Professional Documents

Culture Documents

Technical Description Mechatronics 2014

Uploaded by

JavierRuizThorrens0 ratings0% found this document useful (0 votes)

39 views5 pagesMechatronics

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMechatronics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views5 pagesTechnical Description Mechatronics 2014

Uploaded by

JavierRuizThorrensMechatronics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Mechatronics

National Competition

Abu Dhabi

2014

CONTENTS

Section 1: Introduction

Section 2: Competency and Scope of Work

Section 3: The Test Project

Section 4: Assessment`s Marking, Safety and Equipment

Section 1:

Introduction:

The Mechatronics competition intends to cover the basic skills of mechatroncs

engineering processes

and its main components such as pneumatic technology,

electro-pneumatic technology, PLC programming, troubleshooting, maintenance,

simulation and optimization. The test project is designed to assure an objective

evaluation of all test project components that are used on real job sites of industrial

automation processes. Test Project is split into four main modules and they are partially

dependent. Further, in order to ensure sustainable development of this skill in the future,

use of common parts and equipment pursued in the Test Project. Test Project is also

designed to give quick visual understanding to visitors and related parties of Emirates

Skills members attracting their interests and attentions so that it helps them understand

how important the mechatronics skill is.

Section 2:

Competency and Scope of Work:

The competition is a demonstration and assessment of the competencies associated

with this skill. The test project consists of hands on and knowledge skills that master

and reflect the full implementation of the Pneumatic, electro pneumatic, programmable

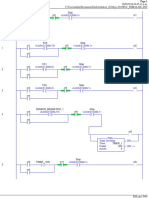

logic controllers (PLC) and control circuit diagrams. Designing, simulating and building a

mechatronic system are the main objectives as well as choosing the correct

components and the operational settings according to the given conditions. The

designed system and the control circuit diagram will be simulated on fluidSIM software

platform. Interfacing the PLC to the circuit and writing the PLC program in order to

achieve the given task.

.

Practical Work

Competitors have to carry out independently the following tasks:

Understanding pneumatic &electro pneumatic circuits.

Choosing the correct components.

Building pneumatic & electro pneumatic circuits.

Using FluidSIM software to construct, evaluate and simulate the circuit.

Understanding the function of all input sensing components.

Interfacing and connecting electro-pneumatic circuits to the PLC.

PLC programming either using Ladder logic or using FBD language.

Using PLC programming software such as LOGO Soft-comfort.

Understanding

practical

applications

related

to

electro-pneumatic

and

Programmable logic controllers.

Designing & building an electric control and a pneumatic control circuit according

to a given sequence by using fluidSIM software.

Building these circuits practically using the work stations.

Modifying and troubleshooting of a circuit given.

Understand the professional practice of the work being done.

Section 3:

The Test Project: (Will be available very soon)

The Competitors have to carry out the following tasks:

Building a pneumatic system

Drawing the pneumatic circuit according to the given cylinders sequences.

Testing the designed circuit using fluidSIM software.

Placing the required pneumatic components and other actuators.

Connecting all components using the provided workstations.

Checking the circuit against any air leakage.

Operating the circuit achieving the required sequences and operating conditions.

professional practice.

Building an electro- pneumatic system

Designing an electro-pneumatic circuit that achieves a certain cylinders sequence.

Simulating the circuit using fluidSIM software.

Placing and connecting all required electro-pneumatic components according to the

circuit diagram.

Connecting the circuit power supply.

Checking the circuit against any short circuit connection.

Operating the circuit achieving the required sequences and operating conditions.

professional practice.

Programming task 2 using PLC and LOGO soft comfort software

Programming the circuit functionality using PLC and LOGO soft comfort software.

Connecting the circuit power supply.

Checking the circuit against any circuit malfunctions.

Operating the circuit achieving the required sequences and operating conditions.

For PLC safety operation, all solenoid valves and input sensors should be connected

through electric relays.

professional practice.

Modifying and troubleshooting Task 3

Replacing a specific part (input or output device).

Troubleshoot some generated malfunctions in the circuit as well as in the LOGO

program.

Modifying the circuit in such way that achieves certain operating conditions.

professional practice.

Description of Project and Tasks:

Test Project of Mechatronics Competition is composed of 4 tasks in total. Jobs included

in each task as follows:

Task Number

Time required (hours)

Module 1

3 Hours

Module 2

3 Hours

Module 3

3 Hours

Module 4

2 Hours

Total

12 Hours

Notes:

Please Download the attached document (Competition summary of Mechatronics

Skills) and practice as much as you can on the listed areas.

Professional practice notes is available right now, so practice it as much as you

can.

You might also like

- SWOT AnalysisDocument6 pagesSWOT Analysishananshahid96No ratings yet

- Plants Life Cycles and PartsDocument5 pagesPlants Life Cycles and PartsseemaNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- EPCOS Power Factor Correction Product ProfileDocument104 pagesEPCOS Power Factor Correction Product ProfileJavierRuizThorrensNo ratings yet

- EPCOS Power Factor Correction Product ProfileDocument104 pagesEPCOS Power Factor Correction Product ProfileJavierRuizThorrensNo ratings yet

- M Tech Fluid Power ManualDocument27 pagesM Tech Fluid Power ManualAnand RajNo ratings yet

- Design Your Loyalty Program in 2 WeeksDocument53 pagesDesign Your Loyalty Program in 2 WeeksLorena TacuryNo ratings yet

- Click and Start M340 EN - V1 - ModifiedDocument71 pagesClick and Start M340 EN - V1 - Modifiedshaikhsajid242No ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- To Perform SIL and PIL Testing On Fast D PDFDocument4 pagesTo Perform SIL and PIL Testing On Fast D PDFgil lerNo ratings yet

- CGL Flame - Proof - MotorsDocument15 pagesCGL Flame - Proof - MotorspriteshNo ratings yet

- PLC and Robotics Upgrade ProposalDocument5 pagesPLC and Robotics Upgrade Proposalvan hangNo ratings yet

- PLC Simulation ReportDocument62 pagesPLC Simulation ReportAsraful Goni NirabNo ratings yet

- Manual Arduino UnoDocument8 pagesManual Arduino UnoNuwando IbrahimaNo ratings yet

- Industrial Automation Summer Training Report, PLC, SCADA, HMI Instrumentation - ShamsherDocument49 pagesIndustrial Automation Summer Training Report, PLC, SCADA, HMI Instrumentation - ShamsherMd Shamsher86% (28)

- Report On PLC & ScadaDocument30 pagesReport On PLC & ScadaRajmal Menariya60% (10)

- STEP 7 - Function Block Diagram For S7-300 and S7-400Document220 pagesSTEP 7 - Function Block Diagram For S7-300 and S7-400ntrtfNo ratings yet

- STEP 7 - Function Block Diagram For S7-300 and S7-400Document220 pagesSTEP 7 - Function Block Diagram For S7-300 and S7-400ntrtfNo ratings yet

- SRS documentation of Virtual Classroom System , SRS documentation of Personal Identity Management ,SRS documentation of EMentoring for women system , SRS Documentation of Employee Performance Management SRS Documentation of Online TicketingDocument79 pagesSRS documentation of Virtual Classroom System , SRS documentation of Personal Identity Management ,SRS documentation of EMentoring for women system , SRS Documentation of Employee Performance Management SRS Documentation of Online Ticketingsaravanakumar1896% (26)

- PLC and SCADA Automation ReportDocument48 pagesPLC and SCADA Automation ReportsubrampatiNo ratings yet

- Lab: Introduction to Control Apparatus and PLC Control of Asynchronous MotorDocument11 pagesLab: Introduction to Control Apparatus and PLC Control of Asynchronous MotorMuhammad J SherwaniNo ratings yet

- Model-Based Testing of Automotive Systems: Piketec GMBH, GermanyDocument9 pagesModel-Based Testing of Automotive Systems: Piketec GMBH, GermanyGururaj BandaNo ratings yet

- HIL Automotive EngineeringDocument16 pagesHIL Automotive EngineeringMinh NguyenNo ratings yet

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanNo ratings yet

- Wargames Illustrated #115Document64 pagesWargames Illustrated #115Анатолий Золотухин100% (1)

- Skills Competition (Mechatronics)Document13 pagesSkills Competition (Mechatronics)Putri Chairany100% (1)

- Industrial Training Report: Sri.B.SharanappaDocument40 pagesIndustrial Training Report: Sri.B.SharanappaKollu dhruvaNo ratings yet

- PLCDocument56 pagesPLCFelix Lee Kah NgieNo ratings yet

- Final Year Project Report FainalllllDocument45 pagesFinal Year Project Report Fainalllllanon_76743611No ratings yet

- Industrial Automation and Control Sample Paper with AnswersDocument3 pagesIndustrial Automation and Control Sample Paper with AnswersMatthew SibandaNo ratings yet

- Teaching Model-Based Design and Rapid Prototyping To Undergraduate StudentsDocument6 pagesTeaching Model-Based Design and Rapid Prototyping To Undergraduate StudentsMKTR_AHMETNo ratings yet

- Industrial AutomationDocument4 pagesIndustrial AutomationNarayanan IyerNo ratings yet

- Automatic Plant Irrigation SystemDocument43 pagesAutomatic Plant Irrigation SystemObula ReddyNo ratings yet

- Mechanic (Embedded Systems and PLC)Document6 pagesMechanic (Embedded Systems and PLC)sbos1100% (1)

- Advanced Industrial Automation CourseDocument2 pagesAdvanced Industrial Automation CourseAmaldev ThakurNo ratings yet

- DC Motor Closed LoopDocument11 pagesDC Motor Closed Looprichard chombaNo ratings yet

- Api I C2Document31 pagesApi I C2mihai37No ratings yet

- "Programmable Logic Controller": Degree of Bachelor of TechnologyDocument42 pages"Programmable Logic Controller": Degree of Bachelor of TechnologyVikas VermaNo ratings yet

- Advanced PLC and Sensor Integration in AutomationDocument3 pagesAdvanced PLC and Sensor Integration in AutomationRoss Mel Bautista LingonNo ratings yet

- 2171103Document4 pages2171103snehalNo ratings yet

- 1Document2 pages1DollaRaiNo ratings yet

- Operator PLC SystemDocument6 pagesOperator PLC SystemNisar AhmedNo ratings yet

- PLC e-Textbook on Programmable Logic ControllerDocument121 pagesPLC e-Textbook on Programmable Logic ControllerVicky VickyNo ratings yet

- Industrial AutomationDocument4 pagesIndustrial AutomationmeghasugauliNo ratings yet

- BLDC Motor Control Design in MATLAB/SimulinkDocument5 pagesBLDC Motor Control Design in MATLAB/SimulinkWilliam Javier Rosero VargasNo ratings yet

- Prem Project Report PLC Final Traffic - 1Document50 pagesPrem Project Report PLC Final Traffic - 1Mohammed FazalNo ratings yet

- PLC 2Document11 pagesPLC 2Muhammad J SherwaniNo ratings yet

- How To Plan For ProjectDocument5 pagesHow To Plan For ProjectVarun VarmaNo ratings yet

- Mte 510 Laboratory ManualDocument8 pagesMte 510 Laboratory Manualsani danjumaNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- Cim Automation Lab Manual 10me78Document57 pagesCim Automation Lab Manual 10me78chandrashekar mNo ratings yet

- Project PLCDocument12 pagesProject PLCmajumderabhijit85No ratings yet

- 05Document42 pages05tt_aljobory3911No ratings yet

- Embedded PLC Implementation Using ARMDocument5 pagesEmbedded PLC Implementation Using ARMsnehagoyankaNo ratings yet

- Control Logic: Industrial Automation Training CentreDocument18 pagesControl Logic: Industrial Automation Training CentrejaganmohanrsNo ratings yet

- AC500 - Application Note 3ADR0105688SIMULINKDocument13 pagesAC500 - Application Note 3ADR0105688SIMULINKwissemNo ratings yet

- 2171103Document4 pages2171103narayanNo ratings yet

- EAT237 Microprocessors and PLC's - PLC PartDocument5 pagesEAT237 Microprocessors and PLC's - PLC PartAli MohammedNo ratings yet

- Control Engineering Lab Semester: Winter 2021 Session: FALL 2018Document5 pagesControl Engineering Lab Semester: Winter 2021 Session: FALL 2018abdullah anwarNo ratings yet

- J450 Power Electronics: AC 800PEC Matlab/SimulinkDocument1 pageJ450 Power Electronics: AC 800PEC Matlab/SimulinkNikolaBuljaNo ratings yet

- Summer TrainingDocument42 pagesSummer TrainingAman yadavNo ratings yet

- I M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseDocument5 pagesI M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseGoran MiljkovicNo ratings yet

- Object Oriented C++ Programming in SIMULINK - A Reengineered Simulation Architecture For The Control Algorithm Code ViewDocument6 pagesObject Oriented C++ Programming in SIMULINK - A Reengineered Simulation Architecture For The Control Algorithm Code Viewgreen_way26No ratings yet

- Rajasthan Technical University: Bachelor of TechnologyDocument40 pagesRajasthan Technical University: Bachelor of TechnologyJaishree VyasNo ratings yet

- Design Projects in A Programmable Logic Controller (PLC) Course in Electrical Engineering TechnologyDocument10 pagesDesign Projects in A Programmable Logic Controller (PLC) Course in Electrical Engineering TechnologyKhai LaNo ratings yet

- Design Projects in A Programmable Logic Controller (PLC) Course in Electrical Engineering TechnologyDocument10 pagesDesign Projects in A Programmable Logic Controller (PLC) Course in Electrical Engineering TechnologyMohammed Fadhl AlbadwiNo ratings yet

- Design Projects in A PLCDocument10 pagesDesign Projects in A PLCSam B.medNo ratings yet

- MCT-319 IA 2010 Lab Manual 1Document4 pagesMCT-319 IA 2010 Lab Manual 1junaid chNo ratings yet

- Riya Katiyar 1712910Document131 pagesRiya Katiyar 1712910Ram SinghNo ratings yet

- C2000 MCU Real-Time Industrial Control TrainingDocument4 pagesC2000 MCU Real-Time Industrial Control TrainingPhạm Văn TưởngNo ratings yet

- Unknown - Unknown - Advanced - Tools - Control - Industry - 4.0Document6 pagesUnknown - Unknown - Advanced - Tools - Control - Industry - 4.0gesmarjuniorNo ratings yet

- Descargar Allen Bradley PLC (RSLogix 500 Pro, RsLinx) Torrent - Kickass TorrentsDocument5 pagesDescargar Allen Bradley PLC (RSLogix 500 Pro, RsLinx) Torrent - Kickass TorrentsJavierRuizThorrensNo ratings yet

- NECAMSID DC/AC Pure Sine Wave InverterDocument57 pagesNECAMSID DC/AC Pure Sine Wave InverterohjenNo ratings yet

- First Steps With CodesysDocument10 pagesFirst Steps With CodesystynizNo ratings yet

- Proteus DSO PrintingDocument1 pageProteus DSO PrintingFarid AfandiNo ratings yet

- RSLogix 5000 Report(s) Empacadora 28-Mayo-2016Document8 pagesRSLogix 5000 Report(s) Empacadora 28-Mayo-2016JavierRuizThorrensNo ratings yet

- NECAMSID DC/AC Pure Sine Wave InverterDocument57 pagesNECAMSID DC/AC Pure Sine Wave InverterohjenNo ratings yet

- Descargar Allen Bradley PLC (RSLogix 500 Pro, RsLinx) Torrent - Kickass TorrentsDocument5 pagesDescargar Allen Bradley PLC (RSLogix 500 Pro, RsLinx) Torrent - Kickass TorrentsJavierRuizThorrens0% (1)

- BridgesDocument50 pagesBridgesJagannath SahooNo ratings yet

- Linear Power SupplyDocument16 pagesLinear Power SupplyMorganChaitaNo ratings yet

- User Manual and Installation Notes: UT2000 - 3000 Series Digital Storage OscilloscopesDocument29 pagesUser Manual and Installation Notes: UT2000 - 3000 Series Digital Storage Oscilloscopespablo190381No ratings yet

- Proteus PCB ARES 7.10 Help Converted by Atop CHM To PDFDocument203 pagesProteus PCB ARES 7.10 Help Converted by Atop CHM To PDFphangiangchau83No ratings yet

- Documentación Del Usuario LOGO!Soft ComfortDocument108 pagesDocumentación Del Usuario LOGO!Soft Comfortandres_a1017No ratings yet

- Electrical Measurements Module: Methods and InstrumentsDocument62 pagesElectrical Measurements Module: Methods and InstrumentsJR DevienteNo ratings yet

- 2117 PAC Project 94 Release NotesDocument8 pages2117 PAC Project 94 Release NotesJavierRuizThorrensNo ratings yet

- (Converson 6 Bits A BCD)Document11 pages(Converson 6 Bits A BCD)carlitogotoNo ratings yet

- Rele de Proteccion de Transformador M-3310-Sp BeckwithDocument16 pagesRele de Proteccion de Transformador M-3310-Sp BeckwithAlberto OrmazavalNo ratings yet

- 2039 PAC Project 93 Release NotesDocument8 pages2039 PAC Project 93 Release NotesJavierRuizThorrensNo ratings yet

- Ic 7404 (2) HD74LS04PDocument6 pagesIc 7404 (2) HD74LS04PBurhanudin SyamNo ratings yet

- TwidoSuite - Getting StartedDocument72 pagesTwidoSuite - Getting StartedJavierRuizThorrensNo ratings yet

- BR6000 Controlador de FPDocument6 pagesBR6000 Controlador de FPJavierRuizThorrensNo ratings yet

- First Steps With CodesysDocument10 pagesFirst Steps With CodesystynizNo ratings yet

- 1681 PAC Project Basic Pro Comparison ChartDocument2 pages1681 PAC Project Basic Pro Comparison ChartJavierRuizThorrensNo ratings yet

- 1641 Optotutorial Snap Pac PidDocument84 pages1641 Optotutorial Snap Pac PidJavierRuizThorrensNo ratings yet

- 1066 SNAP Analog Output Mods Data SheetDocument18 pages1066 SNAP Analog Output Mods Data SheetJavierRuizThorrensNo ratings yet

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDocument4 pagesAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoNo ratings yet

- Cuplock Scaffold 18mPHx1.6mx2.5m SafetyDocument1 pageCuplock Scaffold 18mPHx1.6mx2.5m SafetyDIGITAL SIRNo ratings yet

- IBM Systems Journal PerspectivesDocument24 pagesIBM Systems Journal PerspectivesSmitha MathewNo ratings yet

- Government of The Punjab Primary & Secondary Healthcare DepartmentDocument3 pagesGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorNo ratings yet

- North American Countries ListDocument4 pagesNorth American Countries ListApril WoodsNo ratings yet

- Evolution BrochureDocument4 pagesEvolution Brochurelucas28031978No ratings yet

- METRIC_ENGLISHDocument14 pagesMETRIC_ENGLISHKehinde AdebayoNo ratings yet

- Data Validation and Verification - BBC BitsizeDocument56 pagesData Validation and Verification - BBC BitsizeluciferothegoatNo ratings yet

- Cypress Enable Basic Rer Erence ManualDocument2 pagesCypress Enable Basic Rer Erence ManualCarlos RodasNo ratings yet

- Teacher Commitment and Dedication to Student LearningDocument8 pagesTeacher Commitment and Dedication to Student LearningElma Grace Sales-DalidaNo ratings yet

- Experiment Vit CDocument4 pagesExperiment Vit CinadirahNo ratings yet

- After EffectsDocument56 pagesAfter EffectsRodrigo ArgentoNo ratings yet

- Design of Steel Structures Handout 2012-2013Document3 pagesDesign of Steel Structures Handout 2012-2013Tushar Gupta100% (1)

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- Primary Homework Help Food ChainsDocument7 pagesPrimary Homework Help Food Chainsafnaxdxtloexll100% (1)

- Lesson Plan 12 Climate ChangeDocument5 pagesLesson Plan 12 Climate ChangeRey Bello MalicayNo ratings yet

- Team Dynamics and Behaviors for Global ExpansionDocument15 pagesTeam Dynamics and Behaviors for Global ExpansionNguyênNo ratings yet

- Cisco Lab 2.2.4.3Document5 pagesCisco Lab 2.2.4.3vcx100100% (6)

- Mercury QCDocument23 pagesMercury QCMarcus MeyerNo ratings yet

- Funny Physics QuestionsDocument3 pagesFunny Physics Questionsnek tsilNo ratings yet

- Women Safety AppDocument18 pagesWomen Safety AppVinod BawaneNo ratings yet

- Product Data: T T 13 SEER Single - Packaged Heat Pump R (R - 410A) RefrigerantDocument36 pagesProduct Data: T T 13 SEER Single - Packaged Heat Pump R (R - 410A) RefrigerantJesus CantuNo ratings yet

- COP2251 Syllabus - Ellis 0525Document9 pagesCOP2251 Syllabus - Ellis 0525Satish PrajapatiNo ratings yet