pipe DIN 2605

or in segments

PE corrosion-proofing jacket acc. to DIN 30672.

as per description in the approval documents (see also Worksheet SMR 5.03.01)

T-branch

Consisting of: outer pipe and inner pipe branch, T-branch acc. to DIN 2615, 2618 or Weldolet

as per description in the approval documents (see also Worksheets SMR 5.04.01 - 5.04.05)

End seal

Provides a pressure and vacuum-tight seal of the annular gap between outer and inner pipe, frictionally welded with

simultaneous lead-through of the inner pipe, incl. the connection for the leak detector as per description in the approval

documents (see also Worksheet SMR 5.14.01).

Bearings

Spacers

The inner pipe is carried on axial bearings which guarantees the openness of the surveillance space. As per description in

the approval documents (see also Worksheet SMR 5.10.01/5.11.01/5.12.01)

Leak monitoring

The annular gap, annular volume max. 10 m, between the inner and outer pipe serves as a surveillance space.

Monitoring of the pipe is done either on the positive pressure or vacuum principle, adapted to the actual operating pressure of the inner pipe, by means of an approved leak detector.

Flammable liquids Classes AI, AII, AIII and B, as well as WGK 1 to 3

Flammable liquids (AIII) and non-flammable liquids

As per description in the approval documents

01.10.2009

Subject to technical changes

BRUGG-STAMANT Safety Pipe

SMR 5.201

BRUGG-STAMANT construction elements

BRUGG-STAMANT safety piping construction elements already include all necessary fittings such as elbows, T-branches,

reducing sleeves and end seals. The standard length of the construction elements is 12.0 metres. Longer elements can be

delivered after consultation. The maximum length of the elements is only limited by the availability of suitable transport.

Construction elements in a completed installation

12100

3100

6000

3000

1

BV

LA

LA

upside

BRUGG-STAMANT Safety Pipe

BE 01

upside

Flange

End seal

Connection leak detector

number stamp 0 = upside

transport cap

1500

BV

LA

end seal

connection leak detector

LA

upside

elbow 90

T-piece

IP reducing sleeve

OP reducing sleeve

2600

2000

LA

LA

BE 05

BRUGG-STAMANT Safety Pipe

elbow 90

OP elbow

(assembled from

pipe segments)

735

5

upside

BV

7490

990

8480

All dimensions in mm

01.10.2009

Subject to technical changes

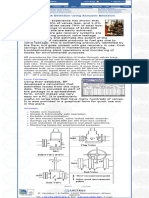

BRUGG-STAMANT Safety Pipe

Leak monitoring

BRUGG-STAMANT safety piping is permanently monitored using pneumatic leak detection equipment/ leak detectors.

These regulate the monitoring pressure in the surveillance space and register any changes of pressure which may occur.

The surveillance space is filled with the leak detection medium (an inert gas) and prevents uncontrolled spillages of the

transport medium when leaks occur. The surveillance space must be so constructed that the functioning and operative security of the leak detection system (the leak detector) is assured at all times when the leak monitoring system is

connected.

If the pipe is damaged the alarm is given by acoustic and optical signals.

Definition of leak detection equipment/leak detector

Leak detection equipment/leak detector according to the currently valid regulations refers to a device which automatically and under all operating conditions gives warning of leaks in the walls of double-walled piping in which waterhazardous (flammable and non-flammable) fluids are transported. The term leak detection equipment/leak detector

includes all the equipment necessary for the detection of leaks.

The main components are:

the leak detector/leak detection equipment (LAZ)

the connection between the surveillance space (R) and leak detector (LAZ)

double-walled piping

the surveillance space (R)

a leak detection medium

The use of this system complies with the most stringent European safety standards (Class 1). Systems of this class give

warning of a leak above or below the fluid level in a double-walled protective system. They are constructed on the principles of absolute safety and ensure that spillages of products into the environment cannot occur.

Leak detection equipment/leak detector (LAZ)

We distinguish two types of differential pressure leak detection equipment:

Leak surveillance to detect leaks in double-walled piping on the vacuum principle

and on the positive pressure principle (using an inert gas).

BRUGG-STAMANT safety piping with a vacuum leak detector

BRUGG-STAMANT safety piping with a positive-pressure leak detector

Approval/suitability

All leak detection equipment/leak detectors in use must comply with the basic criteria laid down for construction and

testing standards. All such preconditions which could have a bearing on the functional and operative safety of the system

must therefore be observed. It therefore goes without saying that the conditions for operative use have been tested by

the competent authorities and clearly defined and set down in the documents of approval issued by them.

BRUGG-STAMANT safety piping with leak monitoring is an approved leak detection equipment/leak detector system.

The advantages of the system

Using double-walled BRUGG-STAMANT safety piping with leak monitoring offers, besides a high degree of operative

safety, substantial economic advantages:

the entire system can be easily and simply monitored at any time without interrupting operations

requirements such as e.g. pressure/volume measurements, pressure tests or route surveys can be dispensed with.

01.10.2009

Subject to technical changes

SMR 5.400

BRUGG-STAMANT Safety Pipe

SMR 5.410

Leak detection on the vacuum principle

The leak detector on the vacuum principle is suitable and approved for monitoring

BRUGG-STAMANT Safety Piping for the transport of:

flammable water-hazardous substances with an ignition point > 55 C only in the Ex version

non-flammable water-hazardous substances.

VLR ...

Principles of functioning

The vacuum pump installed in the leak detector creates a partial vacuum inside the surveillance

space. By monitoring this partial vacuum, leaks in the walls of the piping are automatically

detected.

In the event of a drop in the partial vacuum (a rise in pressure) due to a leak below the lower

value of the monitoring level of partial vacuum, an optical and acoustic alarm is triggered.

Minimal, unavoidable permeability (not leaks) are regulated automatically by the leak detector

without triggering the alarm if they lie between the upper and lower values of the monitoring

partial vacuum. Evacuation to compensate is carried out by the vacuum pump in the leak

detector.

In every case in which the alarm is triggered, the vacuum pump is automatically switched off.

It can only be switched on again by throwing the toggle switch installed for this purpose on the

outside of the leak detector.

Technical basis

The scope of application of the leak detection device must be limited to fixed maximum pipe

lengths due to the laws of physics. These depend on the high and low points of the BRUGGSTAMANT safety pipe used and the type of laying.

Approval / suitability

All leak detection systems/ leak detectors used must comply with the stipulated construction

and test principles. Subject to these, all conditions must therefore be taken into account which

could influence the functioning or the operating safety of the system.

For this reason the conditions under which the devices can be used are tested by the official

testing offices and clearly defined and laid down in the approval documents issued by them.

BRUGG-STAMANT Safety Piping with leak detection is an approved leak detection system /

leak detector

BRUGG-STAMANT Safety Pipe

01.10.2009

Subject to technical changes

BRUGG-STAMANT Safety Pipe

SMR 5.450

Leak detection on the positive pressure principle

The leak detector on the positive pressure principle is suitable and approved for monitoring

BRUGG-STAMANT Safety Piping for the transport of:

flammable water-hazardous substances

non-flammable water-hazardous substances.

Principles of functioning

The operating pressure necessary in the surveillance space of the BRUGG-STAMANT Safety

Piping is regulated by the actual pressure in the operating pipe (inner transport pipe) and is

generated by topping up, regulated by pressure changes, from a stationary nitrogen pressure

reservoir which is connected to the surveillance space

operating mode Stationary

or from a mobile pressure reservoir which is only connected when the line is put into

operation or during a function test

operating mode Mobile

The leak detectors can be set to operating mode S or M by means of a switch for the two operating modes installed on the outside of the leak detector.

The surveillance space is connected to the leak detector by means of the connecting cables.

The positive pressure which is generated is measured by the pressure sensor. When there is a

drop in pressure to the predetermined ALARM ON setting due to a leak, an optical and acoustic

alarm is triggered.

In operating mode S, the monitoring pressure, after switching on, is regulated by pressure changes which are compensated by topping up from a stationary nitrogen pressure reservoir which is

permanently connected to the surveillance space and fitted with a reducing regulator.

In operating mode M, the monitoring pressure (SET PRESSURE) is generated when the system

is switched on just once at the outset by a pressure reservoir connected for the purpose. There

is no further pressure-regulated topping up during subsequent operations. A drop in pressure

to the predetermined ALARM ON setting due to a leak which triggers the alarm must therefore

be compensated by connecting the pressure reservoir until the pressure again reached the SET

PRESSURE.

Approval / suitability

All leak detection systems/ leak detectors used must comply with the stipulated construction

and test principles. Subject to these, all conditions must therefore be taken into account which

could influence the functioning or the operating safety of the system.

For this reason the conditions under which the devices can be used are tested by the official

testing offices and clearly defined and laid down in the approval documents issued by them.

BRUGG-STAMANT Safety Piping with leak detection is an approved leak detection system /

leak detector.

BRUGG-STAMANT Safety Pipe

01.10.2009

Subject to technical changes

DLR-G ...

BRUGG-STAMANT Safety Pipe

SMR 5.470

Leak detection special design high pressure

BRUGG-STAMANT Safety Pipe is a product custom-made for every single project. Consequently also the associated leak

detection systems are planned individually and in an economic way for any application.

By use of the vacuum leak detection system a working pressure up to 25 bars with and without explosion protection can

be realized.

A positive pressure leak detection system anables pipe systems with feed pressure up to 300 bars to be monitored.

These systems are equipped with high-pressure fittings and safety components (spring-loaded valves, blow-out discs,

digital pressure switches etc.).

Leak detector

Pressure switch

Spring-loaded valve

01.10.2009

Subject to technical changes

Blow-out disc

BRUGG-STAMANT Safety Pipe

SMR 5.601

Excerpt from components list for standard product range

Spacers

Axial bearings

Acc. to Worksheet SMR 5.10.01

Guide rails

Acc. to Worksheet SMR 5.11.01

Base plate

Acc. to Worksheet SMR 5.12.01

Acc. to Worksheet SMR 4.610

Double-walled elbow

Concentric curve

Acc. to Worksheet SMR 5.03.01

Outer pipe curve assembled from pipe segments

Acc. to Worksheet SMR 5.03.01

Acc. to Worksheet SMR 4.603

Double-walled T-piece

T-piece acc. to DIN 2615

Acc. to Worksheet SMR 5.04.01

T-piece with saddle connection

Acc. to Worksheet SMR 5.04.01

T-piece with Weldolet

Acc. to Worksheet SMR 5.04.01

Acc. to Worksheet SMR 4.604

End seal

End seal

Acc. to Worksheet SMR 5.14.01

Axial compensator seal

Acc. to Worksheet SMR 5.14.01

Acc. to Worksheet SMR 4.602

01.10.2009

Subject to technical changes

Lentiform compensator seal

Acc. to Worksheet SMR 5.14.01

BRUGG-STAMANT Safety Pipe

SMR 5.801

Details for underground works

Trench cross-section

7

0.5

1.50

0.1

T min.

0.1

0.4

B3

BV

0.2

0.2

B1

0.5

0.1

T min.

0.1

0.4

0.2

0.2

0.2

B2

1

2

3

4

5

6

7

8

4

3

2

All dimensions in m

BRUGG-STAMANT Safety Pipe

Pipe connection with end seal

Connection to leak detector

Wall through-connection/seal

Working space in front of buildings, manholes and in the area

of building connections (BV)

Warning tape

(available from BRUGG Rohrsysteme, installation by the contractor)

Sand bedding (K +/ - 2mm)

Backfill materia

The trench width B is a recommended value.

Please observe all valid technical regulations, guidelines and accident prevention rules.

BRUGG-STAMANT Safety Pipe

min. outer diameter

min. cover t at SLW 60

min. cover t at SLW 30

trench width

trench width

front trench width

01.10.2009

Subject to technical changes

(outer pipe)

d (mm)

(m)

(m)

B1 (m)

B2 (m)

B3 (m)

DN 65

77.9

min. 0.90

min. 0.75

0.48

0.76

1.56

DN 80

90.7

DN 100 DN 150

116.3

170.3

DN 200

221.1

DN 300

326.1

DN 400

408.6

DN 500 DN 600

510.5

612.1

0.49

0.78

1.58

0.52

0.84

1.64

0.62

1.04

1.84

0.73

1.25

2.05

0.81

1.42

2.22

0.91

1.62

2.42

0.57

0.94

1.74

1.02

1.83

2.63

10/09/1000 ex. D/ 84680016 / pictures by Key

Pipe systems for the future

District heating Industry Petrol stations System packages

Your partner for pipe systems

We are the people you should talk to when

you need to fi nd effi cient solutions for

transporting liquid materials. With our

project engineers, development department,

in-house production unit, and our professional team of fi tters, we have the know-how

and the resources to look after your projects

competently and reliably in the sectors of

heating systems, petrol station construction,

industrial plant construction, and system

packages.

Brugg Rohrsystem AG

Industriestrasse 39

CH-5314 Kleindttingen

phone +41 (0)56 268 78 78

fax

+41 (0)56 268 78 79

pipesystems@brugg.com

www.pipesystems.com

BRUGG Rohrsysteme GmbH

Adolf-Oesterheld-Strae 31

D-31515 Wunstorf

phone +49 (0)50 31 170-0

fax

+49 (0)50 31 170-170

info@brugg.de

www.brugg.de

A company of the BRUGG Group

International network

Our global partnership network can be

reached on site at any time. More than

34 partners in 20 different countries will

look after you wherever you are.

Customer-specific solutions

Brugg is the full service provider in the fi eld

of single-wall, double-wall and insulated

pipe systems. This know-how allows us to

manufacture project-specifi c customised

items.

Give us a call!

Our engineers would be pleased to advise you

and fi nd a made-to-measure solution.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ASTM-F2338-09 Leak TestDocument13 pagesASTM-F2338-09 Leak TestYustinus Ericko100% (3)

- Loss of Containment TopsidesDocument1 pageLoss of Containment TopsidesRoberto Burgos0% (1)

- Ojt Narrative ReportDocument10 pagesOjt Narrative ReportGian MalabananNo ratings yet

- Relining of Urea Reactor Top at Abu Qir FertilizersDocument19 pagesRelining of Urea Reactor Top at Abu Qir Fertilizersasirul_meNo ratings yet

- IWA Leak Detection and Repair - Guidance NotesDocument71 pagesIWA Leak Detection and Repair - Guidance NotesAnonymous vLJN1U5PDNo ratings yet

- Double Wall Tank Installation InstructionsDocument4 pagesDouble Wall Tank Installation InstructionsalokinstNo ratings yet

- Air Cooled Installation Manual IM140514 1.7Document47 pagesAir Cooled Installation Manual IM140514 1.7Alhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Failure - Investigation of Pipeline Failure Cathodic Protection CP Thermally Insulated SegmentsDocument510 pagesFailure - Investigation of Pipeline Failure Cathodic Protection CP Thermally Insulated SegmentsYousuf Memon100% (1)

- Offshore & Pipeline Control Instrument Design ReportDocument8 pagesOffshore & Pipeline Control Instrument Design ReportSaoloan NaiborhuNo ratings yet

- Tank Testing ProcedureDocument99 pagesTank Testing ProcedureishfaqurrehmanpkNo ratings yet

- Leak Detection Practices and Techniques:: A Practical ApproachDocument2 pagesLeak Detection Practices and Techniques:: A Practical ApproachrogerNo ratings yet

- Sensor-Based Gas Leakage Detector SystemDocument48 pagesSensor-Based Gas Leakage Detector SystemKartik mondalNo ratings yet

- Commercial Pumps: Series 4030 Starnorm Base Mounted PumpsDocument8 pagesCommercial Pumps: Series 4030 Starnorm Base Mounted PumpsAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Armacell - Master Insulation Guide SpecDocument12 pagesArmacell - Master Insulation Guide Spechengyuen3653No ratings yet

- Centrifugal Pump Accessories Performance Curves: Curve Booklet B-860BDocument25 pagesCentrifugal Pump Accessories Performance Curves: Curve Booklet B-860BAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- AP Coilflex: Conformable Duct LinerDocument4 pagesAP Coilflex: Conformable Duct LinerAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Product SelectionDocument28 pagesProduct Selectionarisqi wahyuNo ratings yet

- PD Vs Cetrifugal Pump PDFDocument3 pagesPD Vs Cetrifugal Pump PDFneharoybhushanNo ratings yet

- Viking General Purpose Special Mounted Pumps: 56 and 456 Series FeaturesDocument6 pagesViking General Purpose Special Mounted Pumps: 56 and 456 Series FeaturesAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Installation and Service Instructions: DC Free Cooling Unit SystemDocument107 pagesInstallation and Service Instructions: DC Free Cooling Unit SystemAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- 48.11L Motor Data SheetDocument4 pages48.11L Motor Data SheetAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- SMARDT Catalogue Ta ClassDocument18 pagesSMARDT Catalogue Ta ClassAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Installation and Maintenance of Water Quality and Treatment for EHU Series HumidifiersDocument8 pagesInstallation and Maintenance of Water Quality and Treatment for EHU Series HumidifiersAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Installation and Service Instructions: DC Free Cooling Unit SystemDocument87 pagesInstallation and Service Instructions: DC Free Cooling Unit SystemAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Installation Operation Manual 30XA 252 1702Document58 pagesInstallation Operation Manual 30XA 252 1702Alhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- User'S Application Guide and Technical Product Overview: Manual: 2100-034G Supersedes: 2100-034F Date: 12-17-20Document21 pagesUser'S Application Guide and Technical Product Overview: Manual: 2100-034G Supersedes: 2100-034F Date: 12-17-20Alhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Liebert Dse Ibc Seismic Supplemental 125 KW Downflow User Manual PDFDocument32 pagesLiebert Dse Ibc Seismic Supplemental 125 KW Downflow User Manual PDFAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- C&D BateriasDocument45 pagesC&D BateriasAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Installation Instructions: Wall Mounted Packaged Air ConditionerDocument30 pagesInstallation Instructions: Wall Mounted Packaged Air ConditionerAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Mini Refrigeration System Analyzer Quick Guide InstructionsDocument1 pageMini Refrigeration System Analyzer Quick Guide InstructionsAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Ts221bi PDFDocument1 pageTs221bi PDFAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- DS System Design Manual en NA SL 18827 R12!15!2016Document192 pagesDS System Design Manual en NA SL 18827 R12!15!2016Alhgasjsghjagjsdajlsd Asdalsdlkaksd0% (1)

- Daad 407Document72 pagesDaad 407Alhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Medias Can AsDocument2 pagesMedias Can AsAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Nibco PDFDocument1 pageNibco PDFAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Honeywell Manual - Chiller, Boiler, & Distribution System Control ApplicationsDocument108 pagesHoneywell Manual - Chiller, Boiler, & Distribution System Control ApplicationsAlhgasjsghjagjsdajlsd Asdalsdlkaksd100% (1)

- EBT720 721 - PH720 721 1980497 WebDocument64 pagesEBT720 721 - PH720 721 1980497 WebAlhgasjsghjagjsdajlsd Asdalsdlkaksd100% (1)

- EBT720 721 - PH720 721 1980497 WebDocument64 pagesEBT720 721 - PH720 721 1980497 WebAlhgasjsghjagjsdajlsd Asdalsdlkaksd100% (1)

- Manual tm-10098 Rev 05-27-08Document203 pagesManual tm-10098 Rev 05-27-08Alhgasjsghjagjsdajlsd Asdalsdlkaksd100% (1)

- Technical Data: AT159 Polycoated Matt Cloth TapeDocument1 pageTechnical Data: AT159 Polycoated Matt Cloth TapeAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Alberta Pipeline RulesDocument56 pagesAlberta Pipeline RulesFredrick MartinNo ratings yet

- Tracetek TTFFS Leak DetectionDocument2 pagesTracetek TTFFS Leak DetectionalokinstNo ratings yet

- SmartPlugIsolationTechnology Brochure LTR 052014 Web OptDocument5 pagesSmartPlugIsolationTechnology Brochure LTR 052014 Web OptMORELLI silvioNo ratings yet

- Natres CaseDocument51 pagesNatres CaseRen ConchaNo ratings yet

- Track Presentation Type Asme Paper Nupaper Title Author First Nam Author Last NamcompanyDocument7 pagesTrack Presentation Type Asme Paper Nupaper Title Author First Nam Author Last NamcompanyYvesfNo ratings yet

- Liebert PDX PCW Thermal Management System User ManualDocument184 pagesLiebert PDX PCW Thermal Management System User ManualJeffNo ratings yet

- Manual 005Document64 pagesManual 005Mohammed Mostafa El HaddadNo ratings yet

- Remote Leak Detection Utilising GPRS and 3G Communications: Phocus3m Is An Acoustic Logger ThatDocument2 pagesRemote Leak Detection Utilising GPRS and 3G Communications: Phocus3m Is An Acoustic Logger ThatKhalid HiluNo ratings yet

- Vacuum Decay Container Closure Integrity Leak Test Method Development and Validation For A Lyophilized Product-Package SystemDocument22 pagesVacuum Decay Container Closure Integrity Leak Test Method Development and Validation For A Lyophilized Product-Package SystemHECHUANNo ratings yet

- 11 Improvement Plan Outline by Valentine Kaupa MALAWI 2Document15 pages11 Improvement Plan Outline by Valentine Kaupa MALAWI 2Hasibullah HasibNo ratings yet

- OPW FMS Family of Products BrochureDocument20 pagesOPW FMS Family of Products BrochureKadine HurtadoNo ratings yet

- Complete Sanctioned GAC (UWSS Rajasthan)Document31 pagesComplete Sanctioned GAC (UWSS Rajasthan)Rajesh GangwalNo ratings yet

- Valve Leak Detection Using Acoustic EmissionDocument1 pageValve Leak Detection Using Acoustic EmissionAliNo ratings yet

- UreaKnowHow - Mark Brouwer (PAPER)Document15 pagesUreaKnowHow - Mark Brouwer (PAPER)Usama JawaidNo ratings yet

- Spectrumxli CatalogDocument84 pagesSpectrumxli Catalogwaldo_astudilloNo ratings yet

- LNG Supply - Gas Power Plants in Indonesia: LNG Pipe-In-Pipe System Description Gorontalo & Kendari Project CasesDocument13 pagesLNG Supply - Gas Power Plants in Indonesia: LNG Pipe-In-Pipe System Description Gorontalo & Kendari Project CasesLiauw CooperationNo ratings yet

- EN1779 EnglishDocument12 pagesEN1779 Englishgion_ro40100% (1)

- Defense Works Int ST Inspect Maint and Test at Petrol Sites MechandElec PDFDocument53 pagesDefense Works Int ST Inspect Maint and Test at Petrol Sites MechandElec PDFbiglee82No ratings yet

- Cable Detetor de Fuga Hidoarburos - TraceTekTT5000fuelsensing-PentairDocument4 pagesCable Detetor de Fuga Hidoarburos - TraceTekTT5000fuelsensing-PentairQuiroa, Antonio JNo ratings yet