Professional Documents

Culture Documents

11-820 Installation Procedure

Uploaded by

David Echeverria NivelaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11-820 Installation Procedure

Uploaded by

David Echeverria NivelaCopyright:

Available Formats

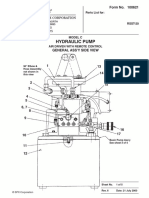

Gate System Installation Procedure

Wedge Air Bladder

Junquillo 11-820

Table of Contents

1.0

2.0

3.0

4.0

5.0

6.0

SCOPE OF THIS DOCUMENT

GATE SYSTEM DEFINITIONS

ABUTMENT PLATE INSTALLATION

MAIN ANCHOR BOLT INSTALLATION

AIR PIPING

FOUNDATION FINISH, EMBEDDED PNEUMATIC PIPING,

CONDENSATE PURGE LINE and INCLINOMETER CONDUIT

7.0 SPILLWAY GATES

8.0 INSTALLATION OF INTER-PANEL SEALS

9.0 ABUTMENT & J-BULB SEAL INSTALLATION

10.0 RESTRAINING STRAPS

11.0 LOCATING AND ANCHORING AIR SUPPLY, ACC and PLC

12.0 ELECTRICAL

13.0 FIELD TESTING

14.0 TORQUES AND TOOLS

15.0 COMMON CONSTRUCTION ERRORS AND TIPS

16.0 CHECK LISTS

16.1 Abutment Plate

16.2 Main Anchor Bolt

16.3 Concrete

Created By

PAC

Approved

Date

Sept 18, 2013

This Document is property of Obermeyer Hydro, Inc.

and is not to be used, disclosed, reproduced or

transmitted by electronic or any other means without

prior written authorization from OHI.

COPYRIGHTED, OBERMEYER HYDRO, INC.,

2005

Revision

Created Install Procedure

No.

1

OBERMEYER HYDRO, INC.

PO BOX 668, FORT COLLINS,

CO 80522 TEL 970-568-9844

FAX 970-568-9845

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

1.0 SCOPE OF THIS DOCUMENT

Note: This is a general guide only. Actual field conditions may dictate different

construction methods.

This procedure is to be used by the CONTRACTOR installing the OHI gate system. This

document is divided into several sections:

Definition of spillway gate components.

Civil works: Installation of Abutment Plates, Main & Restraining Strap Anchor

Bolts, Spillway Finish, and Pneumatic Piping.

Spillway Gates: Installation of the Gate Panels, Air Bladders, Hinges, Clamp

Castings, Seals & Restraining Straps and other associated hardware.

Installation of air controls including Air Compressor, Blowers, ACC and PLC

Cabinets.

Site specific construction requirements to follow torque values, and tolerances

set by design drawings and proper construction tools required

OHI field inspection responsibilities

General Notes: Use anti-seize compound on all threads. Use Teflon tape and thread

sealant compound pipe dope on all air fittings. Caulk must be 100% silicone or

aquarium grade. Silicone will not bond to wet surfaces, so keep them clean and dry.

Keep sharp objects and surfaces away from rubber parts.

OBERMEYER Hydro Inc.

2 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

2.0 GATE SYSTEM DEFINITIONS

The spillway gate assembly comprises the components found on the spillway and

includes the air bladders, gate panels, anchor bolts, etc. The air bladders inflate to raise

the gate system and deflate to lower the gate system.

GATE PANEL

The Gate Panel acts as a movable, rigid barrier to the water. The Gate Panels attach

along the upstream edge to the Hinge Flap. Two adjacent Gate Panels are connected

together using the Inter-Panel Seal.

MAIN ANCHOR ASSEMBLY

The gate and bladder system are anchored to the spillway with the Main Anchor

Assembly. The Main Anchor Assembly is a continuous fabricated steel unit that spans

the channels width and has a series of anchor bolts that fasten the assembly to the

spillway. In some cases this may be a series of studs anchored to the spillway,

depending on construction techniques. These are large studs extending upwards from

the assembly, which are used to fasten the Air Bladder, Hinge Flap, Inner-Panel Seal,

and Abutment Seals via clamp castings. The Main Anchor Assembly therefore evenly

transmits the larger hydrostatic forces generated by the Gate Panel downward into the

concrete. It also provides for water stop under the bladder.

AIR BLADDER

The Air Bladders rest on top of the spillway and are held in place by Clamp Castings

that mount to the upstream edge of the spillway. When inflated, the Air Bladder imparts

the upward and upstream force on the Gate Panel that impounds the water. The air

control system is connected to the underside of the Air Bladder by means of a threaded

fitting and flexible hose.

The Hinge Flap

Hinge Flap connects the Gate Panel to the dam surface and acts as a water seal. The

upstream wedge section is compressed along with the Air Bladder wedge sections in

the Clamp Castings. The downstream portion of the Hinge Flap connects to the Gate

Panel using the bottom row of Gate Panel studs with the provided Hinge Flap Retainers,

washers and hex nuts. In the fully raised position, with the Air Bladder inflated, the

Hinge Flap transmits a compressive force from the Clamp Castings to the bottom edge

of the Gate Panel.

NOTE: Inflation of an Air Bladder, even under low pressure, without clamps

securely tightened, can cause permanent damage or rupture of the Air Bladders.

The Air Bladder should never be inflated unless properly installed.

OBERMEYER Hydro Inc.

3 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

CLAMP CASTINGS

The Clamp Castings are positioned over the Main Anchor Bolts and retain the Air

Bladder and Hinge Flap in place. The Clamp Castings transmit a force to the bottom

edge of the Gate Panel through the Hinge Flap. This force, and the force imparted to

the Gate Panel by the inflated portion of the Air Bladder, provides the moment required

to support the cantilevered Gate Panel. The Clamp Castings also provide the sealing

mechanism for the Air Bladder.

HINGE FLAP RETAINERS

The Hinge Flap Retainers clamp the Hinge Flap to the upstream edge of the Gate

Panel. With the gate fully raised or fully lowered, the forces tending to pull the Hinge

Flap out from under the Hinge Flap Retainers are low. At intermediate gate positions,

high forces occur, which requires the Hinge Flap Retainers be kept tightly clamped.

RESTRAINING STRAPS

The Restraining Straps are the reinforced rubber strips that attach to the spillway and to

the bottom side of the Gate Panel. The Restraining Strap limits the upstream travel and

height of the Gate Panel during inflation and insures that the Gate Panel does not flip

over upstream when the gate system is fully raised and the water elevation is less than

full pond depth.

RESTRAINING STRAP CLAMPS

The Restraining Strap Clamps fasten the Restraining Strap to the spillway and to the

Gate Panel. The Restraining Strap Anchor Bolts used to fasten the clamp to the

spillway and the hex head bolts used to fasten the clamp to the Gate Panel are typically

of the same diameter and should be kept tight at all times.

NAPPE BREAKERS

The Nappe Breakers divide the water flowing over the top edge of the raised gate

system. This provides an air path to the otherwise closed off space under the raised

Gate Panel created by the water wall. Without the Nappe Breakers, a vacuum could

occur behind the water wall and high gate loads or vibration may occur.

ABUTMENT PLATES

The Abutment Plates may consist of concrete, stainless steel or UHMW polyurethane.

The Abutment Plate component is located at each section end of the gate system. It

provides a smooth vertical surface for the Abutment Seal that is attached at each end of

the Gate system to create a watertight seal.

ABUTMENT SEALS

The Abutment Seals are the reinforced rubber strip that seals the end Gate Panels to

the Abutment Plates.

OBERMEYER Hydro Inc.

4 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

ORIENTATION

GATE

RIGHT

Flow

NOTE: Left and

Right are defined

by looking

downstream (into

flow)

LEFT

OBERMEYER Hydro Inc.

5 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

3.0 ABUTMENT PLATE INSTALLATION

1. Abutment plate dimensions, materials, and construction for this project are detailed

on project drawings 11-820-240L-F&R and 11-820-240R-F&R.

2. Installation and construction methods are provided on drawings 11-820-112 and 11820-240L-F&R & 240R-F&R. Contractor to form abutment walls. These plates may

be installed during the initial construction of the abutment walls or with the required

block-out for later installation depending on the contractors preferred method.

Stainless Steel Abutment Plates will be positioned and adjusted in the block out

space using Contractor provided hardware so that they are plumb to within 3mm

and are perpendicular to the Main Anchor Bolt centerline. The Abutment Plate to

Abutment Plate distance must be maintained pursuant to the construction drawings

to within 6mm. The Abutment Plate must be installed so that it is coplanar to within

6mm.

3. The plates must be secure and capable of withstanding the hydrostatic forces the

grout placed behind the plates creates. Any shifting of the Abutment Plates during

grouting may require the removal of the plate and reinstallation, at the Contractors

expense.

4. Tolerances for Abutment Plate installation are critical.

OBERMEYER Hydro Inc.

6 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

4.0 MAIN ANCHOR BOLT INSTALLATION

NOTE: Under no circumstances will welding of any metal to the anchor bolts be allowed.

Unapproved heating of the bolts could lead to failure of the anchoring system.

1. Formation of the concrete cross section where the Main Anchor Clamp Casting sits

will be made using OHI provided foam forms. Refer to drawings 11-820-207-A5-1

through 11-820-A5-3.

2. Contractor will secure into place the provided OHI foam forms. Contractor will check

that form placement does not interfere with any expansion joints in the concrete

spillway.

3. Refer to drawings 11-820-101,102 for plan view detail layout of Main Anchor Bolt

locations. Refer to drawing 11-820-111 for section view of Main Anchor Bolt detailed

layout.

4. The Pivot Embed (See drawings 11-820-208-1 through 11-820-208-3) and Wedge

Embed (See drawings 11-820-209-1 through 11-820-209-3) are fastened to the OHI

foam form. Refer to drawing 11-820-102 for assembly of embeds to the foam forms.

5. Contractor to ensure the OHI foam form pans are firmly secured using tie rods that

are embedded in concrete as needed. Contractor to finalize method of fastening tie

rods. Contractor can submit anchorage methods to Obermeyer Hydro for ideas and

approval.

6. After pouring of concrete, Contractor to apply extra vibration near the forms to

ensure no air pockets form under the foam forms. Honeycomb formation under the

OHI foam form pans, Pivot & Wedge Embeds, or around the Main Anchors Bolts

shall be avoided.

7. Contractor to ensure Main Anchor Bolts are to be 142mm above finished concrete

surface. Refer to drawing 11-820-111 for section view.

8. After concrete has cured, the Pivot & Wedge Embed studs welded to the embed

angles shall be cutoff and ground flush. All grinding must be done with a new or

non-contaminated grinding media.

9. Restraining Strap Anchor Bolts may be poured in place or core drilled and epoxy set

to adhere bolt to concrete. Drawing 11-820-101 gives plan view detailed location

layout of bolts. Drawing 11-820-111 gives section view of bolts in relation to Main

Anchor Bolts.

10. Restraining Strap Anchors are to be 102mm above finished surface in concrete

block-out. Refer to drawing 11-820-111 for section view.

OBERMEYER Hydro Inc.

7 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

5.0 AIR PIPING

1. The piping between the Main Air Supply and Air Control Cabinet (ACC) should

have a working pressure of at least 150 psig. The piping between the Air Bladders

and the Air Control Cabinet will normally contain pressures less than 50 psig.

2. All piping should be blown out with air to remove any scale or debris prior to

connection to the ACC or the Air Bladders.

3. Providing all piping and wiring and the installation of all piping and wiring is the

responsibility of the Contractor. Installation of the compressors, blowers, dryers,

filters, tanks, drain valves, ACC and associated equipment is the responsibility of

the Contractor.

4. Contractor to provide means of removing condensate from air line at low point of

air pipe system or at control side abutment. Refer to drawing 11-820-125 for

recommended details of condensate purge locations.

5. Any exposed portions of the piping shall be securely supported, as outlined in the

local building code or project specification.

6. All air piping shall utilize welded fittings. All welding to be in accordance with AWS

Structural Welding Specifications. All pipe joints to be leak proof.

7. Before installation of gate system, the entire run of pipe and connections shall be

inspected and pressure tested to 50 psig and each joint checked for leaks with the

owners representative present.

8. All electrical conduit shall be up to code and as specified in the plans

9. Piping at expansion joints to be sleeved to allow for movement of concrete.

10. All piping and conduit shall be rigid, except that flexible metal conduit may be used

in short lengths where needed to connect to vibrating equipment.

THE LOWEST POINT OF ALL AIR SUPPLY LINES MUST BE AT THE

CONDENSATE PURGE

OBERMEYER Hydro Inc.

8 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

6.0 FOUNDATION FINISH, EMBEDDED PNEUMATIC PIPING,

CONDENSATE PURGE LINE and INCLINOMETER CONDUIT

1. Embedded Air Piping

a) The air supply pipes between the gate and the air control cabinet shall be

tested prior to final embedment in concrete by pressurizing to 50 psi for a

continuous 24 hour period. Pressure readings and ambient air temperature

shall be recorded at six different times during the test.

b) A wet test of the air lines may be performed with a leak detection solution at 50

psi in place of the 24 hour timed test.

c) Any joints or fittings exhibiting leakage during this time shall be repaired or

replaced.

2. The concrete area along the spillway crest to which the clamping assembly is to be

bolted shall be made level and flat with a high quality smooth surface. The areas

that supports the bladders will be made smooth (trowel finish) and shall be free of

sharp or abrasive objects or protrusions, which could damage the air bladder.

3. The pneumatic and conduit piping shall be placed in accordance with the drawings.

A plan view of the conceptual pneumatic & conduit piping layout are shown in

drawing 11-820-101 & 125. Contractor to review drawing to ensure Pneumatic

Piping, Inclinometer, and Condensate Purge Line(s) are correct size.

4. See drawing 11-820-111 for section elevation view of Main Air Supply & Air BlockOut detailed layout.

5. Contractors scope to include piping stub out into the air-connection block-out that

terminates with a female thread. See drawing 11-820-123 for details.

6. Contractor to provide for and construct Condensate Purge Valve(s) at low point(s)

in piping system. See drawing 11-820-125 for recommended section view of

piping layout.

OBERMEYER Hydro Inc.

9 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

7.0 SPILLWAY GATES

Bladders, Hinges, and Gate Panels

1. Spillway Prep: Clean spillway of dirt & debris, especially wedge area. Wire brush

anchor bolt threads to remove any concrete splatter. Repair damaged threads with

3-corner file or proper die size.

*** USE COPPER OR NICKEL-BASED ANTI-SEIZE LUBRICANT ON ALL

THREADS ***

2. Locate Gate Panels.

3. Locate Air Bladder and Hinge Flaps.

4. Prior to bolting respective Gate Panels together, apply silicon for each Gate Flange

and around bolt holes. Set aside. See pic. 4.1 and drawing 11-820-120-1.

pic 4.1

5. Install Hinge Flaps onto Gates Panel using Hinge Retainers and stainless steel

fastening hardware. On larger gates it may be necessary to cut the hinge and

install it in multiple sections. (use generous amounts of copper or nickel-based

anti-seize lubricant on all stainless steel threads)

6. On the Gate Panel apply silicon around all the threaded holes and one big bead

along the joint or the round stock and flat as well as up and over where the ribs

come into the round stock (see pic 4.2).

OBERMEYER Hydro Inc.

10 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

Silicon

pic 4.2

7. Locate Air Bladders and miscellaneous air plumbing hardware.

a. Attach brass elbow to brass bulkhead fitting located on bottom surface

of Air Bladder.

b. Connect stainless steel barb to end of Contractor supplied air piping.

8. Refer to drawing 11-820-123 to install air assembly (Use Teflon tape and pipe

dope on all screw type pipe fittings).

a. Locate the precut Poly reinforced hose with the stainless spiral insert.

b. Bend the end of the spiral insert so it will not slip over the end of the hose

barb during installation. Measure the length of the spiral insert and make

sure it will span the length between the hose barbs, minus the plastic insert.

c. Insert the clear plastic insert in the hose between the stainless spiral and

the brass barbed fitting on the bladder and clamp the hose to the brass

fitting with provided Mikalor clamp.

9. Position the wedge of Air Bladder on spillway just downstream of Main Anchor

Bolts. The wedge should touch the upstream wall of the wedge embed. Make

sure the Air Bladder fitting fits correctly into Air Block-Out.

OBERMEYER Hydro Inc.

11 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

10. Roll the Air Bladder in half from left to right, or lift the wedge of the bladder to

expose Air Bladder connection.

a Loop the hose back around to the stainless fitting and secure with provided

Mikalor clamp

b Fill the Air Block-Out with expandable foam isolation, in geographical

locations where freezing is present.

11. Roll Air Bladder into final position. Make sure the air supply line does not kink.

12. Repeat steps 4 thru 11 for remaining Air Bladder(s).

13. Apply generous amounts of copper or nickel-based anti-seize lubricant on all

stainless steel threads.

14. Place assembled Gate Panel/Hinge Flaps onto Air Bladders. Reference drawing

11-820-110 for section view. Align the upstream edge of Hinge Flap with the Air

Bladder wedges. The upstream profile of the two 30 degree Air Bladder wedges

and the single Hinge Flap 30 degree wedge should follow a circular 90 degree

arc.

15. Locate Main Anchor Clamp Castings. Position Main Anchor Clamp Castings over

the Air Bladder and Hinge Flap wedges so the hinge wedge is tight against the

arch of the clamp. Make sure to use generous amounts of copper or nickel-based

anti-seize lubricant on all stainless steel threads and on bearing surfaces of

stainless steel nuts. Tighten nuts enough to get the next clamp placed

16. Install Abutment Seals. Refer to Section 8.0

17. Do not torque anchor bolts or inflate the system until the Abutment Seals are

installed.

18. Tighten stainless steel hex nuts starting at the Abutment Seals working toward the

middle of each bladder. After all nuts are snug (135-270 N-m), torque to 1400 Nm, working from the ends of the bladders to the middle. Make sure the main

anchors are tightened evenly to keep the clamp even. Make sure to use generous

amounts of copper or nickel-based anti-seize lubricant on all stainless steel

threads and on bearing surfaces of stainless steel nuts.

19. Repeat steps 14 through 18 for remaining Gate Panel(s). Double check the

abutment-to-abutment direction measurement after placing each gate, to ensure

that Gate Panels and Air Bladders are set correctly.

20. Beginning at the Abutment seal and working toward the center of the Air Bladder,

re-torque each of the Main Anchor Bolts to 1400 N-m

OBERMEYER Hydro Inc.

12 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

21. Starting at one end re-torque all Main Anchor Bolts to 1400 N-m.

22. Wait 24 hours and again torque all anchor bolts 1400 N-m. (Note: 1400 N-m is

an estimated only, temperature affects on the rubber may require a higher torque

value to seat rubber into casting)

23. Inflate gate system to proper height of 3 M and then lower the gate and re-torque

the bolts.

CAUTION: Be careful when inflating the system at this time. Since the

Restraining Straps are not installed yet, the gates can tip over upstream if raised

to far. See Section 9.0 to install the Restraining Straps.

24. Install Nappe Breakers on downstream top edge of each Gate Panel.

8.0 ABUTMENT SEAL INSTALLATION

NOTE: Cold vulcanize seals at joint areas. Install Abutment Seals before vulcanizing in

order to maximize the time sensitive materials involved in the process. See vulcanization

technique in OHI-SPEC-3004 and drawing 11-820-120-1 for cross sectional views.

1. The Abutment Seals incorporate a 30 degree wedge section at the upstream end

(same as the Hinge Flap). Trim back Hinge Flap so the Abutment Seal wedge

section fits snuggly against the Hinge Flap section. Allowing a 3mm interference

on each side works well. Test fit Abutment Seal, securely positioning the wedge

between the Hinges.

2. Use anti-seize lubricant or marking paint, coat the tops of the studs holding the

Abutment Seal. By hand, push the Abutment Seal against the Abutment Plate so

the flat sealing surface of the seal is flush with the Abutment Plate. This is so the

seal will have tension on the Abutment Plate and make a seal. Holding it in place,

hit the seal with the sledge hammer directly over the first stud, marking the

underside of the seal. This marks the upstream to downstream location.

3. Measure the distance from the first stud to the Abutment Wall. Transpose that

measurement onto the Abutment Seal and mark location (Measurement A).

Measure from bladder side the distance to marked location (Measurement B).

Use this distance (Measurement B1) to locate the studs right to left. A slight

oblong hole (perpendicular to Abutment Wall) is preferred for adjustment. A good

reference point for locating the holes is the location of the first stud past the formed

section for the clamp plate. Remove the seal and either punch or cut the holes in

the seal.

OBERMEYER Hydro Inc.

13 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Bladder Side

Upstream

Printed: 9/18/2013

Location of First Stud

B1

Downstream

Abutment Side

4. Install seal using generous amount of 100% silicone caulk between the seal and

the Gate Panel. Place a bead of silicone caulk along the edge of the Gate Panel

where the Abutment Seal will be bolted to the gate. Place a bead of silicone caulk

on the bladder before placing the Abutment Seal down.

5. Locate Abutment Seal Retainers, washers, and nuts. Install according to drawing

11-820-120-1. Do not forget to apply generous amounts of copper or nickel-based

anti-seize lubricant on all stainless steel threads and on bearing surfaces of

stainless steel nuts.

6. Refer to Section 14 for the required torque values.

Cold vulcanizing may be performed at this time. If it is too

difficult to cold vulcanize the Abutment Seal and Hinges in there

current positions proceed to step 7. This molds everything into

place and makes it easier.

7. Place Clamp Casting over wedges and Main Anchor Bolts and torque Main Anchor

Bolts to 1400 N-m.

8.

Beginning at the ends of the Gate Panels and working toward the middle of the

bladder, re-torque each of the Main Anchor Bolts to 1400 N-m.

9. Test seal by checking for any visual gaps between the seal and the Abutment

Plate with the gates in the fully closed position. Adjust seal as required so that no

visual gap is present.

10. Wait 24 hours, and again torque all anchor bolts 1400 N-m.

OBERMEYER Hydro Inc.

14 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

8.0 RESTRAINING STRAPS

1. Locate Restraining Strap Clamps and fasteners that match up with both the

concrete and gate. See drawing 11-820-124 for visual guide.

2. Raise the gate about halfway. Be careful not to over rotate the gate as it can flip

over without the Restraining Straps installed.

3. Attach one end of the molded Restraining Strap to the gate with the clamp, nuts,

and washers. The nylon rod should be positioned just upstream of and contacting

the clamp. Attach the other end of the molded Restraining Strap to the concrete

spillway with the molded in nylon rod positioned upstream of the clamp. Reference

the photo below for installation.

GATE

LONG SIDE OF CLAMP

MOLDED NYLON ROD

UPSTREAM SIDE

NYLON ROD

LONG SIDE OF CLAMP

CONCRETE

UPSTREAM SIDE

4. Tighten the Restraining Strap anchor nuts to avoid slippage of the strap

temporarily.

5. Torque all restraining strap anchors to 350 N-m.

OBERMEYER Hydro Inc.

15 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

9.0 LEAK TEST GATE SYSTEM

***ONCE THE GATE IS INSTALLED COMPLETELY THE

SYSTEM MUST BE CHECKED FOR LEAKS. ***

* TESTING

-THE GATES SHOULD BE RAISED TO AN

INTERMEDIATE LEVEL.

- THE ABUTMENT SEALS SHOULD BE MARKED AT THE

ABUTMENT WALLS AND CHECKED AFTER 24 HRS.

-THIS LEVEL WILL BE SUBJECT TO FLUCTUATIONS

BASED ON AMBIENT TEMPERATURE

*TESTING ALTERNATE (PREFERRED)

- FLOOD THE UPSTREAM SIDE OF THE GATE ENOUGH

TO SUBMERGE THE MAIN ANCHOR CLAMPS.

- FLOOD THE DOWNSTREAM SIDE OF THE GATES

JUST ENOUGH TO COVER THE SPILLWAY BY 3-4

INCHES OF WATER.

- INFLATE THE GATE TO 5 PSI FOR APROXIMATELY 12

HOURS

- LOOK FOR VISIBLE SIGNS OF AIR LEAKAGE ALONG

THE BLADDERS AND CLAMPS.

- RE-TORQUE AS NECESSARY

OBERMEYER Hydro Inc.

16 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

10.0 LOCATING AND ANCHORING AIR SUPPLY, ACC and PLC

1.

Place Air Control Cabinet (ACC) into its final position.

2.

Using a marker, mark the holes on the wall or floor accordingly. Move the

cabinet away from the marked holes.

3.

Using the concrete drill, bore holes which match the manufacturers

recommended depth and diameter for the stainless steel wedge type anchors.

Install the wedge type anchors.

4.

Place the cabinet in the appropriate position. Tighten anchors until the cabinet

is firmly anchored.

5.

Connect the pipes to appropriate ports per the project drawings.

6.

Repeat the process for the air compressor equipment, blowers, and Program

Logic Controller (PLC).

11.0 ELECTRICAL

1. Contractor to supply and install control wiring between the ACC and PLC per

applicable building codes.

2. All electrical conduit shall be as specified in the drawing.

3. Contractor to supply and install power supply conduit and wiring between the

circuit breaker and compressor & blower motors per project drawings.

4. Contractor to supply and install sensor cabling between external termination

boxes and the PLC cabinet per project drawings.

5. Contractor to procure circuit breaker panel per project drawings and install in

accordance with appropriate building codes.

12.0 FIELD TESTING

1. An OHI field representative should be on site for system start up.

2. The air supply pipes shall be tested prior to covering with concrete, backfilled,

or otherwise concealed. The air piping between the gate and the air control

cabinet shall be tested by pressurizing to 50psi for 24-hours. Pressure

readings and ambient air temperature shall be recorded at six different times

during the test.

OBERMEYER Hydro Inc.

17 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

3. A wet test of the air lines may be performed with a leak detection solution at 50

psi in place of the 24 hour timed test.

4. Any joints or fittings exhibiting leakage during this time shall be repaired or

replaced.

5. The air piping between the air control cabinet and high pressure equipment

shall be tested by pressurizing to 150 psi for 24-hours. Pressure readings and

ambient air temperature shall be recorded at six different times during the test.

Any joints or fittings exhibiting leakage during this time shall be repaired or

replaced.

6. After installation of the gate system, before removing the cofferdam the spillway

gates shall be fully raised and lowered three (3) times using a portable air

supply. The gate shall operate smoothly with no binding.

7. Do not inflate air bladder past the operating pressure found in the hydraulic

calculations.

OBERMEYER Hydro Inc.

18 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

13.0 TORQUES AND TOOLS

a. Torque Values: The following Torque settings will be used for the project:

Main Anchor Bolt (1-3/4- 5 UNC x 1000mm):

Gate Panel Flange Bolt (M24 x 75mm):

Restraining Strap Anchor (M30 x 460mm):

Restraining Strap Bolt (M30 c 100mm):

Hinge Flap Retainers (M30):

Abutment/J-Bulb Seal Retainers (M16):

Nappe Breaker Bolt (M12 x 40mm):

1400 N-m

270 N-m

350 N-m

270 N-m

270 N-m

100 N-m

50 N-m

b. Required Tools

Controls & Compressor (tools)

Adjustable wrenches

Pipe wrenches

Screw driver

Fine point permanent marker

8 Stainless steel M12 diameter x 150mm length wedge anchors

Concrete drill for M12 diameter wedge anchor

Lifting/moving apparatus

Gate System Installation (tools)

Wrench and socket for Main Anchor Bolts. Air impact wrench in

combination with manual torque wrench is satisfactory. A hydraulic

torque wrench is more convenient if available.

Sockets and ratchet wrenches for seal retainer and hinge flap nuts.

Utility knives for cutting rubber

3lb hammer and (7/8=22mm) rubber punches for Abutment/J-Bulb seals

Anti-seize compound sufficient for all studs, washers, and nuts.

32 tubes of 100% silicone or aquarium grade caulk and 2 caulk guns.

Rags for cleaning up silicone messes.

Abrasive cutoff saw and motorized reciprocating saw (e.g. Sawzall) or

chain saw for trimming Hinge Flaps to length.

Air bladder lifting clamps (designed by OHI).

Hand held angle grinder.

Lifting shackles to fit Gate Panel lifting holes, spreader bar for bladders.

2 Pry bars approximately 1M long.

Electric drills.

Pipe joint compound and Teflon tape for air fittings.

Pipe wrenches for air fittings.

Pliers

Shackles to fit crane hook to L shaped clamp casting lifting bracket.

Thread File.

Thread cutting dies to fit all smaller threads for repair if required.

OBERMEYER Hydro Inc.

19 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

14.0 COMMON CONSTRUCTION ERRORS AND TIPS

c. Common Construction Errors

Remember !!!

Mistakes cause rework and delays Lost Contractor Profit

Mistakes create loss of gate performance Lost Owner Revenue

Abutment Plate to Abutment Plate Spacing Not Correct This is a very common

mistake. If the span width is too great the gate system may not seal properly.

If the span width is too short, the gates may not fit. There could also be permit

issues related to insufficient waterway width.

Anchor Bolt Assemblies Not Secured for Concrete Placement - Anchor bolt

assemblies can move from pressure of concrete causing shifting so they are no

longer perpendicular to abutment wall (which creates interference with how the

gate swings up and down), or to drift left or right (which will cause the clamp

castings and bladders to not fit.

Projection of Anchor Bolts - Anchor bolt projection not enough (making

installation of clamps difficult or impossible) or projection is too much (reducing

embedment length and reducing pull out strength.

Anchor Bolt Spacing Anchors are not spaced properly because hole pattern

not used properly or other reason. This will cause clamp castings to not fit.

Abutment Walls Not Plumb When abutment walls are not cast plumb, the OHI

supplied Abutment Plates (either stainless steel or UHMW plastic) will not be

plumb. This will create a variable width gap between the Abutment Wall and

gate which could lead to gate interference and water leakage.

Abutment Walls Bowed Insufficient form bracing can cause the Abutment

Walls to bow out. If this exceeds 12mm the OHI Abutment Seals will not work

properly. This may lead to the gate system not sealing as it should. Steel form

work is recommended.

Concrete Surface not Level If top of concrete elevation varies by more than

12mm over a span of 1.5M, or more that 50mm over the width of the waterway,

the clamp castings will not seat as designed possibly leading to leak paths

between the Gate Panels (that can not be sealed) or a total gate system crest

height that varies, which reduces overall storage capacity.

Spillway Elevation variations in elevation across the spillway will result in

even larger variations in the top-of-gate elevation. This is because low sections

of the gate are further lowered by greater water pressure. A 50mm variation in

spillway crest elevation result in a 100mm top of gate elevation. Keep the top

of concrete crest LEVEL.

OBERMEYER Hydro Inc.

20 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

d. Tips for a Successful Project

ANCHOR BOLTS

Check that anchor bolt templates match drawing

Double check bolt to bolt spacing on assemblies

Ensure bolt to bolt spacing is correct between anchor bolt assemblies

Double check concrete pour depth with design bolt projection

Double check that all anchor bolts are within 3mm of alignment.

Form a 3 4 5 triangle (to create 90 degrees) and ensure the centerline of

anchor bolts is exactly perpendicular to both abutment walls

CONCRETE LEVEL ON ANCHOR BOLT CENTERLINE

If stainless steel heel and pivot angle embeds are supplied, pre-level and use

as screed line surfaces

If no other embeds are provided (except anchor bolts) pre-survey top of

concrete lines and double check.

ABUTMENT WALLS

Check that abutment wall forms are plumb

Check design of abutment wall formwork. Is lateral support adequate? Are

forms properly braced and tied off?

Are abutment wall perpendicular to anchor bolts.

CONCRETE QUALITY

Concrete should be trowel finish quality under all rubber surfaces

Concrete should be trowel finish quality 600mm in both directions of the anchor

bolt line

All air assembly, instrument junction box and restraining strap block outs should

have a 25mm chamfer cast in place. Chamfer must be ground after pour to a

radius.

EPOXY GROUTING OF ANCHOR BOLTS

Use proper drill template

Ensure all holes are properly washed and dried prior to application of epoxy.

Store epoxy per supplier requirements

Do not exceed manufacturers recommended hole diameter. An excessively

large hole may result in excessive epoxy shrinkage, failure of the epoxy bond to

the concrete, and anchor bolt pullout.

BLOCK OUTS AND PIPING

Cap all air lines prior to concrete pours. Make efforts to keep normal

construction debris and wildlife (fish, rodents, insects, snakes, crustaceans) out

of the airlines.

Double check location of block-outs. Are dimensions called out to the center

line or the edge of the block out? The number of air block outs matches the

number of bladders.

OBERMEYER Hydro Inc.

21 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

15.0 CHECK LISTS

e. Abutment Plate Check List

A.

Abutment face to Abutment face dimension

a)

At base near anchors

b

b)

At tip of gate in up position

c)

At tip of gate in down position.

a

PER DRAWING

(mm)

TOLERANCE +/- 6mm

All three measurements should be within 6mm of above dimension

B.

Abutment Plate Plumb

(difference between top and bottom of each section)

d.1)

Left Abutment at anchors bolt plane

d.2)

Right Abutment at anchors bolt plane

e.1)

Left Abutment at middle of lowered gate

e.2)

Right Abutment at middle of lowered gate

f.1)

Left Abutment at lowered gate tip plane

f.2)

Right Abutment at lowered gate tip plane

TOLERANCE +/- 6mm

Total out of plumb measurement must be within 6mm

OBERMEYER Hydro Inc.

22 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

C.

Abutment Plate Horizontal Flatness (deflection across plate)

g.1)

Left Abutment vertical at anchor bolts

g.2)

Right Abutment vertical at anchor bolts

h.1)

Left Abutment vertical middle

h.2)

Right Abutment vertical middle

i.1)

Left Abutment vertical gate up

i.2)

Right Abutment vertical gate up

Sketch shows section looking at top or side of abutment

plate using a taught string line between the two stand

off points.

Abutment Plate edge view

2 stand off

at edge of

plate

Measured Offset

2 stand off

at edge of

plate

TOLERANCE +/- 6mm

No point on each horizontal line can be more than 6mm out of plane

OBERMEYER Hydro Inc.

23 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

D. Squareness of Anchor Bolt Alignment to Abutment Plate

Actual Angle

Left Abutment

Actual Angle

Right Abutment

j.1)

Angle between Left Abutment and Centerline of anchor bolts

j.2)

Angle between Left Abutment and Centerline of anchor bolts

TOLERANCE +/- 0.1 degree

Calculate Angle A by laying out a 3-4-5 triangle,

then measure what the 4 leg actually is.

5 ft

Angle A = arccos (16 b2) / (6b)

b(? ft)

If b = 4, the anchor bolts are perpendicular to

the abutment wall.

B

A

3 ft

OBERMEYER Hydro Inc.

24 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

f. Main Anchor Bolt Check List

A.

Anchor Bolt Spacing

N1 = distance from face of right

abutment wall to centerline of first

main anchor bolt

N2 = distance from face of left

abutment wall to centerline of first

main anchor bolt

Right Abutment Plate

Left Abutment Plate

k.1)

Distance between Right Abutment Plate Face to Center of nearest anchor bolt

k.2)

Distance between left Abutment Plate Face to Center of nearest anchor bolt

B. Straightness of Anchor Bolt Alignment

Centerline of anchor bolts drawn with taught

string line between two outer most anchor bolts

Distance of center of anchor

bolt most out of alignment

l)

Distance between center line of anchor bolts and bolt most out of alignment

OBERMEYER Hydro Inc.

25 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

g. Concrete Check List

Elevation (top of concrete & anchors) Across the Spillway

m.1)

Difference between highest and lowest elevations across the spillway crest (measured near

the main anchor bolts

(mm)

n.2)

Difference between highest and lowest elevations of main anchors ______________(mm)_

OBERMEYER Hydro Inc.

26 of 27

GATE SYSTEM INSTALLATION PROCEDURE

Junquillo 11-820

Printed: 9/18/2013

Positioning of Block outs

Distance between Left

abutment wall and

centerline of first air

assembly block out

Distance between

centerline of first air

block out and center of

second air block out

o.1)

Distance between Left abutment wall and centerline of first air assembly block out

__

o.2)

Distance between CL first left air block out and CL of second air block out

__

p.1)

Distance between Right abutment wall and centerline of first air assembly block out

__

p.2)

Distance between CL first right air block out and CL of second air block out

__

q.1)

Distance between Left abutment was and centerline of first restraining strap block out _____

q.2)

Distance between CL first left restraining strap block out and CL of second restraining strap

block out _______

r.1)

Distance between Right abutment was and centerline of first restraining strap block out ____

r.2)

Distance between CL first right restraining strap block out and CL of second restraining strap

block out _______

OBERMEYER Hydro Inc.

27 of 27

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Jis G3445 PDFDocument15 pagesJis G3445 PDFhbook100% (1)

- Din en 74-3#0 - Din en 74-3 - 2007-07Document13 pagesDin en 74-3#0 - Din en 74-3 - 2007-07YasserMohsenNo ratings yet

- Promag 10L1F PDFDocument36 pagesPromag 10L1F PDFAnonymous NR3qZ30No ratings yet

- 1576 2-2016 PDFDocument61 pages1576 2-2016 PDFChan NovNo ratings yet

- MFL68061232Rev01 211118 - EnglishDocument26 pagesMFL68061232Rev01 211118 - EnglishGawed AlameriNo ratings yet

- 2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLDocument11 pages2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLnicholas_j_vaughanNo ratings yet

- Boiler Magnetite Exfoliation Report June 2005Document23 pagesBoiler Magnetite Exfoliation Report June 2005lacoste11111100% (1)

- Types of Pipes, Classification of PipesDocument4 pagesTypes of Pipes, Classification of PipeschkibiNo ratings yet

- HELE 6 Unit 4 Module 1Document13 pagesHELE 6 Unit 4 Module 1fordmayNo ratings yet

- Hose Reel Catalogue 2018Document12 pagesHose Reel Catalogue 2018FrancisNo ratings yet

- Introduction Letter KsiDocument2 pagesIntroduction Letter KsiKamlesh Steel industriesNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Ecrl FS01 - Tunjung - Ugc - Schedule HDocument14 pagesEcrl FS01 - Tunjung - Ugc - Schedule Hlkt_pestechNo ratings yet

- Expansion Joint BasicsDocument35 pagesExpansion Joint BasicsRajivharolikarNo ratings yet

- Drainage Handbook: Optional Pipe MaterialsDocument38 pagesDrainage Handbook: Optional Pipe MaterialsedgarabrahamNo ratings yet

- 161 en Installation Manual Victory Turbo Kit For Sea Doo SparkDocument12 pages161 en Installation Manual Victory Turbo Kit For Sea Doo SparkwilsonNo ratings yet

- Maxitech International: Consolidated ReportDocument12 pagesMaxitech International: Consolidated ReportSatheesh PurushothamanNo ratings yet

- Unit 302/001: Understand and Apply Domestic Cold Water System Installation, Commissioning, Service and Maintenance TechniquesDocument5 pagesUnit 302/001: Understand and Apply Domestic Cold Water System Installation, Commissioning, Service and Maintenance TechniquesP_DaviesNo ratings yet

- Petroplas Installation Manual UsDocument34 pagesPetroplas Installation Manual UsRogerio Pinto AndradeNo ratings yet

- Claudius Peters Pneumatic Conveying Brochure enDocument16 pagesClaudius Peters Pneumatic Conveying Brochure enLucas MeirellesNo ratings yet

- General Manual TrussDocument10 pagesGeneral Manual TrussjillianixNo ratings yet

- Fabric Brochure Letter Rev2 Web PDFDocument28 pagesFabric Brochure Letter Rev2 Web PDFMoamenNo ratings yet

- Single Data Sheet Linear Luminaire With LED GRP - 6402-4128-6100-152-2222-22-8500 - 267053 - en-GBDocument6 pagesSingle Data Sheet Linear Luminaire With LED GRP - 6402-4128-6100-152-2222-22-8500 - 267053 - en-GBAlla Naveen KumarNo ratings yet

- OSERIX GammaSafeDocument22 pagesOSERIX GammaSafeskynyrd75No ratings yet

- Complaint CodesDocument35 pagesComplaint CodesRajneesh JaswalNo ratings yet

- Infraset Product Catalogue (2014)Document55 pagesInfraset Product Catalogue (2014)Christian JordaanNo ratings yet

- RSST 20Document10 pagesRSST 20Bonta CorporativoNo ratings yet

- VRV Engineering DataDocument62 pagesVRV Engineering DatastelandreouNo ratings yet

- Ansi Awwa C520-2014 PDFDocument36 pagesAnsi Awwa C520-2014 PDFEslam Elsayed100% (1)

- A Brief Strategic Analysis of Aziz Pipes Limited: Course Name: Strategic Management Course No. F-624Document14 pagesA Brief Strategic Analysis of Aziz Pipes Limited: Course Name: Strategic Management Course No. F-624Dharmendra B MistryNo ratings yet