Professional Documents

Culture Documents

The Origin and History of Coconut Oil

Uploaded by

jayesh_korna01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Origin and History of Coconut Oil

Uploaded by

jayesh_korna01Copyright:

Available Formats

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

A PROJECT REPORT ON

TO STUDY THE PROCESS OF MAKING PARACHUTE

OIL

SUBMITTED IN PARTIAL FULFILMENT OF THE

REQUIREMENT FOR

MASTER OF COMMERCE (M.COM)

ACCOUNTANCY GROUP

SEMESTER- I

IN THE SUBJECT

ADVANCE COST ACCOUNTING

TO UNIVERSITY OF MUMBAI

BY

JAYESH KORNA

ROLL NO. 13A116

2013-2014

UNDER THE GUIDANCE OF

PROF.P. DR. AMIT PRAJAPATI

CHETANAS

H. S. COLLEGE OF COMMERCE & ECONOMICS

& SMT KUSUMTAI CHAUDHARI COLLEGE OF ARTS

BANDRA (EAST), MUMBAI 400 051

1 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

DECLARATION

I, JAYESH KORNA, student of Master of Commerce

(M.Com) Accountancy Group Semester- I, Roll No.

13A116 of Chetanas H. S. College of Commerce &

Economics & Smt. K. C. College of Arts, (CHETANAS M.

COM. CENTRE) Bandra (East), Mumbai 400 051,

hereby declare that I have completed the project on To

Study The Process Of Making Parachute Oil in the

subject Advance Cost Accounting for the Academic Year

2013-14.

_________________________

JAYESH KORNA

Date: 29TH August, 2013

2 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

CERTIFICATE

I, PROF.DR AMIT PRAJAPATI hereby certify that JAYESH

KORNA , Roll No 13A116 of M.Com. Semester I of

Chetanas M.Com Centre , has successfully completed

project on To Study The Process Of Making Parachute Oil

in the subject Advance Cost Accounting for the Academic

Year 2013-14.

________________

Internal Guide

Guide

________________

__________________

3 | Page

_________________

External

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Coordinator

Principal

4 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

ACKNOWLEDGEMENT

At this juncture, I would like to express my sincere

gratitude to those who have helped me directly or

indirectly during this project.

My sincere thanks to Prof. Dr Amit Prajapati for his

whole

hearted

support,

constructive

advice

and

practical guidance. I would also like to thank the college

library for the reference material and information used.

_________________________

Jayesh korna

5 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

CONTENT

SR. NO

DESCRIPTION

PAGE NO.

Part I

6-9

Part II

Overview of coconut oil

Industry

Origin and History of

Coconut Oil

Objective, limitation and

executives summary

Research methodology

Part III

Interpretation and analysis

10-42

1.

Coconut Oil and Global

Economy

Coconut Oil and Indian

Economy

Coconut Oil and Local

Economy

Conclusions

10-22

1.

2.

2.

3.

Part IV

6 | Page

6-7

8

9

23-34

35-42

43

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

The Origin and History of Coconut Oil :

Coconut oil is derived from the seed of the palm, Coconut, Cocosnucifera. The

origin

of Coconut is believed to be from the islands of the Western Pacific and eastern

Indian oceans. The coconut seeds germinate even after floating in ocean

currents for 3- 4months, enabling their dispersal across the Indo-Pacific belt.

Further dispersal to different parts of the world was enabled through human

intervention through navigators of Arab, Polynesian, Malay and European

origin.

Reference to the coconut is made in ancient Sanskrit writings of India,

dated to 4thCentury BC and in Tamil literature as early as between the 1 st and 4th

century AD.From historical data such as use in rituals, southern coastal India

appears to have usedcoconut much ahead of the north.

Cultural context of Coconut :

In South Asia Coconut is considered a complete tree and often addressed as

kalpavriksh (tree that provides whatever is wished for). It is also referred to as

sriphala(fruit of the gods) since, every part of the palm can be used for some

purpose related to human need food, shelter and fibre. It is an essential

component in every Indian ritual as it symbolises divine consciousness1.

7 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Relevance of Coconut oil in Dietary and Cosmetic habits of Humans :

Coconut oil is one of the important products from Coconut. It is extracted from

the dried kernel, referred to as copra. It has been used over centuries as a hair

tonic and a skin care product, due to its moisturizing properties. It therefore

finds high demandfrom the cosmetic industry in the preparation of soaps, hair

oils, body oils, and the like.Coconut oil is used as a cooking medium in southern

parts of India, especially Kerala state. It has of late gained popularity in other

markets as a medium of cooking due to increased research on its health benefits.

The oil is also popular in the preparation of confectionaries such as margarine,

ice creams.

8 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

OBJECTIVE OF STUDY:

To study the coconut oil industry

To get broad knowledge of uses of coconut oil

To study the potiential of industry

LIMITATION :

It is limited to some countries only

It is the small part of oil industry

It is less in demand as compared to petroleum product

Available substitute

Less in demand in foreign countries

Less amount of total consumption

SMore competition form substitute oil

SUMMARY:

The project is based on the secondary data collected from the various sits and reference

books. Project consist of the numerical figure for understanding of coconut oil industry.

9 | Page

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

RESEARCH METHODOLOGY:

The present investigation is a descriptive types of study under taken to estimate the potential

of coconut oil industry all over the world.

SAMPLE SIZE:

For the purpose of analysis a sample size of coconut oil industry in india were selected. The

sample size taken was india (countries).

SAMPLING METHOD :

The sample method used for the project was Random sampling this types of sampling is

also knows as probability has an equal chance of inclusion in the sample and each of the

possible sample .the procedure give each item is an equal probability tobe selected.

DATA COLLECTION SECOUNDARY DATA :

The secondary data was collected by referring through web sit and final data was analysis

systematically to achieved the dersiredresult.

DATA ANALYSIS AND INTERPRETATION :

After analysis the data come to the following interpretation .interpretations has been done on

the basis of the feature mention in the data.

The industry potential is limited to some extend

There is less demand due to the available of substitute

It is used by only some countries

Technology use in production were not so efficient

Potential is limited to cultural countries only

10 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

PART II

Coconut Oil and

Global Economy

Global Trade in Coconut Oil :

Coconut oil is listed among the nine internationally traded vegetable oils. Although

considered healthy edible oil, it ranks eight in global production of vegetable oils.

The largest produced and consumed vegetable oils are Soyabean oil and Palm Oil.

Production of Rapeseed and Sunflower seed oils are approximately half of the

production of Soy and Palm oils, while the other oils constitute individually about

one-eight the production of these oils.

Table

World Production of Vegetable Oils

11 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Vegetable Oil % to total

Production

Soybean

Palm

Rapeseed

Sunflowerseed

Peanut

Cottonseed

PalmKernel

Coconut

Olive

Average Total

30.14

28.92

14.02

8.72

4.83

3.97

3.53

3.27

2.61

100.82

Production

(2000-2004) Mn MT

Major Producers of Coconut Oil

The largest producers of coconuts and coconut oil are Indonesia and Philippines

followed by India. The production of coconuts over a eight year period from 19972004 has shown a negative growth rate in many producing countries such as

12 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Philippines, Vietnam, Papua New Guinea, Mexico and Sri Lanka. This could be

attributed to the easy and cheaper availability of substitute vegetable oils like Palm oil

and Soya Bean oil.

Global Production of coconuts (Million nuts)

13 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Source: FAO Statistics

Table :

Country- Wise Production of Coconut Oil (Million MT)

14 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Source:http://www.foodmarketexchange.com/datacenter/product/fruit/coconut/detail/dc_p

i_ft_coconut0603_02.htm

The global Coconut oil trade is worth around 20 million USD. World Production of

coconut oil has grown at a modest rate of 0.5 per cent per annum over a 11 year period

(1993-94 to 2004). Consumption of coconut oil has grown at a rate of about eight per

15 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

cent per annum for the same period. Production appears to follow a lag price, as is

evident from the global production and price data (1993-2004). Thus, when prices in

a year increase, production in the following year increases, leading to a reduction in

prices due to possible oversupply.

Source: http://www.fas.usda.gov/oilseeds/circular/1998/98-06/jun98opdt1.htm

16 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Major Buyers of Coconut oil :

Coconut oil accounts for about 4.5 to 5 per cent (in volume) of the total global trade in

vegetable oils. International trade in coconut oil is modest and prone to price

fluctuations, indicating an elastic demand. A look at the figures in Table 6 indicate

that imports in any given year that follows years with high prices reduce, pushing

prices down for the subsequent year. This indicates a fairly high degree of price

sensitivity of the oil, chiefly due to the availability of other edible oil substitutes. In

terms of international trade, coconut oil ranks fourth both in terms of global exports

and imports, followed by cotton seed oil, olive oil, rapeseed oil, palm kernel and

peanut oils. Global imports of coconut oil have grown at the rate of 2 per cent per

annum from 1993 to 2004, closely corresponding with the annual growth rate of 1.4

per cent of exports of the oil. The major importers of coconut oil include the European

Union, USA, Malaysia, South Korea and Others.

17 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Table

Percentage share of coconut oil in global trade of vegetable oils

18 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Source://www.foodmarketexchange.com/datacenter/product/fruit/coconut/detail/dc_pi_ft_

coconut0706.htm

Global prices for coconut oil are fixed at c.i.f. Rotterdam in The Netherlands. Price

trends for coconut oil fluctuate between years. Considering the figures in Table 7

along with the price index represented in Fig (2 ), it can be seen that the prices tend to

fluctuate between alternate years, possibly due to situations of oversupply and excess

demand, respectively. Global prices also indicate seasonality of demand, with demand

peaking during June-September that coincides with period of rains, when coconut oil

production is affected (Fig 3). With the availability of cheaper substitute edible oils,

especially of Palm oil (that constitutes about 56 per cent of the total trade in vegetable

oils) the demand for coconut oil for edible purposes has been affected.

19 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Figure

Monthly global prices of coconut oil (USD/ tonne) c.i.f. Rotterdam

20 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Grades of coconut oil traded:

RBD (Refined Bleached and Deoderized) oil is the common grade of coconut oil

traded. Virgin oil (oil from coconut milk) is gaining popularity in niche markets.

Grades of coconut oil traded :

RBD (Refined Bleached and Deoderized) oil is the common grade of coconut oil

traded. Virgin oil (oil from coconut milk) is gaining popularity in niche markets.

2005Global

R & D in Coconut :

Global research in coconut and its products is promoted by the International Plant

Genetic Resources Institute (IPGRI), based in Rome through its COGENT network

(International Coconut Genetic Resources Network).

Although not directly involved in varietal improvement or technological upgradation,

the Food and Agriculture Organization undertakes research on the production and use

of coconuts as a commodity.

21 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

PART III

Coconut Oil

Coconut Oil and

Indian Economy

22 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Relevance of Coconut oil to the Indian population :

As mentioned earlier, India is the third largest producer of coconut oil. The area under

coconut and production of coconuts have grown at the rate of about 2 per cent per

annum since 1949-2003. However, it is not a major global player in trading in coconut

oil as most of the oil produced in the country is consumed domestically.

The state of Kerala is the largest producer of coconuts and coconut oil in India, with

the largest area under coconuts. However, Tamilnadu state leads in the productivity of

coconuts. The poor yields in Kerala are being attributed to the old palms that need to

be replaced. It can be said with a fair degree of certainty that the state of Kerala

consumes the highest amount of coconut oil.

Between 1949-50 and 2002-03, four points in time can be identified where the

productivity and thereby production has leaped. These years are 1984-85(see

highlighted in Table 9), 1988-89, 1992-93 and 1994-95.

It can be observed that between the years 2001 and 2003, the area under coconuts has

reduced, consequently affecting production (around 6 per cent lesser than the previous

year). This reduction is possibly due to the low prices on the product. Between the

years 1994 and 2001, the production has reduced (by about 2 per cent

23 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Table

State wise Area, Production and Productivity of Coconuts in India

24 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Table 9

All India Area (Million Hectares), Production (00 Million nuts) and Yield

(Nuts/ Hectare) of Coconuts (1949- 200

25 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

26 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

27 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

28 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

As per data from the Foreign Agricultural Service of the United States Development

Agency, the per annum growth in production of coconut oil in India is around 4.6 per

cent; while consumption for edible purposes is a modest 2.4 per cent. However,

industrial consumption of coconut oil (that includes hair oils, toiletteries and other

non-edible uses) has grown at the rate of 8.4 per cent per annum over a 19-year period

(1986-2004).

India consumes most of the coconut oil it produces and the export/ import of the oil is

not significant. Of the total production of coconut oil, about 48 per cent is consumed

by the industrial (non-edible) sector and the rest for household purposes and in the

preparation of confectionaries. The domestic coconut oil sector is worth at least Rs

220 million

29 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

All India Production, Consumption and trade in Coconut oil

30 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

31 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Price Trends in Coconut Oil in India :

The major markets for coconut oil in India are Kochi, Kerala and Kangayam,

Tamilnadu.

From the Table (Table 11) and the Fig (2), it is evident that the prices of copra and

coconut oil move very close, which is not surprising considering that the demand for

copra is derived from the demand for coconut oil. In both cases, prices have been

rising till 2000 (with occasional dips), followed by a sudden dip after 2000. There has

been an uptrend in the prices since 2002-03. This is being attributed to increased

demand due to development and promotion of diversified products such as hair oils,

tender water, coconut milk powder, etc. In addition to this, it is believed that with the

onset of Futures trading in coconut oil, demand has perked up for the product.

32 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Table

Average price of Copra and Coconut oil (Rs/ Qtl) in India

(Kochi prices 1993-2003)

33 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

(Source: CDB)

Interestingly, the price indices of coconut oil in Indian and Global markets show a

contradictory trend till 1999-2000, subsequent to which they move in the same

direction. Indian prices move at a higher rate compared to the global prices, possibly

due to the higher demand and consumption rate in the domestic market. In addition,

the crop has been afflicted by diseases and pest infestation affecting production and

quality of the produce

Minimum Support Price for Coconut

The Commission on Agricultural Costs and Prices (CACP) fixes Minimum Support

Prices (MSP) for about 25 commodities, copra being one of them. Copra prices are

fixed for both Ball and Milling Copra. This serves as a benchmark to ensure that

farmers/ producers get a good rate for their produce. The National Agricultural Cooperative

Marketing Federation (NAFED) through the co-operative societies procures

the coconuts/ copra, for further sale, export and distribution.

34 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

R & D in India :

In India, research on coconut is carried out through the Coconut Development Board.

Research includes development of new varieties, development of improved

technology for better efficiency in coconut utilisation, and in development and

promotion of diversified products from coconut.

The Indian Council of Agricultural Research, through the network of State

Agricultural Universities and the Central Plantation Crops Research Institute

(specifically the Center at Kasargode) also conducts research on coconut

development. This includes varietal improvement programmes for yield, pest and

disease resistance, agronomic practices and the like.

Value Chain

The steps involved in the value addition process of coconut oil are as follows:

Coconuts--------------Copra---------------Coconut oil

Coconuts are either sun-dried or smoke dried. Copra is processed using rotary chucks

(which is quite common) or expellers (considered more efficient). The coconut oil is

then further processed as per market requirements.

35 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Marketing Channels for Coconut Oil

Producer-Co-operative Society-End User

Producer-Processing Mill-Trader/ End User

Producer-Agent-Processing Mill/ Trader-End User

Major Brands of Coconut Oil

Marico Industries (Parachute, Hair and Care, Oil of Malabar and Shanti Amla),

Hindustan Lever Ltd (All Clear) and Dabur India (DaburVatika, DaburAmla) are the

major producers of branded hair oils. Marico is the market leader amongst the

companies, having 52% of the market share through its flagship brand, Parachute Oil.

However, branded oils are estimated to form only about one-third of the total market

for hair oils2, the rest being catered by the loose oil segment.

36 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

PART IV

Coconut Oil and

Local Economy

Impact of Coconut Oil in a local economy

This section explores the relevance of coconut oil in the economy of a community,

through the cases of the partner communities of Just Change. For this, representatives

of three partner communities (AdivasiMunnetraSangam, Gudalur; SAWARD,

Calicut and BVM, Nilambur) were invited for separate focus group discussions (FGD)

in their respective areas of operation (at Gudalur, Calicut and Nilambur) and relevant

information on demand for coconut oil and production processes of the commodity

were elicited and documented.

Consumption Patterns

Coconut oil is the preferred edible oil in all the three communities. It is also used as a

hair and cosmetic oil, usually in raw form. On an average, a family consumes about

1.25 litres of coconut oil in a month. Members of BVM consume between 2-2.5 lts of

37 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

oil. It is generally bought in packets from local shops or directly from the mills. AMS

members buy unpacked oil in small quantities, as per their daily requirement.

Seasonal variations in demand

Demand for the oil rises during holidays and festivals, with consumption peaking

during months between March to May, and prices rising during the monsoon (JulySeptember).

Preferred Varieties/ Brand Names

Kera, Maveli, Shudhi and Parachute are the popular varieties, of which Kera is

preferred in terms of both quality and price

Average price paid and maximum willing to pay

The communities pay between Rs.50 (from Mills) and Rs 65-70 (in packets) per litre

of oil. The maximum price that they are willing to pay ranges between Rs 70-75/- per

litre, beyond which they will reduce consumption of the oil and use substitute oils for

edible purposes. However, they will continue to buy for hair and cosmetic purposes in

small amounts if the price goes beyond Rs 90 per litre, as no substitute is envisaged

for the purpose. This throws an opportunity for exploring the hair/ cosmetic oil market

through product diversification. AMS members currently pay around Rs 80/ litre of

coconut oil, by way of paying more for the small, frequent purchases of oil. In case

demand for oil is more, they substitute other refined oils such as palm oil for coconut

oil. BVM and SAWARD members are also producers of coconuts. Hence, their

willingness to pay is dependent on the price they receive for their coconut produce.

38 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

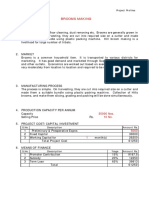

Production of Coconut oil

Production of coconut oil involves three stages- production of coconut; conversion of

coconut to copra and milling of copra to get coconut oil. SAWARD is the only group

involved in the commercial production of coconut oil. However, both BVM and

SAWARD members grow coconut and make copra, even if for domestic purposes.

Hence, an economic analysis of the different stages of the value addition chain will

help understand the economic impact of the crop on the communities.

Production of Coconuts

All production activities related to a coconut farm are reported on a per palm basis.

Hence, the costs analysed are also on a per palm basis. The fixed costs incurred at the

time of planting include cost of seedling and digging pits for planting. Pre-bearing

costs (upto 8 years after planting) including costs of manuring, mulching and

provision of required nutrients (Table 13). Pre-bearing costs are discounted at the rate

of 10 per cent per annum to get the present value of the costs. This, then with the.

planting cost when amortized at 10 per cent per annum over 50 years (the average

economic life of a coconut) results in an annual fixed cost of Rs.34/ palm.

Maintenance costs including cost of inputs, opening and closing the basin of a palm

each year works out to about Rs. 75/ palm. Harvest cost per palm (even if for one

coconut) is Rs 5/-. Hence, the total production cost works out to Rs 114 per palm.

Cost of marketing is a minimum of Rs.25/ 100 coconuts (=40 kgs). A good palm

yields around 600 coconuts in a year. Hence the total cost per palm is around Rs.300/-

39 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

40 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Table

Cost of Production of a coconut palm in Kerala

41 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Sale and Returns

Returns

The market rate in Kozhikode for coconuts is Rs.8.75/ kg. Hence, the potential returns

from a good yielding palm (around 600 coconuts per year) is around Rs.2100/- per

annum. Members of BVM get only Rs.3.50 per kilo as agents directly buy the

coconuts from their doorstep. They would hence get only Rs.420/ per palm per annum

for a palm that yields around 300 coconuts, about Rs.600 less than what they could

potentially earn. By selling to traders at Nilambur markets, they get around Rs 7.5 per

kilo. If they bring to a larger market close by, their revenue will be higher. The

argument for such sale is that the families have few palms making it unremunerative

to market such distances. However, by pooling their produce it is possible to achieve a

higher bargaining position in the market.

42 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Production of Copra and Coconut Oil

The next stage in the value addition chain is the drying of coconuts to yield copra.

Commercial drying involves the use of driers, where a single unit can dry about 1000

coconuts in a batch every 3 days. Around 130 batches are processed in a year. The

costs and returns involved in the production of copra and later milling to produce

coconut oil are highlighted below. Annual fixed costs work out to around Rs 4,900/- at

the rate of 10 per cent discount rate (Table 14). This includes cost of drier, balance,

implements and other items. Maintenance costs include cost of coconuts, labour for

breaking and arranging the coconuts on the drier, shelling costs, fuel costs.

Once dried, the copra is graded and milled. 1000 coconuts give around 105 kg of

copra. Milling costs work out to Rs.3.5/ kg of copra. Cost of bottling and labeling

work out to around Rs.5.25/- per bottle

Table 14

Cost of production of Copra and Coconut oil

43 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

Returns

Coconut oil is sold at the rate of Rs.60 per litre as unpacked oil and at the rate of

Rs.65/ litre in bottles at a nominal margin of about 8 per cent. This oil is of fine

quality. The prices of coconut oil in the market vary between Rs.50-75 per litre. It is

believed that the low prices are a consequence of blending different edible oils, or

different grades of coconut oil.

44 | P a g e

TO STUDY THE PROCESS OF MAKING PARACHUTE OIL

PART V

Conclusions

Coconut oil production is an economical venture as long as there is effective demand

for the oil. With substitutes easily available at cheaper prices for the edible oil, pricing

of the oil becomes a crucial aspect in marketing. Given the inelastic demand for hair

oil, it will be worth exploring the production and market opportunities for such oils

and other cost-effective value added products of coconut.

45 | P a g e

You might also like

- Value Chain Management Capability A Complete Guide - 2020 EditionFrom EverandValue Chain Management Capability A Complete Guide - 2020 EditionNo ratings yet

- Edible Oil Marketing StrategiesDocument60 pagesEdible Oil Marketing StrategiesVidya Sonawane0% (1)

- Contents of Project ReportDocument4 pagesContents of Project ReportJaya LekshmiNo ratings yet

- GUPTA - Export Import Management-MC GRAW HILL INDIA (2017)Document354 pagesGUPTA - Export Import Management-MC GRAW HILL INDIA (2017)rUTHNo ratings yet

- JDocument64 pagesJSelman FarishNo ratings yet

- Final Case Study Kellogg'sDocument22 pagesFinal Case Study Kellogg'sTanu ShreeNo ratings yet

- Fini 619 Internship Report On Iqbal Rice MillsDocument43 pagesFini 619 Internship Report On Iqbal Rice MillsRohit Singh100% (1)

- Group Assignment 4 Al AinDocument5 pagesGroup Assignment 4 Al AinRambo DeyNo ratings yet

- Export Packaging Unit3Document36 pagesExport Packaging Unit3Kirubas KaranNo ratings yet

- MRS Mijan Coconut Oil ProductionDocument22 pagesMRS Mijan Coconut Oil ProductionMAVERICK MONROENo ratings yet

- Ch-10 Selecting The Right Investment Products For InvestorsDocument16 pagesCh-10 Selecting The Right Investment Products For InvestorsrishabhNo ratings yet

- Os PCBLDocument7 pagesOs PCBLJibin KuriakoNo ratings yet

- The Raymond Limited: A Study: Director (Research) ICSI-CCGRT, Navi MumbaiDocument14 pagesThe Raymond Limited: A Study: Director (Research) ICSI-CCGRT, Navi Mumbaioptra ceraNo ratings yet

- Swot Matrix ItcDocument3 pagesSwot Matrix ItcRiya PandeyNo ratings yet

- Case Study Asian PaintsDocument20 pagesCase Study Asian PaintsRajan Girdhar100% (1)

- ABM 111 Theory NotesDocument32 pagesABM 111 Theory NotesDeepti SinglaNo ratings yet

- AssignmentsDocument1 pageAssignmentsWena Marie B. DAGONDON50% (2)

- Marketing StrategyDocument16 pagesMarketing StrategyPraveen Kumar100% (1)

- CHAPTER 10 Strategy Implementation: Staffing & DirectingDocument25 pagesCHAPTER 10 Strategy Implementation: Staffing & DirectingAngelo Donato100% (1)

- Agricultural Marketing - AgribusinessDocument5 pagesAgricultural Marketing - AgribusinessashisbhuniyaNo ratings yet

- A Project Report ON Batch Costing: Bharat ApparelDocument18 pagesA Project Report ON Batch Costing: Bharat ApparelChinmay AcharyaNo ratings yet

- Ratio Analysis Numerical QuestionsDocument9 pagesRatio Analysis Numerical Questionsnsrivastav1No ratings yet

- Ratio Analysis Tirupati Cotton Mills LTDDocument102 pagesRatio Analysis Tirupati Cotton Mills LTDHarish Babu Gundla PalliNo ratings yet

- VivaDocument29 pagesVivaA. ShanmugamNo ratings yet

- A Study On The Influence of Packaging in Brand Selection in Toothpaste IndustryDocument12 pagesA Study On The Influence of Packaging in Brand Selection in Toothpaste IndustryAshish Garg100% (1)

- Assumptions of Ideal Capital MKT and Its ViolationsDocument17 pagesAssumptions of Ideal Capital MKT and Its Violationssuchitracool133% (3)

- Tools For Marketing DecisionsDocument9 pagesTools For Marketing DecisionsMianAbdURRehmanNo ratings yet

- Nilgiris Mechanized Bakery - Organizational-StudyDocument50 pagesNilgiris Mechanized Bakery - Organizational-Studyvirus_hackeyNo ratings yet

- Productions and Operations Report of Cargill, Incorporated: Pulilan Plant BranchDocument21 pagesProductions and Operations Report of Cargill, Incorporated: Pulilan Plant BranchCatherineSapianNo ratings yet

- Project Report EditedDocument16 pagesProject Report EditedKishor PakhareNo ratings yet

- Mango Pulp Manufacturing Unit: Group 7 Ashwin - Madhumitha - Neha - Seshadri - VimalDocument16 pagesMango Pulp Manufacturing Unit: Group 7 Ashwin - Madhumitha - Neha - Seshadri - VimalVimal AnbalaganNo ratings yet

- Auto ComponentsDocument9 pagesAuto ComponentsbattlestrokerNo ratings yet

- Multiplier Approach To Share ValuationDocument2 pagesMultiplier Approach To Share ValuationI am IndianNo ratings yet

- EdpDocument18 pagesEdpAbhinav VermaNo ratings yet

- Module 2 - Concept of Global Marketing & Global Marketing StrategyDocument18 pagesModule 2 - Concept of Global Marketing & Global Marketing StrategyAriel Bobis100% (1)

- STPD of Jyoti LaboratoryDocument6 pagesSTPD of Jyoti LaboratoryMonisha BhatiaNo ratings yet

- Battle in The Domestic SkiesDocument2 pagesBattle in The Domestic SkiesSagar chaudhariNo ratings yet

- (Research Report) Truck Turnaround Time in Customer BaseDocument59 pages(Research Report) Truck Turnaround Time in Customer BaseAnonymous d2ZSDE0% (3)

- Multi-Variable SegementationDocument16 pagesMulti-Variable Segementationkripa duduNo ratings yet

- Mis Role in Production 12Document18 pagesMis Role in Production 12pugs_rockon100% (10)

- A Research Proposal OnDocument4 pagesA Research Proposal OnRukhsan AraNo ratings yet

- Monopoly in PakistanDocument3 pagesMonopoly in Pakistanali hassan71% (7)

- Recommendation On Inventory Control System - TermpaperDocument4 pagesRecommendation On Inventory Control System - TermpaperiftezarNo ratings yet

- Internal Environment AnalysisDocument3 pagesInternal Environment AnalysisArifHossainNo ratings yet

- Tax Planning & JV AbroadDocument16 pagesTax Planning & JV AbroadAmit KapoorNo ratings yet

- Project On Chocolate IndustryDocument20 pagesProject On Chocolate IndustryCongthu JosephNo ratings yet

- Brooms MakingDocument3 pagesBrooms MakingGohilaRajNo ratings yet

- Risk Return RelationshipDocument10 pagesRisk Return RelationshipJunaid PantheeranNo ratings yet

- N.k.proteins Ltd.Document65 pagesN.k.proteins Ltd.mbawarriorssiem67% (3)

- Final Project On Century Textiles Industry LTDDocument27 pagesFinal Project On Century Textiles Industry LTDBhagyashree MohiteNo ratings yet

- Swot Analysis 1Document4 pagesSwot Analysis 1Viswa KeerthiNo ratings yet

- Powerpoint Presentation On Financial & Ratio Analysis of Pharmaceutical CompanyDocument17 pagesPowerpoint Presentation On Financial & Ratio Analysis of Pharmaceutical CompanyAviral Tripathi100% (2)

- Tile SectorDocument33 pagesTile SectorMike LassaNo ratings yet

- Starbucks Case StudyDocument27 pagesStarbucks Case StudyPardeep KapilNo ratings yet

- Edp NotesDocument48 pagesEdp NotesSantosh SunnyNo ratings yet

- Habib Oil Mills Compensation Management ReportDocument22 pagesHabib Oil Mills Compensation Management Reportsjay cwNo ratings yet

- 5.2 Q JPMorgan Chase FXDocument7 pages5.2 Q JPMorgan Chase FXSanaFatimaNo ratings yet

- Analysis of Various Brands of Soyabean Refined Oil in The MarketDocument38 pagesAnalysis of Various Brands of Soyabean Refined Oil in The MarketDouglas OrtizNo ratings yet

- A Pragmatic Study On Buyers of Edible OilsDocument36 pagesA Pragmatic Study On Buyers of Edible OilsNeha Motwani100% (3)

- Nitin AgnihotriDocument64 pagesNitin AgnihotriTahira KhanNo ratings yet

- ICICI Prudential For 7months Back Office Executive: Curriculum ViateDocument2 pagesICICI Prudential For 7months Back Office Executive: Curriculum Viatejayesh_korna01No ratings yet

- Labeling of Imported Shipments: Confidential - 1Document2 pagesLabeling of Imported Shipments: Confidential - 1jayesh_korna01No ratings yet

- Labeling of Imported Shipments: Confidential - 1Document2 pagesLabeling of Imported Shipments: Confidential - 1jayesh_korna01No ratings yet

- Project Report On Value Added Tax (VAT)Document77 pagesProject Report On Value Added Tax (VAT)Royal Projects100% (6)

- Project Report On Value Added Tax (VAT)Document77 pagesProject Report On Value Added Tax (VAT)Royal Projects100% (6)

- Final Bajaj ProjectDocument28 pagesFinal Bajaj Projectjayesh_korna01No ratings yet

- Session 1Document10 pagesSession 1tuantu_51No ratings yet

- Palm Oil Report 2012Document152 pagesPalm Oil Report 2012S J100% (1)

- CACP ReportDocument200 pagesCACP Reportsuresh_shakkarwarNo ratings yet

- Effect of Blending On Physico-Chemical Properties of Palm Oil and Palm Oil Products With Soyabean OilDocument8 pagesEffect of Blending On Physico-Chemical Properties of Palm Oil and Palm Oil Products With Soyabean OilAristonNo ratings yet

- Japan-Indonesian Symposium & Expo - Unsada - KemayoranDocument30 pagesJapan-Indonesian Symposium & Expo - Unsada - KemayoranJuf LewisNo ratings yet

- Big Data Real World Application in Palm Oil IndustryDocument4 pagesBig Data Real World Application in Palm Oil IndustrymaryNo ratings yet

- Biobased Surfactants and DetergentsDocument512 pagesBiobased Surfactants and DetergentsEdgardo Ed RamirezNo ratings yet

- Deforestation: March 2020Document7 pagesDeforestation: March 2020RISHIKHESANNo ratings yet

- Little Helps Plan Kpis - Data SummaryDocument15 pagesLittle Helps Plan Kpis - Data Summaryjho elpeNo ratings yet

- A Guide To Palm Oil in IndonesiaDocument87 pagesA Guide To Palm Oil in IndonesiaclarissaNo ratings yet

- ISCC Guidance WR From Palm Oil Mills V3.0Document13 pagesISCC Guidance WR From Palm Oil Mills V3.0Henry XieNo ratings yet

- An Economic Analysis of Oilpalm Cultivation in West Godavari District of Andhra PradeshDocument7 pagesAn Economic Analysis of Oilpalm Cultivation in West Godavari District of Andhra PradeshpaulNo ratings yet

- WWF 2021 Palm Oil Buyers Scorecard Full ReportDocument55 pagesWWF 2021 Palm Oil Buyers Scorecard Full ReportMaxime Stanislas TCHOHOUNGBONo ratings yet

- Sinarmas Tes Sep10Document3 pagesSinarmas Tes Sep10Andi_Dwi_Lakso_2729No ratings yet

- Godrej AgrovetDocument19 pagesGodrej Agrovetsaurabh018No ratings yet

- 22 2 23 RSPOCertSearchPDFDocument4 pages22 2 23 RSPOCertSearchPDFWiwik KurniatiNo ratings yet

- Fcpo-Bmd News: Futures Tumble Dragging Cash Prices Lower To Compete With Us$80 Reduction in Indonesian LevyDocument4 pagesFcpo-Bmd News: Futures Tumble Dragging Cash Prices Lower To Compete With Us$80 Reduction in Indonesian Levykunal singhNo ratings yet

- Types of Oil Seed Used in Oil Processing AreDocument27 pagesTypes of Oil Seed Used in Oil Processing AredagimNo ratings yet

- Group Assignment Management Ethics BaruDocument17 pagesGroup Assignment Management Ethics BaruMaizurah AbdullahNo ratings yet

- Is It True That Oil Palm Plantations Are The Main Driver of Indonesia's Tropical Forest Deforestation?Document10 pagesIs It True That Oil Palm Plantations Are The Main Driver of Indonesia's Tropical Forest Deforestation?amaNo ratings yet

- GAR PPT 4Q 2018 Mar 2019 1Document24 pagesGAR PPT 4Q 2018 Mar 2019 1jagrat_pNo ratings yet

- Industri Hilir Kelapa Sawit Indonesia & PTPN Group PrintDocument14 pagesIndustri Hilir Kelapa Sawit Indonesia & PTPN Group PrintAzhari RizalNo ratings yet

- All India Open Mock CAT 01 2022 Direction (1-4) : Study The Following Information and Answer The Questions That FollowDocument11 pagesAll India Open Mock CAT 01 2022 Direction (1-4) : Study The Following Information and Answer The Questions That FollowMax Caulfield 14No ratings yet

- Effects of Adulterated Palm Cooking Oil On The Quality of Fried Chicken NuggetsDocument11 pagesEffects of Adulterated Palm Cooking Oil On The Quality of Fried Chicken NuggetsKiruthick DonNo ratings yet

- Evans Sustainability-Report-2020 PDFDocument60 pagesEvans Sustainability-Report-2020 PDFArfiyunanto MalikaNo ratings yet

- Rasta Palm OilDocument15 pagesRasta Palm OilJill MitchellNo ratings yet

- Production of Cocoa Butter Equivalent From Mango Seed Almond Fat and Palm Oil Mid-Fraction PDFDocument7 pagesProduction of Cocoa Butter Equivalent From Mango Seed Almond Fat and Palm Oil Mid-Fraction PDFosamamusaNo ratings yet

- A Perspective of Oil Palm and Its Wastes: Journal of Physical Therapy Science January 2010Document12 pagesA Perspective of Oil Palm and Its Wastes: Journal of Physical Therapy Science January 2010Deodata Leela AndiavitriNo ratings yet

- Malaysia's Beef Cattle IndustryDocument21 pagesMalaysia's Beef Cattle IndustrySaipolNo ratings yet

- EMIS Insights - Colombia Agriculture Sector Report 2019 - 2020Document76 pagesEMIS Insights - Colombia Agriculture Sector Report 2019 - 2020Agroempresa Sostenible La TrinidadNo ratings yet