Professional Documents

Culture Documents

Hydro Pneumatic Tank.

Uploaded by

bryesanggalangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro Pneumatic Tank.

Uploaded by

bryesanggalangCopyright:

Available Formats

Drinking Water Tech Tips:

Simple Control Systems – Hydropneumatic Tanks

A hydropneumatic tank contains pressurized air and water. It does not have a bladder and air is in direct

contact with the water. The compressed air acts as a cushion exerting or absorbing pressure. This type of tank

serves three main functions:

1. Delivers water within a selected pressure range so the well pump is not continuously running.

2. Prevents a pump from starting up every time there is a minor call for water from the distribution system.

3. Minimizes pressure surges (water hammer).

Well pumps and booster pumps work with pressure tanks to maintain a consistent pressure range in the

system. The pressure tank maintains the pumping-cycle rate required to avoid overheating the pump motor

and premature motor failure.

Hydropneumatic tanks work best with an air cushion of ¼ to ½ the tank capacity. This cushion decreases as

water absorbs air and the tank loses its ability to pressurize the system. To keep that from happening, there

must be an automatic way to replenish the air volume. Adding air manually is not the best way to ensure

proper pressure-tank operation over time. (See page 2 for ways to add air.)

If a pressure tank becomes waterlogged, the motor cycles on and off too frequently (more than six times

an hour). This leads to:

• Higher energy costs. It takes a lot of electricity to get a pump motor started and operating at full speed.

• Inefficiency. The deeper the well, the longer it takes the pump to move water up and out into the system.

A well pump may cycle so frequently that only a small amount of water reaches the distribution system

before it turns off again.

• Equipment failure. Frequent starts and stops can overheat the pump and lead to premature motor failure.

Air – Water Control Unit

ASME Pressure • Air compressor

Relief Valve • Water level electrode sensor

Pressure • Solid state relay

Pressure Gauge

Switch for Tank Access

Well Appurtenances Well Pump

• Well vent Opening

• Source sample tap

• Air release valve

• Pressure relief valve Pressure

• Sounding tube Tank

Sight

Tube

Water Gate

Meter Valve

Tank Drain

Surge Control Valve

Vertical Protects system from

Turbine Well pressure surges

Pump End of

Pressure Tank

Tank supports bolted to

a concrete foundation

DOH PUB. #331-380

November 2007

Two ways to add air to a pressure tank

Air

Air volume control systems feature an oil-less air compressor, a Compressor

solid-state liquid-level switch with a time delay relay, and a pressure

switch. These features may be together inside a cover mounted on

top of the tank or installed separately. Pressure Switch

(controls air

The liquid-level switch senses the water level with an Solid State compressor)

electrode suspended inside the tank. The pressure switch Relay Switch

senses the air pressure in the tank. Both sensors are set to

maintain the desired water level inside the pressure tank by

controlling when the air compressor runs.

Pressure Switch

As air dissolves into the water, (controls well pump) Water Level Sensor

the water level inside the tank rises Electrode

and air pressure falls. The compressor

begins to pump air into the tank when

Water Level

the water level rises above the electrode

and the air pressure falls below the

pressure switch setting. A time-delay circuit

in the liquid-level switch prevents rapid cycling

of the air compressor due to waves in the tank.

Air Volume Control Unit

Air charging systems maintain the proper water level by mechanically adding and releasing air into the

pressure tank. There are no sensors or switches. There are many types of air charging systems. They are

most common on older galvanized tanks.

One air charge system uses a bleeder orifice and a snifter valve on the well-pump discharge line to add air

whenever the pump cycles. The bleeder orifice allows water to drain out of the riser pipe and the snifter valve

lets air into the pipe when the pump stops. Check valves prevent water from flowing back into the well.

When the pump starts again, the air that replaced the water in the pipe between the snifter and bleeder orifice

is pushed into the tank. That air lowers the water level in the tank. As the water level drops, the float

attached to the air release valve swings downward opening the air release valve, which lets excess air out.

When the float rises to set point, the release valve closes. When the pump Air Release

Valve

starts again, the process repeats.

Float

Another air charge system uses a Schrader valve

to draw air into the line before the pressure tank.

An air release valve discharges excess air from

the tank. Water

Well Vent

When a jet pump is used, the suction line

introduces air into the tank through a snifter or

Snifter Schrader valve.

Valve Air Flowing In

Air Flowing In

Water Level For more information

Bleeder

Water Flowing Out View the following publication online at

Orifice http://www4.doh.wa.gov/dw/publications/ Schrader Valve

publications.cfm

Troubleshooting Bladder Pressure Tanks (331-342)

Call your Office of Drinking Water regional office:

Eastern Region – Spokane (509) 456-3115

Northwest Region – Kent (253) 395-6750

Southwest Region – Tumwater (360) 236-3030

You might also like

- Water Demand CalculationDocument6 pagesWater Demand CalculationValium MorphineNo ratings yet

- Sprinkler DesignDocument10 pagesSprinkler Designsk lukoNo ratings yet

- Design of Optimal Water Distribution Systems Using WaterGEMSDocument8 pagesDesign of Optimal Water Distribution Systems Using WaterGEMSKinal SoniNo ratings yet

- Silt ControlDocument34 pagesSilt ControlTaha Usama100% (1)

- Drainage and SlopesDocument42 pagesDrainage and SlopesKlenz CuraNo ratings yet

- Canal Lining ITRC Paper No. P 11-006Document3 pagesCanal Lining ITRC Paper No. P 11-006Fiaz GujjarNo ratings yet

- PSI Principals and Advantages of On-Site Sodium Hy PDFDocument33 pagesPSI Principals and Advantages of On-Site Sodium Hy PDFprabal ray100% (1)

- 16 Astral - Pool Heating 2008Document38 pages16 Astral - Pool Heating 2008drožmanićNo ratings yet

- MRP Catalogue Web PDFDocument152 pagesMRP Catalogue Web PDFbalajiNo ratings yet

- Aludecor Timber E-CatalogueDocument12 pagesAludecor Timber E-CatalogueRitwik Ashish DasguptaNo ratings yet

- Water Treatment Catalogue GuideDocument12 pagesWater Treatment Catalogue GuideJim TsikasNo ratings yet

- Ale132av4-Cc5m 01Document18 pagesAle132av4-Cc5m 01Thanh BarcaNo ratings yet

- Storage Tank Assessment SpreadsheetDocument68 pagesStorage Tank Assessment Spreadsheetdewiriya23No ratings yet

- Air Tools and Air Consumption PDFDocument13 pagesAir Tools and Air Consumption PDFNEDALNo ratings yet

- Irrigation Structures - Diversion Head Works ComponentsDocument13 pagesIrrigation Structures - Diversion Head Works Componentslakumas15No ratings yet

- 48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 7 - Fluid 1 - Flow MeasurementsDocument19 pages48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 7 - Fluid 1 - Flow Measurementssishu21No ratings yet

- Simple Methods for Water PurificationDocument206 pagesSimple Methods for Water Purificationsumitanurag100% (1)

- Earth Dam LectureDocument32 pagesEarth Dam Lecturejahid shohagNo ratings yet

- WWTFSP App.F1 Wastewater Flow ProjectionsDocument67 pagesWWTFSP App.F1 Wastewater Flow ProjectionsHuy NguyenNo ratings yet

- Rainfall Analysis 1Document64 pagesRainfall Analysis 1jojo3jNo ratings yet

- Footwear Test Results for ESD ProtectionDocument14 pagesFootwear Test Results for ESD ProtectionJenniferValleNo ratings yet

- Design of Vertical Drop Fall: Surface FlowDocument3 pagesDesign of Vertical Drop Fall: Surface FlowMohammedNo ratings yet

- Compressor House Unit-3Document199 pagesCompressor House Unit-3Priyanka BasuNo ratings yet

- PM 2017 LNT RefDocument30 pagesPM 2017 LNT Refjigyesh sharmaNo ratings yet

- Wa 726 2Document185 pagesWa 726 2Jamshed AlamNo ratings yet

- Calculating Pressures and Volumes for Horizontal Tanks in Hydro SystemsDocument5 pagesCalculating Pressures and Volumes for Horizontal Tanks in Hydro SystemsAnand TatteNo ratings yet

- NetafimDocument67 pagesNetafimxtianNo ratings yet

- SLXBobinwoundfiltersDocument1 pageSLXBobinwoundfiltersKAMALNo ratings yet

- Guidelines For Adopting Multi Use of Stormwater Management FacilitiesDocument24 pagesGuidelines For Adopting Multi Use of Stormwater Management FacilitiesMohamedNo ratings yet

- Process calculation for STP (Township and PlantDocument30 pagesProcess calculation for STP (Township and PlantKamod RaiNo ratings yet

- Permeate Line Pressure Drop CalculationsDocument2 pagesPermeate Line Pressure Drop Calculationsask.kulkarni KulkarniNo ratings yet

- Memcor UF Product Data Sheet CPII MemRackDocument2 pagesMemcor UF Product Data Sheet CPII MemRackDio MiNo ratings yet

- Preq Al Jaber Engineering Wiltz TemboDocument279 pagesPreq Al Jaber Engineering Wiltz Tembo721917114 47No ratings yet

- Specsheet 75Document2 pagesSpecsheet 75realchic100% (1)

- Sewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDocument38 pagesSewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDhruv MudgalNo ratings yet

- Hydraulic Jump Length Calculator 111205Document2 pagesHydraulic Jump Length Calculator 111205abhishek5810No ratings yet

- Electrical Load Data Sheet Site PlanDocument1 pageElectrical Load Data Sheet Site Plangag aaNo ratings yet

- IrrigationDocument4 pagesIrrigationBibek BasnetNo ratings yet

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXNo ratings yet

- Lec 5 Fire Demand & Variation in Water Consumption PDFDocument19 pagesLec 5 Fire Demand & Variation in Water Consumption PDFchyousuf75% (4)

- Inventaris Alat Medis 2020Document9 pagesInventaris Alat Medis 2020wahyuwiarsoNo ratings yet

- 39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionDocument56 pages39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionNaveen NagisettiNo ratings yet

- Chapter 1 Introduction Water Demand 71Document13 pagesChapter 1 Introduction Water Demand 71Ambu DeviNo ratings yet

- Sanitary Sewer Design StandardsDocument14 pagesSanitary Sewer Design StandardsElvi PapajNo ratings yet

- SIMPLIFIED SEWERAGE DESIGN CHARTDocument54 pagesSIMPLIFIED SEWERAGE DESIGN CHARTkartika tarmudiNo ratings yet

- BMS-CJS Final Presentation EditDocument56 pagesBMS-CJS Final Presentation Editfarwa rizviNo ratings yet

- Estimate Baghpat STP RevisedDocument23 pagesEstimate Baghpat STP Revisedankur yadavNo ratings yet

- Grit Removal & Treatment for Sustainable Grit RecyclingDocument47 pagesGrit Removal & Treatment for Sustainable Grit RecyclingRavena RemaditaNo ratings yet

- Percolation - Tank DesignDocument25 pagesPercolation - Tank DesignSanthosh Kumar Baswa100% (1)

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument13 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- Lift Station Calculation - REV2Document13 pagesLift Station Calculation - REV2Rawan Alwan ZarifNo ratings yet

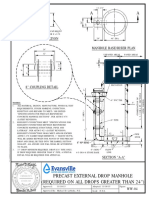

- External Drop Manhole DesignDocument1 pageExternal Drop Manhole DesignorganicspolybondNo ratings yet

- 2.3.8.a ResidentialWaterSupplyDocument30 pages2.3.8.a ResidentialWaterSupplyiuiuiooiuNo ratings yet

- Growth and Capacity Evaluation Warrenton 05072015Document16 pagesGrowth and Capacity Evaluation Warrenton 05072015Fauquier NowNo ratings yet

- Sewer Pipes and Flows in SewersDocument28 pagesSewer Pipes and Flows in SewersBalanlan PenalesNo ratings yet

- Rational Formula Q 10 C I A Area MM/HR Hectre Hectre Q 62.3732 Cum/hr Lps Pump HP Calculation PumpDocument4 pagesRational Formula Q 10 C I A Area MM/HR Hectre Hectre Q 62.3732 Cum/hr Lps Pump HP Calculation PumpBanerjee SuvranilNo ratings yet

- Tekla SoakwayDocument2 pagesTekla SoakwayBalaji Naik100% (1)

- Hydropneumatic Tank Control Systems: Drinking Water Tech TipsDocument2 pagesHydropneumatic Tank Control Systems: Drinking Water Tech TipsBlancaNo ratings yet

- Hydropneumatic Schemematics331 380Document2 pagesHydropneumatic Schemematics331 380wnewell1No ratings yet

- DKK2443 Process Instrumentation and ControlDocument50 pagesDKK2443 Process Instrumentation and ControlFaiz AimanNo ratings yet

- Water Quality Parameter Estimation in A Distribution SystemDocument12 pagesWater Quality Parameter Estimation in A Distribution SystembryesanggalangNo ratings yet

- Water Distribution Valve Topology ForDocument7 pagesWater Distribution Valve Topology ForbryesanggalangNo ratings yet

- Some Models For WaterDocument13 pagesSome Models For WaterbryesanggalangNo ratings yet

- Optimization and Capacity Expansion of A Water Distribution SystemDocument11 pagesOptimization and Capacity Expansion of A Water Distribution SystembryesanggalangNo ratings yet

- Genetic Algorithm For Optimization of Water Distribution SystemsDocument10 pagesGenetic Algorithm For Optimization of Water Distribution SystemsbryesanggalangNo ratings yet

- Sanggalang, Bryan Jay M.Document2 pagesSanggalang, Bryan Jay M.bryesanggalangNo ratings yet

- Removal of Soft Deposits From The Distribution SystemDocument10 pagesRemoval of Soft Deposits From The Distribution SystembryesanggalangNo ratings yet

- Optimization of Water Distribution SystemDocument13 pagesOptimization of Water Distribution SystembryesanggalangNo ratings yet

- Reliability Simulation of Water Distribution Systems SingleDocument9 pagesReliability Simulation of Water Distribution Systems SinglebryesanggalangNo ratings yet

- Reliability Analysis of Regional Water Distributuion SystemsDocument8 pagesReliability Analysis of Regional Water Distributuion SystemsbryesanggalangNo ratings yet

- Modified Lag Rang Ian Method For Modeling Water Quality inDocument16 pagesModified Lag Rang Ian Method For Modeling Water Quality inbryesanggalangNo ratings yet

- Optimization Algorithms of Operative ControlDocument19 pagesOptimization Algorithms of Operative ControlbryesanggalangNo ratings yet

- Fmea TableDocument18 pagesFmea TablebryesanggalangNo ratings yet

- Behavior of Tri Halo Me Thanes and Halo Acetic Acids in A DrinkingDocument16 pagesBehavior of Tri Halo Me Thanes and Halo Acetic Acids in A DrinkingbryesanggalangNo ratings yet

- Discolour at Ion in Potable Water Distribution SystemDocument11 pagesDiscolour at Ion in Potable Water Distribution SystembryesanggalangNo ratings yet

- Chapter II - Review of Related LiteratureDocument14 pagesChapter II - Review of Related Literaturebryesanggalang80% (10)

- Bio Stability Analysis For Drinking WaterDocument12 pagesBio Stability Analysis For Drinking WaterbryesanggalangNo ratings yet

- Analyzing Water Distribution Systems For Swine GrowingDocument12 pagesAnalyzing Water Distribution Systems For Swine GrowingbryesanggalangNo ratings yet

- Chapter IV - ObservationDocument8 pagesChapter IV - ObservationbryesanggalangNo ratings yet

- Chapter Iii - Study MethodologyDocument1 pageChapter Iii - Study MethodologybryesanggalangNo ratings yet

- Booster PumpDocument5 pagesBooster Pumpbryesanggalang0% (1)

- Analysis of Water Distribution Systems Using ADocument8 pagesAnalysis of Water Distribution Systems Using AbryesanggalangNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsbryesanggalangNo ratings yet

- Chapter III - Study MethodologyDocument1 pageChapter III - Study MethodologybryesanggalangNo ratings yet

- Chapter V - Analysis and DiscussionDocument2 pagesChapter V - Analysis and DiscussionbryesanggalangNo ratings yet

- Chapter I. IntroductionDocument6 pagesChapter I. IntroductionbryesanggalangNo ratings yet

- Chapter Vii - RecommendationsDocument1 pageChapter Vii - RecommendationsbryesanggalangNo ratings yet

- High Rise Structures:Plumbing Design Guidelines.Document6 pagesHigh Rise Structures:Plumbing Design Guidelines.shrikant85% (27)

- K Value of FittingsDocument4 pagesK Value of FittingsJoydip Misra100% (6)

- Galaxy NanoporeDocument11 pagesGalaxy NanoporeDeborah ShirleenNo ratings yet

- AWWA Bacterial Regrowth in Distr Sys PDFDocument368 pagesAWWA Bacterial Regrowth in Distr Sys PDFsaishankarlNo ratings yet

- 3ixso2idq334tonwmfhk0rrcDocument2 pages3ixso2idq334tonwmfhk0rrcrishikeshraj2021No ratings yet

- Chapter 1 Engineering ManagementDocument4 pagesChapter 1 Engineering ManagementGeorge Russell80% (5)

- Effect of Usage of Sinter in BOF Steelmaking As A Replacement To Iron Ore As Coolant For Thermal BalanceDocument11 pagesEffect of Usage of Sinter in BOF Steelmaking As A Replacement To Iron Ore As Coolant For Thermal BalancesomnathNo ratings yet

- PLOTINUS: On Beauty (Essay On The Beautiful)Document12 pagesPLOTINUS: On Beauty (Essay On The Beautiful)Frederic LecutNo ratings yet

- Ahmed 2022Document20 pagesAhmed 2022Mariela Estefanía Marín LópezNo ratings yet

- Estudio CarmenaDocument11 pagesEstudio CarmenaAlfredo BalcázarNo ratings yet

- Eko 75 Spare Part ListDocument23 pagesEko 75 Spare Part ListРустам Хайретдинов100% (1)

- MA 102 Tutorial Sheet No. 2 on Limits and ContinuityDocument1 pageMA 102 Tutorial Sheet No. 2 on Limits and ContinuityKanan KumarNo ratings yet

- 01 UM Nutrition Training PlanDocument11 pages01 UM Nutrition Training PlanJohn Leclair100% (2)

- Adept Conveyor Technologies Product ManualDocument32 pagesAdept Conveyor Technologies Product ManualBagus Eko BudiyudhantoNo ratings yet

- Modul Cemerlang Matematik JPN Kedah 2016 PDFDocument102 pagesModul Cemerlang Matematik JPN Kedah 2016 PDFAnna ZubirNo ratings yet

- SWZ Upgrade Points 062022Document19 pagesSWZ Upgrade Points 062022IcyAviatorNo ratings yet

- Surface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweDocument9 pagesSurface-Based Transport Model For Mixed-Size Sediment: Peter R. Wilcock, M.ASCE, and Joanna C. CroweEdwinNo ratings yet

- Kerr Injection WaxesDocument1 pageKerr Injection WaxesmarosnaxNo ratings yet

- Section 09 - Traction Electrification SystemDocument47 pagesSection 09 - Traction Electrification SystemAbu Monsur Ali100% (1)

- WK-3508F IPTV Gateway DatasheetDocument7 pagesWK-3508F IPTV Gateway DatasheetComunidad Tecnolibre.netNo ratings yet

- Aspirasi MekoniumDocument17 pagesAspirasi MekoniumimanNo ratings yet

- Epson LQ-2090Document248 pagesEpson LQ-2090Dejan StamenovNo ratings yet

- Chapter 6 Exercises (Bonds & Interest)Document2 pagesChapter 6 Exercises (Bonds & Interest)Shaheera SuhaimiNo ratings yet

- Oneccc Detection Assignment Grupo1.Ipynb - ColaboratoryDocument9 pagesOneccc Detection Assignment Grupo1.Ipynb - ColaboratoryAna VelezNo ratings yet

- Elcometer Wet-Film Gage 115 Spec SheetDocument2 pagesElcometer Wet-Film Gage 115 Spec SheetMary CasillasNo ratings yet

- John 16 33 Sweet Peace For Tried Believers - Charles SpurgeonDocument15 pagesJohn 16 33 Sweet Peace For Tried Believers - Charles Spurgeonstevel75No ratings yet

- Sony Ericsson K610i, K610m, and V630i Service ManualDocument53 pagesSony Ericsson K610i, K610m, and V630i Service ManualJane TodoroskiNo ratings yet

- Table of PenaltiesDocument2 pagesTable of PenaltiesEzekiel FernandezNo ratings yet

- Serospin Operating Manual 20100407Document19 pagesSerospin Operating Manual 20100407Verdana50% (2)

- Turbofarmer P 34.7: AustraliaDocument2 pagesTurbofarmer P 34.7: AustraliaDenis OhmakNo ratings yet

- 02 - AFT - Know Your Pump & System Curves - Part 2ADocument8 pages02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNo ratings yet