Professional Documents

Culture Documents

12 Maintenance Inspection

Uploaded by

dsn_sarmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 Maintenance Inspection

Uploaded by

dsn_sarmaCopyright:

Available Formats

12th North Sea Offshore Cranes &

Lifting Conference 2007

Maintenance, Inspection, Temporary

Cranes & Crane upgrades

Part 1

Part 2

Part 3

Part 4

Part 5

Maintainability of Cranes, Access to Components,

Standardisation of Component Interfaces

Condition Monitoring, Lubricant Analysis,

Oil Flow Monitoring

Data Logging/Recording/Monitoring

Analysis and Value of Recorded Data

Temporary/Mobile Cranes

What has to be considered?

Crane Upgrades

A real example

http://www.liebherr.com

Offshore Division

Version 1.0, dd. 17.04.07

Part1 Maintainability of Cranes

Maintainability

Due to more stringent rules (i.e. exhaust emissions),

increased maintenance intervals, decreased size etc.,

installed components to cranes become more and more

complex. Maintenance and repair to the component on

site has become more difficult. Special tools and specific

knowledge is required and in most cases the environment

needed can not be achieved offshore. In addition, down

time of the crane shall be kept at a minimum.

New philosophies in regards to maintainability have

therefore to be considered for the latest generation of

cranes.

http://www.liebherr.com

Offshore Division

Part1 Maintainability of Cranes

Standardise interfaces of components

I.e. Standardised instrumentation via Can-Bus of diesel engine one

plug only. Access to main components by maintenance crane allows

replacement without another crane.

Un-park

maintenance crane

Slew gearbox

replacement

Engine

replacement

Remove radiator

and hood

Lift engine to deck

http://www.liebherr.com

Offshore Division

Part1 Maintainability of Cranes

Standardise interfaces of components

Simplified and standardised interfaces allow a quick and

problem free replacement of the whole component.

I.e. Standardised winch flanges with four pins. No special

tensioning equipment required. Winch is installed to allow

exchange without major lifting equipment.

Remove bolted diagonals

http://www.liebherr.com

Remove pins from winch

flange

Replace winch

Offshore Division

Part2 Condition Monitoring

Condition Monitoring

Mainly external measuring equipment like vibration

analyses, noise analyses or oil sampling are considered

as condition monitoring.

All this monitoring is prone to failure, oil samples might be

taken from the wrong port or are not taken at all.

However, they are a tool for evaluating the condition of

any component and in some cases the only option for a in

situ evaluation.

It is therefore important to implement in line monitoring

without any interaction of the operator/user.

http://www.liebherr.com

Offshore Division

Part2 Condition Monitoring

Lubricant Analyses

Lubricant analyses are a good and simple measure for

condition monitoring but when not carefully taken a

completely wrong result can be created.

The latest control systems are offering monitoring without

any interaction of the operator/user assuring the exact

same measurement/sampling method.

I.e. In line flow monitoring, allows constant monitoring

of all hydraulic components. Together with a machine

data recorder (refer to part 3 of this presentation) a

database of the leak oil development is created.

http://www.liebherr.com

Offshore Division

Part2 Condition Monitoring

In Line Oil Flow Monitoring

The leak oil is a direct indication of wear which gives a

good and reliable indication of the current condition of all

installed hydraulic motors and pumps. No additional

measurements are required.

Principle Layout for a hydraulic flow monitoring system.

Le ak Oil Me asure me nt

(leak oil pe r minute wit h 100 bar sys tem pres sur e)

Amoun t in Li tres Per Unit

Date o f

Runni ng

Insp ection Hours

Date o f

Runni ng

Insp ection Hours

DESCRIPTI ON

Type

DESCRIPTI ON

Type

aux. hoist motor no. 1

aux. hoist motor no. 2

main hoist motor no. 1

main hoist motor no. 2

luff ing mot or

sle win g ge ar motor no . 1

sle win g ge ar motor no . 2

A2F80

8

7,5

7

6,5

6

5,5

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

DESCRIP TION

http://www.liebherr.com

A2F125

A2F90

A2F45

A2F45

Ident. No. Max . Allow able Actu al Diffe rence

Leak Oil (max .) Leak Oil

in %

Ident. No. Max . Allow able Actu al Diffe rence

Leak Oil (max .) Leak Oil

in %

510229614

2,00

0, 00% acc ep table

2,00

0, 00% acc ep table

510229714

3,00

0, 00% acc ep table

3,00

0, 00% acc ep table

2,50

0, 00% acc ep table

510229514

1,50

0, 00% acc ep table

1,50

0, 00% acc ep table

Leak Oil (max.)

aux. hoist

aux . hois t

moto r no. 1 motor no. 2

Leak Oil

main hoi s t main hois t luf fing motor slew ing gear s lew ing gear

moto r no. 1 mot or no. 2

motor no. 1 moto r no. 2

Offshore Division

Part3 Data Logger

Existing Data Logger

Limited information such as time, average weight of lift is

recorded. The information content is very limited.

date

load cycle

time start

time end

cycle time

TT.MM.JJ

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

24.03.1998

No.

0

1

2

3

4

5

6

7

8

9

10

hh:mm:ss

09:38:13

09:41:46

09:44:24

09:48:03

09:55:59

09:59:25

10:01:45

10:04:12

10:07:33

10:10:42

10:13:52

hh:mm:ss

09:39:55

09:42:41

09:45:36

09:48:23

09:57:08

10:00:35

10:02:44

10:06:02

10:09:03

10:12:03

10:14:40

hh:mm:ss

00:05:15

00:03:33

00:04:51

00:08:16

00:04:35

00:03:30

00:03:26

00:05:11

00:04:39

00:04:31

00:07:35

http://www.liebherr.com

average load

(t)

18,7

7,9

13,7

4,8

10,6

5,9

7,8

17,7

7,3

14,2

5,9

average load

max load plus dead weight utilization

22t

(t)

50

40,4

43,2

33,6

44,8

47,2

45,1

49

51,9

44

38,6

(t)

40,7

29,9

35,7

26,8

32,6

27,9

29,8

39,7

29,3

36,2

27,9

(%)

115,6

93,2

99,8

77,7

103,5

109,1

104,1

113,1

120

101,6

89,2

Offshore Division

Part3 Machine Data Recorder

Machine Data Recorder (MDR)

What is a MDR?

MDR is the permanent measurement and recording of

machinery conditions using the existing instrumentation.

The recording contains loading spectrum and maximum

values for main components of the crane.

Unlimited information which can be used for

maintenance, condition monitoring without guessing and

assumptions.

Gives data for all installed components.

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Data recorded via existing instrumentation

Master

CPU

Ethernet/RS232

CAN 1...4

http://www.liebherr.com

- All rights reserved - E. & O. E -

Offshore Division

Part3 Machine Data Recorder

Maximum Value Recorder

10 maximum values inclusive of date and time are

recorded.

At the same time when maximum value arises, also

additional parameters will be recorded to describe the

environmental field

Load Spectrum Recorder

The monitored process variable (i.e. load) is subdivided

into categories.

During operation the process variable usually passes

through several categories in which the time of stay will

be summed up.

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Maximum Value Recorder

10 maximum values inclusive of date and time are

recorded.

At the same time when maximum value arises, also

additional parameters will be recorded to describe the

environmental field

utilization MDE [%]

start time

31.05.2001

15:54:28

stop time

30.08.2001

08:44:54

date

time

utilization MDE [%] outreach LML [m] operation mode

load l.m.l. [to] slewing angle []

%MD1.73

%MD1.24

%MD1.8

%MD1.18

%MD4.18

MDutilizationMde MDoutreachLML MDoperationMode MDloadLML SDVslewingAngle

31.07.2001

10:26:01

106.81

38.70

8

55.00

131.54

05.07.2001

20:47:58

106.59

36.55

8

59.25

72.45

07.08.2001

04:43:10

106.36

42.99

8

47.48

79.97

05.07.2001

21:32:02

105.64

38.64

8

54.51

73.44

30.07.2001

09:19:53

105.49

38.96

8

53.80

64.67

26.08.2001

09:19:00

104.98

40.62

8

50.61

49.10

20.06.2001

03:29:21

104.95

38.34

8

54.74

44.33

20.06.2001

03:10:29

104.26

37.05

8

56.82

48.51

08.07.2001

00:02:42

104.14

36.95

8

56.99

96.21

09.07.2001

03:46:11

103.02

38.98

8

52.50

144.86

10 maximum values

of recorded process variable

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Load Spectrum Recorder

The monitored process variable (i.e. load) is subdivided

into categories.

During operation the process variable usually passes

through several categories in which the time of stay will

be summed up.

monitored

summed up

process variable

time shares

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Possible use of MDR data, results

Classification

according to FEM

Recorded Stress

Cycles

Stress Cycle

Spectrum

Expected Rest

Life Time of

Component

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Results from recorded data:

Power Spectrum per Speed

Power Spectrum

Speed Spectrum

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Results from recorded data:

Slewing angle versus load

Multi Dimensional

Analyses

Exact details about

Load Spectrum

Preventive

maintenance based

on real and actual

utilization/usage of

each installed

component

http://www.liebherr.com

Offshore Division

Part3 Machine Data Recorder

Summary of Machine Data Recording:

The machine data recording is permanently recording data of the

condition of the crane. The data recorded and analysed will be

supportive for the evaluation of the condition, utilisation and theoretical

calculated remaining life time of components.

The data recorded supports and is used for

establishing major maintenance and service intervals according

to FEM, DIN, BS or equivalent standards

establishing of strategic and preventative maintenance

remaining life time calculations

analyses of crane data, i.e. heavy load and overload situations

http://www.liebherr.com

- All rights reserved - E. & O. E -

Offshore Division

Part4 Temporary Cranes

Temporary/Mobile Cranes used offshore! What has to be considered?

In the recent past, we have been approached more and more to use mobile/crawler

cranes as temporary lifting aids offshore.

However there is a big

difference between such a

standardised land based

machine compared with an

offshore crane.

Since the offshore standards

have become more and more

stringent, many points have to

be considered before such a

crane can be used offshore.

http://www.liebherr.com

Offshore Division

Part4 Temporary Cranes

Rough comparison

Offshore Cranes

Land based mobile/crawler crane

- Certified material and welding

- Material certification not traceable

- Failure Mode Charts required

- Free standing machine not connected

to platform structure

- AOPS/MOPS required

speed not

- AOPS/MOPS not installed, hoisting

sufficient

- Big cabins with specific access

requirements

- Small cabins used, required exits and

access size not according to offshore

rules

- Emergency lowering required

- Emergency Lowering not installed

- Dynamic load charts considering

offshore wind speeds, off- and side

leads and heel/trim considered

- Land based load charts only

- Emission standards

- New machines will fulfil required

emission standards, but certification

is generally not available

http://www.liebherr.com

Offshore Division

Part4 Temporary Cranes

Other issues

The maximum allowed deck loads to be considered, crawlers

and other free standing machines are generally quite heavy

(counter weight). Edge loads implemented to the deck are

therefore quite high which requires a heavy structure

distributing the forces to the deck.

Cabin is positioned very low which causes many blind lifts.

For cranes designed for an onshore environment, corrosion

protection has to be specifically checked (i.e. slew pinions

outside).

Conclusion

Based on the above, a lot of effort is required to allow using

a crawler/mobile crane for an offshore application (off site

lifts), still requiring a lot of compromises. In many cases it is

more practical to use an offshore crane on a suitable frame

or a temporary pedestal as a temporary solution.

The minimum component weight for the installation has been

found to be similar for both offshore and crawler/mobile

cranes.

http://www.liebherr.com

Offshore Division

Part5 Crane upgrade

Why to upgrade an existing crane:

Changes of requirements

Higher reliability

Unavailability of spare parts (obsolete)

Shorter delivery time as a new crane

Difficulties replacing entire machine (restricted lifting aids, access, etc.)

It is more cost efficient (existing crane in very good condition, crane is very big, etc.)

Possible upgrades:

Power pack

Control system

Load Indicator / Moment Limiter

Increase of Lifting Capacity

Upgrade of man riding capability

Upgrade to suite new rules

Boom extension

More speed

http://www.liebherr.com

Offshore Division

Part5 Crane upgrade

Basis of such a Project:

Review/Availability of Crane Documentation

Review of requirements/owners

specification/scope of work

Crane survey (if required)

Example:

Crane Model:

Capacity:

Monarch 6032

21,8to at 8m, 2-fall operation

Requirements:

Replace of existing winches with wet running

drive splines and additional brakes

Install a new hydraulic open loop system

Install a new LML/SLI (Mipeg 2000 Type)

Install new electrics as required (Including winch

rotation indicators)

http://www.liebherr.com

Offshore Division

Part5 Crane upgrade

Requirements:

Replace hoisting and luffing winch against new winch

New winch with

wet running drive splines

additional brakes (suitable for man riding)

winch frame

New Winch

Existing Winch

http://www.liebherr.com

Offshore Division

Part5 Crane upgrade

Requirements:

Install a new hydraulic open loop system for hoisting and luffing circuit and a separate

closed loop for the slewing circuit

New pumps and hydraulic motors

New radiator and filtration system

New Joysticks

Use existing tank and under floor piping from tank to pumps

http://www.liebherr.com

Offshore Division

Part5 Crane upgrade

Requirements:

Install a new LML/SLI

Mipeg 2000 recording

New load cell and angle sensor

New rope sheave to suite new load cell

Install new electrics

Winch rotation indicators

Control panel

http://www.liebherr.com

Offshore Division

Thank you for your attention.

http://www.liebherr.com

Offshore Division

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Crane Safety and Awareness: Internal Use OnlyDocument99 pagesCrane Safety and Awareness: Internal Use Onlydsn_sarmaNo ratings yet

- Understanding The TaskDocument6 pagesUnderstanding The Taskdsn_sarmaNo ratings yet

- Don't Gamble With Your Lifting Equipment: LMM LMP RCSDocument78 pagesDon't Gamble With Your Lifting Equipment: LMM LMP RCSdsn_sarma0% (1)

- Chain Inspection & MaintenanceDocument22 pagesChain Inspection & MaintenanceRajesh Kumar ChaubeyNo ratings yet

- Kriskoberg Settingupforsuccess4 151001175717 Lva1 App6892Document75 pagesKriskoberg Settingupforsuccess4 151001175717 Lva1 App6892dsn_sarma100% (1)

- Osha 3146Document48 pagesOsha 3146s sanjaiNo ratings yet

- Elevator Rope Catalogue PDFDocument24 pagesElevator Rope Catalogue PDFdsn_sarmaNo ratings yet

- Wire Rope Install GuideDocument32 pagesWire Rope Install GuideSayed Kassar100% (2)

- Personal Fall Protection Equipment - Personal Fall Protection Systems-BS en 363-2008Document20 pagesPersonal Fall Protection Equipment - Personal Fall Protection Systems-BS en 363-2008usuarionovodoscribd100% (1)

- Elevator Rope CatalogueDocument184 pagesElevator Rope Cataloguedsn_sarmaNo ratings yet

- Elevator Rope CatalogueDocument24 pagesElevator Rope CataloguejaydeepNo ratings yet

- Crane Safety and Awareness: Internal Use OnlyDocument99 pagesCrane Safety and Awareness: Internal Use Onlydsn_sarmaNo ratings yet

- Formula Sheet Applied Mechanics Design PDFDocument11 pagesFormula Sheet Applied Mechanics Design PDFdsn_sarmaNo ratings yet

- Mobile and Locomotive Cranes: March 2014 Draft RevisionsDocument46 pagesMobile and Locomotive Cranes: March 2014 Draft RevisionsJuan Marcos SellarésNo ratings yet

- Verif EPI Bloqueur Procedure EN PDFDocument6 pagesVerif EPI Bloqueur Procedure EN PDFdsn_sarmaNo ratings yet

- IOSH Mobile Cranes Dec 2011Document52 pagesIOSH Mobile Cranes Dec 2011Hussein BeqaiNo ratings yet

- Pad Eye Calculation AllDocument3 pagesPad Eye Calculation Alldsn_sarmaNo ratings yet

- Som PDFDocument195 pagesSom PDFSonu Kumar100% (1)

- Launch Event 18th March SlidesDocument33 pagesLaunch Event 18th March SlidesimmortalwortelNo ratings yet

- Demag - Franna Risk Assessment PDFDocument35 pagesDemag - Franna Risk Assessment PDFdsn_sarmaNo ratings yet

- Verif EPI IDS IDL RIG Procedure enDocument5 pagesVerif EPI IDS IDL RIG Procedure endsn_sarmaNo ratings yet

- Verif Epi Ids Idl Rig Suivi enDocument1 pageVerif Epi Ids Idl Rig Suivi enDimasDianaFerreiraNo ratings yet

- Kriskoberg Settingupforsuccess4 151001175717 Lva1 App6892Document75 pagesKriskoberg Settingupforsuccess4 151001175717 Lva1 App6892dsn_sarma100% (1)

- CP 0n SLO in The Workplace-Lifting Plan - 6 Slides Per Page - R2Document6 pagesCP 0n SLO in The Workplace-Lifting Plan - 6 Slides Per Page - R2s_bharathkumarNo ratings yet

- SFD and BMDDocument278 pagesSFD and BMDRama KumarNo ratings yet

- Stainless Edition 3 PDFDocument137 pagesStainless Edition 3 PDFdsn_sarmaNo ratings yet

- Safety Assessment en 13001-3-2Document8 pagesSafety Assessment en 13001-3-2Anonymous MahXzLfNo ratings yet

- INDG339 Thorough Examination & Testing of LiftsDocument5 pagesINDG339 Thorough Examination & Testing of LiftsDavid GeeNo ratings yet

- KAHRAMAA RegulationsDocument126 pagesKAHRAMAA RegulationsJoey Magdaraog100% (2)

- Moving Loads in Structural Dynamics of Cranes: Bridging The Gap Between Theoretical and Practical ResearchesDocument7 pagesMoving Loads in Structural Dynamics of Cranes: Bridging The Gap Between Theoretical and Practical Researchesdsn_sarmaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fce Speaking TipsDocument28 pagesFce Speaking TipsAnonymous fLpGQVv100% (2)

- DTC 5618Document20 pagesDTC 5618Gajaram SutharNo ratings yet

- Completion CertificateDocument9 pagesCompletion CertificateakinladekingsleyNo ratings yet

- Microsoft Word - Exercise 3 Subsea P&PDocument5 pagesMicrosoft Word - Exercise 3 Subsea P&PKRNo ratings yet

- Russian Codes: Catalog of Regulations Available To OrderDocument2 pagesRussian Codes: Catalog of Regulations Available To OrderHpafin54No ratings yet

- 3M Scotchkote - Custom Coating GuideDocument16 pages3M Scotchkote - Custom Coating GuideUgoRibeiroNo ratings yet

- Slide Chooser PDFDocument2 pagesSlide Chooser PDFArchana LenkaNo ratings yet

- APL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResDocument48 pagesAPL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResarrsshaNo ratings yet

- Correctos Calculos en Blow DownDocument4 pagesCorrectos Calculos en Blow Downroberdani12100% (2)

- Jobs Movie ReviewDocument2 pagesJobs Movie ReviewSaleh RehmanNo ratings yet

- Specification For Foamed Concrete: by K C Brady, G R A Watts and Ivi R JonesDocument20 pagesSpecification For Foamed Concrete: by K C Brady, G R A Watts and Ivi R JonesMaria Aiza Maniwang Calumba100% (1)

- Sony Blitz h36 - ManualDocument212 pagesSony Blitz h36 - ManualBohorc Ivica JerryNo ratings yet

- CHAPTER 2 Eff Comm ModelsDocument9 pagesCHAPTER 2 Eff Comm ModelsSubhash SoniNo ratings yet

- Comparative Analysis of Wear Rate of Coated Hss Tool and Non-Coated Hss Tool by Using Cr-Zn-NiDocument21 pagesComparative Analysis of Wear Rate of Coated Hss Tool and Non-Coated Hss Tool by Using Cr-Zn-Nithai avvaiNo ratings yet

- Pumps: Vane Type Single PumpsDocument2 pagesPumps: Vane Type Single PumpsFernando SabinoNo ratings yet

- Synopsis On Turing MachineDocument4 pagesSynopsis On Turing MachineVivek MishraNo ratings yet

- Hot Products 2014Document8 pagesHot Products 2014inclumarhNo ratings yet

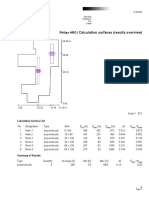

- Calculation Surfaces (Results Overview) : Philips HRODocument4 pagesCalculation Surfaces (Results Overview) : Philips HROsanaNo ratings yet

- Document 1Document14 pagesDocument 1bismarckandresNo ratings yet

- Assessing The Impact of Premier Information Systems Research OverDocument20 pagesAssessing The Impact of Premier Information Systems Research OvergasibuteaNo ratings yet

- Mals-11, Family Readiness Newsletter, July 2011, The Devilfish TidesDocument9 pagesMals-11, Family Readiness Newsletter, July 2011, The Devilfish TidesDevilfish FRONo ratings yet

- Assignment 3 - 2 Microcontrollers With DatasheetsDocument2 pagesAssignment 3 - 2 Microcontrollers With Datasheetsapi-42328551276% (45)

- Plasma TV SMPS TroubleshoutingDocument5 pagesPlasma TV SMPS TroubleshoutingmindjokerNo ratings yet

- 01-RH124 Red Hat System Administration IIDocument4 pages01-RH124 Red Hat System Administration IIpimentel-diogo2056No ratings yet

- Acer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07aDocument143 pagesAcer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07acvotechnicalsNo ratings yet

- Atlas Bradford (Ver03-Apr05)Document8 pagesAtlas Bradford (Ver03-Apr05)Gabriel IbarraNo ratings yet

- Company in India" DTDC Constantly Endeavours To Meet & Exceed Customers'Document7 pagesCompany in India" DTDC Constantly Endeavours To Meet & Exceed Customers'Vinod KumarNo ratings yet

- Materi 1 - Analisis SinyalDocument17 pagesMateri 1 - Analisis SinyalUsmanNo ratings yet

- Manual Safety Relays 3SK2 en-USDocument352 pagesManual Safety Relays 3SK2 en-USKarina Ospina100% (3)

- Manual de Partes LDW1003 (6B01E0)Document54 pagesManual de Partes LDW1003 (6B01E0)Enrique AssmannNo ratings yet