Professional Documents

Culture Documents

The Effects of Palladium, Gold, and Iron Nanoparticles As Medical Catalysis

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effects of Palladium, Gold, and Iron Nanoparticles As Medical Catalysis

Copyright:

Available Formats

IOSR Journal of Applied Chemistry (IOSR-JAC)

e-ISSN: 2278-5736.Volume 8, Issue 2 Ver. I. (Feb. 2015), PP 44-48

www.iosrjournals.org

The effects of Palladium, Gold, and Iron Nanoparticles as

Medical Catalysis

Hasan Tuhmaz Hamad

1

Thi-Qar University, College of medicine,Iraq

Abstract: Thin layers and nanoparticles of metals on or oxide surfaces are of great importance in catalysis,

sensors, and even in anticancer therapies and nanotoxicology. The applications of the metals that are studied in

this study act the one of the important techniques in the biological science and medicine. Cancer

nanotherapeutics are rapidly progressing and are being implemented to solve several limitations of

conventional drug delivery systems such as nonspecific bio distribution. To improve the bio distribution of

cancer drugs, naoparticles have been designed for optimal size and surface characteristics to increase their

circulation time in the bloodstream. We report a theoretical study of the behavior of Au, Pd and Fe

nanoparticles anchored onto -Fe2O3 substrate. By simulation of the data which is noticed in reference of

Philip R. Davies et.al and using the Matlab program with a curve fitting method to study the effected of

increasing the Au nanoparticles appear upon a growing layer of -Fe2O3 through limit time. We discuss these

results by using a curve fitting method that is a theoretical method to test the system. It is noticed that the

theoretical results are in agreement with the experimental results and this work expanded the ranges of kinetic

energy with intensity in the case of Au, Pd and Fe on -Fe2O3.

Keywords: Intensity, Binding Energy, Concentration, Temperature Effect.

I.

Introduction

The recent study of the effects of performance and structure highlights the importance of the oxidation

state of Pd on the catalyst surface. Nanogold supported on TiO2 or is the most active material for lowtemperature oxidation, and it has recently been used for other important applications such as peroxide synthesis3

and selective oxidation reactions [1,2]. Furthermore, a major problem in catalysis is the stability of

nanoparticles, which is limited at elevated temperatures because of a variety of ripening processes [3,4]. Using a

combination of STM and LEIS spectroscopy the fabrication of Au/Pd bimetallic nanoparticles supported on Fe2O3 using metal vapor deposition under ultra high vacuum. Au and Pd particles were sequentially deposited

onto the iron oxide substrate and after brief thermal treatment the two species alloyed to form AuPd coreshell

particles [2]. These supported particles could be used as models for real AuPd catalysts to explore mechanisms

which are highly active for numerous reactions [2,5]. A simple and efficient principle for nanopatterning with

wide applicability in the sub- nanometers regime is chemisorption of nanoparticles; at homogeneous substrates,

particles carrying surface charge may spontaneously self-organize due to the electrostatic repulsion between

adjacent particles. Gold surfaces modified with monolayers of functional thiols or disulfides [1] are often used

for analytical purposes, not at least for biosensor applications [3] or as models for investigation of biological

surface interactions [6]. Methods used to identify functional groups include temperature programmed

desorption (TPD) and infrared spectroscopy (IR) but the former is a rather indirect probe and IR is only reliable

for the identification of functional groups with strong transition dipoles [7]. It is possible for minority species to

dominate the infrared spectrum whilst the majority state is undetected [1,3]. Although they were able to

demonstrate the importance of the oxygen functionality at the surface the authors were unable to distinguish

between the roles of the different possible oxygen groups in the attachment of the gold. Nanoparticles could be

sintered into the substrate by gentle heat treatment prior to modification with these, giving a chemically

homogeneous, but nanostructured interface [8,9]. Using this approach, the adsorption of charge-stabilized gold

nanoparticles onto the modified surfaces is randomized, but the distance between adjacent particles will reflect

their mutual electrostatic repulsion [9]. At saturation, the particle coverage can therefore be tuned by controlling

the ionic strength of particle solution, thereby altering the Debye screening of the particles surface charges [1015]. The researchers report how such electrostatic control can be used for the deposition of nanoparticles in

gradient nanopatterns, induced by controlling the diffusion of ions into a particle solution [5].

II.

Theory

Metal oxides, in particular transition metal oxides, exhibit a wide-ranging array of properties and

phenomena [1,16]. The diverse structures adopted by the metal oxides are helpful to demonstrate the

relationship between structures and properties [1,2]. Correlation of structure and physical properties of transition

DOI: 10.9790/5736-08214448

www.iosrjournals.org

44 |Page

The effects of Palladium, Gold, and Iron Nanoparticles as Medical Catalysis

metal oxides requires an understanding of the valence electrons that bind the atoms in the solid state. The band

theory and the ligand field theory have been invoked to explain the electronic properties of transition metal

oxides [1,12]. The important properties of oxides that are of interest are magnetic, electrical, dielectric, optical,

Lewis acid/base, and redox. Oxides in heterogeneous metal catalysts facilitate well-observed phenomena such

as hydrogen [6,7]. Surface science of metal oxides has received tremendous attention during recent years. The

advent of several advanced techniques to probe their surfaces has led to a new understanding of their surface

properties and structures [17-20]. This in turn has helped catalyst scientists to tailor the properties of the

oxidized materials for appropriate applications [5-9]. In this paper I introduce the theoretical study of

nanoparticles such as Au/ -Fe2O3, Fe/ -Fe2O3and Pd/ -Fe2O3. By using the Mat-lab program with curve

fitting method, one can find results that enhance the experimental results [1,2] which can be introduced for all

cases. Au, Pd and Fe nanoparticles metals are assembled in the same substrate. A theoretical method to study

Au, Fe and Pd nanoparticle that self-assembly in the same substrate was demonstrated [2]. When using the

Matlab program to find the equation that describes the most effects of binding energy and intensity with

temperature and for a time.

In this research, we introduce the theoretical method for Matlab program and addition to introducing

the experimental results of assembled for example Au/ -Fe2O3, Fe/ -Fe2O3and Pd/ -Fe2O3 where.

The effects lead to differentiating between nanoparticles of different composition related to the

experimental strategy of Au and Pd particles with different and distinct sizes. Our theoretical results agree with

experimental data.

III.

Results and Discussion

Au Nanoparticles on -Fe2O3 : When studying the effects of increasing in the intensity and kinetic energy

together with time, we find that intensity increases with increasing the kinetic energy that increases in the limit

range. These variables agree with the experimental study [2] but I study these effects at limit ranges. The

intensity is arriving too fast increasing at critical domain. The polynomial function which describes the effect of

temperature on kinetic energy (KE) and intensity is given by the polynomial equation which is produced from

using the curve fitting to the experimental data

I 8 106 KE 4 0.029 KE 3 40 KE 2 .2.4 104 KE 5.5 10 6 ( 1 )

Where I is the intensity.

Study of the effects which result from deposition of Fe on -Fe2O3: We study the effect of concentrations

(cps) of Mo with a binding energy where we note that the binding energy arrived to critical value which

corresponding to the high value of intensity. The equation which describes the effect of the binding energy

with intensity (cts /s) unit is given by the polynomial equation which is produced from using the curve fitting to

the experimental data

I 3.510 6 KE 4 0.012 KE 3 15 KE 2 8.2 103 KE 1.7 10 6 ( 2 )

Spectrum analysis of Pd/ -Fe2O: There are many results calculated from the spectrum of Au/ -Fe2O3 for

intensity with different times and at limited values of binding energy, we note that limit range of values of

kinetic energy with high value of intensity. The equation which describes the effect of the kinetic energy with

intensity at different of times is given by:

I 8.8 107 KE 4 0.0031 KE 3 4 KE 2 2.3 103 KE 4.9 10 5 ( 3 )

The range of variation of kinetic energy and intensity with time is summarized in Table 1. Figure, 1 shows the

variation of intensity with time on Au/ -Fe2O3. Figure, 2 shows to the variation of kinetic energy and intensity

Au/ -Fe2O3.. Figure 3 represents the effect of the increasing of kinetic energy with intensity with time (1-2

minute) on Au/ -Fe2O3.

Table 1, summarizes the results of variations of kinetic energy and intensity with time at the limit ranges.

Table 2, summarizes the results of variations of binding energy with intensity at the specific values.

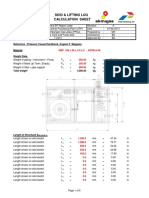

Table 1:Results of variations of kinetic energy in intensity at the limit ranges

Intensity (cts/s)

Kinetic Energy (eV)

Time (min)

1000

875

2200

1000

DOI: 10.9790/5736-08214448

www.iosrjournals.org

45 |Page

The effects of Palladium, Gold, and Iron Nanoparticles as Medical Catalysis

Table 2:Results of Variations of kinetic Energy with intensity at the Specific Values.

Intensity (cts/s)

kinetic Energy (eV)

Time (min)

2800

725

4800

900

Table 2 summarizes the results of variations of kinetic energy with intensity at the specific values. The equation

which describes the effect of the kinetic energy with intensity at different of times is given by:

I 8.8 107 KE 4 0.0031 KE 3 4 KE 2 2.3 103 KE 4.9 10 5 ( 3 )

Table 3: Results of Variations of Kinetic Energy with intensity (cts/s) at the range of Specific Values.

Intensity (cts/s)

kinetic Energy (eV)

Time (min)

1600

825

2200

900

Figure 4, shows the variation of kineticenergy with increasing the intensity, and Figure 5 shows the variation of

kinetic energy with increasing the intensity (cts/s) at different times.

Figure 1: Time variation of intensity of Au -Fe2O3 structure.

Figure 2: Variation of intensity wit kinetic energy of Au/ -Fe2O3 structure .

Figure 3: Three dimensional plot of the variables variation on the Au/

DOI: 10.9790/5736-08214448

www.iosrjournals.org

-Fe2O3 structure .

46 |Page

The effects of Palladium, Gold, and Iron Nanoparticles as Medical Catalysis

Figure 4: Variation of intensity with kinetic energy of Fe/ -Fe2O3 structure.

Figure 5: Variation of intensity with kinetic energy of Pd/ -Fe2O3 structure.

IV.

Conclusion

More applications require careful weighing of all the parameters. We conclude that the overall concepts

are better than that of the others. In this work the results summarize the effects of three types of nanoparticles,

which assembled on the same substrate (-Fe2O3). We notice that our theoretical results agree with the

experimental results and for the different range the same behaviors are noticed . When using the Matlab

program with curve fitting method, we note that Fe metal is larger affected by increasing the kinetic energy with

time when it compared to Pd and Au. The reason for this behavior of Fe is produced from the matching

between the Fe and the substrate. The simulation of these structures is lead to be predicted by the spectrum of

these structures at different ranges of variables. We observe that there are critical values of intensity which are

corresponding to the limit values of kinetic energy for each of our structures. But, the maximum intensity

values of all structures are different. One each of three types of structures (Au/ -Fe2O3) is important in the

medical catalysis where Au is used in the treatment of cancer.

Acknowledgements

I introduce my acknowledgements to my researches in my college.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

G.A. Somorjai, Introduction to Surface Chemistry and Catalysis. 1st ed., Wiley, New York, 1994, p. 667.

M. Bowker, J. J. Crouch, A. F. Carley, P. R. Davies, D. J. Morgan, G. Lalev, S. Dimov,and D. T. Pham, Encapsulation of Au

nanoparticles on a silicon wafer during thermal oxidation, Journal of Physical Chemistry C 117 (41), 2013, 21577-21582.

Davies, R. et.al, A facile route to model catalysts: the synthesis of Au@Pd core-shell nanoparticles on y-Fe2O3 (0001),

Nanoscale 5, 2013, 9018-9022.

Kwangjae Cho, XuWang, Shuming Nie, Zhuo (Georgia) Chen, and Dong M. Shin, Therapeutic Nanoparticles for Drug Delivery in

Cancer, American Association for Cancer,2008.

Bamroongwongdee, C. et al. , Fabrication of complex model oxide catalysts: Mo oxide supported on Fe3O4 (111), Faraday

Discussions 162, 2013, 201-212,

Altass, H. et al. , Enhancing surface reactivity with a noble metal. Chemical Communications 49 (74), 2013, 8223-8225.

F. Zaera, Prog. Surf. Sci. 69 (2001) 198.

D.W. Goodman, Chem. Rev. 95 (1995) 523536.

D.W. Goodman, Surf. Sci. 299/300 (1994) 837848.

F. Besenbacher, I. Chorkendorff, B.S. Clausen, B. Hammer, A.M. Molenbroek, J.K. Nrskov, and I. Stensgaard, Science 279

(1998) 19131915.

J. Greeley, J.K. Norskov, and M. Mavrikakis, Annu. Rev. Phys. Chem. 53 (2002) 319348.

DOI: 10.9790/5736-08214448

www.iosrjournals.org

47 |Page

The effects of Palladium, Gold, and Iron Nanoparticles as Medical Catalysis

[12].

[13].

[14].

[15].

[16].

[17].

[18].

[19].

[20].

[21].

I. Chorkendorff and J.W. Niemantserdriet, Concepts of Modern Catalysis and Kinetics. Wiley-VCH, Weinheim, 2003.

K.W. Kolasinski, Surface Science: Foundations of Catalysis and Nanoscience, Wiley, West Sussex, 2002. 28. J.W.

Niemantsverdriet, Spectroscopy in Catalysis. VCH, New York, 1993.

D.P. Woodruff and T.A. Delchar, Modern Techniques of Surface Science-Second Edition, Cambridge Solid State Science Series.

Cambridge University Press, Cambridge, 1994.

A.K. Santra and D.W. Goodman, Size-dependent electronic, structural, and catalytic properties of metal clusters supported on

ultrathin oxide films, in Catalysis and Electrocatalysis at Nanoparticle Surfaces, eds. A. Wieckowski, E.R. Savinova, and C.G .

Vayenas, Marcel Dekker, New York, 2003, 281309.

S.A. Chambers, Surf. Sci. Reports 39 (2000) 105180.

H.-J. Freund, H. Kuhlenbeck, and V. Staemmler, Rep. Prog. Phys. 59 (1996) 283347.

R. Franchy, Surf. Sci. Reports 38 (2000) 199294.

D.W. Goodman, J. Phys. Chem. 100 (1996) 1309013102.

D.W. Goodman, J. Catal. 216 (2003) 213222.

Q. Guo, W.S. Oh, and D.W. Goodman, Surf. Sci. 437 (1999) 4960.

DOI: 10.9790/5736-08214448

www.iosrjournals.org

48 |Page

You might also like

- Effects of Formative Assessment On Mathematics Test Anxiety and Performance of Senior Secondary School Students in Jos, NigeriaDocument10 pagesEffects of Formative Assessment On Mathematics Test Anxiety and Performance of Senior Secondary School Students in Jos, NigeriaInternational Organization of Scientific Research (IOSR)100% (1)

- Study The Changes in Al-Ahwaz Marshal Using Principal Component Analysis and Classification TechniqueDocument9 pagesStudy The Changes in Al-Ahwaz Marshal Using Principal Component Analysis and Classification TechniqueInternational Organization of Scientific Research (IOSR)No ratings yet

- Philosophical Analysis of The Theories of Punishment in The Context of Nigerian Educational SystemDocument6 pagesPhilosophical Analysis of The Theories of Punishment in The Context of Nigerian Educational SystemInternational Organization of Scientific Research (IOSR)No ratings yet

- Project Based Learning Tools Development On Salt Hydrolysis Materials Through Scientific ApproachDocument5 pagesProject Based Learning Tools Development On Salt Hydrolysis Materials Through Scientific ApproachInternational Organization of Scientific Research (IOSR)No ratings yet

- Comparison of Selected Anthropometric and Physical Fitness Variables Between Offencive and Defencive Players of Kho-KhoDocument2 pagesComparison of Selected Anthropometric and Physical Fitness Variables Between Offencive and Defencive Players of Kho-KhoInternational Organization of Scientific Research (IOSR)No ratings yet

- Youth Entrepreneurship: Opportunities and Challenges in IndiaDocument5 pagesYouth Entrepreneurship: Opportunities and Challenges in IndiaInternational Organization of Scientific Research (IOSR)100% (1)

- Development of Dacum As Identification Technique On Job Competence Based-Curriculum in High Vocational EducationDocument5 pagesDevelopment of Dacum As Identification Technique On Job Competence Based-Curriculum in High Vocational EducationInternational Organization of Scientific Research (IOSR)No ratings yet

- The Effect of Instructional Methods and Locus of Control On Students' Speaking Ability (An Experimental Study in State Senior High School 01, Cibinong Bogor, West Java)Document11 pagesThe Effect of Instructional Methods and Locus of Control On Students' Speaking Ability (An Experimental Study in State Senior High School 01, Cibinong Bogor, West Java)International Organization of Scientific Research (IOSR)No ratings yet

- Necessary Evils of Private Tuition: A Case StudyDocument6 pagesNecessary Evils of Private Tuition: A Case StudyInternational Organization of Scientific Research (IOSR)No ratings yet

- Students' Perceptions of Grammar Teaching and Learning in English Language Classrooms in LibyaDocument6 pagesStudents' Perceptions of Grammar Teaching and Learning in English Language Classrooms in LibyaInternational Organization of Scientific Research (IOSR)No ratings yet

- Geohydrological Study of Weathered Basement Aquifers in Oban Massif and Environs Southeastern Nigeria: Using Remote Sensing and Geographic Information System TechniquesDocument14 pagesGeohydrological Study of Weathered Basement Aquifers in Oban Massif and Environs Southeastern Nigeria: Using Remote Sensing and Geographic Information System TechniquesInternational Organization of Scientific Research (IOSR)No ratings yet

- Comparison of Psychological Variables Within Different Positions of Players of The State Junior Boys Ball Badminton Players of ManipurDocument4 pagesComparison of Psychological Variables Within Different Positions of Players of The State Junior Boys Ball Badminton Players of ManipurInternational Organization of Scientific Research (IOSR)No ratings yet

- Enhancing Pupils' Knowledge of Mathematical Concepts Through Game and PoemDocument7 pagesEnhancing Pupils' Knowledge of Mathematical Concepts Through Game and PoemInternational Organization of Scientific Research (IOSR)No ratings yet

- Need of Non - Technical Content in Engineering EducationDocument3 pagesNeed of Non - Technical Content in Engineering EducationInternational Organization of Scientific Research (IOSR)No ratings yet

- Child Mortality Among Teenage Mothers in OJU MetropolisDocument6 pagesChild Mortality Among Teenage Mothers in OJU MetropolisInternational Organization of Scientific Research (IOSR)No ratings yet

- Microencapsulation For Textile FinishingDocument4 pagesMicroencapsulation For Textile FinishingInternational Organization of Scientific Research (IOSR)No ratings yet

- Advancing Statistical Education Using Technology and Mobile DevicesDocument9 pagesAdvancing Statistical Education Using Technology and Mobile DevicesInternational Organization of Scientific Research (IOSR)No ratings yet

- Comparison of Explosive Strength Between Football and Volley Ball Players of Jamboni BlockDocument2 pagesComparison of Explosive Strength Between Football and Volley Ball Players of Jamboni BlockInternational Organization of Scientific Research (IOSR)No ratings yet

- Study of Effect of Rotor Speed, Combing-Roll Speed and Type of Recycled Waste On Rotor Yarn Quality Using Response Surface MethodologyDocument9 pagesStudy of Effect of Rotor Speed, Combing-Roll Speed and Type of Recycled Waste On Rotor Yarn Quality Using Response Surface MethodologyInternational Organization of Scientific Research (IOSR)No ratings yet

- Auxin Induced Germination and Plantlet Regeneration Via Rhizome Section Culture in Spiranthes Sinensis (Pers.) Ames: A Vulnerable Medicinal Orchid of Kashmir HimalayaDocument4 pagesAuxin Induced Germination and Plantlet Regeneration Via Rhizome Section Culture in Spiranthes Sinensis (Pers.) Ames: A Vulnerable Medicinal Orchid of Kashmir HimalayaInternational Organization of Scientific Research (IOSR)No ratings yet

- Comparative Effect of Daily Administration of Allium Sativum and Allium Cepa Extracts On Alloxan Induced Diabetic RatsDocument6 pagesComparative Effect of Daily Administration of Allium Sativum and Allium Cepa Extracts On Alloxan Induced Diabetic RatsInternational Organization of Scientific Research (IOSR)No ratings yet

- Application of Xylanase Produced by Bacillus Megaterium in Saccharification, Juice Clarification and Oil Extraction From Jatropha Seed KernelDocument8 pagesApplication of Xylanase Produced by Bacillus Megaterium in Saccharification, Juice Clarification and Oil Extraction From Jatropha Seed KernelInternational Organization of Scientific Research (IOSR)No ratings yet

- Core Components of The Metabolic Syndrome in Nonalcohlic Fatty Liver DiseaseDocument5 pagesCore Components of The Metabolic Syndrome in Nonalcohlic Fatty Liver DiseaseInternational Organization of Scientific Research (IOSR)No ratings yet

- Lipoproteins and Lipid Peroxidation in Thyroid DisordersDocument6 pagesLipoproteins and Lipid Peroxidation in Thyroid DisordersInternational Organization of Scientific Research (IOSR)No ratings yet

- Research Analysis On Sustainability Opportunities and Challenges of Bio-Fuels Industry in IndiaDocument7 pagesResearch Analysis On Sustainability Opportunities and Challenges of Bio-Fuels Industry in IndiaInternational Organization of Scientific Research (IOSR)No ratings yet

- A Review On Refrigerants, and Effects On Global Warming For Making Green EnvironmentDocument4 pagesA Review On Refrigerants, and Effects On Global Warming For Making Green EnvironmentInternational Organization of Scientific Research (IOSR)No ratings yet

- Factors Affecting Success of Construction ProjectDocument10 pagesFactors Affecting Success of Construction ProjectInternational Organization of Scientific Research (IOSR)No ratings yet

- Investigation of Wear Loss in Aluminium Silicon Carbide Mica Hybrid Metal Matrix CompositeDocument5 pagesInvestigation of Wear Loss in Aluminium Silicon Carbide Mica Hybrid Metal Matrix CompositeInternational Organization of Scientific Research (IOSR)No ratings yet

- Parametric Optimization of Single Cylinder Diesel Engine For Specific Fuel Consumption Using Palm Seed Oil As A BlendDocument6 pagesParametric Optimization of Single Cylinder Diesel Engine For Specific Fuel Consumption Using Palm Seed Oil As A BlendInternational Organization of Scientific Research (IOSR)No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fluid Mechanics EssayDocument2 pagesFluid Mechanics EssayKismaury Shamelle Maldonado PegueroNo ratings yet

- JEE Mains 2024 Question Paper Shift 2 27 JanDocument4 pagesJEE Mains 2024 Question Paper Shift 2 27 JanAnjali SahooNo ratings yet

- MOTOR BASES FOR INDUSTRIAL APPLICATIONSDocument8 pagesMOTOR BASES FOR INDUSTRIAL APPLICATIONSbogdanalaciNo ratings yet

- RF-Microwave PCB Design and LayoutDocument33 pagesRF-Microwave PCB Design and LayoutName100% (8)

- Chem 542 Spring2010 Lecture 3 PDFDocument45 pagesChem 542 Spring2010 Lecture 3 PDFwuachinnNo ratings yet

- Unit & DimensionsDocument10 pagesUnit & DimensionstosifNo ratings yet

- Chemical Solution Density & ViscosityDocument18 pagesChemical Solution Density & ViscosityLee JianNo ratings yet

- ELECTRON DISPLACEMENTDocument11 pagesELECTRON DISPLACEMENTNaveen VNo ratings yet

- Decrease in Level of Sound Pressure and Sound IntensityDocument1 pageDecrease in Level of Sound Pressure and Sound IntensitySreeNo ratings yet

- Daily Practice Problems Chapter Provides Accurate Physics PracticeDocument4 pagesDaily Practice Problems Chapter Provides Accurate Physics PracticePritam kumar100% (1)

- Feni: Formation and Reversal of Silicon: Egil J.M. Jahnsen July 4, 2007Document21 pagesFeni: Formation and Reversal of Silicon: Egil J.M. Jahnsen July 4, 2007Egil JahnsenNo ratings yet

- Mep365 Deadweight Tester Exp04Document4 pagesMep365 Deadweight Tester Exp04rituneshmNo ratings yet

- MSL Technical Guide 18 Resistance Measurement For ThermometryDocument5 pagesMSL Technical Guide 18 Resistance Measurement For ThermometrydlonguinhoNo ratings yet

- Tugas Ujian FIXDocument3 pagesTugas Ujian FIXNofi RahmayantiNo ratings yet

- CBSE Grade 12 Physics Project 2015: Refractive Indices of Some Common LiquidsDocument24 pagesCBSE Grade 12 Physics Project 2015: Refractive Indices of Some Common LiquidsSyed Husam100% (1)

- Technorama Hausprospekt enDocument42 pagesTechnorama Hausprospekt enSriheri DeshpandeNo ratings yet

- Effective Nuclear ChargeDocument3 pagesEffective Nuclear Chargekalloli100% (1)

- Earthquake Loads Calculation - NSCP 2015Document2 pagesEarthquake Loads Calculation - NSCP 2015Bhong LucenecioNo ratings yet

- 0600 C0050 0E Medium Voltage EbookDocument114 pages0600 C0050 0E Medium Voltage EbookasssasasNo ratings yet

- Reactive Power Compensation Using STATCOMDocument18 pagesReactive Power Compensation Using STATCOMNeha Jain100% (2)

- Plastic analysis of frame structuresDocument65 pagesPlastic analysis of frame structuresgirma kebedeNo ratings yet

- Deposition and Characterization of Copper Oxide Thin FilmsDocument5 pagesDeposition and Characterization of Copper Oxide Thin FilmsmirelamanteamirelaNo ratings yet

- Engineering Mechanics Beam ProblemsDocument16 pagesEngineering Mechanics Beam ProblemsAnupEkboteNo ratings yet

- Mwe Word Hand BookDocument34 pagesMwe Word Hand Bookdevanga1No ratings yet

- Measurement and Prediction of Densities and Viscosities of Aqueous Binary and Ternary Solutions at Temperatures From 20 To 60 °c PDFDocument42 pagesMeasurement and Prediction of Densities and Viscosities of Aqueous Binary and Ternary Solutions at Temperatures From 20 To 60 °c PDFnoviNo ratings yet

- Skid Calculation Make Up Water Tank Rev A.by AmDocument8 pagesSkid Calculation Make Up Water Tank Rev A.by AmPriyo Jati WahyonoNo ratings yet

- Optical FiberDocument4 pagesOptical FiberFaisal ShafiqueNo ratings yet

- Simulation of The Plug Assisted Thermoforming of Polypropylene Using A Large Strain Thermally Coupled Constitutive ModelDocument26 pagesSimulation of The Plug Assisted Thermoforming of Polypropylene Using A Large Strain Thermally Coupled Constitutive ModelFadi DabbitNo ratings yet

- Simulation of 3D Unsteady Multi-phase Flow in Flushing with Fake PoopDocument10 pagesSimulation of 3D Unsteady Multi-phase Flow in Flushing with Fake PoopLight HouseNo ratings yet