Professional Documents

Culture Documents

Power Electronics Circuit

Uploaded by

Sohail IrfanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Electronics Circuit

Uploaded by

Sohail IrfanCopyright:

Available Formats

MOSFET Failure Modes in the Zero-Voltage-Switched Full-Bridge

Switching Mode Power Supply Applications

Alexander Fie1 and Thomas Wu

International Rectifier

Applications Department

El Segundo, CA 90245, USA

Reduction of switching losses enables higher

switching frequency and requires less heat sink.

Higher switching frequency will also lead to smaller

reactive and filter components, and result in higher

power density. Less dynamic stresses increase the

reliability on power devices.

However, power MOSFET failures have been

reported recently in the ZVS full bridge topology [2,

31. Slow reverse recovery of the intrinsic body diode

under low reverse voltage is believed to be the root

cause for the MOSFET failures. Screening the

reverse recovered time of power MOSFETs is one of

the solutions, but customers need to pay the price

penalty. Another solution is a complicated network

of paralleled fast-recovery diodes to divert current

from the body diode of the MOSFET [3,4]. The best

solution is to expedite the reverse recovery process

on the body diode [2].

The other field failure is also reported at no or

low load conditions in the ZVS circuitry. Unable to

achieve ZVS condition at no or low load has forced

the power MOSFET to experience hard-switched

tum-on and tum-off. The possible failure mode for

this operation is the Cdv/dt shoot-through [5].

Detailed failure analysis on the Cdv/dt shoot through

problem, together with the silicon and system

solutions, will be described in this article.

The in-depth understanding of the failure modes

in the ZVS operation has led to the development of a

new

generation

fast-body-diode

MOSFET

technology that reduces reverse-recovery time,

increases dv/dt

stress capability, minimizes the

Cdv/dt shoot-through, and therefore is suitable for

the high frequency, high power phase-shifted ZVS

applications.

Abstract-As the demand for the telecom/server power is

growing exponentially, the need for higher power density

increases each year. Increasing power density relies on less

component counts, smaller reactive component size, and/or

better system efficiency. Higher switching frequency leads to

the smaller reactive and filter component size. Better efficiency,

which reduces the heat sink or paralleled devices, requires the

reduction either in conduction losses or switching losses, or

both. Therefore, phase-shified zero-voltage-switching (ZVS)

full bridge topologies are gaining popularity due to their

extremely low switching losses in the power devices even at

higher switching frequency.

However the intrinsic body diode is required to conduct in

order to create the ZVS turn-on condition for the power

MOSFET. Due to the extremely low reverse voltage, the

reverse recovery charges might not be swept out before turning

off the MOSFET.

Therefore, the body diode might be

subjected to the dv/dt stress when it is not yet capable of

blocking reverse voltage.

Also not able to maintain the ZVS operation at low load

will force the on-state MOSFET to turn off at hard-switching

condition. Like in the hard-switched full bridge topology, the

cdv/dt shoot-through current might produce a voltage spike at

the gate of the off-state MOSFET on the same leg and cause

devices failure.

Several silicon technologies will be presented to resolve

the above-mentioned failure modes in the ZVS topology. Fast

reverse recovery time and better dv/dt ruggedness make this

new MOSFET technology suitable for higher frequency ZVS

full-bridge applications. Inherent with extremely high silicon

density and low gate charge, these new MOSFETs can reduce

the component count with the same or better performance and

will enable much higher power density for the next generation

telecom/server SMPS designs.

I. INTRODUCTION

Demand for higher power density, especially in

the telecodserver power applications, has driven the

power electronics industry to the innovation of better

topologies and power devices. The design trends are

higher power density and more reliable power

devices. Increasing power density from 5-7 W/in3

now to 10 W/in3 in the same form factor is an

incredible challenge for power supply designers.

Phase-shifted zero-voltage-switching (ZVS)

topology [l] seems to be the remedy for achieving

higher power density and increased device

reliability. The advantages of ZVS operation are

minimized switching losses, higher operation

frequency, less dvldt and dildt dynamic stresses.

0-7803-6618-2/01/$10.00

0 2001 IEEE

11. MOSFET FAILURE MODES IN ZVS

OPERATION

A full-bridge ZVS topology is displayed in

Figure 1 where diodes Dl-D4 are the intrinsic body

diodes of power MOSFETs Ql-Q4. Capacitors C l C4 represent either the output capacitances of power

1247

MOSFETs or extemal capacitors if more capacitance

is required. The stray inductor L or Lr represents

the leakage inductor of the transformer, or the

external inductance. Detailed operation and analysis

of a full-bridge ZVS circuit can be found in [l].

Typical waveforms of a one kilowatts ZVS full

bridge circuit are shown in Figure 2 with 110 KHz

switching frequency. Notice that the drain voltage

waveform does not show any overshoot voltage

spikes that are often seen in the hard-switched bridge

topology.

diode D3 will conduct current and Q3 can be tumed

on any time during tl and t2. Q2 will be tumed off

and Q4 are tumed on at tz to force current to change

direction. Body diode D3 will be in reverse recovery

after t3. If the reverse recovery process is not

completed by t5, the time when Q3 is tumed off, D3

will not be able to block the reverse voltage and

cause failure of the MOSFET.

1

1

Vdr

m --

D3 Q

@%"

I

D2 Cl

I

"T

LOAD

Figure 3. Simplified waveform of 43

A. Full Load Failure Mode

Fig. 1. Phase-Shifted Full Bridge ZVS converter.

Some MOSFET failure modes are inherent to

the full-bridge ZVS converter. The power MOSFET

is tumed on at zero voltage because its body diode

needs to conduct first and clamps the drain-source to

0.7V in the phase-shifted ZVS full-bridge topology.

No dynamic voltage stress is imposed on the drain of

the power MOSFET when the body diode is in

reverse recovery. But it will take longer for the

body diode to sweep the charges out from the drift

region and for the depletion region to be built up

under light load and low voltage conditions. The

reverse recovery time (trr) of the body diode

increases as the applied voltage becomes lower.

9 2 Vds

43 Vds

Q3 Id

Fig. 2. Phaseshifted ZVS circuit waveforms.

Figure 3 shows a simplified device waveform of

4 3 . Q1 is turned off at to to start ZVS turn-on of

4 3 . The resonant network C 1, C2, and L or Lr force

to discharge C3 to zero voltage. At tl, the body

1248

Once the body diode is in reverse recovery, two

conditions could trigger the failure mode [5, 61. The

first is due to the peak reverse recovery current

(IRRM). Reverse recovery currents flow from drift

region into P+ implant. The horizontal component

of IRRMwill produce voltage drop on the P+ implant

resistance (Rb) and might turn on the parasitic BJT.

Secondly, tum-off dv/dt might induce a current

through the drain-to-base capacitance Cdb and Rb,

and subsequently tum on the parasitic BJT. These

reverse recovery current flows are shown in Figure 5.

Source

n

Fig. 4. Reverse voltage effect on reverse recovery

The reverse voltage effect on the body diode

during the reverse-recovery process for a standard

5OOV power MOSFET is shown in Figure 4. Notice

that for a conventional power MOSFET, the reverse

recovery time increases as the applied reverse

voltage decreases. In Table 1 the estimated trr at 1V

of reverse voltage is 3.73 ps, compared to the 3.6 p

on time for the MOSFET channel in Figure 3. The

assumption here is the body diode conducts all the

current. Of course, the reverse recovery time is

dependent of forward current, dildt, and junction

temperature. Since the MOSFET can be gated on

any time before t2 in Figure 3, it is likely the body

diode will conduct less than the full current.

Reverse

Fig. 5. Cross-sectionof a standard MOSFET showing current

flow during reverse recovery.

Comment

Estimated

100

400

1.09

0.57

0.32

Measured

All the above-mentioned problems can be

resolved by developing the new generation power

MOSFETs with the following characteristics:

Measured

Measured

.

..

Table 1. Reverse recovery time versus voltage at 100A/ps on a

standard 500V MOSFET

However, it is clearly shown in Figure 3 the

body diode of 4 3 needs to complete the reverse

recovery before t = t5. Otherwise, the body diode D3

is not yet fully recovered and may not be able to

block reverse voltage. If the remaining charges are

still in the junction and turning on the MOSFET Q1,

the resulting dv/dt may trigger on the parasitic

bipolar junction transistor (BJT) and might destroy

the power MOSFET.

Fast reverse recovery of body diode especially at

lower reverse voltage;

Low reverse recovery charge of body diode;

More ruggedness to reduce tendency for second

breakdown.

B. Low and No Load Failure Mode

There is another failure mode of the ZVS fullbridge topology which occurs at no or low load

condition. The necessary condition for the ZVS

1249

operation is the stored inductive energy in L or Lr is

sufficient to swing the capacitor voltage on C1 and

C3 when Q1 is tumed off at to.

Developing a new generation power MOSFET

with the following characteristics will increase

Cdvldt immunity and decrease the likelihood of

shoot-through while the phase-shifted ZVS is

operating at no or low load condition:

Lower QgdQgs ratio

Lower internal Rg

Increased threshold voltage

At no or low load current, the capacitor C3 will

not be filly discharged to zero voltage at tl. The

body diode D3 will never conduct current before

turn-on of 4 3 . Figure 6 shows the measured

waveform of 4 3 at low load conditions in the ZVS

full bridge topology, Notice that a little voltage

spike shows at the gate corresponding to the sharp

change on the drain voltage. The current waveform

in Figure 6 indicates the device 4 3 is tumed on

again when it is supposed to be off. This is known

as the Cdvldt shoot-through problem with both the

Q1 and 4 3 on at the same time causing the leg to

short.

:I

111. NEW ZVS POWER MOSFETS

The potential problems on the power MOSFET

for the full-bridge ZVS operation have been well

addressed and studied by the authors. The power

MOSFET in a ZVS converter needs a fast intrinsic

body-diode and low reverse recovery charges. The

reverse recovery of the body diode should be fast

especially at lower reverse voltage. Figure 8 shows

the comparison of the body diode reverse recovery

characteristics with the data of reverse recovery time

(TIT), charge (Qrr) and peak reverse current (I-)

listed in Table 2.

m3

Figure 6. Measured low load waveform in ZVS topology.

Drain

P

Fig. 8. Body diode reverse recovely comparison.

Gate

Body

Diode

b

Source

Trr

Devices

Standard

Company A

(ns)

1050

205

IRFPS40NSOL

147

Qrr

(pC)

IRRM

11.91

1.26

0.69

26

10

8

(A)

Table 2. Comparison of bodydiode reverse recovery characteristics

( IF= 20A, di/dt-82 N p s , VR=25V,T=25 'C ).

Figure 7. Equivalent circuit showing Cdv/dt shoot-through.

1250

Table 3 shows the comparison of total gate

charge (Qg), gate-to-source charge ( Q g s ) and gateto-drain Miller charge (Qgd). The total charge and

Miller charge on IRFPS40N5OL, in S ~ p e r 2 4 7 ~ ~

package are the lowest in the same class. The

extremely low gate charge on the L series makes

driver design much easier and simpler.

Device

Company A

IRFPS4ONSOL

Qg Qgs

(nC> (nC)

420

55

290

66

Qgd

w>

215

110

Table 3. Comparison of gate charge

( ID= 25A, v D s 4 o o v , VGeIOv, T=25

c ).

The in-circuit testing results of 3 KW ZVS unit

at 100 KHz switching frequency are shown in Table

5. The die size of Company As is 60% bigger than

IRFPS40NSOL. However, Company A shows just

5% better in total device power dissipation compared

to IRFPS40NSOL.

On the other hand, the Cdv/dt shoot-through

failure mode can be resolved by reducing the

Qgd/Qgs ratio [7] and by decreasing the internal

gate resistance. The new silicon technology and

process, associated with the L series power

MOSFETs, have minimized the gate voltage spike

dramatically and also increased ruggedness. The incircuit waveform from three different technologies is

shown in Figure 9.

Device

Company A

Body diode dv/dt (V/ns)

5

IRFPS4ONSOL

22

Table 4. Body diode dv/dt comparison.

As discussed above, the charges within the body

diode of the MOSFET in a ZVS converter must be

removed before the device being tumed off.

Otherwise the tum-off dv/dt could trigger the BJT

and cause device second breakdown while body

diode is still in reverse recovery. The problem will

get worse when the converter works at high

frequency in which less time is available for the body

diode to remove and recombine the charges.

Therefore, the body diode should be able to sustain

the dv/dt stress without tuming on the parasitic BJT.

The IRFPS40NSOL has been structured successfully

in this way and has no any negative impacts on the

other superior performance of the device. The body

diode dv/dt number is listed in Table 4. Thus the L

series device would be significantly less prone to the

second breakdown in ZVS applications.

Devices

Company A

Relative Die Size

1.6

Typical

Rdon

@,25C

77 mR

Qg loss

I 0.502 W

Bodv diode loss I 0.114 W

Total Conduction

5.264 W

Total

Device

5.765 W

1 5 v DC:.

.5

lap&

v oc

DC

-I-

oc

128

F0

Figure 9. Cdv/dt improvement by silicon technology.

With the combination of the lower QgdQgs ratio

and the reduction of the intemal Rg, the voltage

spike associated with the Cdv/dt shoot-through has

been reduced by 50% with Technology B, as shown

in Table 6. The decrease in the Cdvldt spike reduces

the possibility of tum-on of the MOSFET and

occurrence of shoot-through. The new L series

power MOSFET family employed similar silicon

technology as those of Technology B. Therefore the

L series MOSFET devices can effectively reduce

the Cdv/dt shoot through problem at no or low load

conditions in the phase-shifted ZVS topology.

IRFPS40NSOL

1

2 . 1

82 mR

0.441 W

0.121 w

5.604 W

Device

IRFP450A

Tech. A

Tech. B

6.046 W

3.8

1.9

1.95

1.47

1.03

0.62

Table 6 Cdv/dt improvement with different technologies.

Table 5. Incircuit comparison breakdown of power losses.

1251

I s ~ ~ ~ ~ ) ~ , / ~ g s ~

IV. CONCLUSION

[6] Thomas Wu, et al, Dynamic Stresses Might

Cause Power MOSFET Failure, PCIM Magazine,

April, 2000.

[7] International Rectifier IRF7809/IRF7811 data

sheet.

A new L series MOSFET family with low onresistance, fast recovery body diode and more

ruggedness has been studied with the phase-shifted

full-bridge ZVS converter. The low on-resistance

reduces the conduction loss so that the device will

work at a lower junction temperature or reduce the

number of paralleled devices. The fast body diode

reverse recovery time (:. 250 ns maximum) ensures

its reverse recovery charges are cleared completely

before the MOSFET device can be turned off,

especially at a low drain voltage and high switching

frequency. The 22V per nanoseconds dvldt

ruggedness of the IRFPS40NSOL ensures the device

can sustain higher turn-off stress. With the lower

Qgd to Qgs ratio along with the reduction of the

internal Rg, it has been shown that the Cdvldt

immunity of the L series MOSFETs has been

increased to eliminate the potential shoot-through

effect at no load or low load conditions in the phaseshifted ZVS full bridge topology. Measurement

results show that the L series power MOSFETs are

more suitable for the high-voltage, high-power ZVS

converter and makes the circuit capable of operating

at higher switching frequencies.

V. REFERENCES

[l]. Milan M. Jovanovic, et al., Zero-VoltageSwitching Technique In High-Frequency Off-Line

Converters, IEEE Proceedings of Applied Power

Electronics Conference, pp. 23-32, 1988.

[2]. Leo Saro, Richard Redl, Kenneth Dierberger,

High-Voltage MOSFET Behavior in Soft-Switching

Converter: Analysis and Reliability Improvements,

International Tel-communication Conference, San

Francisco, 1998.

[3]. Hubert Aigner, et al., Improving the FullBridge Phase-shift ZVT Converter for Failure-Free

Operation Under Extreme Conditions in Welding

and Similar Applications, IEEE proceedings of

Industrial Applications Society Annual Meeting, St.

Louis, 1998.

[4]. D. Grant, HEXFET 111: A New Generation of

Power

MOSFETs,

International

Rectifier

Application Note 966A.

[ 5 ] . D.L. Blackbum, Tum-Off Failure on Power

MOSFETs,

Power

Electronics

Specialists

Conference Records, pp. 429-435, 1985.

1252

You might also like

- Arellano 2015Document6 pagesArellano 2015Sohail IrfanNo ratings yet

- IPST05 Paper044Document6 pagesIPST05 Paper044aletaifa7No ratings yet

- Technical Interview Questions For Instrumentation EngineeringDocument45 pagesTechnical Interview Questions For Instrumentation EngineeringMohamed AlmahdiNo ratings yet

- A Single DC Source Based Cascaded Hbridge 5level InverterDocument6 pagesA Single DC Source Based Cascaded Hbridge 5level InverterSohail IrfanNo ratings yet

- The Optimization of Power Dispatch For Hydro-Thermal Power SystemsDocument7 pagesThe Optimization of Power Dispatch For Hydro-Thermal Power SystemsSohail IrfanNo ratings yet

- Fall 2015 - Class Schedule Electrical & Computer EngineeringDocument1 pageFall 2015 - Class Schedule Electrical & Computer EngineeringSohail IrfanNo ratings yet

- CS610 Handouts 1 45Document155 pagesCS610 Handouts 1 45Khubbaib NaeemNo ratings yet

- LC 13 Dual SimplexDocument19 pagesLC 13 Dual SimplexSohail IrfanNo ratings yet

- Assignment 4Document3 pagesAssignment 4Sohail IrfanNo ratings yet

- LC 13 Dual SimplexDocument19 pagesLC 13 Dual SimplexSohail IrfanNo ratings yet

- Allied Telesyn at 9424t SPDocument738 pagesAllied Telesyn at 9424t SPykatiuska100% (2)

- LC 13 Dual SimplexDocument19 pagesLC 13 Dual SimplexSohail IrfanNo ratings yet

- s85 s97 Cli Ug A PDFDocument218 pagess85 s97 Cli Ug A PDFAndrew WoodNo ratings yet

- Power System EngineeringDocument5 pagesPower System EngineeringSohail IrfanNo ratings yet

- Hello To WorldDocument1 pageHello To WorldSohail IrfanNo ratings yet

- Hello To The WorldDocument1 pageHello To The WorldSohail IrfanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Westinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsDocument28 pagesWestinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsRodney PimentaNo ratings yet

- Powermos Transistors Irfp460 Avalanche Energy Rated: Features Symbol Quick Reference DataDocument7 pagesPowermos Transistors Irfp460 Avalanche Energy Rated: Features Symbol Quick Reference DataRio CandrapurwitaNo ratings yet

- Eng Cs 82181 Soft Shell Catalog 0508 82181 Soft Shell Catalog-Aav10Document232 pagesEng Cs 82181 Soft Shell Catalog 0508 82181 Soft Shell Catalog-Aav10norbertscribdNo ratings yet

- TTD 101002 eDocument30 pagesTTD 101002 eWaheed Ahmed100% (3)

- IRF7103 (Dual)Document9 pagesIRF7103 (Dual)tabassam7801No ratings yet

- Td01203013e PDFDocument12 pagesTd01203013e PDFPao CastillonNo ratings yet

- Tiristor PresspcaDocument19 pagesTiristor PresspcasebastianNo ratings yet

- Push Push VFODocument4 pagesPush Push VFOName100% (2)

- Marko Rodin Coil, Steven Mark TPU, Tom Bearden MEG, Sweet VTA (SQM), Annis&Eberly GeneratorDocument711 pagesMarko Rodin Coil, Steven Mark TPU, Tom Bearden MEG, Sweet VTA (SQM), Annis&Eberly GeneratorNiculae George Razvan100% (1)

- ISO9001、ISO14001 Certification Enterprises Main Feature: Plastic Sealed TypeDocument2 pagesISO9001、ISO14001 Certification Enterprises Main Feature: Plastic Sealed Typealphhabeta100% (1)

- D350E Series II Articulated Truck 2XW00001-UP (MACHINE) POWERED by 3406E Engine (SEBP2783 - 52) - Sistemas y ComponentesDocument4 pagesD350E Series II Articulated Truck 2XW00001-UP (MACHINE) POWERED by 3406E Engine (SEBP2783 - 52) - Sistemas y Componentescristhian_tbbNo ratings yet

- Modulo 4 b2 Ame Question Quiz Part1Document8 pagesModulo 4 b2 Ame Question Quiz Part1Angel RuizNo ratings yet

- Precision Voltage References: LT 6657 LT6658Document2 pagesPrecision Voltage References: LT 6657 LT6658Jonatan Saavedra AguirreNo ratings yet

- 08 Article 680 Pools and Similar Installations PART 1Document12 pages08 Article 680 Pools and Similar Installations PART 1Andrew RinconNo ratings yet

- Assets - Dmsdocuments - 2705 - IEC 60079 11 Ed6 2011ISH6 2019Document4 pagesAssets - Dmsdocuments - 2705 - IEC 60079 11 Ed6 2011ISH6 2019Jhon Stiven Loaiza RodriguezNo ratings yet

- High Speed Transistor Optocouplers - HP2530Document14 pagesHigh Speed Transistor Optocouplers - HP2530Lucía MitchellNo ratings yet

- Ss 30Document2 pagesSs 30vicky khanNo ratings yet

- 5204 Assign 16 ADocument6 pages5204 Assign 16 AbashabddhkNo ratings yet

- Product Data Sheet: Radwin Indoor UnitsDocument2 pagesProduct Data Sheet: Radwin Indoor UnitsPaul IdrogoNo ratings yet

- CNMC N30013Document1 pageCNMC N30013Kirk DouglasNo ratings yet

- Geep 114Document5 pagesGeep 114friendkwtNo ratings yet

- GWI529-27elec SimulatorDocument3 pagesGWI529-27elec SimulatortoolsboxNo ratings yet

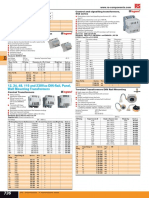

- Transformers: 12, 24, 48, 115 and 230vac DIN-Rail, Panel, Wall Mounting TransformersDocument1 pageTransformers: 12, 24, 48, 115 and 230vac DIN-Rail, Panel, Wall Mounting TransformersЛеха ЯнчукNo ratings yet

- 14F3001X00 Welding Cable Wire Wisdom US enDocument2 pages14F3001X00 Welding Cable Wire Wisdom US enzaphossNo ratings yet

- Title: 21 W Standby Power Supply Using TNY280PDocument28 pagesTitle: 21 W Standby Power Supply Using TNY280PGeorge90 AbreuNo ratings yet

- Suntech Stp280 24vd enDocument2 pagesSuntech Stp280 24vd enFifi TottiNo ratings yet

- Gamma Plus MPPT Utl Solar InverterDocument26 pagesGamma Plus MPPT Utl Solar InverterAbdul Vazeer0% (1)

- WairingDocument6 pagesWairingDiecky ChristiawanNo ratings yet

- Wireless DC Motor Speed and Direction Control Using RFDocument3 pagesWireless DC Motor Speed and Direction Control Using RFNidhin MnNo ratings yet

- TDS Biwdn 40W Led WH Ec CD P - 114416 - R1Document1 pageTDS Biwdn 40W Led WH Ec CD P - 114416 - R1Mahesh MundeNo ratings yet