Professional Documents

Culture Documents

MEMORIU TEHNIC - Eng

Uploaded by

Mihai DiaconuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MEMORIU TEHNIC - Eng

Uploaded by

Mihai DiaconuCopyright:

Available Formats

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 1/13

TECHNICAL DESCRIPTION

Volume 3, Part D

Technical Description

Thermo-technological installations

CONTENT

1.

GENERAL DATA..................................................................................................................... 2

1.1.

Object of the project..........................................................................................................2

1.2.

Work location.................................................................................................................... 2

1.3.

General considerations.....................................................................................................2

2. REFERENCE DOCUMENTS...................................................................................................2

2.1.

International agreements..................................................................................................2

2.2.

Agreements and approvals CNCF CFR.........................................................................3

3. EXISTING SITUATION............................................................................................................. 3

3.1.

Cmpina station................................................................................................................ 3

3.2.

Comarnic station...............................................................................................................3

3.3.

Valea Larg operation halt................................................................................................4

3.4.

Sinaia station.................................................................................................................... 4

3.5.

Buteni station..................................................................................................................4

3.6.

Azuga station....................................................................................................................4

3.7.

Azuga Predeal section...................................................................................................5

4. GENERAL PRINCIPLES FOR REHABILITATION WORKS....................................................5

4.1.

General principles for Smax. 120 km/h...........................................................................5

4.2.

Types of designed works..................................................................................................5

5. DESCRIPTION OF THE DESIGNED WORKS.........................................................................5

5.1.

Cmpina station................................................................................................................ 5

5.2.

Comarnic station...............................................................................................................6

5.3.

Valea Larg operation halt................................................................................................7

5.4.

Sinaia station.................................................................................................................... 8

5.5.

Buteni station..................................................................................................................9

5.6.

Azuga station.................................................................................................................. 10

5.7.

Azuga Predeal section.................................................................................................11

6. TYPES OF MATERIALS PROVIDED FOR THE WORKS......................................................11

6.1.

New materials................................................................................................................. 11

6.2.

Reused materials............................................................................................................ 11

7. WORKS.................................................................................................................................. 11

8. SCHEDULES FOR CHECKING THE WORKS PERFORMANCE, QUALITY AND

ACCEPTANCE............................................................................................................................... 11

9. LABOR PROTECTION MEASURES AND FIRE PROTECTION...........................................12

10. ENVIRONMENT PROTECTION.............................................................................................12

11. ECONOMIC DOCUMENTATIONS.........................................................................................12

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 2/13

TECHNICAL DESCRIPTION

Volume 3, Part D

Technical Description

Thermo-technological installations

TECHNICAL DESCRIPTION

1.

GENERAL DATA

1.1. Object of the project

The technical-economic documentation is drawn up for the rehabilitation of Bucharest Braov

railway line, component part of the Pan-European Corridor IV, Cmpina Predeal section (Km.

94+680 Km. 142+525).

The works included in the documentation refer to the works category thermo-technological

installations.

1.2. Work location

Cmpina Predeal section, 47,845 km long crosses Bucegi mountains from South to North,

following the valley of Prahova river. The railway line crosses Prahova river in 17 points.

1.3. General considerations

Ploieti Predeal railway line, which comprises Cmpina - Predeal section, was granted by G.B.

Crawley and then by L. Guilloux and put into operation, step by step on sections, during 01 June

01 December 1879. The specialty literature reported that the line was designed and built in

accordance with the German and Austrian technical norms. The doubling of the railway line and

the development systemization of the stations were completed in 1939. The electrification ended

in 1969.

As a result of the development modernizing, maintenance repair and consolidation works carried

out over the years, at present there are both old works (more than 100 years) and recent works

(the last 20 years).

2.

REFERENCE DOCUMENTS

2.1. International agreements

The railway route of the pan-European Corridor IV is reported in the international agreements and

conventions Romania adhered to, for the integration of the national railway network into the

European network:

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 3/13

TECHNICAL DESCRIPTION

-

European agreement on the main international railway lines (A.G.C.),

European agreement on the main combined transport lines and collimated installations

(A.G.T.C.),

- Project for the achievement of trans-European railways (T.E.R.).

The railway route of the pan-European Corridor IV has been established at the last Pan-European

Conference on Transports held in Helsinki during 23 25 June 1997.

2.2. Agreements and approvals CNCF CFR

Before drawing up the Technical Project + Specifications, the following are required:

- Feasibility study CTE CNCF CFR SA approval, no. 18 / 19.06.1998,

- SUBJECT OF DESIGN for Technical Project + Specifications + Tender Documentation

CTE CNCF CFR SA approval, no. 136 / 26.09.2002,

- Rehabilitation of Cmpina Braov railway line, component part of the pan-European

Corridor IV, ISPA application

- Updating the program data in view of drawing up the PTH (Technical Project), DDE

(Detailed Project) and DL (Tender Documentation), CTE CNCF CFR SA approval, no.

6 / 17.02.2005.

3.

EXISTING SITUATION

3.1. Cmpina station

3.1.1. IS Building

The IS building is provided with 900 700C hot water central heating installations.

The heat carrier is supplied by the thermal station at the basement of the passenger building. At

present, the old room for the thermal station contains the boiler (which is to be demounted), used

to provide hot water for the passenger building.

The central heating installation is about 40 years old, having cast iron radiators; the heating units

and the pipes are in poor condition; no overhaul works have been carried out until now.

The (old and obsolete) power unit is mounted in the IS building. This room has no ventilation

installation.

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

3.1.2. CL District

The CL District building is provided with central heating installations, having its own thermal station

(900 700C hot water).

At present, the thermal station is provided with AIACS 8 boiler modified for natural gas operation,

unfortunately at low efficiency.

The central heating installation is about 40 years old, having cast iron radiators; the heating units

and the pipes are in poor condition; no overhaul works have been carried out until now.

3.2. Comarnic station

The passenger building, which also comprises IS rooms, was provided with a modern thermal

station two years ago. The thermal station is not in operation, as it does not have the gas operation

permit; at present, the heating is provided by gasos fuel stoves.

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 4/13

TECHNICAL DESCRIPTION

The thermal station is placed in a room at the ground floor, is provided with 90/70 0C heat carrier

boiler with pit gas burner and is connected to an improper smoke chimney (section smaller than

required).

The indoor heating installation is incomplete and badly dimensioned.

The heating units are steel radiators, generally mounted under the windows.

The distribution network is placed at the floor level; it is made out of steel pipes for the thermal

station and copper pipes for the rest of the building.

The heating units are provided with valves on the supply pipe and on the return pipe as well as

with hand driven air-release valve on the radiator.

The domestic hot water is not prepared in the existing thermal station.

The power unit (old and obsolete) is placed in a room independent from the passenger building.

The power unit room has no ventilation installation.

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

Nowadays, the public toilet is of non heated latrine type.

3.3. Valea Larg operation halt

The IS building has no heating installation; at present, the heating is provided by solid fuel stoves.

The (old and obsolete) power unit is mounted in the IS building. This room has no ventilation

installation at present.

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

3.4. Sinaia station

The heating installations of the Official Station building and the Passenger building are in very poor

condition. At present, the heat carrier source for these buildings is its own thermal station place din

the Official Station building.

The (old and obsolete) power unit is mounted in the Official Station building. This room has no

ventilation installation at present.

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

3.5. Buteni station

The IS building has no heating installation; at present, the heating is provided by stoves.

The (old and obsolete) power unit is mounted in the IS building. This room has no ventilation

installation at present

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

Nowadays, the public toilet is of non heated latrine type.

3.6. Azuga station

The passenger building, which also comprises IS rooms, was provided with a modern thermal

station two years ago. The thermal station is placed in a room at the ground floor and is provided

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 5/13

TECHNICAL DESCRIPTION

with 90/700C heat carrier boiler with pit gas burner, pumps, expansion vessel and a collector

distributor pipe.

The indoor heating installation is new (about 2 years) and is in operation.

The heating units are steel radiators, generally mounted under the windows.

The distribution network is placed at the floor level and the ground floor ceiling; it is made out of

steel pipes for the thermal station and copper pipes for the rest of the building.

The heating units are provided with valves on the supply pipe and on the return pipe as well as

hand driven air-release valve on the radiator.

The domestic hot water is not prepared in the existing thermal station.

The power unit (old and obsolete) is placed in a room independent from the passenger building.

The power unit room has no ventilation installation.

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

Nowadays, the public toilet is of non heated latrine type.

3.7. Azuga Predeal section

The control block building in Predeal has no heating installation; at present, electric radiators are

used for heating.

In the rooms for the railway traffic control installations and afferent staff, there is no air conditioning

to improve the working conditions.

4.

GENERAL PRINCIPLES FOR REHABILITATION WORKS

4.1. General principles for Smax. 120 km/h

The traffic speed along Cmpina Predeal section does not influence the thermo-ventilation works

in the buildings.

4.2. Types of designed works

New central heating installations, air conditioning installations and ventilation installations were

designed for each passenger building with IS rooms, each IS building and for the power unit

rooms.

5.

DESCRIPTION OF THE DESIGNED WORKS

5.1. Cmpina station

IS building

Indoor heating installation

The IS building was provided with new heating installations with static units (steel radiators).

The type of each radiator is written on the relevant plan.

The thermal source consists in a new KESTON module (80/60 0C hot water) thermal station placed

at the ground floor; this module does not require the use of a chimney.

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 6/13

TECHNICAL DESCRIPTION

The hot water distribution (supply) network is placed at the ground floor ceiling and the return pipe

is partly laid at the ground floor level and partly under the ground floor ceiling.

After the completion of the heating installation, it has to be tested, primed and oil painted

complying with the norms in force.

The exhaust gas resulted from the hot water KESTON module is to be evacuated through PVC

pipe mounted in the existing masonry chimney.

The thermal energy required for heating is 61.128 W (52.570 kcal/h).

In the thermal station at the basement of the passenger building, a 100l boiler is to be mounted for

instant preparation of the domestic hot water, instead of the existing boiler in the IS building which

shall be demounted.

Ventilation installation

The power unit room needs a vent installation. When the power unit operates, the heat engine and

the generator unit are heated and part of the heat is released in the room. The fan of the heat

engine evacuates the hot air outside through a sheet piping. The compensation of the evacuated

air as well as the fresh air required for the combustion is introduced into the room by an axial fan

mounted to the wall.

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff rooms. The powers of these devices were settled by calculating the heat input

from the outside during the summer season as well as the heat releases of the afferent device,

from the artificial lighting, as well as from the persons working in the room.

The dispatcher room is provided with two air conditioning installations with heating /cooling modes

(one in operation and one for backup). Two air conditioning installations (one in operation and one

for backup) are provided in the room where the UPS and the computer cubicles are to be mounted.

The (indoor + outdoor) installations have to be mounted by the supplier.

District LC

Indoor heating installation

The CL District building was provided with new heating installation with static units (steel radiators).

The type of each radiator is written on the relevant plan.

The thermal source consists in a KESTON module (80/60 0C hot water) thermal station placed at

the ground floor; this module does not require the use of a chimney.

The hot water distribution (supply) network is partly placed under the ground floor ceiling and partly

at the ground floor level.

After the completion of the heating installation, it has to be tested, primed and oil painted

complying with the norms in force.

The exhaust gas resulted from the hot water KESTON module is to be evacuated through PVC

pipe.

The distance between the burnt gas evacuation pipe and the air inlet pipe for combustion will be

two meters (vertically).

The thermal energy required for heating is 56.643 W (48.713 kcal/h).

5.2. Comarnic station

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 7/13

TECHNICAL DESCRIPTION

Indoor heating installation

Within this project, modification and completion works were carried out for the existing indoor

central heating installation, depending on the new arrangements for the IS room and on the

standards in force.

A part of the demounted units and cocks were remounted to other positions as required by the

calculus of the heat losses according to SR 1907/1 and 2 1997.

It is necessary to demount ten units of which five are to be remounted. The remaining five units are

placed at the beneficiarys disposal to be further used to other indoor heating works.

Six new heating units of the same type as the existing ones will be additionally mounted.

Small modifications of the distribution network were designed in order to avoid the computers room

of the IS installation.

A new chimney is to be designed for the thermal station and two safety valves shall be mounted on

the supplu pipe of the boiler (according to STAS 7132 / 86).

The thermal energy required for heating is 72.551 W (62.394 kcal/h).

Ventilation installation

The power unit is in a separate room, independent from the station building and needs ventilation

installation. When the power unit operates, the heat engine and the generator unit are heated and

part of the heat is released in the room. The fan of the heat engine evacuates the hot air outside

through a sheet piping. The compensation of the evacuated air as well as the fresh air required for

the combustion is introduced into the room by an axial fan mounted to the wall. During the cold

season, the power unit room is heated by electric radiators.

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff. The powers of the devices were settled by calculating the heat input from the

outside during the summer season as well as the heat release of the afferent device, from the

artificial lighting, as well as from the persons working in the room.

The dispatcher room is provided with two air conditioning installations, with heating/ cooling modes

(one in operation and one for backup). Two air conditioning installations (one in operation and one

for backup) are provided in the room where the UPS and the computer cubicles are to be mounted.

One air conditioning installation was provided in the stationmasters room. The (indoor + outdoor)

installations have to be mounted by the supplier.

Outside sanitary group

Indoor heating installations have been provided for the new WC using steel radiators.

The thermal energy required for heating is 17.441 W (15.000 kcal/h).

The heat carrier, 80/60 gr.C hot water is supplied by a gas operated wall boiler which will supply

the domestic hot water as well.

The boiler is of modern type without chimney; 21.500 kCal/h, mounted in a separate room or in the

tickets sellers cabin.

The WC rooms are to be aerated by the provided windows and the disabled persons cabin shall be

ventilated using special provided fan.

5.3. Valea Larg operation halt

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 8/13

TECHNICAL DESCRIPTION

Indoor heating installation

The IS building was provided with new heating installation with static units (steel radiators).

The type of each radiator is written on the relevant plan.

The thermal source is a hot water electric boiler placed at the ground floor in the C.T room with 90 /

700 C operation temperature.

The hot water distribution (supply) network is placed at the basement ceiling and the return pipe at

the basement floor.

After the completion of the heating installation, it has to be tested, primed and oil painted

complying with the norms in force.

The thermal energy required for heating is 37.475 W (32.229 kcal/h).

Ventilation installation

The power unit room needs ventilation installation. When the power unit operates, the heat engine

and the generator unit are heated and part of the heat is released in the room. The fan of the heat

engine evacuates the hot air outside through a sheet piping. The compensation of the evacuated

air as well as the fresh air required for the combustion is introduced into the room by an axial fan

mounted to the wall.

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff. The powers of the devices were settled by calculating the heat input from the

outside during the summer season as well as the heat releases of the afferent device, from the

artificial lighting, as well as from the persons working in the room.

The dispatcher room is provided with two air conditioning installations, with heating/ cooling modes

(one in operation and one for backup). Two air conditioning installations (one in operation and one

for backup) are provided in the room where the UPS and the computers cubicles are to be

mounted. The (indoor + outdoor) installations have to be mounted by the supplier.

5.4. Sinaia station

Indoor heating installation

In the Official Station building, namely: Power unit room, New IS relay room and Computer

room, and in the passenger building, namely: Office room, Station master office and

Dispatcher office, new static units (steel radiators) were provided. These radiators shall be

connected to the existing columns.

The type of each radiator is written on the relevant plan.

The thermal source consists in the existing thermal station in operation situated in the building of

Sinaia Official Station.

After the completion of the heating installation, it has to be tested, primed and oil painted

complying with the norms in force.

Ventilation installation

The power unit room needs ventilation installation. When the power unit operates, the heat engine

and the generator unit are heated and part of the heat is released in the room. The fan of the heat

engine evacuates the hot air outside through a sheet piping. The compensation of the evacuated

air as well as the fresh air required for the combustion is introduced into the room by an axial fan

mounted to the wall.

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 9/13

TECHNICAL DESCRIPTION

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff. The powers of the devices were settled by calculating the heat input from the

outside during the summer season as well as the heat release of the afferent device, from artificial

lighting, as well as from the persons working in the room.

The dispatcher room is provided with two air conditioning installations, with heating/ cooling modes

(one in operation and one for backup). Two air conditioning installations (one in operation and one

for backup) are provided in the room where the UPS and the computers cubicles are to be

mounted. One air conditioning installation with heating/ cooling mode was provided in the Station

master office. The (indoor + outdoor) installations have to be mounted by the supplier.

5.5. Buteni station

Indoor heating installation

The IS building was provided with new heating installation with static units (steel radiators).

The type of each radiator is written on the relevant plan.

The thermal source is the KESTON 80/60 0C hot water wall-mounted gas fuel boiler placed at the

ground floor of the C.T. room.

The hot water distribution (supply) network is placed on the ground floor ceiling and the return pipe

is laid at the ground floor level.

After the completion of the heating installation, it has to be tested, primed and oil painted

complying with the norms in force.

The burnt gas resulted from the hot water boiler will be evacuated through a PVC pipe.

The distance between the burnt gas evacuation pipe and the air inlet pipe for combustion will be

two meters (vertically).

The thermal energy required for heating is 38.298 W (32.936 kcal/h).

Ventilation installation

The power unit room needs ventilation installation. When the power unit operates, the heat engine

and the generator unit are heated and part of the heat is released in the room. The fresh air is

introduced into the room through an axial fan mounted to the wall. The fan of the heat engine

evacuates the hot air to the outside by a sheet piping.

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff. The powers of the devices were settled by calculating the heat input from the

outside during the summer season as well as the heat release of the afferent device, from artificial

lighting, as well as from the persons working in the room.

The dispatcher room is provided with two air conditioning installations, with heating/ cooling modes

(one in operation and one for backup). Two air conditioning installations (one in operation and one

for backup) are provided in the room where the UPS and the computers cubicles are to be

mounted. The (indoor + outdoor) installations have to be mounted by the supplier.

Outside sanitary group

Indoor heating installations have been provided for the new WC using steel radiators.

The thermal energy required for heating is 17.441 W (15.000 kcal/h).

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 10/13

TECHNICAL DESCRIPTION

The heat carrier, 80/60 gr.C hot water is supplied by a gas operated wall boiler which will supply

the domestic hot water as well.

The boiler is of modern type without chimney; 21.500 kCal/h, mounted in a separate room or in the

tickets sellers cabin.

The WC rooms are to be aerated by the provided windows and the disabled persons cabin shall be

ventilated using special provided fan.

5.6. Azuga station

Indoor heating installation

The existing installation was modified and completed within this project depending on the new IS

room arrangements and the standards in force. The heat carrier is supplied by the thermal station

situated at the ground floor of the building.

A part of the demounted units and cocks were remounted to other positions as required by the

calculus of the heat losses according to SR 1907/1 and 2 1997.

It is necessary to demount five units of which four are to be remounted. The remaining unit is

placed at the beneficiarys disposal to be further used to other indoor heating works.

Four new heating units of the same type as the existing ones will be additionally mounted.

The thermal energy required for heating is 66.112 W (56.856 kcal/h).

Ventilation installation

The power unit is in a separate room, independent from the station building and needs ventilation

installation. When the power unit operates, the heat engine and the generator unit are heated and

part of the heat is released in the room. The fan of the heat engine evacuates the hot air to the

outside by a sheet piping. The compensation of the evacuated air as well as the fresh air required

for the combustion is introduced into the room by an axial fan mounted to the wall. During the cold

season, the room is heated by electric radiators.

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff. The powers of the devices were settled by calculating the heat input from the

outside during the summer season as well as the heat release of the afferent device, from artificial

lighting, as well as from the persons working in the room.

The dispatcher room is provided with two air conditioning installations, with heating/ cooling modes

(one in operation and one for backup). Two air conditioning installations (one in operation and one

for backup) are provided in the room where the UPS and the computers cubicles are to be

mounted. In the station master office, one air conditioning installation was mounted. The (indoor +

outdoor) installations have to be mounted by the supplier.

Outside sanitary group

Indoor heating installations have been provided for the new WC using steel radiators.

The thermal energy required for heating is 17.441 W (15.000 kcal/h).

The heat carrier, 80/60 gr.C hot water is supplied by a gas operated wall boiler which will supply

the domestic hot water as well.

The boiler is of modern type without chimney; 21.500 kCal/h, mounted in a separate room or in the

tickets sellers cabin.

The WC rooms are to be aerated by the provided windows and the disabled persons cabin shall be

ventilated using special provided fan.

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 11/13

TECHNICAL DESCRIPTION

5.7. Azuga - Predeal section

Predeal Control Block Building

Air-conditioning installations

SPLIT air conditioning system was provided in the rooms for the railway traffic control installations

and afferent staff. The powers of the devices were settled by calculating the heat input from the

outside during the summer season as well as the heat release of the afferent device.

Three air conditioning installation with heating/cooling mode (two in operation and one for backup)

were provided in the control block building. One air conditioning installation was mounted in the

battery and rectifier room.

6.

TYPES OF MATERIALS PROVIDED FOR THE WORKS

6.1. New materials

The materials used for the works will be new or reusable.

All materials used for the installations will have the characteristics and tolerances specified in the

standards or in the technical prescriptions of the manufacturers and should comply with all

technical requirements of the project.

All materials should be accompanied by:

-

Suppliers quality certificate

Technical sheets

Instructions for mounting, testing, maintenance and operation

Warranty certificate

Approval and agreement certificates.

6.2. Reused materials

The following materials are to be reused: the radiators and the afferent cocks from the buildings

which are to be demounted, removed from the existing positions and remounted on other

positions. The rest of the thermal units shall be placed at the beneficiarys disposal.

7.

WORKS

The provided thermal ventilation works are performed only inside the buildings or in the close

vicinity and do not require stopping the railway traffic.

All materials resulted from demounting the existing installations will be stored in special rooms until

the contractor will transport them in the places indicated by the beneficiary.

8.

SCHEDULES FOR CHECKING THE WORKS PERFORMANCE, QUALITY AND

ACCEPTANCE

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

Pag. 12/13

TECHNICAL DESCRIPTION

The works quality will be supervised complying with the specific sheet Supervision Schedule for

Works Quality annexed to the project. The contractor should also observe the Law no. 10 /

18.01.1995, referring to the quality and the Performance Guide for Installations (approval

M.L.P.A.T. - C.T.S. no. 18 / 18.02.1996).

The works acceptance will be made complying with:

-

9.

H.G. 273 / 14.06.1994 Acceptance regulation for the construction works and afferent

installations

I 13 - 2002 - Norm for designing and construction of the heating installations, chap. 20

I. 5 - 1998 - Norm for designing and construction of the ventilation and air-conditioning

installations

LABOR PROTECTION MEASURES AND FIRE PROTECTION

The contractor should observe the indications in paragraph 1.8. of the Specifications

corresponding to the present project.

10. ENVIRONMENT PROTECTION

The modernization works for the thermo-technological installations are carried out using

environmentally friendly materials.

The materials resulted after taking out of use the existing constructions (installations) are to be

managed according to the specialty documentation Specific environment protection works,

component part of this project

11. ECONOMIC DOCUMENTATIONS

In volume 4 BILLS OF QUANTITIES, the work volumes (machinery and technological equipment,

including endowments) are specified for the works category Thermo-technological installations.

The drawing up and coding system of the project is presented in volume 4, section 1.

The items description used to draw up the Bills of quantities is presented in volume 4, section 2.

The technical characteristics of the materials or activities specified in the bills of quantities are

presented in the Specifications details, volume 3.

The technical characteristics of the machinery and technological equipment provided in the project

are presented in volume 3, part F. (for the works categories with bills of quantities for machinery

and technological equipment, including endowments).

DEPUTY MANAGER OF R.A.I. DIVISION

eng. D. Caracaleanu

M.Q. EXPERT

eng. A. M. Blaga

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina Predeal

TECHNICAL DESCRIPTION

TECHNICL EXPERT

eng. D. Caracaleanu

HEAD OF TEAM

eng. R. Minea

DRAWN UP

eng. C. Radu

SUPERVISOR

eng. R. Minea

TERMO-TEHNOLOGICAL INSTALLATIONS CNCF 22.01.2015 Mtro Rev 0

Pag. 13/13

You might also like

- Effects of The 3.2-1 Ketogenic Diet On Behavioral Symptoms of Aut PDFDocument58 pagesEffects of The 3.2-1 Ketogenic Diet On Behavioral Symptoms of Aut PDFMihai DiaconuNo ratings yet

- The Ketogenic DietDocument21 pagesThe Ketogenic DietDiana Meca50% (2)

- Ketocal Data Card PDFDocument2 pagesKetocal Data Card PDFMihai DiaconuNo ratings yet

- Arguments in Favor of Ketogenic DietsDocument16 pagesArguments in Favor of Ketogenic DietsoddlogicNo ratings yet

- Antiepileptic DrugsDocument39 pagesAntiepileptic Drugsking_goldNo ratings yet

- Steam AchievementsDocument6 pagesSteam AchievementsMihai DiaconuNo ratings yet

- CAIET DE SARCINI - EngDocument7 pagesCAIET DE SARCINI - EngMihai DiaconuNo ratings yet

- Coduri Siruta RomaniaDocument510 pagesCoduri Siruta RomaniaMihai DiaconuNo ratings yet

- Greutati Specifice Otel PDFDocument18 pagesGreutati Specifice Otel PDFFerencz ZsoltNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- WE20 DrillPlan Coherent Well Construction Planning Solution Product SheetDocument2 pagesWE20 DrillPlan Coherent Well Construction Planning Solution Product SheetWaleedm MariaNo ratings yet

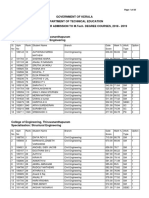

- Kerala MTech SeatDocument63 pagesKerala MTech Seattirursachin0% (1)

- Water Supply and SewerageDocument24 pagesWater Supply and SewerageWilliamWR100% (1)

- Give An Example: BT LevelDocument10 pagesGive An Example: BT LevelMsd7No ratings yet

- Tugas 1Document2 pagesTugas 1Laisa HusrainiNo ratings yet

- MEM23004 - Assessment Task 3 - Occasion 1Document14 pagesMEM23004 - Assessment Task 3 - Occasion 1Aiza ZainabNo ratings yet

- FORM 5 - Complex Engineering Problem SurveyDocument1 pageFORM 5 - Complex Engineering Problem SurveyFNo ratings yet

- DESIGN REPORT (2-Storied Industrial Utility Building)Document40 pagesDESIGN REPORT (2-Storied Industrial Utility Building)Pioneer Design and Development LimitedNo ratings yet

- Welworth - Phase - III Rate AnalysisDocument167 pagesWelworth - Phase - III Rate AnalysisnvnrevNo ratings yet

- Pestan Hdpe Water PipesDocument6 pagesPestan Hdpe Water PipesAmar Jabar Al BaajiNo ratings yet

- Kaajma Cover Block BrochureDocument12 pagesKaajma Cover Block BrochureSOURAV RANJAN KHANRANo ratings yet

- 4281 - 06 Sandwich StructuresDocument26 pages4281 - 06 Sandwich StructuresAndrew Gilbride100% (1)

- Brochure ClimbingBracket BMK USADocument4 pagesBrochure ClimbingBracket BMK USAgrishil07No ratings yet

- Ymca Date Sheet Appear)Document3 pagesYmca Date Sheet Appear)NaveenNo ratings yet

- Batch 23 AdvtDocument6 pagesBatch 23 AdvtV. Krishna ThejaNo ratings yet

- CV - Aqeel Ahmed Qazi Updated - Rev - CompressedDocument4 pagesCV - Aqeel Ahmed Qazi Updated - Rev - Compressedsidiq7No ratings yet

- Course OutlineDocument2 pagesCourse OutlineSamarth ShuklaNo ratings yet

- SCM 18ME653 NotesDocument110 pagesSCM 18ME653 NotesManvanth B C100% (7)

- Oil&Gas ProjectDocument4 pagesOil&Gas ProjectMelannie Adante100% (1)

- Behavior and Strengths of Single Cast-In Anchors in Ultra-High-PerformanceDocument10 pagesBehavior and Strengths of Single Cast-In Anchors in Ultra-High-PerformancePrayush RajbhandariNo ratings yet

- Sequence of Works For Building ConstructionDocument2 pagesSequence of Works For Building ConstructionBoni Amin76% (34)

- 16 Sindur P Mangkoesoebroto PaperDocument16 pages16 Sindur P Mangkoesoebroto PaperfadliamaliaNo ratings yet

- PCB DesignDocument30 pagesPCB DesignACer DanNo ratings yet

- Euro CokeDocument13 pagesEuro Cokedhawal gargNo ratings yet

- Micropiles Seminar ReportDocument42 pagesMicropiles Seminar ReportAbhishek Trivedi100% (2)

- Banner Mini Screen SystemDocument60 pagesBanner Mini Screen SystemMauricio Sanchez PortillaNo ratings yet

- Adv Geotech Forensic Eng CompileWebDocument277 pagesAdv Geotech Forensic Eng CompileWebfarahazuraNo ratings yet

- Continuity Development Between PrecastDocument332 pagesContinuity Development Between PrecastAnonymous Vi1lrHNo ratings yet

- Channel Court Shopping CentreDocument2 pagesChannel Court Shopping CentrePi SopiNo ratings yet

- Standards Comparison Steels For Offshore StructuresDocument9 pagesStandards Comparison Steels For Offshore Structureshvdb72No ratings yet