Professional Documents

Culture Documents

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

Uploaded by

Kishore KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

Uploaded by

Kishore KumarCopyright:

Available Formats

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

1 of 7

http://www.procentec.com/faq/profibus/

PROCENTEC

Home

Training

Service and support

Products

Frequently Asked PROFIBUS Ques ons

Your contacts for support

Troubleshoo ng and Commissioning

Installa on and Cabling

PROFIBUS DP

PROFIBUS PA

Product Development and Cer ca on

Others

Troubleshoo ng and Commissioning

What can I do with an oscilloscope?

With the oscilloscope the signal quality of the data communica on can be veried. By inspec ng

the signals al kinds of problems can be iden ed, like: short-circuits, wire breaks, missing

termina on, extra termina on, EMC and bad electrical interfaces in the devices. Handling the

oscilloscope requires some training, but this will be nothing compared to me and money you safe

during troubleshoo ng and commissioning.

Elmer

Joost

Elco

Tel.: +31-174-671800

support@procentec.com

What happens if the PROFIBUS cable has a short-circuit?

A short-circuit in the PROFIBUS cable will in most cases disturb the data communica on in the

par cular segment. The devices in that area will NOT get damaged! The short-circuit can easily be

detected with an oscilloscope and even the distance to the problem point. If the end-user wants to

keep the installa on running during a short-circuit he can pick the following solu ons:

Install a redundant system.

Divide the installa on in more parallel segments coupled by repeaters, OLMs or ProHubs.

Install the cable in secured cable trays.

Why are termina on problems the most common fault?

A lot of people are aware that termina on has to be powered and ac vated at both ends of the

cable. What they do not know, is that it has to be ac vated again when you are using repeaters,

OLMs or Prohubs. Every segment has to be terminated! This o en slips in when people are using

lots of bre op c and there is only a short length of copper cable in the cabinets. Even this short

cable has to be terminated at both ends.

Which tools do you need for troubleshoo ng a running PROFIBUS installa on?

There are 2 basic tools which are absolutely necessary! You need a bus analyzer to verify

the protocol quality and an oscilloscope to verify the signal quality. With these tools

combined you can nd 99 % of all errors. ProTrace 2 is a Combi-Analyzer that has both tools

integrated. The mul -meter is NOT useable for signal analysis! It will only be used to check a

connec on between 2 points.

ProTrace

Installa on and Cabling

What is the story about pin-5 of the M12 connector (Shield)? Is it used or not?

The current situa on is that pin 5 shall NOT be used anymore as Shield pin! The thread of the M12

connectors has to carry the shield. In the past pin 5 was used. But, this did not protect the

PROFIBUS signals well enough due to pig-tails and ferrules. The shield should be covering the wires

and not be buried in the wires (A-B line). The current diculty is that s ll lots of connec on

materials out there are based on pin 5. The user has to verify this, because connec on materials are

not cer ed.

Can PROFIBUS repeaters be used in PROFIsafe and MPI networks?

YES, MPI is using PROFIBUS FDL telegrams with its own user data implementa on and PROFIsafe is

concentrated in the data area of PROFIBUS DP telegrams. Every standard PROFIBUS repeater and

bre op c coupler can interpret and forward these telegrams. Also the cabling rules are the same

for PROFIsafe and MPI.

VIDEO

1/29/2015 11:33 PM

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

2 of 7

http://www.procentec.com/faq/profibus/

I am using a Busterminal with non-Siemens devices, but it does not work. What am I doing

wrong?

A Busterminal is a very simple repeater that consumes +90 mA power supply from the DB9

connector of the a ached device (5V from pin 5 and 6). Lots of devices cannot exceed 10 mA,

because the power supply on the DB9 is ini ally implemented to solely provide power to an external

termina on (even with cer ed devices). Please check the manual of the Busterminal. It should

contain a list of devices that can be used with this product. Of course, these are only the devices

from this manufacturer.

Will the PROFIBUS plugs with diagnos c LEDs have inuence on the busload?

The input resistance of the diagnos c plugs is approx. 1,5..2,0 MOhm (analog comparator input).

This is 100 mes higher as the RS 485 receiver input impedance (e.g. 75ALS176 has min.12-30

kOhm). In theory this should not cause any problems which have not been detected so far.

How many PROFIBUS DP repeaters can be installed in series?

There are lots of stories out there concerning this subject. The actual answer lies in the electronic

components of the repeater. These determine the actual "maximum number?. The digitaliza on

from and to the opto-couplers in the repeater will make bits smaller or wider. If you put too many

repeaters in series, the bits dieren ate too much and messages are not recognized anymore. There

are also repeaters available with no limit in serial placement.

Check the manual of the repeater! It should state the maximum amount. For example: the Siemens

repeater is 9, the ProHub is unlimited.

Click here for a YouTube video

The second step is changing the busparameters. All repeaters have a delay me. If you put a large

quan ty of repeaters in series you might have to change the Tslot busparameter to a higher value.

Why is termina on important?

Termina on prevents reec ons that can disturb the data communica on. The higher the baudrate

and the longer the cable, the more important termina on becomes. Termina on should be

ac vated/placed at both ends of every bus segment. With PROFIBUS DP the termina on is powered

to provide an idle level when nobody is sending data. With PROFIBUS PA the termina on is a

combina on of a resistor and a capacitor.

Should there be distance between PROFIBUS and power

cables?

YES, even PROFIBUS can get disturbed by interference caused

by parallel high voltage power lines. Always try to have at least

10 cm air space between the cables (depends on the level of

the voltage). Most users mix all cables in one cable tray and

that o en leads to unreliable behaviour. Cables that cross

each other will not cause problems. Crea ng distance is not

the only requirement. Correct shielding is also a must!

Can you give some basic ps for installing a PROFIBUS DP network?

Always use PROFIBUS cable and connectors.

Do not exceed 32 devices per segment (including repeaters, OLMs and couplers).

Make sure the segment length is in contrast with the baudrate.

Make sure every segment has powered termina on on both ends.

Avoid spur lines.

Avoid swapping the wires (A=green, B=red).

Mark how long the cables really are and update the drawings.

A er installa on you should test your work:

Are the addresses correctly set?

No short circuit or break in the cable?

Can you communicate with the devices?

Can I install PROFIBUS DP cable in a PA network?

Lots of users have the impression this will never cause a problem because of the high speed signal

characteris cs of DP cable (even if the impedance is not correct), but there are other factors that

could make it very unstable:

There will be too much voltage loss at the end of the cable because of the higher loop resistance

of standard DP cable (110 Ohm/km). PA cable has a loop resistance of 44 Ohm/km. When it is an Ex

coupler with only 12.xV output, there is a change the last devices "get lost" all the me".

The DP cable gets over-powered because of its "thin" 0.64 mm diameter wires. PA cable wires

have a diameter between 0.8 to 1.5 mm.

PA Coupling components cannot handle the "thin" wires of the DP cable.

When it is an Ex installa on, the DP cable is probably not blue and not suitable for the FISCO Ex

specs.

Our advice is to use only cable that complies with the PA specica ons!

What is the minimum distance between 2 devices on PROFIBUS DP?

When the transmission speed is 1,5 Mbps or higher, it is highly recommended to have at least 1 m of

cable between 2 devices. De input capacitance of both devices will be compensated by the cable in

order to preserve the common impedance. When the devices would be very close together, there is

a big chance the input capacitance causes reec ons in the data communica on (small short

circuits). The eect is much less at transmission speeds lower than 1,5 Mbps.

Does PROFIBUS DP cable always have a violet colour?

NO, because of certain applica on, protec on and isola on classes, PROFIBUS DP cable can have

another colour. Example: ground cable and shipboard cable are black, robust cable is green. The

1/29/2015 11:33 PM

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

3 of 7

http://www.procentec.com/faq/profibus/

standard cable is always violet!

Which pins on the DB9 connector are for communica on?

Pin 3 = B line (red wire)

Pin 8 = A line (green wire)

The metal casing of the connector is used for the shielding.

What are the advantages of bre op c against copper wire?

With bre op c:

Cable lengths can be longer.

Complete electrical isola on.

Elimina on of possible ground loops.

But, bre op c is more expensive than copper (cabling, installa on and the required couplers)!

How do you terminate devices that have an M12 connector?

There are 3 ways to terminate devices that have an M12 connector:

- When it has two onboard M12 connectors, put an M12 terminator on the second connector.

- When it has one M12 connector, apply a t-connector that holds the termina on and the last

connector.

- When the device has onboard termina on, switch it on.

Can 2 Probus cables be installed inside the same metal conduit?

Yes, mul ple (parallel) Probus cables can be installed in a metal conduit. It gives good behaviour

when EMC is involved.

Why is there only 1 termina ng resistor in an RS 485-IS plug?

The PROFIBUS DP - RS 485-IS standard (for Ex environments) has dened that the pull-up and

pull-down resistors have to integrated in the devices. This way they are always charged and can

never cause a problem when somebody is moving the termina on switch on a plug and it is more

dicult to make a direct short circuit on the connector pins of the device (explosion protec on).

The resistor values are also dierent: 510 - 200 - 510.

It looks very confusing compared to regular PROFIBUS DP where the plugs contain 3 resistors. But it

is correct!

Check this link to see a schema c of the RS 485-IS termina ng resistors in a device with a DB9

connector.

When you have a device or repeater with on-board termina on and is equipped with a DB9

connector, what is the best place to ac vate the termina on (when it is the last device)?

The plug is the best place! When you remove the device from the bus you s ll have the termina on

in the plug which is s ll a ached to the bus cable. Maybe the 5V power is gone (which is always

required), but be er this than nothing at all.

Plug is ON, device is OFF.

PROFIBUS DP

Will the choice of addresses inuence the cycle me?

NO, the master will always cyclically communicate with the slaves, so for the cycle me it doesn?t

ma er what addresses they have. The video below explains this.

VIDEO

What is the meaning of the acronym 'GSD' le?

There are lots of interpreta ons concerning the acronym GSD, but the correct version is; 'General

Sta on Descrip on'. More on GSD les can be found here: www.probus.com/nc/technology

/glossary/glossary/detail/general-sta on-descrip on-gsd/G/

Can you explain the diagnos c message structure of DP-V0 devices?

DP-V0 slave devices require a 6 bytes long mandatory diagnos c part. It contains informa on about

the connec on/device status and during cer ca on has to be exactly behaving according the

standard.

Addi onally to the mandatory diagnos c part, devices can also provide a device specic part with a

maximum length of 244 bytes (including the 6 mandatory bytes and headers). The device specic

part can be dened by the device manufacturer (device related diagnos cs) and/or a scheme of the

standard can be implemented (iden er related and channel related diagnos cs). 99% of the device

manufacturers implement only the device related diagnos cs.

It is highly recommended to specify the diagnos c data in the GSD le and manual of the device.

Most DP masters and diagnos c tools can extract the diagnos c informa on and make it available

for the applica on so ware.

What is Tid2 in the busparameter se ngs?

This busparameter denes the delay the sender of an unacknowledged telegram shall wait un l it

may send another telegram. Tid2 is the maximum value of 2 variables:

1) MaxTSDR

2) TQUI + 2*TSET + 2 + TSYN

In most cases MaxTSDR has the highest value (Tid2 = MaxTSDR).

A typical message that uses Tid2 is the Global Control broadcast with PROFIBUS DP.

1/29/2015 11:33 PM

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

4 of 7

http://www.procentec.com/faq/profibus/

Does the PNO update GSD les on their website or CD-ROM?

NO, the manufacturers are responsible to update the GSD les on probus.com. The PNO does not

publish a CD-ROM. The manufacturer website is the best place to download GSD les.

How many DP slaves can be congured in a network?

Most people say 126, but this is NOT true! The total number of DP slaves that can be put in

data-exchange is 124, because of the master that uses an address and the reserved addresses 0 and

126 (these are blocked by the congura on tool). Be careful:

Address 2 could also be blocked for slaves.

The master itself can have a limit.

Can I control the outputs of 1 slave with 2 masters (PLCs)?

NO, only 1 PLC has the right to control the outputs (safety feature). The 2nd PLC can only READ the

inputs/outputs.

What is the most commonly used transmission speed?

1.5 Mbps is the most commonly used transmission speed. This is the default speed when you create

a new project. Most users don't know what it is and keep this value. Our experience is that most

installa on are running on a speed that is much too high for the applica on. When the speed is

lower you can have longer cables and less chance of disturbances.

Can I change some se ngs to make PROFIBUS DP communica on more reliable?

YES, in the busparameters of the master you can change some se ngs to make the communica on

more reliable:

Retries/Repeats = 5

Tqui = 9

MinTSDR = 22

Is it necessary to recongure the bits & bytes in the control system when a new device is added

to PROFIBUS?

When a PROFIBUS device is added in the control system congura on, the device gets new memory

space assigned, which does NOT conict with the exis ng congura on. The exis ng congura on

and program does not need to be touched. This makes PROFIBUS perfect for ?instrument

expansion? or ?complete machine copying?.

How is the term ?plug and play? used in PROFIBUS?

It has a double meaning; if you replace a device with the same type it works directly, because the

congura on is stored in the control system. Also, you can easily integrate a new device in your

congura on by impor ng a GSD le and synchronizing the address of the device. By serving

standardized and prole based device descrip ons PROFIBUS also enables a manufacturer

independent device replacement.

Does PROFIBUS DP have self triggered alarms/diagnos cs?

When a device has diagnos cs it indicates this during the data exchange. The master will

immediately fetch the diagnos cs and makes the informa on available for the end-user. The

diagnos cs from devices are completely event triggered. Diagnos cs are important for smooth and

reliable opera on. Devices report their own device status and indicate when they need service. This

reduces maintenance costs and can increase me between scheduled eld visits.

PROFIBUS PA

I read in the PROFIBUS PA specica ons that the max length of EACH spur is 30/60/120 m, but

with PROFIBUS DP we have dened the spur length parameter as TOTAL spur length. Can you

explain?

Because the baudrate is rela vely low with PROFIBUS PA, spur lines are allowed to be long without

disturbing the data communica on and we can assign a xed maximum length per spur / per device.

With PROFIBUS DP it is a dierent story; the high baudrate limits the spur line length. If we would x

the maximum length per device, it would only be 20 cm per spur for 32 devices and that would not

make sense. To solve this we dene it as a total sum of all spurs together so that the end-user has

more exibility, because not all devices require a spur line.

What is FDE current with PROFIBUS PA devices (Fault Disconnec on Electronics)?

Some PROFIBUS PA devices consume addi onal current when there is a problem internally or with

its I/O. FDE is this addi onal sta c/basic current consump on and has to be wri en in the manual

of the device. Some devices have no FDE current and always consume the regular current. When

the problem intensies, the device shuts itself down from the bus (no more power consump on).

Do simple PA couplers pass through all messages coming from the DP side?

NO, the P+F SK1 coupler does NOT pass the token message (SD4) through.

Can we use EDD and/or DTM on any DP-V1 class 2 master?

NO, each tool uses its own technology:

PDM: Modied EDD (based on PNO EDD, but not 100% compliant with PNO EDD)

FieldCare: FDT/DTM technology

PactWare: FDT/DTM technology

CommuWin: Executable DLL's (non standard solu on)

A PA device has at least 3 func on blocks. What are these blocks and what is their

purpose?

In the process industry it is common to use blocks to describe the characteris cs and

func ons of a measuring/manipula on point and to represent an applica on through a combina on

of these blocks. The specica on of PA devices uses this func on block model to present func onal

1/29/2015 11:33 PM

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

5 of 7

http://www.procentec.com/faq/profibus/

sequences.

Physical Block (PB)

Describes the necessary parameters and func ons of the device itself (e.g. so ware version, serial

number, vendor ID, factory reset command). There is only one Physical block in a PA device.

Transducer Block (TB)

Contains parameters which have eect or describe the type of sensor or actuator. Transducer

blocks may also contain parameters for calibra on and lineariza on. The processed informa on is

passed on to the Func on Block. If a device has more sensors, it has corresponding Transducer

Blocks for every sensor.

Func on Block (FB)

Contains one or more cyclically accessible inputs or outputs parameters (process values). These can

be of analog or discrete nature. Other parameters: setup scaling, alarms and unit factoriza on.

What is a Prole within PROFIBUS PA?

Modern PA devices are intelligent and can execute part of the informa on processing in automa on

systems. This was previously done by the PLCs or DCS systems. The PA prole is designed with

co-opera on of the process industry and denes all func ons and parameters for dierent classes

of instruments. It is based on interna onally accepted func on block technology. The prole

contains descrip ons for the following instrument types:

- Pressure (and dieren al)

- Level, temperature and ow

- Analog/digital inputs and outputs

- Valves and actuators

- Analyzers

The prole is divided into 2 classes (A and B):

Class A of the prole describes common parameters of simple devices. The scope is limited to the

basic func ons. This set consists of the process variables (e.g. temperature, pressure, level) added

by measured value state, the tag name and the engineering unit.

Class B is an extension to class A and will cover more complex applica on func ons for

iden ca on, commissioning, maintenance and diagnosis. The rela onship of the parameters to the

classes is visible within the parameter deni ons and in the conformance statements.

To conclude: The PA prole denes cyclical data + status, diagnos c informa on and parameters.

The PA prole assures ?interoperability? and ?device exchangeability?

What is a Prole Ident Number?

In cases where the device of manufacturer-A should be replaceable by an equivalent device of

manufacturer-B, the standard Ident Number is no longer sucient because a GSD le is associated

with this number. When the device is replaced a change in the congura on is necessary which will

lead to a DCS/PLC stop. Therefore the PNO has assigned number ranges to dedicated device types

(Prole Ident Numbers) in combina on with certain Prole GSD les. A device can support mul ple

Ident Numbers which are set by a parameteriza on tool. The end-user has to decide whether to

select the Manufacturer specic Ident Number or the Prole Ident Number. Examples:

Transmi er 0x9700 to 0x970F

Actuator 0x9710 to 0x971F

Discrete input 0x9720 to 0x972F

Discrete output 0x9730 to 0x973F

How can you measure the length of a PA segment?

This is almost impossible. Because of junc on boxes, spur lines and the input resistance of the

devices it is very hard to do. At the moment there is no tool available.

Product Development and Cer ca on

What is exactly the 'Model_Name' in a GSD le?

It's a keyword in a GSD le that describes the name of a product and can be 32 characters wide. The

congura on tool of the master displays this keyword in the catalog.

Tools like ProTrace display the Model_Name in the Live List when the GSD le of the device is

available in the GSD directory and a Diagnos c telegram (Ident Number) of the device was detected

on the bus.

The Model_Name is in some cases not properly dened by the product developer. When a user has

many GSD les in his catalog, this product 'disappears' in the list because of an unclear name. Many

PROFIBUS experts alter the Model_Name of their GSD les to make them more readable and

understandable. This jeopardizes the cer ca on of the device. The available GSD le checkers can

be a solu on to verify the altered GSD le.

The le ers A and B are inversed comparing the RS 485 driver with the PROFIBUS connector. Any

explana on?

In the late 1980's when PROFIBUS FDL and the DB9 connector were standardized the PROFIBUS

wires were accidently named B and A, without looking at the designa on on the exis ng RS485

drivers. A er PROFIBUS was standardized there was no possibility to change it anymore. We know

that it is very confusing for beginning product developers, but luckily the end-user does not have to

get involved with RS485 drivers.

I will not implement FSAFE_TYPE in my latest PA prole 3.02 rmware of my pressure device (1 AI

block). What is the behaviour? Is this acceptable prac ce?

If the prole parameter FSAFE_TYPE is NOT used; the AI Func on Block behaves like FSAFE_TYPE = 1

(last usable value). So the value that is read is uncertain. This is designed by PI for the prac cal use

and standards in the industry.

Is there a specica on on the implementa on of the LEDs on a PROFIBUS/PROFINET device (BF,

SF, DIA, ON)?

NO, there is a prole (3.522) that describes a recommenda on for LEDs, but it is NOT a

specica on.

1/29/2015 11:33 PM

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

6 of 7

http://www.procentec.com/faq/profibus/

What does the SlotDeni on represent in the GSD le?

The SlotDeni on is used to set a guide for the modules in the congura on so ware. Example:

SlotDeni on

SLOT(1) = "Volumeow" 2 1,2

SLOT(2) = "Totalizer 1" 3 1,3

SLOT(3) = "Totalizer 2/batch" 4 1,4

SLOT(4) = "Totalizer control" 1 1,5

EndSlotDeni on

SLOT(1) to SLOT(4) : available slots

"Volumeow" : Slot name

2 : Default module. This is the module number determined in the module deni on.

1,2 : Allowed modules. These are the module numbers determined in the module deni ons.

For PA cer ca on, does the vendor have to develop its own EDD for the product?

NO, it is not mandatory to have an EDD for PA cer ca on.

For GSD les we can download an editor from probus.com. Is there an editor for EDD available?

NO, for EDD there is no specic editor. Most engineers just use a plain text editor.

Are all PROFIBUS devices cer ed?

NO, it is NOT mandatory for a manufacturer to have a PROFIBUS master or slave cer ed. It is

highly recommended, because in most projects only cer ed devices are selected. At the moment

only masters and slaves can be cer ed. For connectors, cable and repeaters there are no

cer ca on guidelines available. Remark: PROFIsafe and PROFINET devices must be cer ed.

How do I get a cer cate for a tested device?

A er receiving a posi ve test report from the testlab, the manufacturer can apply for a cer cate

for his device. The form ?Applica on for PROFIBUS Cer cate? is used for it. The manufacturer

passes the original of the test report together with the form to the PI Cer ca on Oce which

decides on the cer ca on based on the test report. In case the cer ca on is granted, the

manufacturer receives a cer cate for the device in ques on.

I have an HMS ANYBUS card, which is already cer ed. Do I need to cer fy my device that holds

the card?

The ANYBUS product is part of the en re device and is inuenced by a number of criteria like;

power supply, EMC, the path from PROFIBUS to the ANYBUS card, GSD le, etc. So cer ca on is

s ll very important!

Is it correct that the SD3 telegram is not supported anymore?

YES, most PROFIBUS slave ASICs have not implemented this telegram anymore (as a reply to

requests). This message dates from the FMS days where eciency was very important. It is easier

for the ASIC core to just focus on the SD2 telegram structure for every data size between 1 and 244

bytes. The master ASICs and troubleshoo ng tools are following this trend.

Others

In which standard(s) is PROFIBUS specied?

The PROFIBUS communica on is specied in IEC 61158 Type 3 and IEC 61784. IEC 61158 Type 3

includes the en re range of PROFIBUS, consis ng of the versions DP-V0, DP-V1 and DP-V2. IEC

61784 species the proper es of the Communica on Prole Family CPF 3 which is PROFIBUS.

Addi onally, the IEC published the "Corrigendum 1/2/3" and "Implementa on Guideline" related to

the above men oned documents. The Documents can be purchased from the IEC website

(www.iec.ch).

What is the cost comparison between conven onal and PROFIBUS cabling?

It is a common fact that PROFIBUS reduces cable costs a lot, but there is a more that

comes with it:

Reduc on of cable trays.

Energy savings.

Less documenta on.

Be er overview.

Reduc on of test me.

Less spare parts.

Easy to expand or change.

Shorter down mes because of quick repair.

Easy to dismantle.

This is only infrastructure and the ini al savings. But the real money making starts with the

maintenance and the opera onal costs. PROFIBUS is an excellent choice, but some training is

required to get awareness about the advantages.

What is SINEC L2-DP? Is this dierent than PROFIBUS DP?

SINEC L2-DP is PROFIBUS DP! Siemens did at one me use their own names for product designa on.

However, since this proved to be confusing (with L2 in the name), the L2 part of the designa on was

dropped in favour of just DP to avoid confusion. Another example: SINEC S1 is AS-i.

Is PROFIBUS a single or mul -protocol technology?

Within PROFIBUS there is only one communica on layer implemented which is; PROFIBUS DP.

Based on this communica on layer, several device proles are dened in the applica on layer.

These proles provide common data, diagnos cs and parameters for the end-user. Some mes

people are confused with PROFIBUS DP and PA, but the only dierence is the physical interface. In

fact, a PROFIBUS PA device is a PROFIBUS DP device with an applica on prole suited for the

process industry.

1/29/2015 11:33 PM

FAQ - PROFIBUS Questions - Cabling, DP, PA, Troubleshooting

7 of 7

http://www.procentec.com/faq/profibus/

Can PROFIBUS meet the requirements for fast communica on speed and does it have a longer

message length compared to other buses?

PROFIBUS can run on 12 Mbps, which makes it the fastest eldbus in the world. The messages have

only 9 bytes overhead which makes it very ecient. An installa on with 30 devices can have a cycle

me of less than 1 ms. PROFIBUS is the choice for fast message delivery in the industrial

automa on environments.

What makes PROFIBUS unique in terms of Cycle me, Real-Time behavior and Diagnos cs?

PROFIBUS and PROFINET have the fastest cycle me, which can be less than 1 ms. This cycle me is

extremely stable which makes it Real-Time. For diagnos cs we have standardized formats and

maintenance tools that match perfectly with the demands that maintenance personal has.

What are the benets of PROFIBUS for the end-users compared to other systems?

First of all PROFIBUS is the only eldbus that can be used in all parts of the factory (upstream,

process and downstream). This means you can use 1 type of control system, 1 knowledge package,

1 group of spare parts and 1 design strategy.

PROFBUS also has a very large number of manufacturers oering products and services. This means

for almost every applica on there is solu on and enough backup products available. These products

also have strengths in certain applica on areas such as; mo on control or process control.

PROFIBUS has testlabs that cer fy products. PROFIBUS guarantees that every product always works

with products from other manufacturers. PROFIBUS has Competence Centers that support the

end-users with their automa on ques ons and last but not least, Cer ed Training Centers provide

training. People from the working groups are working close together to create a be er world

considering the cost aspect and the environment. They have a special band! Dierent people from

dierent companies can work together without poli cal, business and personal barriers. All faces

poin ng to the same direc on and we get the job done! The result of their hard work is that;

PROFIBUS and PROFINET can save you energy, weight, materials, spare parts, documenta on and a

lot of eort.

We are a community on which you can rely! Your investment is completely safe for now, the future,

yourself and your children.

Is there an open source implementa on of PROFIBUS available?

PROFIBUS is an open specica on. Every company is allowed to create a master/slave

implementa on. Some patents are relevant to the PROFIBUS DP specica on. The patent holders

have granted free of charge licenses to all members of any RPA. Non-members have to agree on a

license with the patent holders.

If a company wants to release a PROFIBUS implementa on (so ware or hardware) as an

open-source solu on, the rules are relevant that are agreed at the OSADL (Open Source

Development Lab, see www.osadl.org). These rules say that no implementa on can be released as

an open-source solu on if it is covered by patents. This means that neither a PROFIBUS DP slave nor

master can be registered as an open source implementa on.

Sitemap | German site | Dutch site | info@procentec.com - +31-174-671800 - Update: 9 December, 2014

Copyright 2014 PROCENTEC. All rights reserved.

1/29/2015 11:33 PM

You might also like

- Dholavira Sign Board ArticleDocument12 pagesDholavira Sign Board ArticleKishore KumarNo ratings yet

- Ghatti Mudali DynastyDocument3 pagesGhatti Mudali DynastyKishore KumarNo ratings yet

- Asia Pacific Journalism On CastesDocument13 pagesAsia Pacific Journalism On CastesKishore KumarNo ratings yet

- AppSolution InFusion PlantInformationManagementSystem PDFDocument16 pagesAppSolution InFusion PlantInformationManagementSystem PDFKishore KumarNo ratings yet

- 1971 - Rape and Its Consequences The Opinion PagesDocument20 pages1971 - Rape and Its Consequences The Opinion PagesKishore KumarNo ratings yet

- 3BSE080454 en Process Training IntroductionDocument36 pages3BSE080454 en Process Training IntroductionKishore KumarNo ratings yet

- Caste System Under CholasDocument46 pagesCaste System Under CholasKishore Kumar100% (1)

- Cult of The Child-GodDocument4 pagesCult of The Child-Godhari haraNo ratings yet

- Abdi-The Case of The Daiva InscriptionDocument38 pagesAbdi-The Case of The Daiva InscriptionMadhav DeshpandeNo ratings yet

- Ancient Indian Art Provides Evidence of Sailing Ships in the Indian OceanDocument10 pagesAncient Indian Art Provides Evidence of Sailing Ships in the Indian OceanKishore KumarNo ratings yet

- Ancient Indian Art Provides Evidence of Sailing Ships in the Indian OceanDocument10 pagesAncient Indian Art Provides Evidence of Sailing Ships in the Indian OceanKishore KumarNo ratings yet

- Cultural Poetics and Sangam PoetryDocument158 pagesCultural Poetics and Sangam PoetrySreedharan TNo ratings yet

- 3BSE058808D1001304 D en Introduction To R&D Project ManaDocument29 pages3BSE058808D1001304 D en Introduction To R&D Project ManaKishore KumarNo ratings yet

- PROFINET SystemDescriptionDocument28 pagesPROFINET SystemDescriptionAngela SánchezNo ratings yet

- ARM - Arch - A8. ARM ProcessorDocument38 pagesARM - Arch - A8. ARM ProcessorZabihullah KhanNo ratings yet

- 3bds009030-510 A en Ac 800m 5.1 Profibus DP ConfigurationDocument98 pages3bds009030-510 A en Ac 800m 5.1 Profibus DP ConfigurationRavenShieldXNo ratings yet

- 20140114115548661Document4 pages20140114115548661Kishore KumarNo ratings yet

- 2.3bds009029r5001 B en Ac 800m 5.0 5.1 Profibus DP InstallationDocument118 pages2.3bds009029r5001 B en Ac 800m 5.0 5.1 Profibus DP Installationbacuoc.nguyen356No ratings yet

- Working with HART networks: setup, design rules, topologiesDocument14 pagesWorking with HART networks: setup, design rules, topologiescuongnammuNo ratings yet

- User Guide MK IVModbus 01Document31 pagesUser Guide MK IVModbus 01Evgeny TumalevNo ratings yet

- User Guide MK IVModbus 01Document31 pagesUser Guide MK IVModbus 01Evgeny TumalevNo ratings yet

- What Is Can BusDocument2 pagesWhat Is Can Busvdevarajsaran100% (1)

- User Guide MK IVModbus 01Document31 pagesUser Guide MK IVModbus 01Evgeny TumalevNo ratings yet

- Tax DetailsDocument1 pageTax DetailsKishore KumarNo ratings yet

- Ia Series ControllerDocument20 pagesIa Series ControllerdileepNo ratings yet

- Differential Expansion TSIDocument4 pagesDifferential Expansion TSIKishore KumarNo ratings yet

- Ia Series ControllerDocument20 pagesIa Series ControllerdileepNo ratings yet

- 3BSE058808D1001304 D en Introduction To R&D Project ManaDocument29 pages3BSE058808D1001304 D en Introduction To R&D Project ManaKishore KumarNo ratings yet

- What Is Can BusDocument2 pagesWhat Is Can Busvdevarajsaran100% (1)

- 3bds021515-600 - en Ac 800m 6.0 Profinet Io ConfigurationDocument168 pages3bds021515-600 - en Ac 800m 6.0 Profinet Io ConfigurationKishore KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SRC1203Document3 pagesSRC1203RikenzNo ratings yet

- Product Specifications Product Specifications: RV4PX306R RV4PX306RDocument4 pagesProduct Specifications Product Specifications: RV4PX306R RV4PX306RLuis CarlosNo ratings yet

- Dipole-Disk Antenna With Beam-Forming RingDocument6 pagesDipole-Disk Antenna With Beam-Forming RingtamilarasansrtNo ratings yet

- Datasheet IT8512E F V0.4.1Document335 pagesDatasheet IT8512E F V0.4.1Krzysztof BondkaNo ratings yet

- Lab # 8 SolvedDocument10 pagesLab # 8 SolvedZabeehullahmiakhailNo ratings yet

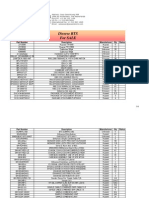

- Diverse BTS For Sale From Power Storm 4SN06200834Document4 pagesDiverse BTS For Sale From Power Storm 4SN06200834Mohamed KsimaNo ratings yet

- Hexagonal Microstrip Patch AntennaDocument2 pagesHexagonal Microstrip Patch AntennaAli ZaidiNo ratings yet

- 40 412M PDFDocument42 pages40 412M PDFpaulpuscasuNo ratings yet

- BS Au 265-2-1995 (2000) Iso 6518-2-1995 PDFDocument16 pagesBS Au 265-2-1995 (2000) Iso 6518-2-1995 PDFamerNo ratings yet

- GE-Surge Capacitors PDFDocument3 pagesGE-Surge Capacitors PDFjohesapaNo ratings yet

- Dynamic Microphone Order # 406.910: Eatures Echnical PecificationsDocument2 pagesDynamic Microphone Order # 406.910: Eatures Echnical PecificationsgbNo ratings yet

- A GSM Based Intelligent Wireless Mobile Patient Monitoring System PDFDocument5 pagesA GSM Based Intelligent Wireless Mobile Patient Monitoring System PDFesatjournalsNo ratings yet

- Section C - Digital MCQ1Document6 pagesSection C - Digital MCQ1viki awsacNo ratings yet

- PIX Firewall 520Document24 pagesPIX Firewall 520seshuaravapalliNo ratings yet

- Hewlett Packard 5305B Service, User ID4961Document48 pagesHewlett Packard 5305B Service, User ID4961cesarmayhemNo ratings yet

- Sorenson DHP-Series DC Power SupplyDocument56 pagesSorenson DHP-Series DC Power SupplySireesh Adimadhyam100% (1)

- F0303202 Data Sheet ENDocument1 pageF0303202 Data Sheet EN7 77No ratings yet

- Bios vs. UefiDocument8 pagesBios vs. UefiWANNA WOHNo ratings yet

- Relay Testing Transient SimulatorDocument6 pagesRelay Testing Transient Simulatorellider18No ratings yet

- HP Prodesk 400 G3 Small Form Factor PC: DatasheetDocument5 pagesHP Prodesk 400 G3 Small Form Factor PC: Datasheetjose berrospiNo ratings yet

- Logic Design Syllabus SummaryDocument193 pagesLogic Design Syllabus SummaryAnup Konnur100% (1)

- Free Course 60 Day PackageDocument5 pagesFree Course 60 Day PackageYves AudreyNo ratings yet

- Si PMDocument10 pagesSi PMKremi TakovaNo ratings yet

- List of RF and IF components for Anthropic DSA815 spectrum analyzerDocument2 pagesList of RF and IF components for Anthropic DSA815 spectrum analyzerInam Ur RehmanNo ratings yet

- (NB24-T554-01D) Specsheet 01152010Document2 pages(NB24-T554-01D) Specsheet 01152010nextekpowerNo ratings yet

- lm358 LM 358 258 158 PDFDocument42 pageslm358 LM 358 258 158 PDFWinexNo ratings yet

- M863G Motherboard Manual ECS PCChips 863G 1 5E EnglishDocument38 pagesM863G Motherboard Manual ECS PCChips 863G 1 5E EnglishMeire Ellen MonteiroNo ratings yet

- AVRDUDE Programming TutorialDocument8 pagesAVRDUDE Programming TutorialBrian JohnsonNo ratings yet

- Analog Electronics July 2017 (2015 Scheme)Document3 pagesAnalog Electronics July 2017 (2015 Scheme)Movies and tv showsNo ratings yet

- Digital Electronics Circuits Laboratory SPICE Experiment-1: Follow Steps Given BelowDocument4 pagesDigital Electronics Circuits Laboratory SPICE Experiment-1: Follow Steps Given BelowrizzzzwanNo ratings yet