Professional Documents

Culture Documents

Machine Room

Uploaded by

Ronnie De Joya AguirreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Room

Uploaded by

Ronnie De Joya AguirreCopyright:

Available Formats

Profis Anchor 2.4.

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

SAUDI TECHNICAL LIMITED

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

NEW DATA CENTER

6/2/2014

Specifier's comments:

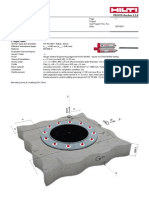

1 Input data

Anchor type and diameter:

KWIK HUS-EZ (KH-EZ) 1/2 (3)

Effective embedment depth:

hef,act = 55 mm, hnom = 76 mm

Material:

Carbon Steel

Evaluation Service Report:

ESR-3027

Issued I Valid:

8/1/2012 | 12/1/2013

Proof:

design method ACI 318-11 / Mech.

Stand-off installation:

eb = 0 mm (no stand-off); t = 10 mm

Anchor plate:

lx x ly x t = 200 mm x 200 mm x 10 mm; (Recommended plate thickness: not calculated)

Profile:

HP shape (AISC); (L x W x T x FT) = 200 mm x 200 mm x 9 mm x 15 mm

Base material:

uncracked concrete, 5000, fc' = 5000 psi; h = 10668 mm

Installation:

hammer drilled hole, installation condition: dry

Reinforcement:

tension: condition B, shear: condition B; no supplemental splitting reinforcement present

edge reinforcement: none or < No. 4 bar

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.3

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

SAUDI TECHNICAL LIMITED

|

2

NEW DATA CENTER

6/2/2014

2 Load case/Resulting anchor forces

Load case: Design loads

y

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

1

0.000

15.000

0.000

2

0.000

15.000

0.000

max. concrete compressive strain:

- []

max. concrete compressive stress:

- [N/mm2]

resulting tension force in (x/y)=(0/0):

0.000 [kN]

resulting compression force in (x/y)=(0/0): 0.000 [kN]

Shear force y

-15.000

-15.000

x 2

3 Tension load

Load Nua [kN]

N/A

Capacity fNn [kN]

N/A

Utilization bN = Nua/fNn

N/A

Status

N/A

Pullout Strength*

N/A

N/A

N/A

N/A

Concrete Breakout Strength**

N/A

N/A

N/A

N/A

Steel Strength*

* anchor having the highest loading

**anchor group (anchors in tension)

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.3

www.hilti.us

Page:

Project:

Sub-Project I Pos. No.:

Date:

SAUDI TECHNICAL LIMITED

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

3

NEW DATA CENTER

6/2/2014

4 Shear load

Load Vua [kN]

15.000

Steel Strength*

Steel failure (with lever arm)*

Pryout Strength**

Utilization bV = Vua/fVn

61

Status

OK

N/A

N/A

N/A

N/A

30.000

32.631

92

OK

N/A

N/A

N/A

N/A

Concrete edge failure in direction **

* anchor having the highest loading

Capacity fVn [kN]

24.674

**anchor group (relevant anchors)

4.1 Steel Strength

Vsa

= ESR value

f Vsteel Vua

refer to ICC-ES ESR-3027

ACI 318-11 Table D.4.1.1

Variables

n

1

Ase,V [mm2]

104

futa [N/mm2]

775.94

fsteel

0.600

f Vsa [kN]

24.674

Calculations

Vsa [kN]

41.124

Results

Vsa [kN]

41.124

Vua [kN]

15.000

4.2 Pryout Strength

Vcpg

= kcp

[(AA ) y

Nc

ec,N

Nc0

yed,N yc,N ycp,N Nb

ACI 318-11 Eq. (D-41)

f Vcpg Vua

ANc see ACI 318-11, Part D.5.2.1, Fig. RD.5.2.1(b)

ANc0 = 9 h2ef

1

2 e'N 1.0

yec,N =

1+

3 hef

ca,min

=

0.7

+

0.3

1.0

yed,N

1.5hef

ca,min 1.5hef

1.0

ycp,N = MAX c , c

ac

ac

1.5

'

Nb

= kc la fc hef

)

)

ACI 318-11 Table D.4.1.1

ACI 318-11 Eq. (D-5)

ACI 318-11 Eq. (D-8)

ACI 318-11 Eq. (D-10)

ACI 318-11 Eq. (D-12)

ACI 318-11 Eq. (D-6)

Variables

kcp

1

hef [mm]

55

ec1,N [mm]

0

ec2,N [mm]

0

ca,min [mm]

yc,N

1.000

cac [mm]

93

kc

27

la

1.000

f'c [psi]

5000

ANc0 [mm2]

27091

yec1,N

1.000

yec2,N

1.000

yed,N

1.000

fconcrete

0.700

f Vcpg [kN]

32.631

Vua [kN]

30.000

Calculations

ANc [mm2]

46842

Results

Vcpg [kN]

46.615

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

ycp,N

1.000

Nb [kN]

26.960

Profis Anchor 2.4.3

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

SAUDI TECHNICAL LIMITED

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

NEW DATA CENTER

6/2/2014

5 Warnings

To avoid failure of the anchor plate the required thickness can be calculated in PROFIS Anchor. Load re-distributions on the anchors due to

elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be sufficiently stiff, in order not to be deformed

when subjected to the loading!

Condition A applies when supplementary reinforcement is used. The factor is increased for non-steel Design Strengths except Pullout

Strength and Pryout strength. Condition B applies when supplementary reinforcement is not used and for Pullout Strength and Pryout

Strength. Refer to your local standard.

Refer to the manufacturer's product literature for cleaning and installation instructions.

Checking the transfer of loads into the base material and the shear resistance are required in accordance with ACI 318 or the relevant

standard!

Hilti post-installed anchors shall be installed in accordance with the Hilti Manufacturer's Printed Installation Instructions (MPII). Reference

ACI 318-11, Part D.9.1

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.3

www.hilti.us

5

NEW DATA CENTER

Page:

Project:

Sub-Project I Pos. No.:

Date:

SAUDI TECHNICAL LIMITED

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

6/2/2014

6 Installation data

Anchor plate, steel: Anchor type and diameter: KWIK HUS-EZ (KH-EZ), 1/2 (3)

Profile: HP shape (AISC); 200 x 200 x 9 x 15 mm

Installation torque: 0.061 kNm

Hole diameter in the fixture: df = 16 mm

Hole diameter in the base material: 13 mm

Plate thickness (input): 10 mm

Hole depth in the base material: 86 mm

Recommended plate thickness: not calculated

Minimum thickness of the base material: 121 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

y

40

120

Coordinates Anchor mm

Anchor

1

2

x

-60

60

y

0

0

c-x

-

c+x

-

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

40

100

100

100

100

100

100

Profis Anchor 2.4.3

www.hilti.us

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

SAUDI TECHNICAL LIMITED

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

NEW DATA CENTER

6/2/2014

7 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

You might also like

- Amazon - USPS Sunday DealDocument48 pagesAmazon - USPS Sunday DealMarla Barbot50% (2)

- Affidavit of Redeem MortgageDocument4 pagesAffidavit of Redeem MortgageDan Just DumoNo ratings yet

- 1 Input Data: WWW - HiltiDocument5 pages1 Input Data: WWW - HiltiCibotaru MihaiNo ratings yet

- Slavery PamphletDocument41 pagesSlavery PamphletCassianoPereiradeFariasNo ratings yet

- HILTI Wedge Anchor DBZ Submittal-MS-01-59Document33 pagesHILTI Wedge Anchor DBZ Submittal-MS-01-59Ghayas JawedNo ratings yet

- Hilti - Profis Anchor Design Report 594Document5 pagesHilti - Profis Anchor Design Report 594Madhu GuptaNo ratings yet

- South Africa Income Tax - Exemptions PBODocument8 pagesSouth Africa Income Tax - Exemptions PBOmusvibaNo ratings yet

- 1 Input Data: Profis Anchor 2.2.4Document6 pages1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Din en Iso 15976Document8 pagesDin en Iso 15976Davi Soares BatistaNo ratings yet

- Comprehensive Topics With AnsDocument14 pagesComprehensive Topics With AnsGrace Corpo100% (3)

- The Attorney-General of Israel v. EichmannDocument2 pagesThe Attorney-General of Israel v. EichmannJD Ballos100% (2)

- Number: CIPT Passing Score: 800 Time Limit: 120 Min File Version: 1Document30 pagesNumber: CIPT Passing Score: 800 Time Limit: 120 Min File Version: 1Mohamed Fazila Abd RahmanNo ratings yet

- Cbydp ResolutionDocument2 pagesCbydp ResolutionJan Alleana Mayo FernandezNo ratings yet

- Anchor Presentation Hilti 2011 PDFDocument8 pagesAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- DetailsDocument28 pagesDetailsNeerajNo ratings yet

- Human Rights Project, 2018Document25 pagesHuman Rights Project, 2018Vishal Jain100% (3)

- VM PresentationDocument29 pagesVM Presentationoshin charuNo ratings yet

- Questions Regarding The Dar Rail ProjectDocument10 pagesQuestions Regarding The Dar Rail ProjectEvarist ChahaliNo ratings yet

- Hollow CoreDocument41 pagesHollow Corepaulo_arrieiroNo ratings yet

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981No ratings yet

- Quinto Vs ComelecDocument3 pagesQuinto Vs ComelecEthan ZacharyNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inpudumaiNo ratings yet

- SAMPLE HILTI SolutionDocument6 pagesSAMPLE HILTI SolutionJester AbucayNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document5 pages1 Input Data: Profis Anchor 2.5.2jasekan.dcNo ratings yet

- 290mm Thick Slab and 540mm EcenDocument6 pages290mm Thick Slab and 540mm EcenihpeterNo ratings yet

- H 200mm Thick Slab - Pa2Document6 pagesH 200mm Thick Slab - Pa2ihpeterNo ratings yet

- Kempinski Hilti Rc-ODocument6 pagesKempinski Hilti Rc-OsobhiNo ratings yet

- Canopy M16 HIT-RE500Document5 pagesCanopy M16 HIT-RE500marchus09No ratings yet

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 pagesPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007No ratings yet

- Rowad Debugging MachineDocument6 pagesRowad Debugging MachineRonnie De Joya AguirreNo ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- Connection d01 1Document6 pagesConnection d01 1Win ThanNo ratings yet

- 6x12 BaseDocument2 pages6x12 Basejmwalker90No ratings yet

- Hilti AnchorDocument6 pagesHilti AnchorantonioNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanNo ratings yet

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15No ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- B3L01 - Detail 1Document7 pagesB3L01 - Detail 1vikramjain66No ratings yet

- 1 Input Data: Profis Anchor 2.6.0Document2 pages1 Input Data: Profis Anchor 2.6.0Collin NguNo ratings yet

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguNo ratings yet

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- Hilti Connection ReportDocument7 pagesHilti Connection ReportFrancisco BonillaNo ratings yet

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocument5 pagesPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiNo ratings yet

- 250x16 Shs Column Base - Pa2123Document5 pages250x16 Shs Column Base - Pa2123ihpeterNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 78Document1 page4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitNo ratings yet

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarNo ratings yet

- PROFIS Anchor 2.0.7Document4 pagesPROFIS Anchor 2.0.7Miky CastenNo ratings yet

- ReportDocument2 pagesReportpravincs_007No ratings yet

- Anchor Bolt PDFDocument7 pagesAnchor Bolt PDFRonnie Albert MonteroNo ratings yet

- Anchor Top Section - Pa2Document2 pagesAnchor Top Section - Pa2albertNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument2 pages1 Input Data: WWW - Hilti.co - UkkarlrossmannNo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- ETV Block 9 (Pressure)Document16 pagesETV Block 9 (Pressure)Sibi SamNo ratings yet

- Check For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)Document3 pagesCheck For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)ARYANo ratings yet

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 pagesHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument3 pages1 Input Data: WWW - Hilti.co - UkshoebNo ratings yet

- 1 Input Data: Profis Anchor 2.8.5Document1 page1 Input Data: Profis Anchor 2.8.5cherian johneyNo ratings yet

- Channel at End of SlabDocument10 pagesChannel at End of SlabOecoep IteemNo ratings yet

- PES Hilti M10 HSA ReportDocument4 pagesPES Hilti M10 HSA ReportCollin NguNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 74Document1 page4597 AAB SC 07 Addendum 2 R0v0 74danieldumapitNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Landlord/Tenant BasicsDocument48 pagesLandlord/Tenant BasicsAlva ApostolNo ratings yet

- Information Management Roles and Responsibilities v200 PublishDocument13 pagesInformation Management Roles and Responsibilities v200 PublishGebreegziabher TeamratNo ratings yet

- Osterhoudt v. Regional Scuba - Decision & Order On Summary Judgment 08-13-2014Document4 pagesOsterhoudt v. Regional Scuba - Decision & Order On Summary Judgment 08-13-2014dgclawNo ratings yet

- GST Invoice: SL No. 1 2.000 KG. 2 2.000 KGDocument2 pagesGST Invoice: SL No. 1 2.000 KG. 2 2.000 KGDNYANESHWAR PAWARNo ratings yet

- E Commerce Notes Chapter 5-10Document5 pagesE Commerce Notes Chapter 5-10Taniya Bhalla100% (1)

- Client Manual Consumer Banking - CitibankDocument29 pagesClient Manual Consumer Banking - CitibankNGUYEN HUU THUNo ratings yet

- 09.D. Gauthier - The Initial Bargaining Position (p.194)Document360 pages09.D. Gauthier - The Initial Bargaining Position (p.194)Iss Criss100% (1)

- Alen Breathe Smart Air Purifier ManualDocument11 pagesAlen Breathe Smart Air Purifier ManualDustin HoangNo ratings yet

- An Opinion Article (CounterfeitingDocument1 pageAn Opinion Article (CounterfeitingYousra HasniNo ratings yet

- 16 How Well Am I Doing Financial Statement Analysis Compatibility ModeDocument41 pages16 How Well Am I Doing Financial Statement Analysis Compatibility ModeVinluan Jerome100% (1)

- FRQ 1999 - 2011asdDocument8 pagesFRQ 1999 - 2011asdmapleking24No ratings yet

- DBRS Rating ScaleDocument1 pageDBRS Rating ScaleJonathan OrdóñezNo ratings yet

- Filipinas Synthetic Fiber Corporation vs. CA, Cta, and CirDocument1 pageFilipinas Synthetic Fiber Corporation vs. CA, Cta, and CirmwaikeNo ratings yet

- Moot Problem-18 PDFDocument3 pagesMoot Problem-18 PDFbhupendra barhat100% (2)

- Melanin What Makes Black People Black! by Llaila Afrika PDFDocument37 pagesMelanin What Makes Black People Black! by Llaila Afrika PDFjeyserenity100% (25)

- Business Plan AluminiumDocument11 pagesBusiness Plan AluminiumSaravanakumar SaravanaNo ratings yet